Maintaining optimal performance of your outdoor machinery requires a clear understanding of its various elements. Each part plays a crucial role in ensuring efficiency and longevity, making it essential to know how they interact with one another. This knowledge can empower users to troubleshoot issues and facilitate smoother repairs.

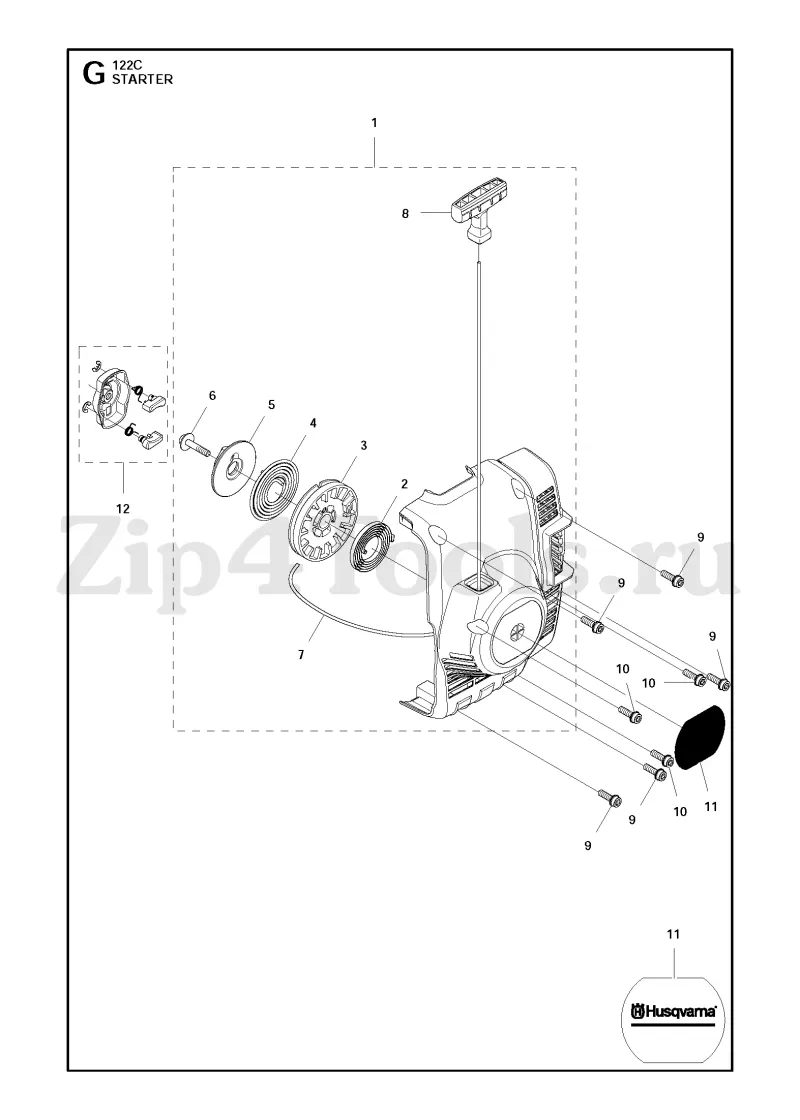

By exploring detailed illustrations of component arrangements, operators can gain valuable insights into the structure of their devices. Such visual aids serve as a guide, simplifying the identification of specific elements and enhancing overall maintenance practices. Equipped with this information, one can approach repairs with confidence and precision.

Additionally, familiarizing oneself with the intricate relationships between different sections can lead to improved performance. A comprehensive grasp of how each piece functions contributes to the ultimate effectiveness of your machinery, ensuring it operates at its best for years to come.

Understanding the Husqvarna 122c Parts

This section delves into the components of a specific outdoor tool, focusing on their roles and functionalities. A thorough grasp of each element not only aids in maintenance but also enhances the user experience, ensuring the equipment operates efficiently and effectively. Knowing how these components interact can prevent common issues and extend the life of the machine.

Key Components Overview

The essential elements of this equipment can be categorized into several groups. Each category plays a vital role in the overall performance and reliability of the device. Below is a table that outlines these groups and their respective functions.

| Component Group | Function |

|---|---|

| Power System | Provides the energy needed for operation, ensuring smooth performance. |

| Cutting Mechanism | Responsible for the actual cutting, allowing for precise work on various materials. |

| Support Structure | Houses and protects internal components, maintaining overall integrity. |

| Control Elements | Allows the user to manage operations, ensuring safety and ease of use. |

Importance of Maintenance

Regular upkeep of these elements is crucial for optimal functionality. Neglecting any specific component can lead to diminished performance or potential failure. Understanding the significance of each part encourages proactive care and timely repairs, ultimately leading to enhanced longevity of the tool.

Importance of Parts Diagrams

Understanding the layout and components of equipment is crucial for effective maintenance and repair. Visual representations serve as essential tools that guide users through the intricacies of various assemblies, enabling them to identify each element accurately. This knowledge not only simplifies the process of reparation but also enhances the overall longevity of the machinery.

Facilitating Repairs

Having a clear visual reference allows individuals to quickly locate and assess components that may require attention. This can significantly reduce the time spent troubleshooting issues, making repairs more efficient and effective. By minimizing confusion, users can focus on resolving problems rather than searching for parts or deciphering assembly details.

Enhancing Maintenance Knowledge

Visual guides also foster a deeper understanding of how different elements work together within a system. This comprehension is beneficial not only for current maintenance tasks but also for future endeavors. By familiarizing oneself with the layout and function of various components, users become more adept at spotting potential issues before they escalate, ultimately promoting better care for the equipment.

Main Components of the 122c

This section focuses on the key elements that make up a well-designed outdoor power tool. Understanding these essential parts helps users appreciate the functionality and efficiency of the machine.

- Engine: The heart of the tool, responsible for providing the necessary power for operation.

- Fuel System: Comprising components that facilitate the delivery of fuel to the engine, ensuring optimal performance.

- Cutting Mechanism: This includes blades or trimmers that perform the actual cutting task.

- Handle: Designed for comfort and control, allowing the user to maneuver the device easily.

- Throttle Control: A mechanism that enables the operator to adjust the engine speed and power output.

Each of these parts plays a crucial role in the overall functionality and efficiency of the tool, making it an indispensable asset for various outdoor tasks.

Common Issues with Husqvarna Parts

When dealing with outdoor power equipment, various complications can arise from components. Understanding these challenges can help users maintain their machines more effectively. Common problems include wear and tear, improper installation, and compatibility issues that can affect performance.

Wear and tear is a natural consequence of frequent use. Components may become damaged or worn out over time, leading to reduced efficiency. Regular inspections are crucial to identify signs of fatigue before they escalate into larger problems.

Improper installation can also cause significant issues. When parts are not fitted correctly, it can lead to malfunctioning equipment, resulting in safety hazards. Ensuring that each component is installed according to manufacturer guidelines is essential for optimal operation.

Compatibility is another critical aspect to consider. Using components that are not designed for specific models can result in poor performance and potential damage. Always verify that the chosen parts match the specifications of the equipment in question.

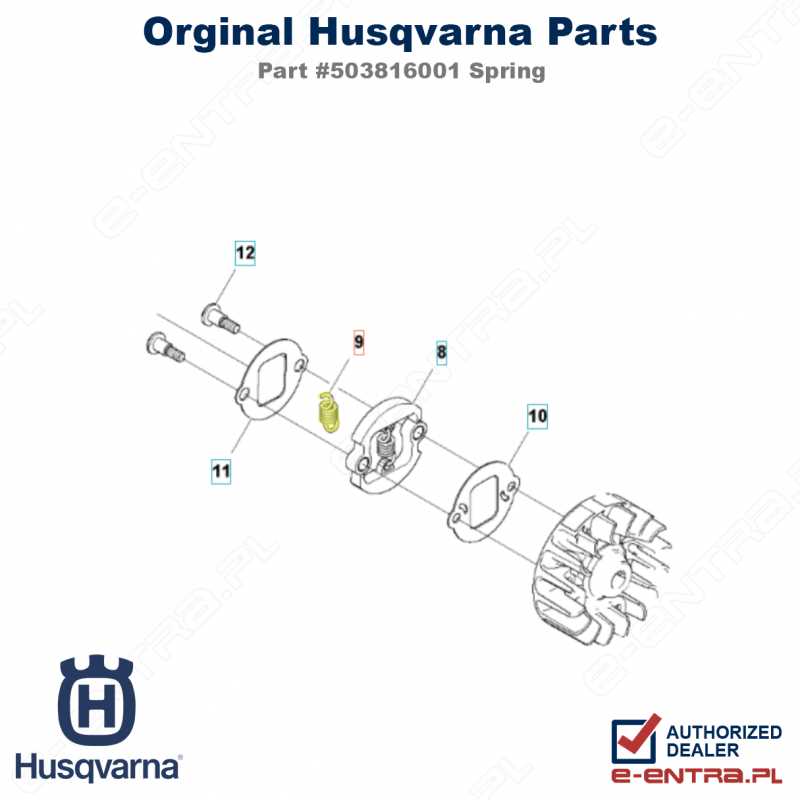

Identifying Replacement Parts

Understanding how to recognize necessary components for your outdoor equipment is crucial for maintaining optimal performance. This process involves examining various elements of the machinery to determine which items need to be replaced due to wear or damage. By familiarizing yourself with the structure and function of each part, you can ensure efficient repairs and prolong the lifespan of your tools.

Common Indicators of Wear

Several signs can indicate that a component requires replacement. Look for unusual noises, decreased performance, or visible damage such as cracks or corrosion. Regular inspections help in catching these issues early, ensuring your equipment operates smoothly and reliably.

Resources for Identification

Utilizing user manuals, online resources, and parts catalogs can greatly assist in identifying the correct components. Many manufacturers provide detailed guides that outline each part’s function and specifications, making it easier to find replacements. Engaging with community forums can also offer insights and recommendations from other users.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular upkeep and attention. By following a few essential practices, you can significantly extend the lifespan of your machine and maintain its performance. Consistent care not only enhances functionality but also reduces the likelihood of costly repairs in the future.

Regular Cleaning: After each use, take the time to remove dirt, grass clippings, and debris. This prevents buildup that can lead to corrosion and mechanical issues. A simple rinse and wipe down can make a big difference.

Check and Change Filters: Air and fuel filters play a crucial role in maintaining optimal engine performance. Inspect these components regularly and replace them as necessary to ensure proper airflow and fuel delivery.

Inspect the Blades: Dull or damaged blades can strain the engine and affect cutting efficiency. Regularly sharpen or replace the blades to ensure smooth operation and a clean cut.

Oil Maintenance: Keeping the engine lubricated is vital. Check the oil level frequently and change it according to the manufacturer’s recommendations to prevent overheating and wear.

Fuel Quality: Use high-quality fuel to ensure efficient combustion and minimize deposits that can harm the engine. Store fuel properly and avoid using stale gas.

Seasonal Storage: At the end of the season, prepare your equipment for storage. Drain fuel, clean the machine thoroughly, and cover it to protect it from dust and moisture. This will help maintain its condition for the next season.

By implementing these maintenance tips, you can enjoy reliable performance and prolong the life of your outdoor equipment. Regular attention and care will yield significant benefits over time.

Where to Find Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. It is crucial to source these items from reliable vendors to ensure quality and compatibility.

Here are some effective avenues to explore:

- Authorized Dealers: Visiting an official retailer is one of the best ways to ensure that you acquire genuine components. These establishments are typically stocked with the correct items tailored for your specific model.

- Manufacturer’s Website: Many manufacturers offer a comprehensive online catalog of their products. This can be a reliable source for identifying and ordering the necessary components directly.

- Reputable Online Marketplaces: Various online platforms specialize in selling equipment parts. Ensure to verify the seller’s reputation and confirm that the items are genuine.

- Local Repair Shops: Established repair facilities often maintain a selection of original components or can assist in ordering the correct ones for you.

- Parts Catalogs: Consulting a detailed catalog or manual can help you identify the exact components you need, making it easier to locate them through various vendors.

Utilizing these sources can significantly enhance your chances of obtaining authentic components that will keep your equipment functioning effectively.

Aftermarket Options for the 122c

Exploring alternative components can enhance the performance and longevity of your outdoor equipment. Aftermarket offerings provide a diverse range of solutions that cater to various needs, whether you seek improved efficiency, durability, or cost-effectiveness. By opting for these alternatives, users can often find enhancements that suit their specific requirements without compromising on quality.

Benefits of Aftermarket Components

One of the main advantages of choosing aftermarket solutions is the availability of upgraded features. Many manufacturers focus on creating enhancements that provide better functionality or increased resilience. Additionally, these components often come at competitive prices, allowing users to save money while maintaining or improving performance. Customization is another key benefit, as users can select parts that specifically meet their individual preferences and usage patterns.

Popular Aftermarket Brands

Several reputable brands specialize in creating high-quality alternatives. These companies typically focus on innovation and rigorous testing to ensure their products meet industry standards. Researching reviews and seeking recommendations can help you find trusted options that align with your equipment needs. Always ensure that any aftermarket components are compatible with your specific model to avoid any operational issues.

Assembly Instructions for Key Parts

When it comes to assembling essential components of your equipment, following clear guidelines ensures optimal functionality and longevity. Proper assembly not only enhances performance but also minimizes the risk of damage during operation. This section provides step-by-step instructions for assembling critical elements effectively.

Required Tools

- Torque wrench

- Socket set

- Phillips and flathead screwdrivers

- Safety gloves

Assembly Steps

- Begin by securing the main body on a flat surface to prevent movement.

- Attach the engine to the base, ensuring that all alignment markers are properly matched.

- Fasten the screws with a torque wrench to the manufacturer’s specifications to avoid over-tightening.

- Connect the fuel lines, making sure there are no kinks or leaks.

- Install the cutting attachment by sliding it onto the designated mount and securing it with the locking mechanism.

- Check all connections and fittings for tightness and stability.

Once assembled, perform a visual inspection and a test run to confirm everything operates smoothly. Address any irregularities before full use.

Tools Needed for Repairs

Performing maintenance and repairs on outdoor equipment requires a specific set of instruments to ensure efficiency and accuracy. Having the right tools not only streamlines the process but also minimizes the risk of damage during disassembly and reassembly.

Essential tools include screwdrivers of various sizes for loosening and tightening fasteners, pliers for gripping and manipulating components, and wrenches for adjusting bolts and nuts. Additionally, a torque wrench is crucial for applying the correct amount of force when securing parts, ensuring optimal performance.

Other valuable instruments are a clean cloth for wiping surfaces and a small brush for removing debris. A parts tray can help keep small components organized, while safety goggles and gloves provide necessary protection during the repair process. By equipping yourself with these tools, you can effectively manage repairs and maintain your equipment in peak condition.

Exploring User Manuals

User manuals serve as essential resources for understanding and maximizing the functionality of various equipment. They provide detailed instructions, maintenance tips, and troubleshooting guidance, ensuring users can operate their tools safely and efficiently. Familiarizing oneself with these documents can significantly enhance the overall experience and longevity of the device.

The Importance of Familiarization

Engaging with the manual before using any device helps users to identify key components and their functions. This knowledge not only fosters confidence but also reduces the risk of damage during operation. Additionally, understanding the specifications and safety precautions outlined in the guide promotes a safer working environment.

Navigating Technical Information

Technical details within user manuals can often seem overwhelming. However, focusing on sections that cover assembly, maintenance schedules, and common issues can demystify the content. Visual aids such as diagrams and illustrations enhance comprehension, making it easier for users to follow along and execute the necessary steps. Regularly consulting the manual can lead to improved performance and a deeper appreciation of the tool’s capabilities.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and replacement components for outdoor power equipment. Here, you will find helpful information that can guide you in ensuring optimal performance and longevity of your tools.

| Question | Answer |

|---|---|

| What should I do if my machine won’t start? | Check the fuel level, ensure the spark plug is functioning properly, and examine the air filter for blockages. |

| How often should I replace the cutting head? | It is recommended to replace the cutting head every 20 to 25 hours of use, or when you notice reduced performance. |

| Where can I find replacement components? | Replacement components can be found at authorized retailers, online marketplaces, or through official service centers. |

| How do I maintain the engine? | Regularly check the oil level, replace the air filter, and clean the fuel system to maintain engine efficiency. |

| What safety gear should I wear? | Always wear protective eyewear, gloves, and sturdy footwear while operating outdoor equipment. |