In the realm of mechanical engineering, the intricate workings of fluid transfer systems play a pivotal role in various applications. These systems, designed for efficiency and reliability, consist of numerous elements that interact seamlessly to ensure optimal performance. A comprehensive grasp of these components is essential for anyone seeking to enhance their knowledge or troubleshoot effectively.

By exploring the layout and relationships between these individual elements, one can ultimately gain valuable insights into their functionality. Understanding how each segment contributes to the overall system empowers engineers and technicians to make informed decisions during maintenance and repairs. Delving into this topic reveals not only the complexity but also the beauty of engineered solutions in fluid mechanics.

As we dissect the arrangement of these crucial components, we will uncover their specific roles and how they collaborate to achieve desired outcomes. This exploration is not merely academic; it serves as a foundation for practical applications, ensuring that systems operate at peak efficiency. Whether for educational purposes or professional development, an in-depth examination of these mechanisms is invaluable.

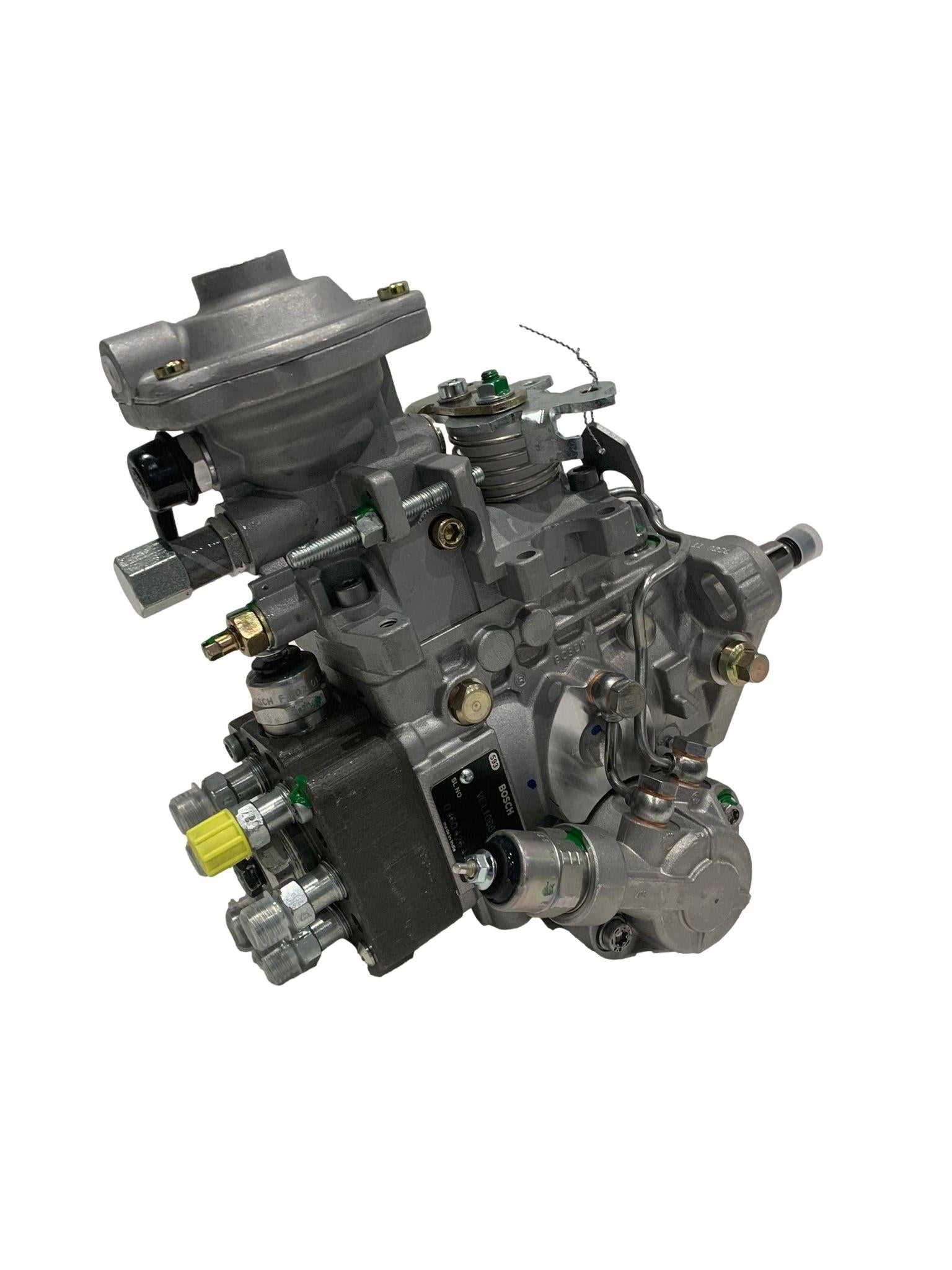

Understanding Bosch VE Pump Functionality

The operation of a specific fuel delivery system is crucial for optimal engine performance. This mechanism ensures precise control over the amount of fuel injected, directly influencing efficiency and emissions. By exploring its components and functions, one can gain insights into how this technology maximizes power output while minimizing waste.

Key Components

Essential elements of this system include an injection mechanism, a control unit, and a timing element. Each component plays a vital role in regulating the fuel flow and ensuring synchronization with the engine’s cycle. Understanding these parts allows for a deeper appreciation of their collective impact on performance.

Operational Principles

This system operates based on hydraulic principles, utilizing pressure differentials to manage fuel distribution. The control unit adjusts the timing and volume of fuel delivery, adapting to varying engine demands. This adaptability is the ultimate key to maintaining efficiency across different operating conditions.

Key Components of VE Pumps

Understanding the essential elements of a specific fuel delivery system is crucial for both performance and maintenance. Each component plays a significant role in ensuring efficiency, reliability, and optimal operation. This section highlights the primary features that contribute to the overall functionality of this intricate mechanism.

Fuel Injection Mechanism

The fuel injection mechanism is vital for precisely delivering fuel to the engine. This component regulates the timing and amount of fuel injected, ensuring optimal combustion. By controlling these parameters, the system enhances engine efficiency and reduces emissions.

Control Unit

The control unit oversees the operation of the entire system. It processes various inputs and adjusts the injection parameters accordingly, allowing for adaptability under different driving conditions. This component is essential for maintaining performance and ensuring that the engine runs smoothly.

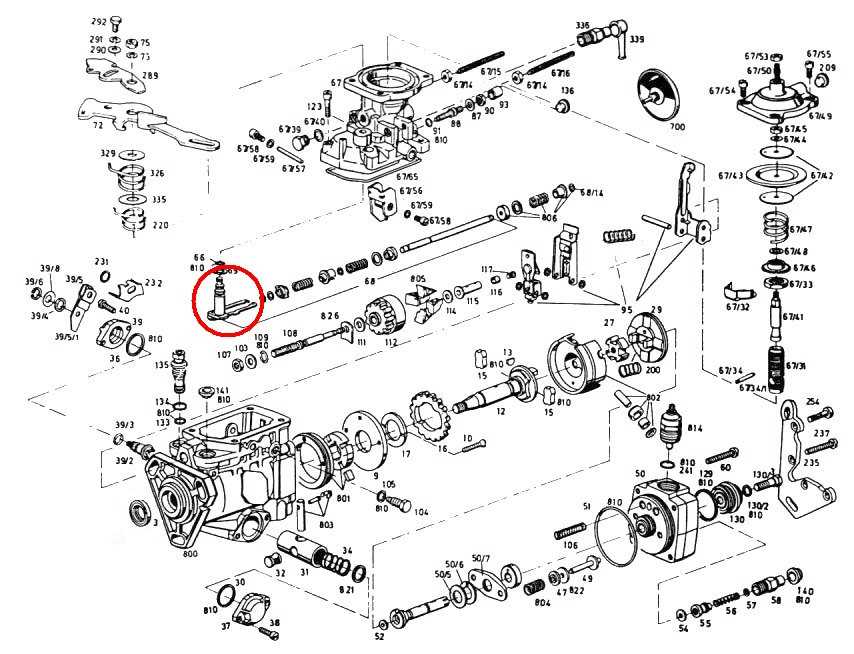

How to Read Pump Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting of fluid transfer systems. These visual representations provide crucial insights into the arrangement and function of various components, helping users identify potential issues and perform necessary repairs. Mastering the interpretation of these schematics can significantly enhance operational efficiency.

Begin by familiarizing yourself with the symbols and notations commonly used in these illustrations. Each element typically corresponds to a specific component, such as valves, connectors, and actuators. Referencing a legend, if available, can clarify the meanings behind these symbols, enabling a quicker comprehension of the system’s layout.

Next, analyze the flow direction indicated in the illustration. Arrows often denote the path that the fluid follows, which is crucial for understanding how different elements interact within the setup. Recognizing this flow can aid in pinpointing areas that may require inspection or adjustment.

Pay attention to the labels and specifications associated with each component. Information such as pressure ratings, sizes, and materials will provide valuable context for evaluating the system’s performance and compatibility. Understanding these details can also guide you in selecting replacement parts when needed.

Lastly, practice interpreting various schematics to build familiarity and confidence. As you gain experience, you’ll become more adept at quickly identifying issues and implementing effective solutions, ultimately leading to improved reliability and functionality in your fluid handling systems.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in the effective understanding and maintenance of complex systems. When individuals interact with intricate machinery, the need for reliable illustrations becomes evident, as they serve as essential guides for both assembly and troubleshooting processes.

Clarity in these representations ensures that users can easily identify components and their respective functions. This eliminates confusion and enhances the overall efficiency of repairs and maintenance tasks. Moreover, well-crafted visuals can significantly reduce the likelihood of errors, as they provide a clear roadmap for assembly or disassembly.

Furthermore, accurate depictions foster effective communication among technicians and engineers. By relying on universally understood symbols and layouts, teams can collaborate more efficiently, ensuring that everyone is on the same page when it comes to project execution. This is particularly important in environments where precision is paramount.

In summary, the significance of accurate representations cannot be overstated. They not only streamline processes but also enhance safety and reliability in the handling of sophisticated machinery.

Common Issues with VE Pumps

In the realm of fuel delivery systems, certain challenges frequently arise that can impact performance and efficiency. Understanding these common concerns is crucial for effective maintenance and troubleshooting.

Fuel Leaks: One of the most prevalent issues involves leaks, which can stem from worn seals or improper fittings. These leaks not only reduce efficiency but can also pose safety hazards.

Insufficient Fuel Supply: Another significant problem is inadequate fuel delivery, often caused by blockages or failures in the internal mechanisms. This can lead to engine performance issues and operational inefficiencies.

Unusual Noises: Uncommon sounds during operation may indicate mechanical wear or damage. Addressing these noises promptly can prevent more severe damage down the line.

Contamination: Fuel contamination from dirt or debris can severely affect the functionality of the system. Regular checks and filtration are essential to mitigate this risk.

Pressure Variations: Fluctuations in pressure can result from various factors, including faulty components or incorrect settings. Maintaining proper pressure levels is vital for optimal operation.

Maintenance Tips for Bosch Pumps

Regular upkeep of mechanical systems is essential for ensuring longevity and optimal performance. Adopting a few proactive measures can significantly enhance the reliability of your equipment, preventing unexpected failures and costly repairs.

Routine Inspections

Conducting frequent checks is crucial. Look for signs of wear, leaks, and irregular sounds. Early detection can save time and resources. Replace any worn components promptly to maintain efficiency.

Lubrication and Cleaning

Keep moving parts well-lubricated to reduce friction and wear. Additionally, cleaning debris and contaminants from surfaces helps prevent clogs and ensures smooth operation. Regular maintenance can lead to the ultimate performance of your machinery.

Identifying Parts in Diagrams

Understanding various components within illustrations is crucial for effective maintenance and troubleshooting. Each element serves a specific function, and recognizing them can enhance operational efficiency.

Common Symbols and Their Meanings

- Circles typically represent pumps or fluid reservoirs.

- Arrows indicate flow direction, showing how substances move through the system.

- Boxes often denote control units or electrical components.

Steps to Analyze Illustrations

- Start by familiarizing yourself with the legend or key provided.

- Identify the main sections and their relationships.

- Focus on specific symbols to understand their roles within the overall structure.

Replacement Parts for VE Pumps

When maintaining or restoring fuel delivery systems, the importance of high-quality components cannot be overstated. Ensuring that each element operates seamlessly is essential for optimal performance and longevity. This section delves into the various replacements that enhance efficiency and reliability in these intricate mechanisms.

Types of Components

Among the most crucial elements are the injectors, which directly impact the combustion process. Regular inspection and timely replacement can lead to significant improvements in engine performance. Additionally, the sealing elements play a vital role in preventing leaks, thus maintaining system integrity.

Choosing the Right Replacements

It is essential to select components that meet stringent quality standards. OEM options are often recommended due to their compatibility and reliability. However, aftermarket alternatives can also provide effective solutions, provided they are sourced from reputable suppliers. Ultimately, making informed choices will contribute to the durability and efficiency of the entire system.

Best Practices for Pump Repair

Ensuring optimal functionality of hydraulic mechanisms is essential for longevity and efficiency. Adopting effective techniques during maintenance and restoration can significantly enhance performance and reduce downtime.

1. Regular Inspection: Consistent examination of components helps identify wear and potential issues before they escalate. Look for signs of leaks, corrosion, or abnormal vibrations.

2. Cleanliness: Maintaining a clean workspace and components is vital. Dirt and debris can lead to malfunctions and reduced efficiency. Always use clean tools and materials.

3. Correct Tools: Utilizing the appropriate instruments for disassembly and assembly minimizes the risk of damage. Ensure all tools are in good condition and suitable for the task at hand.

4. Follow Manufacturer Guidelines: Adhering to the recommendations provided by the manufacturer ensures that repairs meet safety and performance standards.

5. Testing After Repair: Conduct thorough testing post-repair to verify that everything operates correctly. This step is crucial for confirming the success of your efforts.

Implementing these strategies can lead to improved reliability and efficiency in your hydraulic systems.

Tools Needed for Pump Servicing

Effective maintenance of fluid transfer systems requires specific instruments to ensure optimal performance and longevity. Having the right tools on hand not only facilitates the repair process but also enhances safety and efficiency during service operations.

Essential tools include wrenches for loosening and tightening fittings, screwdrivers for removing cover plates, and pliers for handling smaller components. Additionally, a multimeter is crucial for checking electrical connections and ensuring proper functioning of any electronic elements involved.

For tasks that require precise measurements, a caliper is indispensable, allowing technicians to evaluate the condition of internal parts. Moreover, a torque wrench ensures that all connections are secured to manufacturer specifications, preventing leaks or damage.

Lastly, a comprehensive toolbox with assorted sizes and types of tools will help in addressing various challenges that may arise during the servicing process, making the entire operation more streamlined and effective.

Safety Precautions When Working

Ensuring safety in the workplace is essential for protecting both personnel and equipment. By adhering to specific guidelines, individuals can minimize risks and create a secure environment for all. Here are key measures to consider.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and helmets.

- Maintain a clutter-free workspace to prevent accidents and improve efficiency.

- Follow all manufacturer instructions and safety protocols carefully to avoid mishaps.

- Ensure that tools and machinery are in good working condition before use.

- Stay informed about emergency procedures and know the location of first aid kits and exits.

Regular training and awareness programs can further enhance safety practices among workers. Establishing a culture of vigilance helps in identifying potential hazards before they escalate.

- Inspect equipment regularly to detect any signs of wear or damage.

- Communicate clearly with colleagues to ensure everyone is aware of ongoing activities.

- Take breaks to maintain focus and reduce fatigue, which can lead to mistakes.

By implementing these precautions, individuals can foster a safer working atmosphere, ultimately contributing to overall productivity and well-being.

Upgrading Bosch Pump Components

Enhancing the efficiency and performance of mechanical systems is essential for optimal operation. By focusing on key components, users can ensure longevity and reliability. Upgrading elements within these systems can lead to significant improvements in functionality and reduce the likelihood of failures.

Benefits of Component Upgrades

- Improved efficiency and performance

- Increased durability and lifespan

- Enhanced reliability during operation

- Potential cost savings on repairs

Key Components to Consider

- Seals and Gaskets

- Valves and Regulators

- Filters and Strainers

- Motors and Drives

Focusing on these critical components can help users delve into the ultimate potential of their systems, ensuring better results and satisfaction.

Where to Find Reliable Diagrams

Accessing accurate and detailed schematics is crucial for effective maintenance and repair tasks. Knowing where to source these visual aids can significantly enhance your understanding of the equipment and ensure optimal performance.

Official Manufacturer Resources

Many manufacturers provide comprehensive manuals and blueprints on their official websites. These resources are typically updated regularly and reflect the most current information.

Community Forums and Online Platforms

Engaging with online communities and specialized platforms can yield valuable insights. Users often share their findings, making it easier to uncover trusted references and authentic illustrations.