How to Read a Chainsaw Diagram

Understanding mechanical diagrams can seem complex at first, but with a systematic approach, they become valuable tools for maintaining and repairing equipment. These diagrams provide a visual breakdown of the individual components and their relationships within the machine, offering a clear picture of how everything fits and operates together. Learning to navigate these illustrations is crucial for proper troubleshooting and assembly.

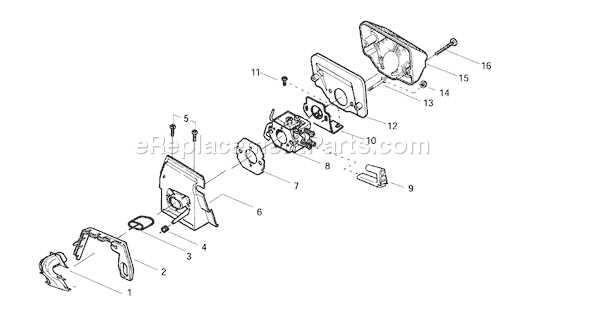

Identifying Components

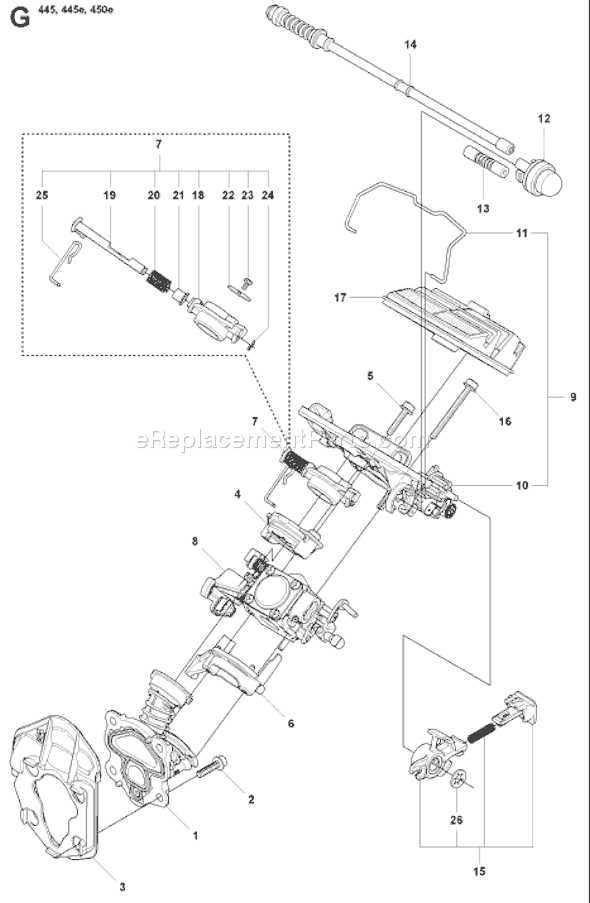

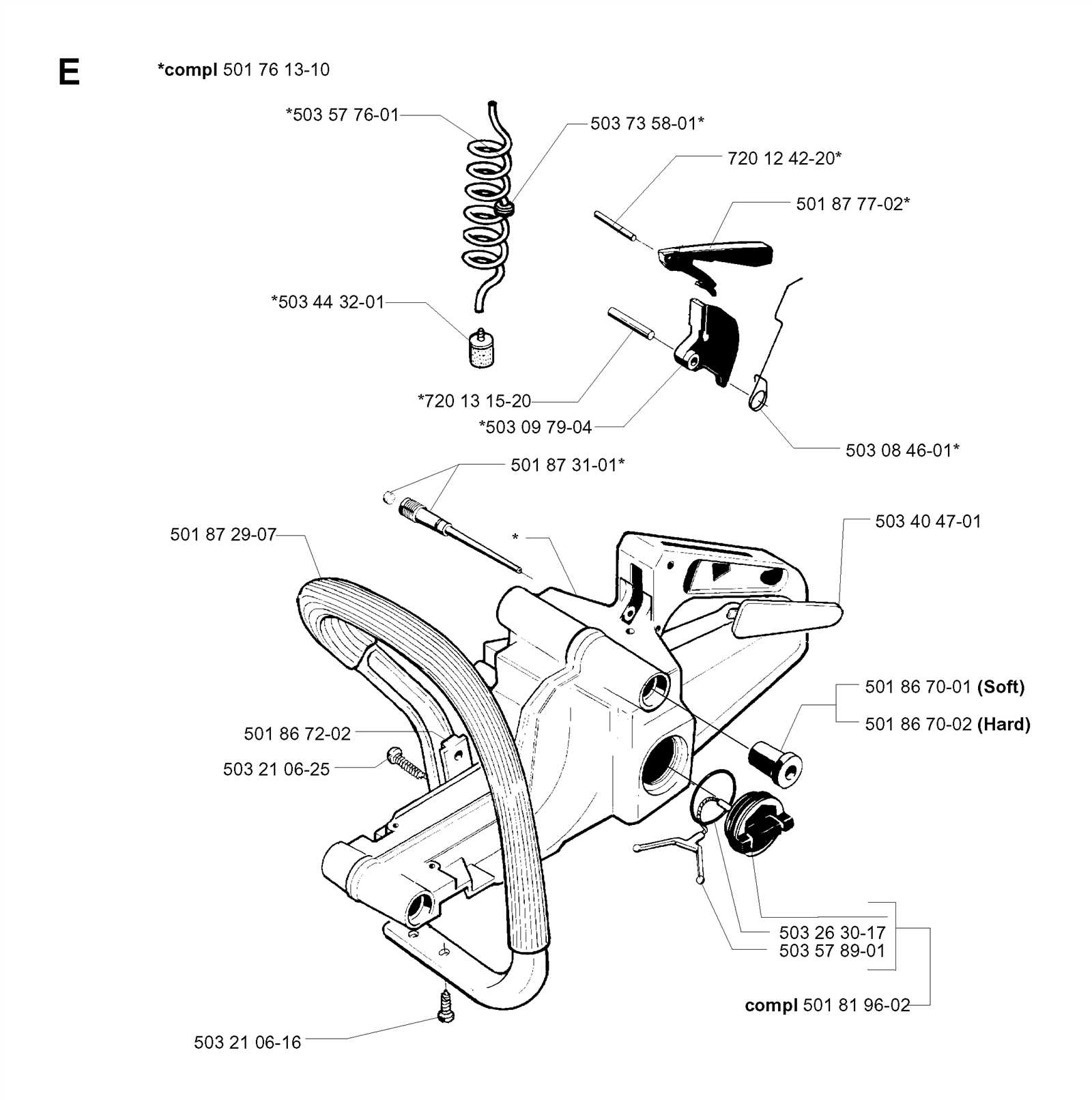

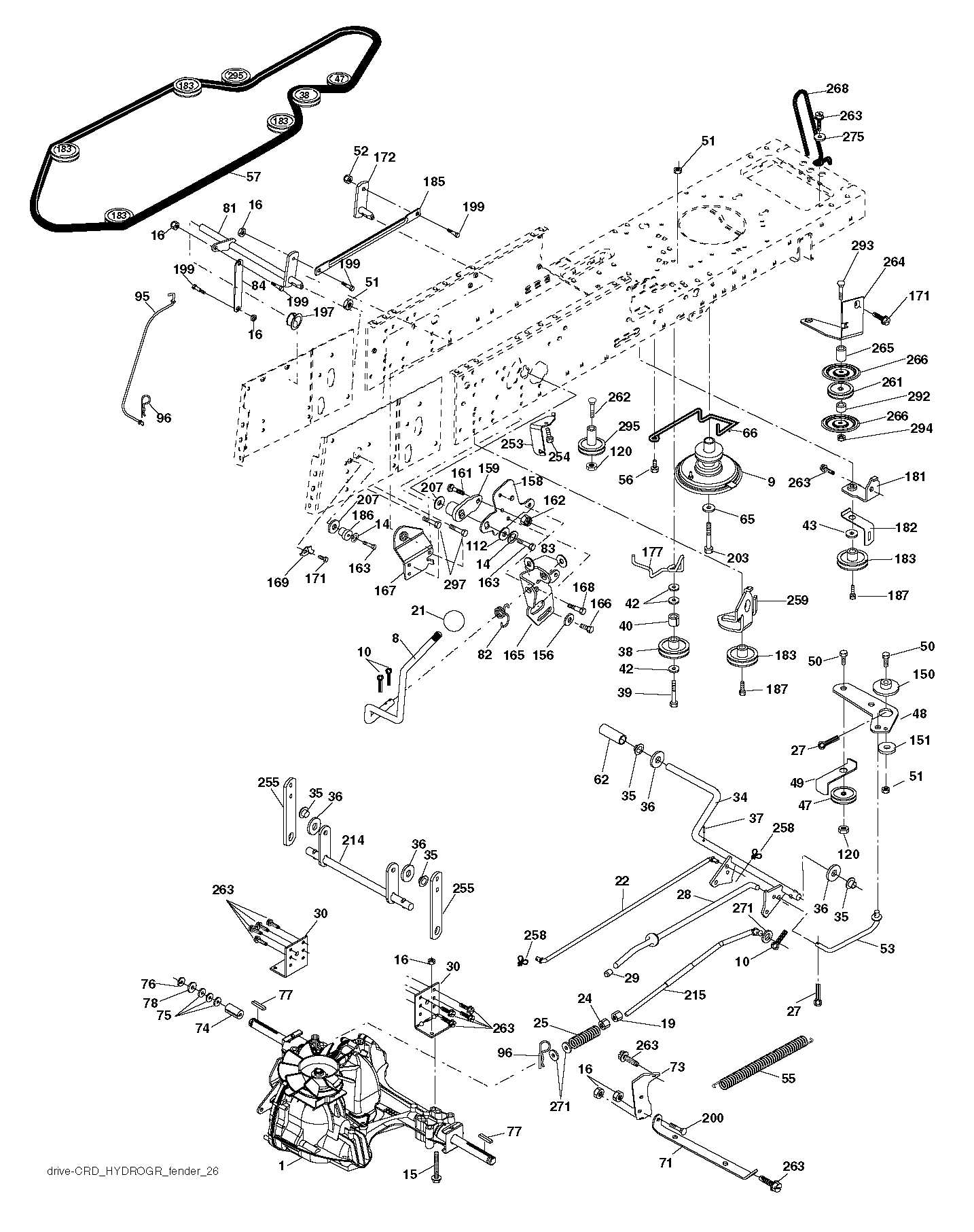

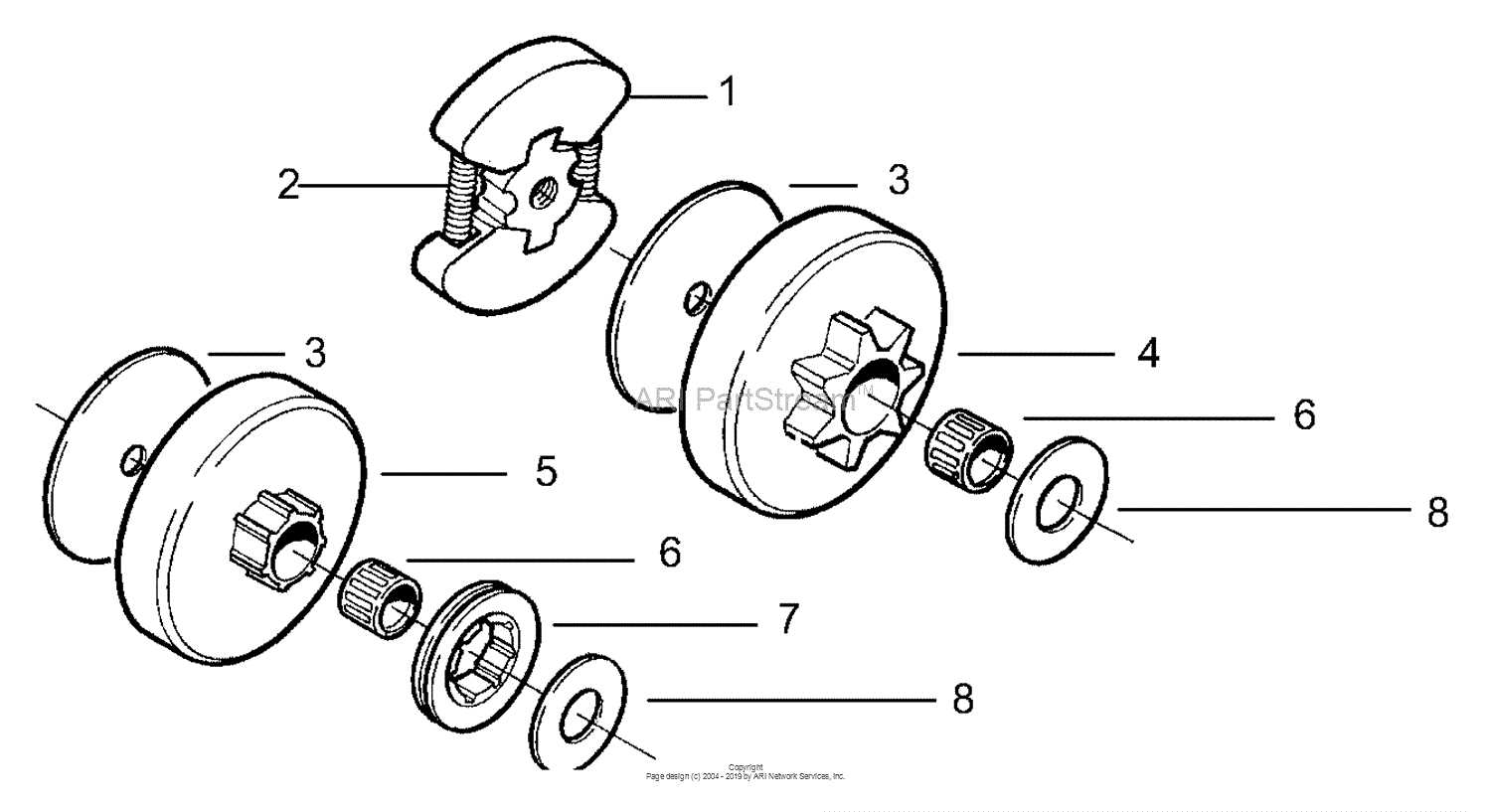

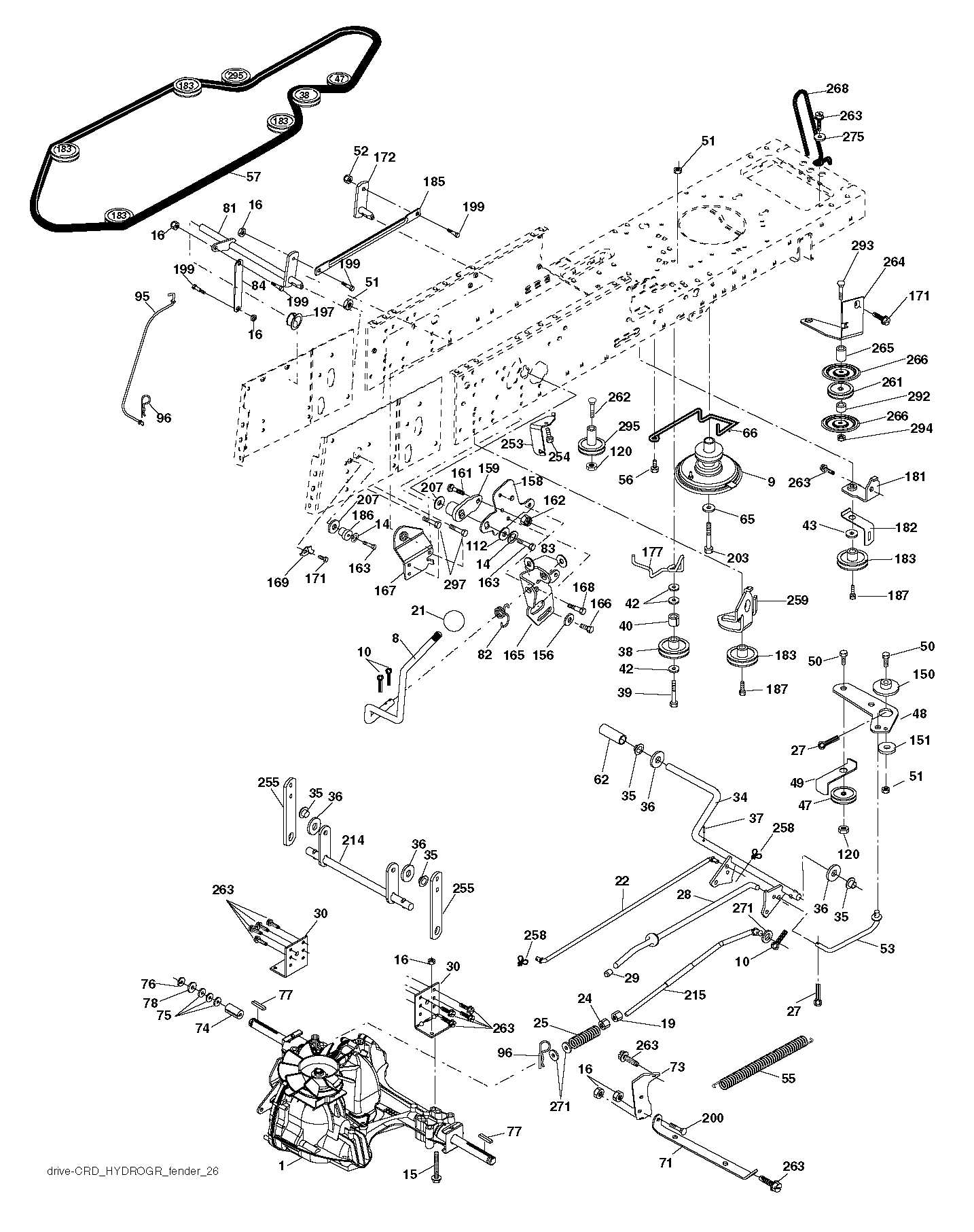

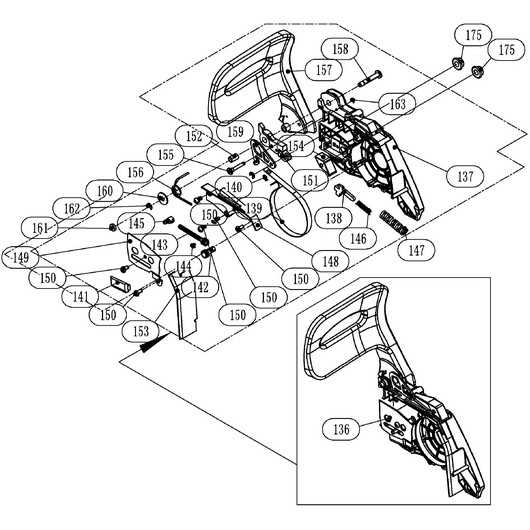

The first step in analyzing a mechanical diagram is to identify the major elements. Each part is usually labeled with a number or symbol that corresponds to a key or legend provided in the diagram. Focus on the most prominent sections first, like the engine or drive mechanisms, as they are central to the overall function of the device. From there, you can trace connections to other parts, which will help in understanding the overall workflow of the machine.

Following the Structure

Once you’ve identified the main components, it’s important to pay attention to how they are linked. The diagram typically uses lines or arrows to indicate movement, power flow, or assembly order. By following these connections, you can see how energy is transferred through the system, which is key to diagnosing issues or ensuring everything is assembled cor

Common Maintenance Parts for Husqvarna 141

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. Various components naturally wear out with use and need replacement to maintain reliability and efficiency. This section highlights the most frequently serviced elements that contribute to smooth operation and extend the lifespan of the tool.

Air Filters

One of the key elements to monitor is the air filter. Responsible for keeping dirt and debris out of the engine, it requires regular cleaning and eventual replacement. A clogged or damaged filter can lead to poor performance and increased fuel consumption. Keeping it in good condition ensures the engine remains protected from harmful contaminants.

Spark Plugs

A spark plug is a small yet crucial component that ignites the fuel mixture. Over time, it may accumulate carbon deposits or wear out, causing starting issues or inconsistent operation. Replacing it periodically will ensure efficient combustion and smooth running of the machine.

Fuel Filters are another important item to check regularly. They help maintain the purity of the fuel, preventing contaminants from entering the engine. Replacing a dirty filter can prevent blockages and e

Chainsaw Chain and Guide Bar Specifications

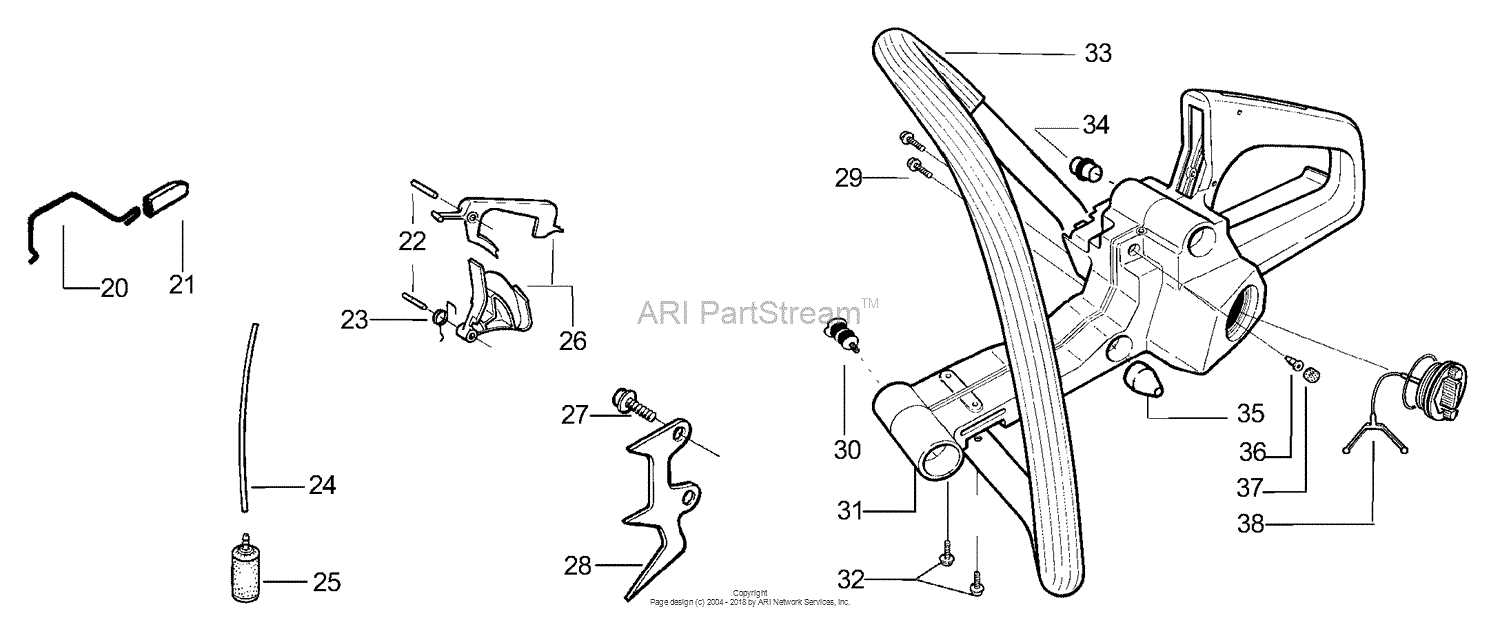

The chain and guide bar are critical components that directly influence the cutting performance and safety of any power tool designed for woodcutting. Understanding the right dimensions and design features for these elements ensures optimal efficiency and minimizes risks during operation.

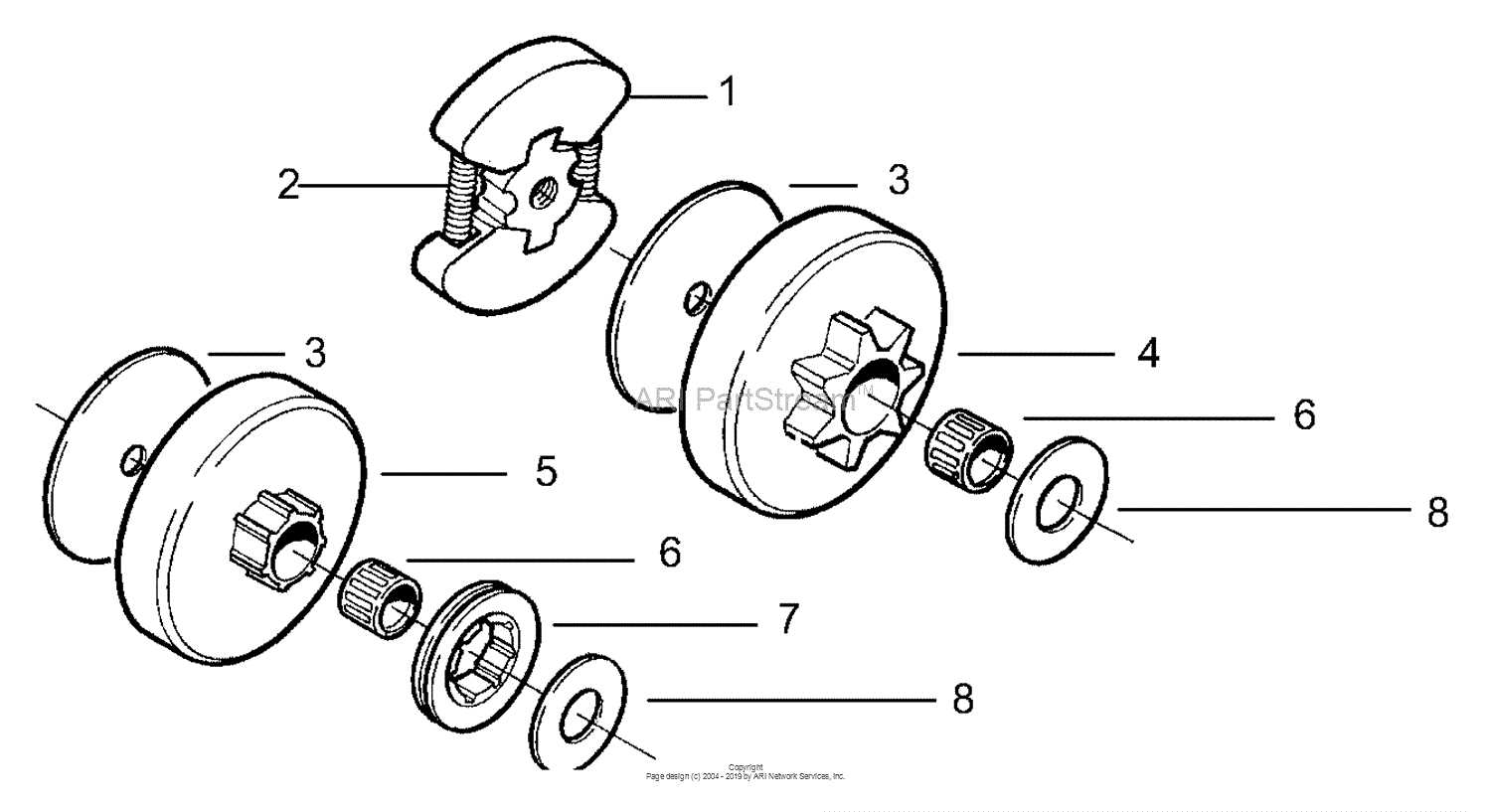

Chain specifications include the pitch, gauge, and the number of drive links. These measurements define the compatibility of the cutting chain with the guide bar and the sprocket system. The pitch refers to the distance between three consecutive rivets, while the gauge measures the thickness of the drive link that fits into the bar groove.

The guide bar specifications focus on length, width, and the design of the nose. The bar length determines the maximum cut capacity, while the nose shape impacts the smoothness of cuts and the risk of kickback. Proper alignment between the bar and chain is essential to maintain balance and avoid unnecessary wear.

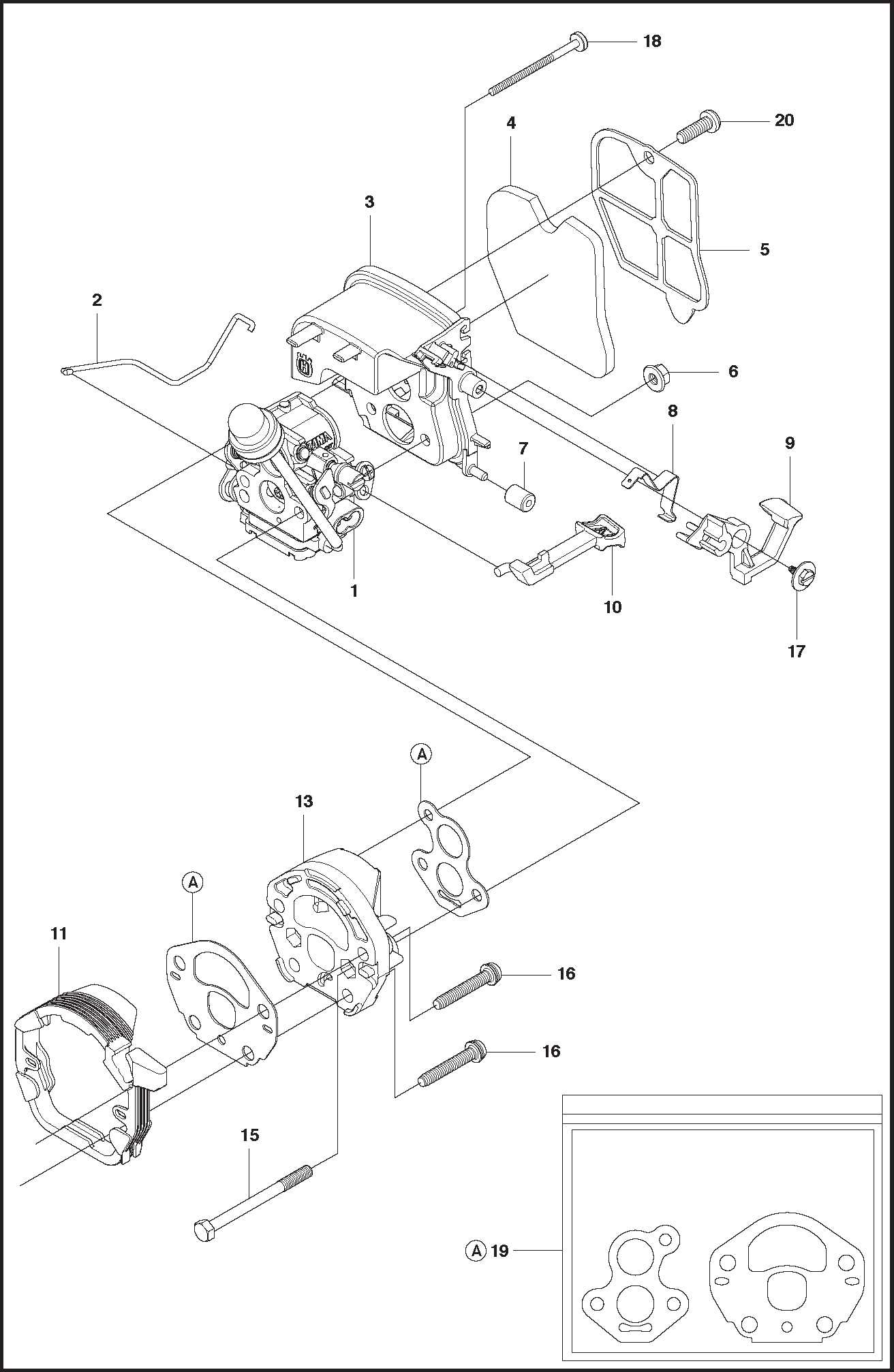

Understanding the Engine Assembly of Husqvarna 141

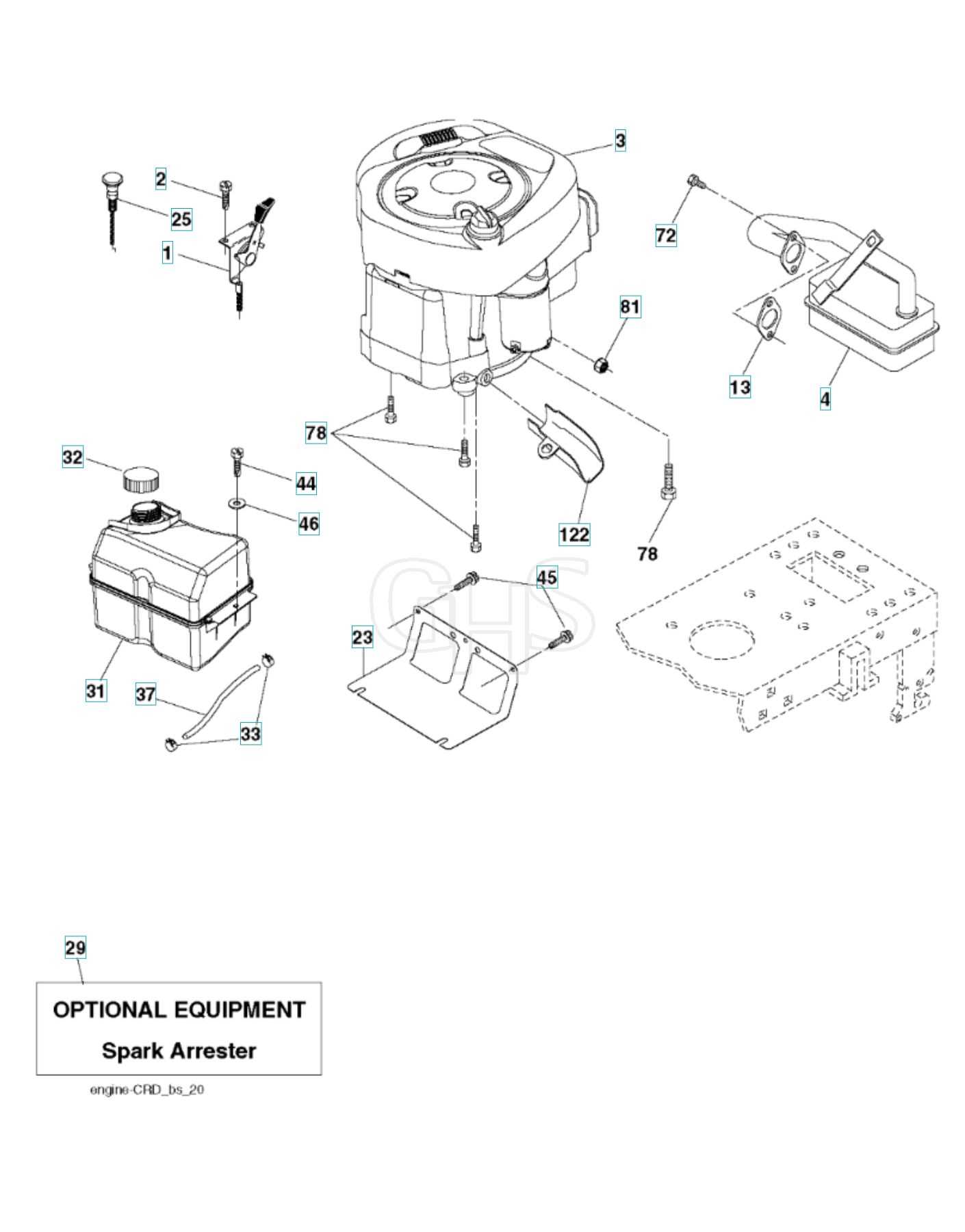

The engine assembly of a small power tool is a complex yet fascinating component, serving as the heart of the machinery. It is essential for users to grasp how this critical system functions and interacts with other parts, ensuring optimal performance and longevity. A well-maintained engine assembly can significantly enhance the efficiency of the device, making knowledge about its components vital for both operation and troubleshooting.

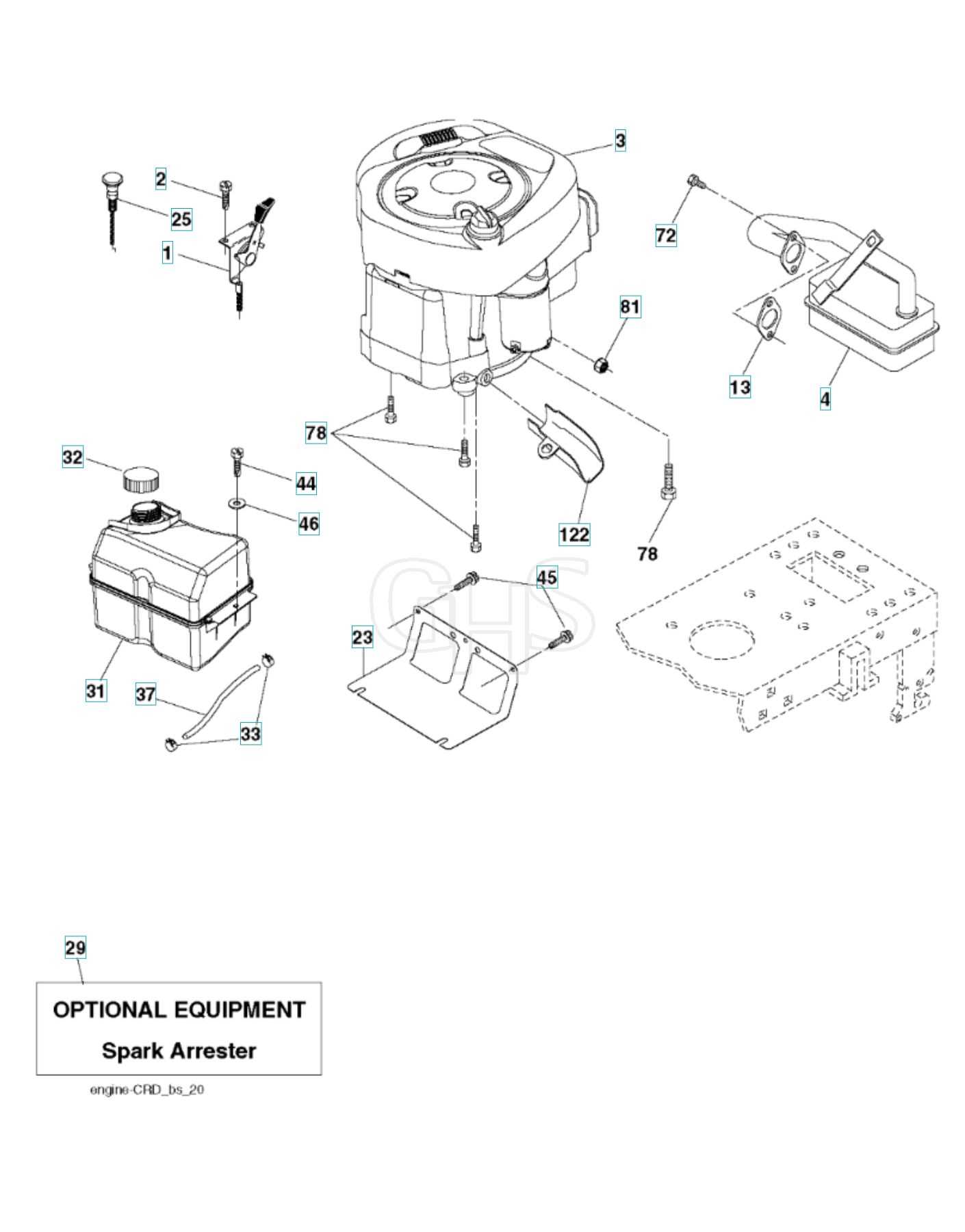

Key Components

At the core of the engine assembly lies the cylinder, where fuel and air mix for combustion. This process generates the necessary power for the tool’s operation. Additionally, the piston moves within the cylinder, driven by the explosive force of the combustion, ultimately transferring energy to the crankshaft. Understanding the role of each part is crucial for anyone looking to maintain or repair their equipment.

Assembly and Maintenance

Proper assembly is imperative for the seamless functioning of the engine. Components such as the crankcase, spark plug, and carburetor must be fitted correctly to ensure optimal airflow and fuel delivery. Regular maintenance, including cleaning and replacement of worn-out parts, helps prevent common issues and prolongs the lifespan of the machine.

Troubleshooting Common Issues

Familiarity with the engine assembly allows users to identify and troubleshoot common problems. For instance, difficulties in starting may often stem from issues with the spark plug or fuel system. Understanding how each component functions aids in diagnosing problems efficiently, reducing downtime and repair costs.

In summary, a thorough comprehension of the engine assembly empowers users to enhance performance, ensure reliability, and undertake effective maintenance of their power tools.

Chainsaw Carburetor: Function and Diagram

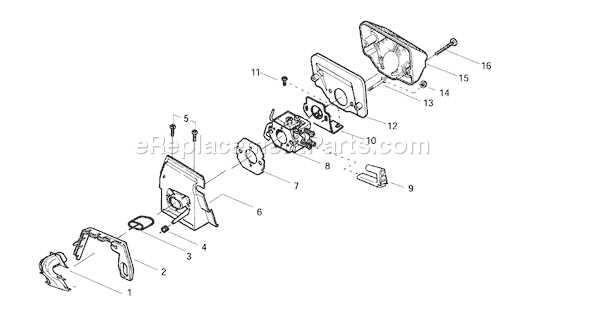

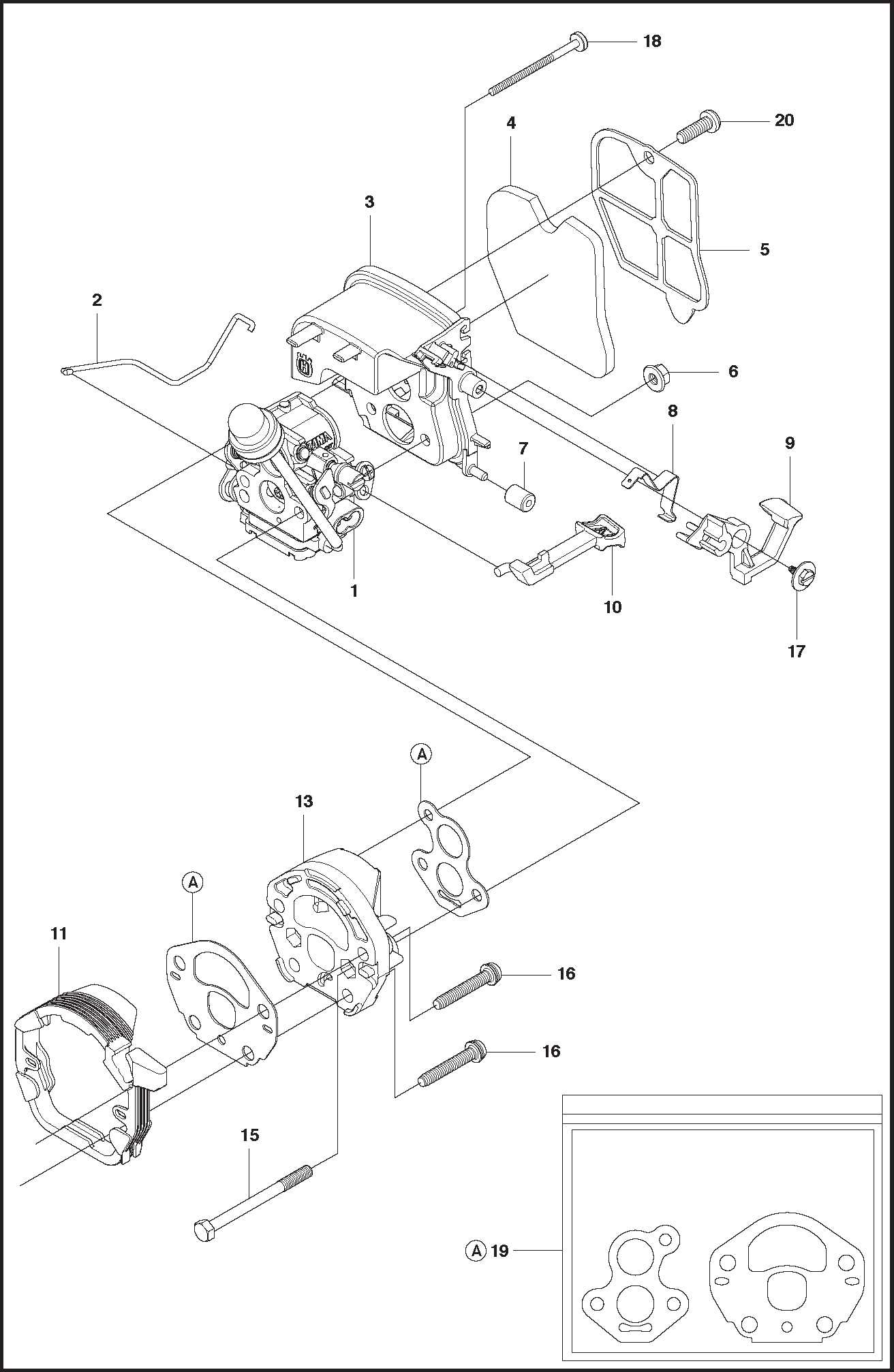

The carburetor is a crucial component in the operation of a two-stroke engine, playing a vital role in the mixture of air and fuel. Its primary function is to ensure the optimal proportion of these elements reaches the combustion chamber, which is essential for efficient performance and reliable starting. Understanding how this mechanism works can help users maintain their equipment effectively and troubleshoot any issues that may arise.

Functionality Overview: The carburetor works by drawing in air through an inlet and mixing it with fuel from the tank. This mixture is then vaporized and directed into the engine, where it ignites to produce power. Various factors, such as engine speed and load, influence the carburetor’s operation, necessitating adjustments to maintain the proper air-fuel ratio.

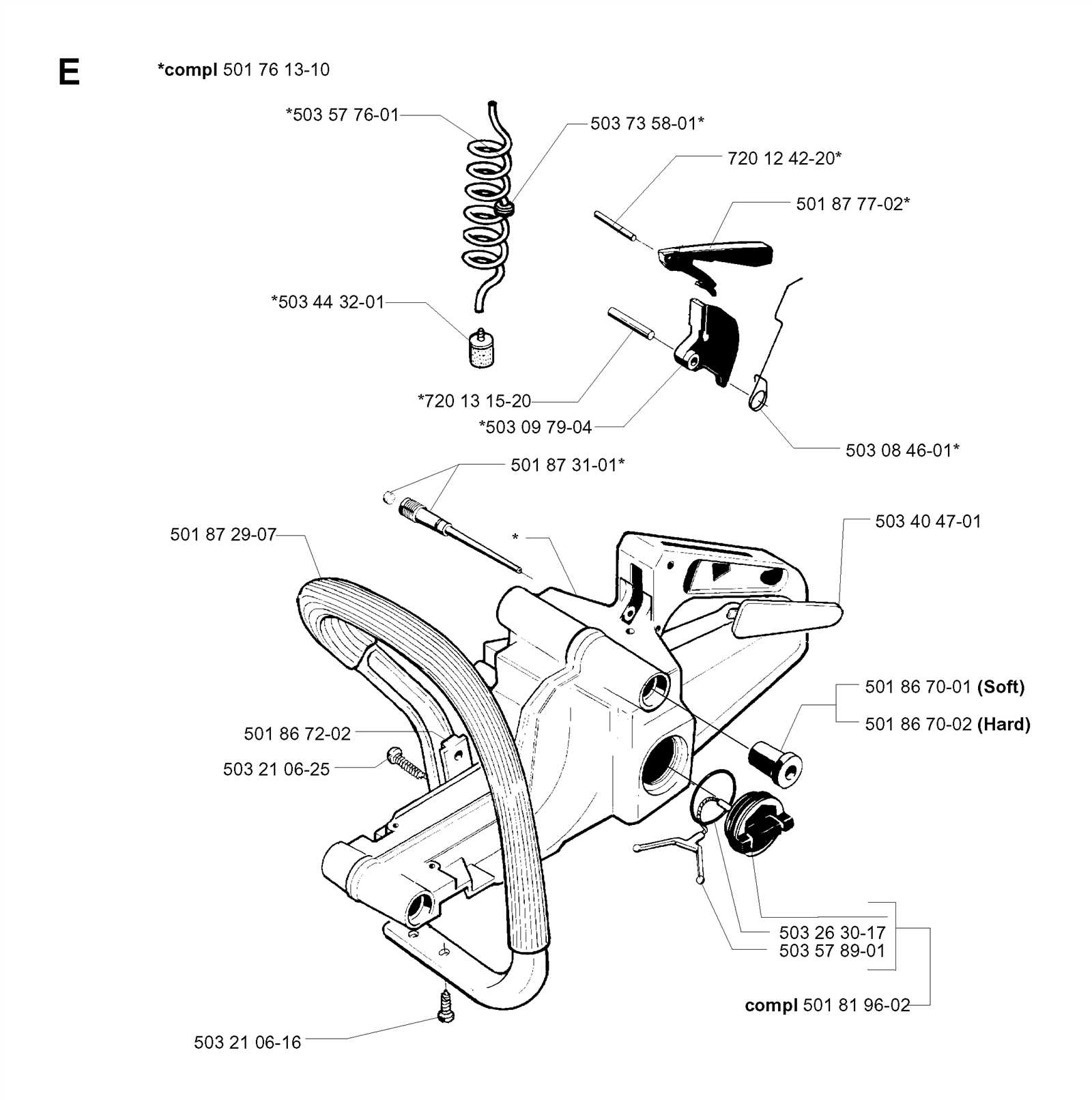

Components: A typical carburetor consists of several key parts, including the float chamber, jets, and throttle valve. The float chamber maintains a consistent level of fuel, while the jets regulate the amount of fuel that enters the air stream. The throttle valve controls the engine’s power output by adjusting the amount of mixture that enters the combustion chamber.

Diagram Analysis: A visual representation of the carburetor can provide further insight into its design and functionality. Key elements such as the float chamber, jets, and throttle can be identified, illustrating how they interact to create the necessary fuel-air mixture. By studying this diagram, users can better understand the inner workings of this essential engine component and identify potential areas for maintenance or repair.

In conclusion, familiarity with the carburetor’s function and its components is essential for anyone seeking to optimize the performance of their two-stroke engine. By understanding how this mechanism operates and the significance of each part, users can enhance their knowledge and skills, leading to improved efficiency and longevity of their equipment.

Replacing the Husqvarna 141 Fuel System

Ensuring the efficiency of any outdoor power equipment often hinges on maintaining its fuel delivery components. Over time, these systems can become clogged or damaged, affecting performance and reliability. This section provides guidance on how to effectively replace the fuel components in your equipment, ensuring it runs smoothly and efficiently.

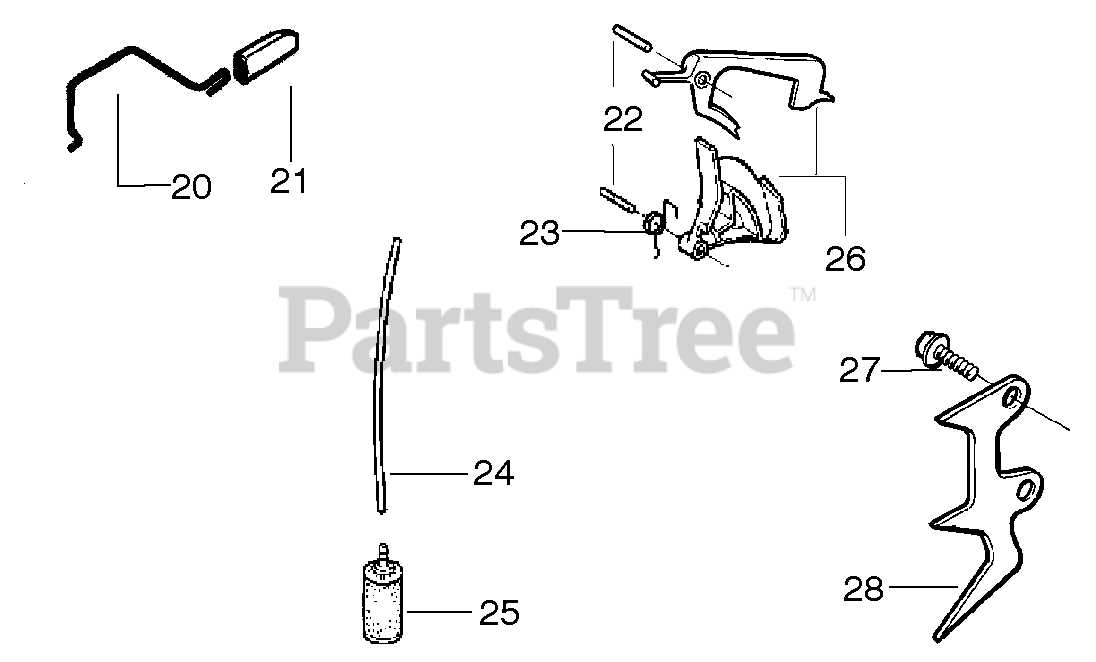

Identifying Issues

Before undertaking any replacements, it is crucial to diagnose the problem accurately. Symptoms such as difficulty starting, irregular engine performance, or stalling can indicate a fuel system failure. Carefully inspect the fuel lines, filter, and pump for signs of wear or blockages.

Gathering Necessary Tools

Preparation is key to a successful replacement. Assemble essential tools including screwdrivers, wrenches, and safety gear. Having the correct replacement parts on hand is also important. Refer to your equipment’s manual to identify the specific components needed for replacement.

Step-by-Step Replacement Process

Begin by disconnecting the power source to ensure safety. Remove any covers or components that obstruct access to the fuel system. Carefully detach the old fuel lines and filter, making note of their arrangement. Install the new components in the same configuration, ensuring a tight and secure fit to prevent leaks.

Testing the System

Once the new parts are in place, reassemble any removed components and reconnect the power source. Conduct a thorough test run to ensure everything functions correctly. Monitor for any irregularities, and check for leaks to confirm the integrity of the newly installed fuel system.

Regular Maintenance

To prolong the life of your equipment, incorporate regular maintenance of the fuel system into your routine. Clean or replace filters as needed, and check fuel lines for wear regularly. This proactive approach will enhance performance and reliability, minimizing the need for frequent replacements.

Ignition System Parts Breakdown

The ignition system is crucial for the efficient operation of any small engine. It serves to ignite the fuel-air mixture, enabling the engine to run smoothly. Understanding the individual components of this system helps in diagnosing issues and ensuring optimal performance. This section delves into the essential elements that comprise the ignition mechanism, highlighting their functions and interrelationships.

Key Components

- Ignition Coil: Converts the battery’s low voltage into a high voltage to create a spark.

- Spark Plug: Generates the spark that ignites the fuel-air mixture within the combustion chamber.

- Flywheel: A magnetized component that passes by the ignition coil, inducing voltage.

- Kill Switch: A safety feature that interrupts the ignition circuit, stopping the engine when engaged.

- CDI Unit: Capacitor Discharge Ignition module controls the timing and intensity of the spark.

Functionality Overview

The ignition coil operates by creating a magnetic field that collapses when the engine’s flywheel rotates. This collapse generates a high-voltage spark that travels through the ignition wire to the spark plug. The spark plug then ignites the fuel-air mixture, leading to combustion. The kill switch allows for immediate engine shutdown in emergencies, while the CDI unit ensures the ignition timing is precise for optimal performance.

By familiarizing oneself with these components, users can effectively troubleshoot ignition-related issues and maintain peak engine performance.

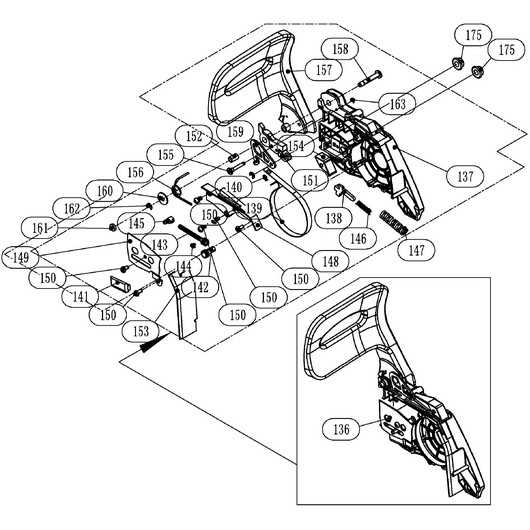

Chainsaw Safety Features: A Detailed Look

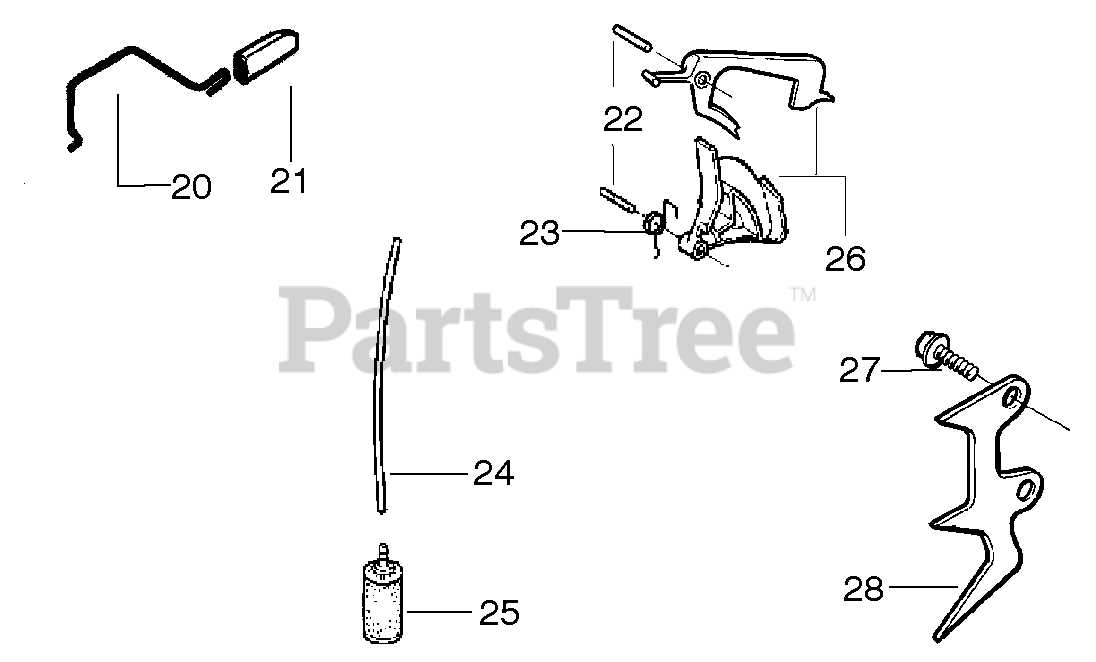

Understanding the safety mechanisms integrated into cutting tools is essential for effective and secure operation. These features are designed to minimize risks and enhance user protection while working with powerful equipment. A thorough examination of these safety elements can significantly contribute to preventing accidents and ensuring a safer working environment.

Emergency Stop Mechanism: One of the primary safety features is the emergency stop mechanism, which allows users to quickly deactivate the tool in case of an unforeseen event. This feature is crucial for reducing the potential for injury and mitigating damage.

Chain Brake: The chain brake serves as an essential safeguard by halting the movement of the cutting element instantly. This feature is particularly useful in situations where kickback occurs, as it helps prevent serious injuries by stopping the chain’s rotation.

Hand Guard: Another vital component is the hand guard, designed to protect the user’s hands from accidental contact with the cutting area. This protective barrier reduces the likelihood of injuries caused by slips or mishandling of the tool.

Anti-Vibration System: To enhance comfort and reduce fatigue, many modern tools incorporate an anti-vibration system. This feature minimizes the impact of vibrations on the user, promoting safer handling and prolonged usage without discomfort.

Safety Switch: A safety switch ensures that the tool cannot be activated unintentionally. This feature requires deliberate action from the operator, thereby reducing the risk of accidents when the equipment is not in use.

Operator Presence Control: This innovative feature guarantees that the equipment operates only when the user maintains a firm grip on the handles. If the operator loses control or releases the handles, the tool immediately shuts off, enhancing safety during operation.

Incorporating these safety features not only protects the user but also promotes responsible operation of cutting tools. Awareness and understanding of these mechanisms are vital for anyone working with such powerful equipment, ensuring a focus on safety and efficiency.

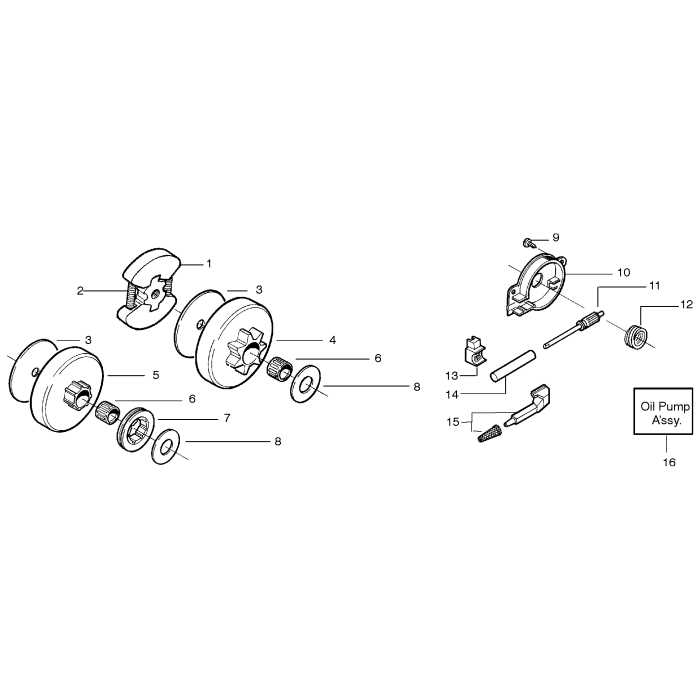

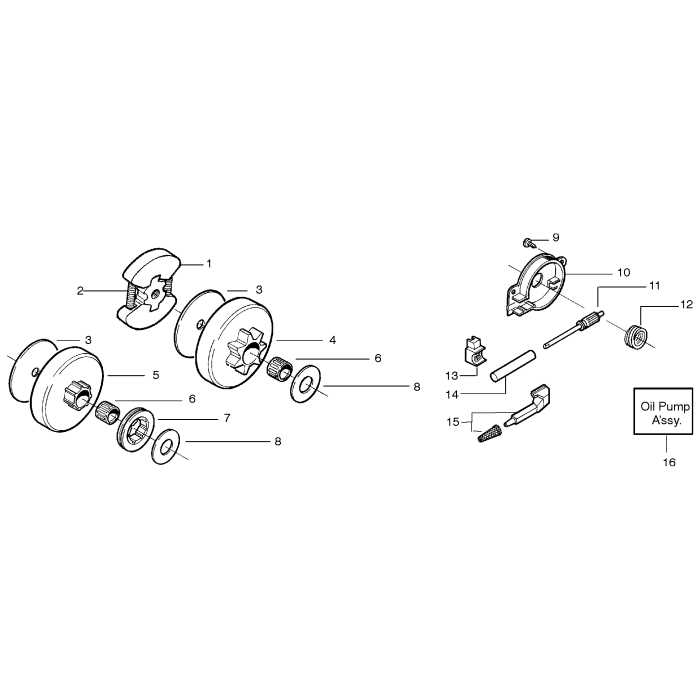

Husqvarna 141 Oiling System Explained

The lubrication mechanism in outdoor power equipment is crucial for maintaining performance and extending lifespan. This system ensures that moving components receive adequate oil, minimizing friction and wear during operation. Understanding how this system functions can help users maintain their tools effectively and troubleshoot any issues that may arise.

Components of the Lubrication System

This lubrication setup comprises several key elements, each playing a vital role in ensuring smooth operation. The primary components include the oil reservoir, pump, delivery lines, and outlet ports. Each part contributes to the overall efficiency and effectiveness of the system.

| Component |

Description |

| Oil Reservoir |

Holds the lubricant needed for the system. |

| Oil Pump |

Facilitates the flow of oil from the reservoir to the moving parts. |

| Delivery Lines |

Connects the pump to the components that require lubrication. |

| Outlet Ports |

Directly supply oil to the necessary parts, ensuring they remain lubricated. |

Functionality and Maintenance

The oiling mechanism operates automatically, triggered by the movement of the engine. Proper maintenance is essential for optimal performance. Regularly checking the oil level, inspecting the pump for blockages, and cleaning the delivery lines can prevent potential failures. Additionally, using the recommended lubricant type will ensure the system operates efficiently.

How to Identify Genuine Replacement Parts

Ensuring the quality and reliability of components for your equipment is crucial for optimal performance and longevity. Authentic replacements not only provide better compatibility but also enhance the efficiency of your machinery. Identifying genuine components involves understanding key characteristics that distinguish them from inferior imitations.

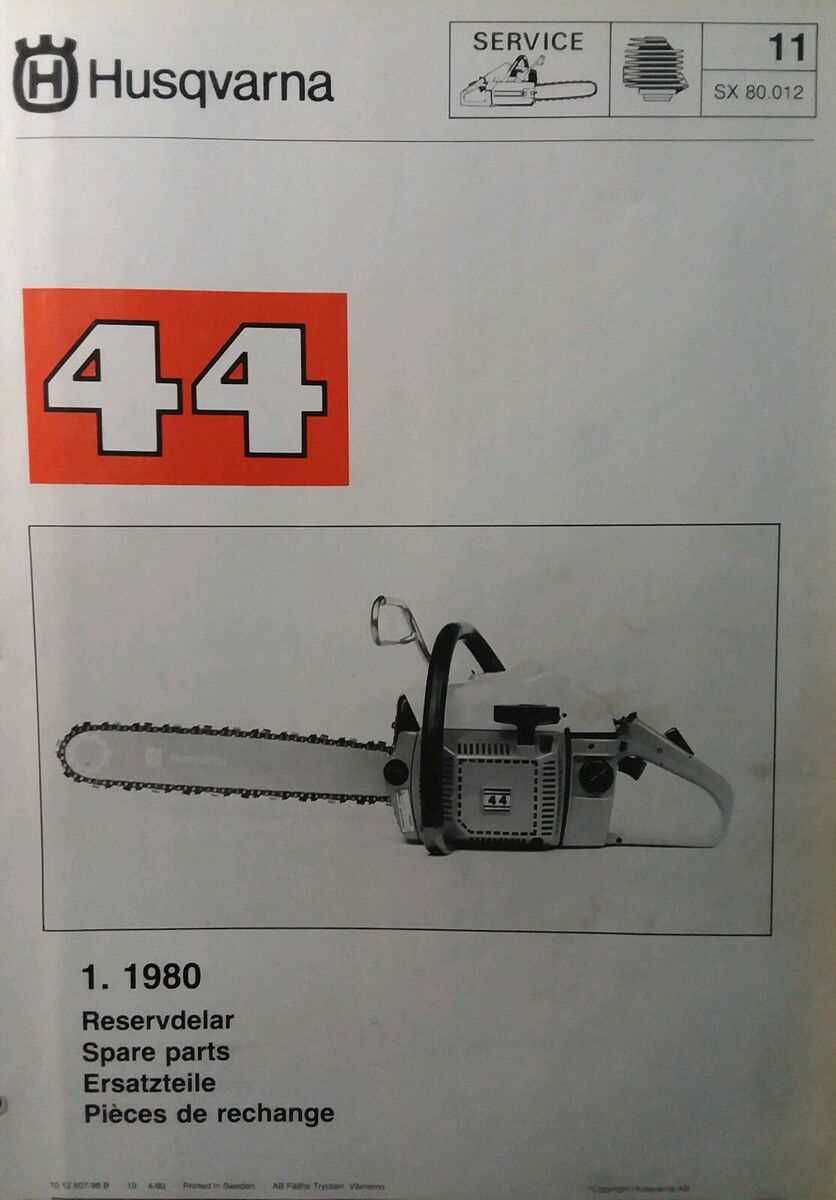

Firstly, examine the packaging. Original manufacturers typically invest in high-quality packaging, which often includes detailed labeling and protective features. Authentic items will display the brand logo prominently, along with part numbers and specific product information. Compare this with any aftermarket alternatives that may lack such attention to detail.

Next, assess the build quality. Genuine components are engineered to meet stringent standards, ensuring durability and reliability. Check for consistent finishes, precise dimensions, and the absence of imperfections. Inferior replicas may show signs of poor craftsmanship, such as rough edges or mismatched colors.

Additionally, consider the price. While it might be tempting to opt for cheaper options, significant price discrepancies often indicate a lack of authenticity. Research the standard market value for the components you need to make informed purchasing decisions. Genuine items may cost more, but they provide a better return on investment through enhanced performance and reduced risk of failure.

Lastly, purchase from reputable suppliers. Authorized dealers and well-established retailers are more likely to stock authentic products. When in doubt, consult the manufacturer’s website or customer service to verify the legitimacy of a seller. By following these guidelines, you can confidently identify genuine replacements that will maintain the functionality of your equipment.

Where to Find Husqvarna 141 Parts Online

When it comes to maintaining and repairing outdoor power equipment, sourcing the right components can be crucial for optimal performance. Fortunately, numerous online platforms cater to enthusiasts and professionals alike, making it easier than ever to locate the necessary items for your machine. Understanding where to look can save time and ensure you receive quality replacements.

Official Manufacturer Websites: One of the most reliable sources for authentic components is the official website of the manufacturer. Here, you can find a comprehensive selection of products, detailed specifications, and helpful guides for installation.

Authorized Dealers: Many authorized retailers specialize in outdoor machinery and their accessories. These dealers often have a robust online presence, allowing you to browse their inventories, compare prices, and read customer reviews.

Online Marketplaces: Well-known e-commerce platforms provide a vast array of options. These sites often feature both new and refurbished items from various sellers, giving you the flexibility to choose based on your budget and preferences. Ensure to check seller ratings to confirm their reliability.

Forums and Community Groups: Engaging with online communities dedicated to outdoor equipment can lead you to valuable resources. Members often share insights on where to find specific items, offer recommendations, and may even have spare components for sale or trade.

Specialty Websites: Certain websites focus exclusively on replacement components for various outdoor machines. These platforms typically provide extensive catalogs and can be a great place to find hard-to-find items, often with detailed diagrams and compatibility information.

Utilizing a combination of these sources can enhance your search and increase the likelihood of finding the right components for your equipment quickly and efficiently.