In the world of small machinery, comprehending the intricate assembly of engine components is essential for maintenance and repair. Every mechanism consists of various parts, each playing a crucial role in ensuring optimal performance. By familiarizing oneself with these components, operators can enhance longevity and functionality.

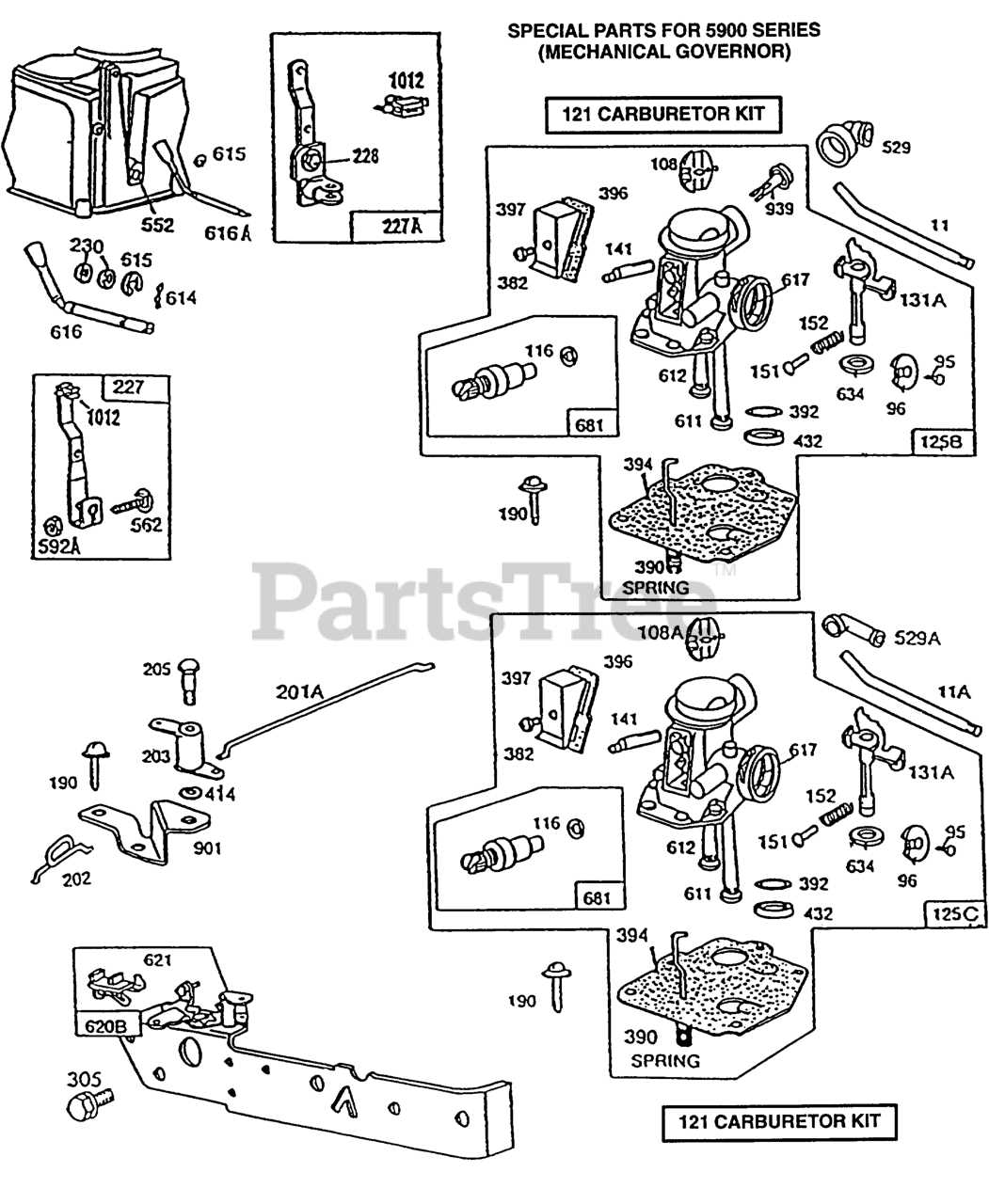

Visual representations of these assemblies provide invaluable insight into how different elements interact. Such illustrations serve as a roadmap for anyone looking to troubleshoot issues or perform upgrades. By carefully studying these schematics, users can pinpoint the necessary adjustments or replacements.

In this guide, we will delve into the specifics of an engine model, offering a comprehensive look at its structure. This knowledge is the ultimate key to achieving effective repairs and maintenance, ensuring smooth operation for years to come.

Understanding Briggs and Stratton YBSXS.2051HF

This section provides an overview of a specific engine model, focusing on its components, functionality, and maintenance aspects. Understanding how each element works together is crucial for optimal performance and longevity.

Key features include:

- Durability and reliability for various applications

- Efficient power generation capabilities

- Simple maintenance procedures for users

To better comprehend the operation of this engine model, it is important to consider its essential components:

- Fuel System: Responsible for delivering the necessary fuel for combustion.

- Ignition System: Ensures that the engine starts efficiently and runs smoothly.

- Cooling Mechanism: Maintains optimal temperature during operation to prevent overheating.

- Exhaust System: Facilitates the expulsion of gases generated during combustion.

Regular checks and timely servicing can significantly enhance the operational life of this engine. Users should familiarize themselves with the individual components to identify potential issues early on.

Overview of Engine Specifications

This section provides a comprehensive look at the characteristics and functionalities of a specific small engine model. Understanding these specifications is crucial for proper maintenance, troubleshooting, and optimal performance in various applications. Key parameters such as displacement, power output, and operational efficiency play a vital role in determining the engine’s suitability for different tasks.

Key Specifications

| Specification | Details |

|---|---|

| Displacement | Various cubic centimeters |

| Power Output | Measured in horsepower |

| Fuel Type | Typically gasoline |

| Cooling System | Air-cooled or liquid-cooled options |

| Ignition System | Electronic ignition for efficient starting |

Performance Metrics

Performance metrics provide insight into the engine’s operational capabilities. Factors such as torque, fuel consumption, and emissions standards are evaluated to ensure the engine meets regulatory requirements while delivering reliable power. Understanding these aspects aids users in selecting the right engine for their specific needs.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations allow users to identify individual elements quickly, facilitating troubleshooting and ensuring the longevity of equipment. These illustrations serve as essential tools for both novices and seasoned professionals in navigating the complexities of mechanical systems.

Enhancing Efficiency

Having access to clear visual guides significantly boosts efficiency during repairs. Technicians can locate necessary components swiftly, reducing downtime and streamlining the overall process. This efficiency is paramount in professional settings where time directly correlates with productivity.

Facilitating Communication

Visual aids also improve communication among team members. When discussing repairs or modifications, referencing specific illustrations minimizes misunderstandings. Such clarity fosters a collaborative environment, enhancing teamwork and ensuring that everyone is on the same page regarding maintenance tasks.

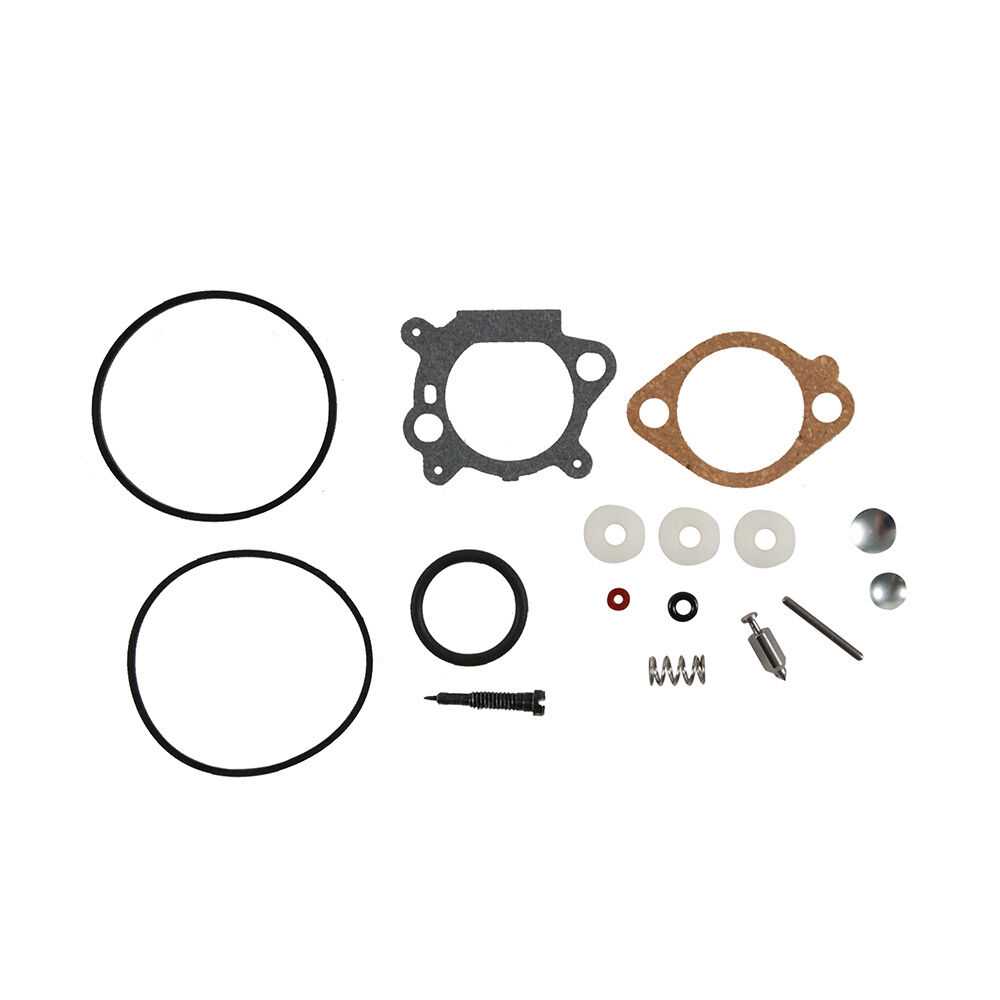

Common Replacement Parts List

When it comes to maintaining outdoor equipment, knowing which components frequently require substitution is essential for ensuring optimal performance. This section highlights key elements that often need replacing, helping users keep their machinery running smoothly.

Essential Components

Among the critical parts, spark plugs are vital for igniting the fuel mixture, while air filters ensure clean airflow to the engine. Additionally, fuel filters play a crucial role in preventing contaminants from entering the fuel system.

Other Notable Items

Another important item is the starter assembly, which is responsible for initiating the engine. Belts and blades are also common areas that require attention due to wear and tear over time. Regularly checking these elements can significantly enhance the longevity and reliability of the equipment.

Step-by-Step Repair Guide

This section provides a comprehensive walkthrough for troubleshooting and fixing common issues. By following these instructions carefully, you can effectively restore functionality and ensure optimal performance.

Tools Needed

- Screwdriver set

- Wrench

- Replacement components

- Cleaning materials

- Protective gloves

Repair Process

- Disconnect the power source to ensure safety.

- Carefully remove the outer casing to access internal mechanisms.

- Identify the faulty part using the troubleshooting guide.

- Replace the damaged component with the new one.

- Reassemble the unit and secure all screws tightly.

- Reconnect the power and conduct a test run.

Where to Find Authentic Parts

Locating genuine components for your machinery can be a challenging endeavor. Ensuring that you use high-quality replacements is essential for optimal performance and longevity. Authentic items not only enhance functionality but also guarantee safety and reliability in operation.

One of the best resources for finding these components is the official manufacturer’s website. Here, you can often find a catalog of approved distributors and retailers who specialize in legitimate items. Additionally, these platforms frequently provide detailed specifications, ensuring compatibility with your equipment.

Another excellent option is local authorized dealers. Visiting a store that specializes in machinery can lead you to knowledgeable staff who can assist in identifying the right components for your needs. They may also have access to exclusive products that are not available through other channels.

Online marketplaces can also be a viable option, but caution is advised. Always look for sellers with strong ratings and positive reviews to ensure you’re purchasing genuine items. It’s crucial to read product descriptions thoroughly to avoid counterfeit alternatives.

Lastly, community forums and user groups can serve as valuable resources. Engaging with fellow enthusiasts or professionals can provide insights and recommendations on where to source authentic items, as well as tips for installation and maintenance.

Identifying Compatible Components

Understanding how to recognize suitable elements for your equipment is crucial for maintaining optimal performance. Compatibility ensures seamless integration, allowing for efficient operation and longevity of your machinery.

Key Factors to Consider

When evaluating components, focus on specifications such as size, shape, and functionality. Ensure that the parts align with the original specifications to avoid issues during installation and usage.

Resources for Verification

Utilize manuals, online forums, and manufacturer websites to gather information about recommended components. These resources can help you delve into the nuances of compatibility and guide you in making informed decisions.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. Simple practices can significantly enhance performance, reduce wear, and ultimately save costs on repairs or replacements. This guide offers key suggestions for maintaining your machinery effectively.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and interior components clean to prevent dirt buildup and corrosion. Use appropriate cleaning agents and tools. |

| Oil Changes | Change the lubricant at regular intervals to ensure optimal functioning and reduce friction between moving parts. |

| Air Filter Inspection | Check and replace air filters as needed. A clean filter improves airflow and efficiency, enhancing overall performance. |

| Spark Plug Maintenance | Inspect spark plugs for wear and replace them periodically to ensure reliable starting and optimal combustion. |

| Seasonal Storage | Prepare equipment for off-season storage by cleaning, draining fluids, and covering to protect from the elements. |

By implementing these practices, you can greatly enhance the reliability and lifespan of your machinery, ensuring it remains in excellent working condition for years to come.

Troubleshooting Common Issues

When dealing with mechanical equipment, encountering problems is a common experience. Understanding how to identify and resolve these issues can enhance performance and extend the lifespan of the machinery.

Common Problems

- Engine fails to start

- Unusual noises during operation

- Excessive vibration

- Fuel leaks

Resolution Steps

- Check the fuel level and quality.

- Inspect electrical connections for corrosion or damage.

- Examine the air filter for clogs.

- Ensure all bolts and screws are tightened.

Safety Precautions During Repairs

When conducting maintenance on machinery, prioritizing safety is essential to prevent accidents and ensure a smooth process. Understanding potential hazards and taking necessary precautions can significantly reduce risks associated with mechanical work.

First, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This gear safeguards against injuries from sharp components and hazardous substances.

Second, ensure that the equipment is completely powered off before beginning any repairs. Disconnecting power sources eliminates the risk of accidental activation during work.

Finally, organize tools and components in a clean workspace to minimize the chances of mishaps. Keeping the area tidy helps maintain focus and prevents the loss of critical parts during the repair process.

Comparing YBSXS.2051HF with Other Models

This section explores the nuances and features of a specific engine model in relation to its counterparts. By examining key specifications and performance metrics, we can better understand how it stacks up against similar options in the market.

When assessing performance, one can notice differences in horsepower, fuel efficiency, and torque output. Some variants may offer enhanced power delivery, making them suitable for more demanding tasks.

Durability and maintenance are also crucial factors. Certain models may incorporate advanced materials or designs that extend lifespan and reduce the frequency of upkeep, which can be a significant advantage for users.

Finally, user experience often varies between models. Features such as ease of starting, noise levels, and vibration control can greatly influence customer satisfaction and overall usability.

Resources for Further Learning

Exploring the intricacies of mechanical systems can be an enriching journey. Numerous materials and platforms are available to enhance your understanding of engines and their components. Whether you are a beginner or seeking advanced knowledge, these resources can provide valuable insights and practical guidance.

Online Courses and Tutorials

Various educational websites offer structured courses covering essential concepts and hands-on practices. Platforms such as Coursera and Udemy feature classes specifically focused on small engine mechanics, allowing learners to progress at their own pace while accessing expert knowledge.

Books and Manuals

For those who prefer traditional learning methods, a selection of books and repair manuals is available that delve into the technical aspects of engine maintenance and repair. These printed resources often include detailed illustrations and step-by-step instructions, making them indispensable for both hobbyists and professionals.