| Ergonomic Design |

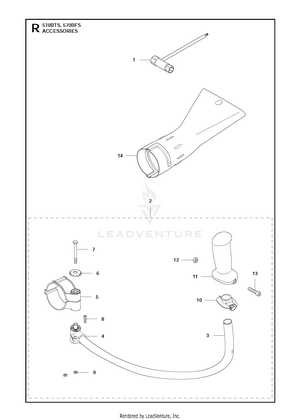

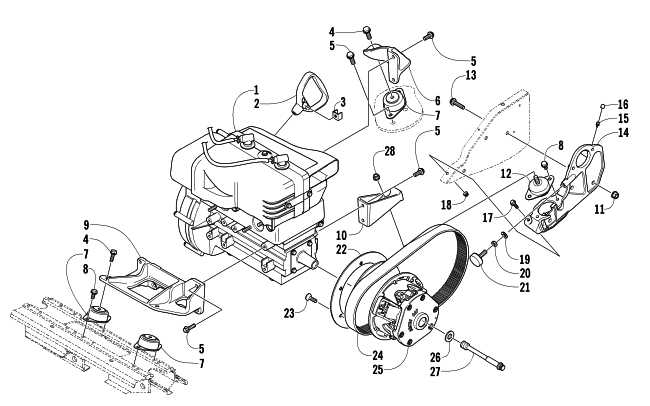

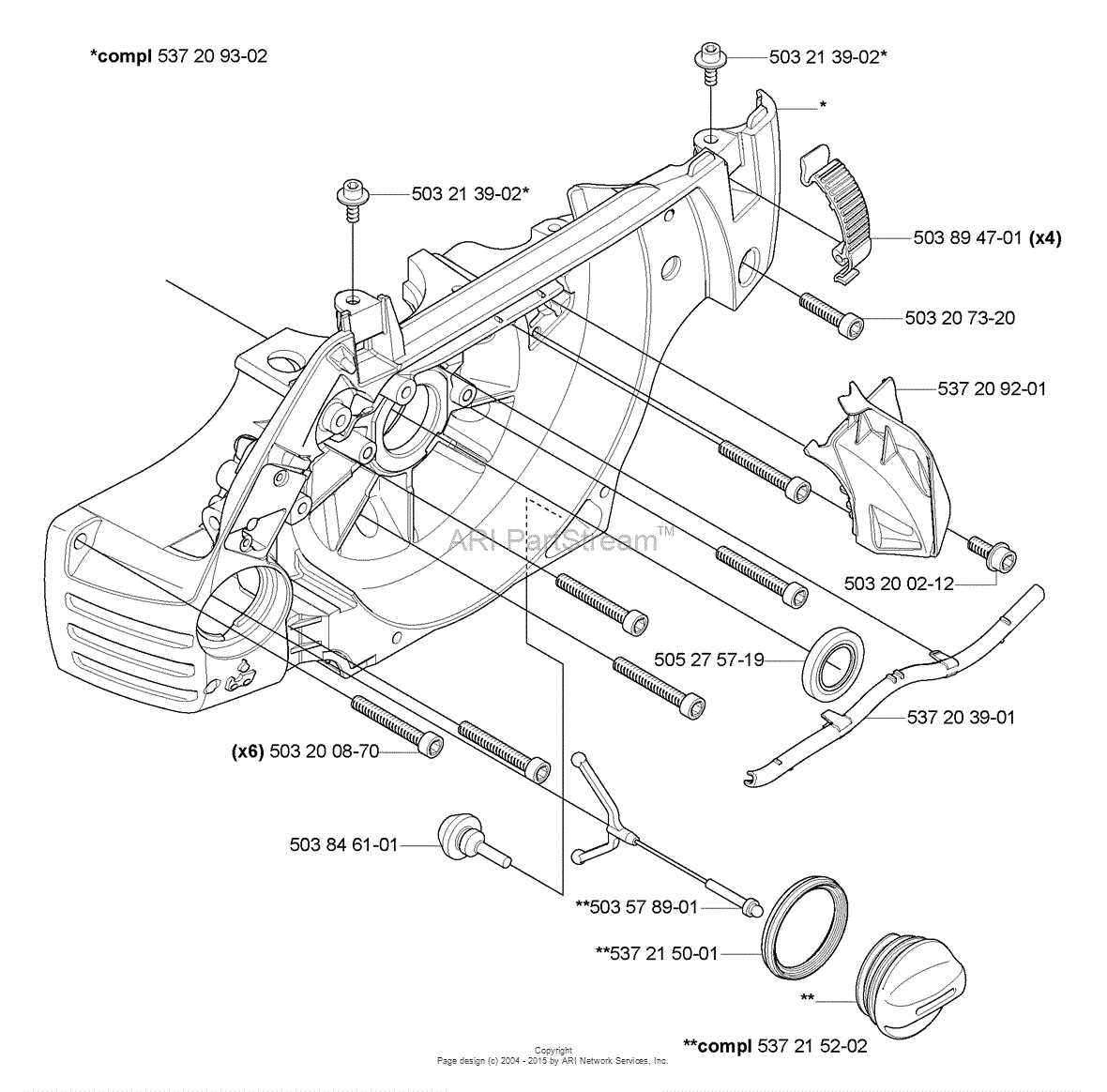

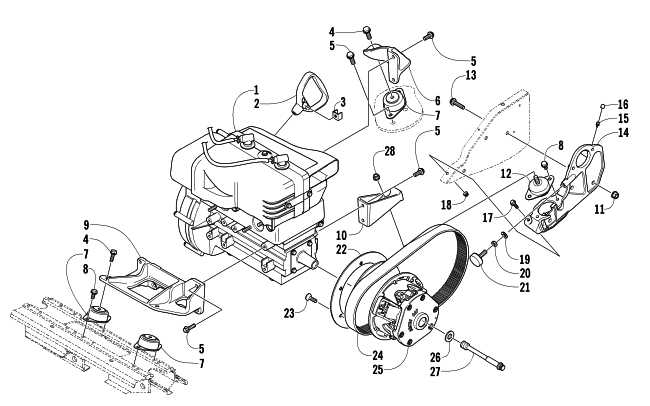

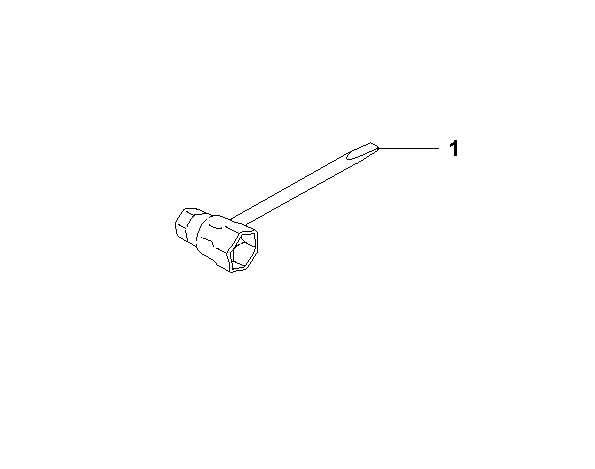

Guide to Identifying Critical Parts

Understanding the essential components of your equipment is key to maintaining its functionality and ensuring long-term performance. Recognizing which elements are vital for operation allows for timely maintenance and replacement, preventing larger issues down the road. This guide will help you pinpoint the most crucial elements, so you can keep your machinery in top condition.

Core Components to Focus On

There are several elements that play a fundamental role in ensuring the smooth operation of your equipment. These include structural elements responsible for stability, key mechanisms involved in functionality, and smaller elements that often require frequent attention due to wear and tear. Identifying these critical elements early can save you from costly repairs and downtime.

Common Wear Points

Another important aspect of maintaining machinery is being aware of parts that typically wear out more quickly. Regular inspection of these areas, especially after extended use, is essential. Look for signs of wear, such as material degradation, loose fittings, or unusual sounds during operation. Addressing these issues before they escalate will

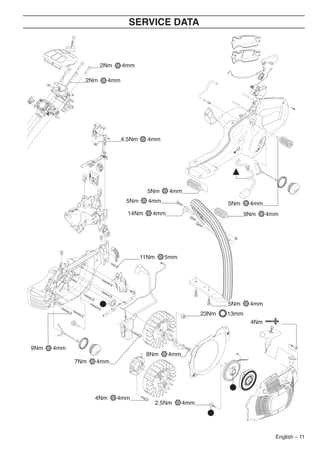

Chainsaw Maintenance with the Husqvarna 570

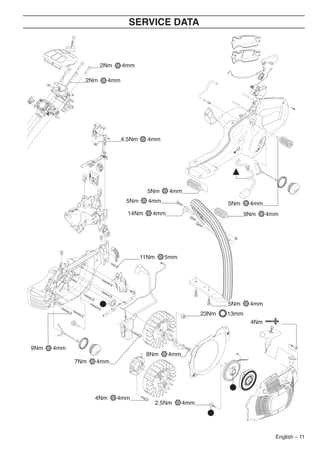

Regular upkeep of your cutting tool is essential to ensure its performance and longevity. Keeping all components in optimal condition not only extends the life of the machine but also enhances safety and efficiency during operation. With proper care, you’ll prevent potential issues and minimize downtime due to malfunction.

Cleaning: After each use, thoroughly clean all external and internal surfaces. Pay close attention to the areas prone to accumulating dust, wood chips, and oil. This will prevent clogging and overheating.

Chain Inspection: Routinely check the chain for signs of wear or dullness. A sharp chain improves cutting speed and precision, while a dull one can cause the tool to overheat and wear out faster. Ensure the chain is properly tensioned before starting any task.

Lubrication: Keep the chain and guide bar well-lubricated to reduce friction and prevent excessive wear. Regularly refilling the oil reservoir and ensuring smooth operation of the oiler mechanism is key to optimal cutting performance.

Filter Maintenance: The air filter must be cleaned or replaced periodically to maintain airflow and prevent debris from entering the engine

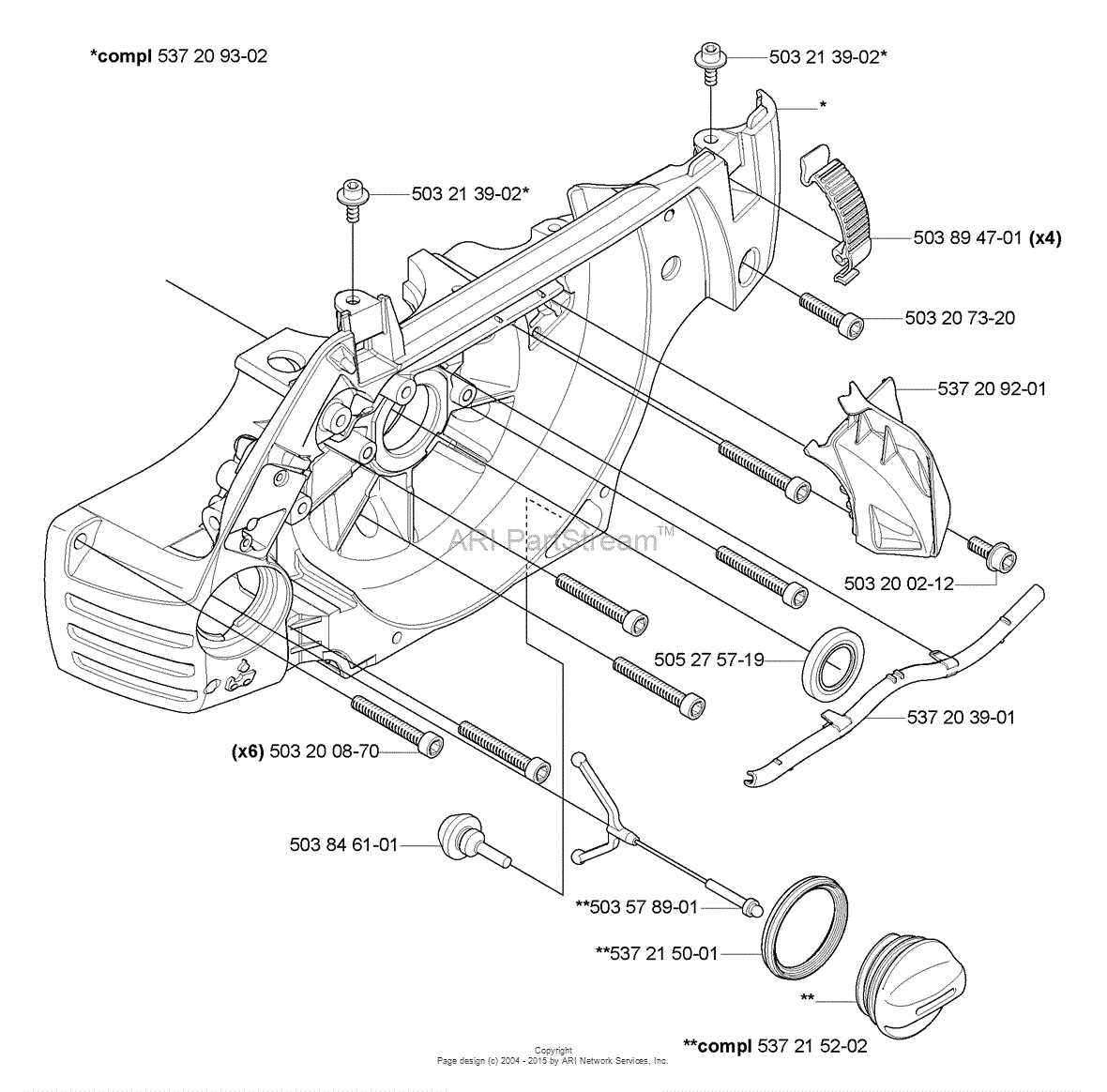

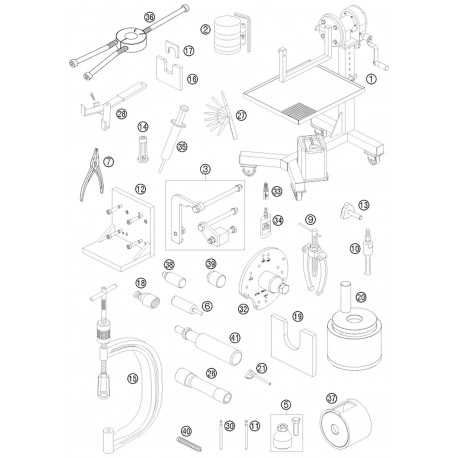

How to Access the Husqvarna Parts Diagram

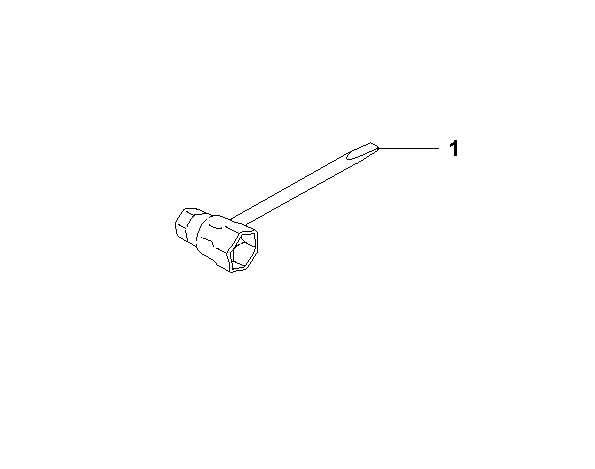

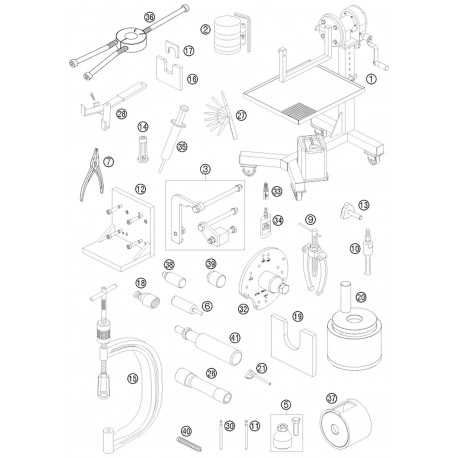

Locating detailed information for machine maintenance and repairs is crucial for keeping equipment running smoothly. To find necessary technical illustrations and assembly details, a few straightforward steps can guide you to the right resources. By using specific tools and platforms, you can quickly locate the required visuals for effective equipment care.

Step-by-Step Process

To begin, navigate to the official support website. Once there, look for the service section, where you can search for detailed illustrations and schematics by entering the model number or browsing the catalog. This will bring up all relevant materials, from technical illustrations to user manuals.

Additional Resources

For enhanced guidance, take advantage of any downloadable manuals or interactive catalogs provided on the site. These tools often allow you to zoom in on specific components, making it easier to identify and order replacement items. Bookmark this section for future use and quick reference during maintenance.

Common Replacement Parts for Husqvarna 570

When it comes to maintaining outdoor power equipment, understanding the essential components that may require periodic substitution is crucial for optimal performance. This section outlines the frequently needed elements that contribute to the efficient operation of these machines, ensuring longevity and reliability for users.

Key Components

Among the vital elements are the ignition system components, which often include spark plugs and ignition coils. These parts play a significant role in starting the engine and maintaining its functionality. Regularly checking and replacing these elements can prevent starting issues and enhance overall efficiency.

Wear Items

Another category encompasses wear items such as filters and fuel lines. Air and fuel filters are essential for keeping debris out of the engine, while fuel lines can degrade over time. Replacing these components not only improves performance but also ensures the longevity of the machine.

Troubleshooting Husqvarna 570 Parts Issues

When it comes to maintaining outdoor power equipment, encountering difficulties with components is a common challenge. Addressing these issues promptly can enhance performance and extend the lifespan of the machinery. Identifying the root cause of malfunctions requires a systematic approach to diagnose the situation effectively.

Common Component Problems

Several typical issues may arise with the equipment’s elements. These can include wear and tear, improper alignment, or malfunctioning parts. Symptoms like reduced power, unusual noises, or difficulties in starting are indicators that something may be amiss. Regular inspections and timely maintenance can help prevent these complications.

Steps to Diagnose Issues

Begin by thoroughly examining each individual part for visible signs of damage or excessive wear. Ensure that all connections are secure and that there are no obstructions affecting the machinery’s function. Referencing the manufacturer’s manual can provide valuable insights into troubleshooting specific challenges. If problems persist, seeking assistance from a qualified technician may be necessary to perform a comprehensive assessment.

Comparing OEM and Aftermarket Husqvarna 570 Parts

When it comes to maintaining outdoor power equipment, the choice between original manufacturer components and third-party alternatives can significantly impact performance and longevity. Understanding the differences between these options is essential for ensuring optimal operation and cost-effectiveness.

Original manufacturer components are specifically designed for the equipment, ensuring precise fit and compatibility. These components often come with warranties that provide peace of mind regarding quality and reliability. However, they may also carry a higher price tag, which can deter some users.

In contrast, third-party alternatives can offer more affordable solutions while providing similar functionality. Many manufacturers create replacement components that meet or exceed industry standards, making them a viable option for budget-conscious consumers. However, it is crucial to consider the reputation of the supplier, as quality can vary widely among different brands.

Ultimately, the decision hinges on individual needs and circumstances. Users should weigh the benefits of guaranteed compatibility and reliability against the cost savings and potential risks associated with third-party options. Researching both types thoroughly can lead to a more informed choice, maximizing the equipment’s performance and lifespan.

Essential Tips for Chainsaw Parts Longevity

Maintaining the lifespan of a cutting tool is crucial for optimal performance and safety. By following a few essential practices, users can ensure that their equipment remains in excellent condition, reducing the frequency of repairs and replacements.

Regular Maintenance Practices

- Keep the tool clean: Remove debris, sawdust, and oil buildup after each use to prevent corrosion and functionality issues.

- Sharpen the blade: A well-maintained edge not only improves cutting efficiency but also reduces strain on the engine.

- Check tension regularly: Proper chain tension minimizes wear and enhances cutting precision.

- Inspect and replace filters: Clean or replace air and fuel filters as needed to maintain engine performance.

Proper Usage Techniques

- Use the correct cutting technique: Employ appropriate angles and pressure to minimize wear on components.

- Avoid overworking the tool: Take breaks to prevent overheating and ensure longer operation times.

- Store in a safe place: Keep the equipment in a dry, protected area to avoid environmental damage.

By adhering to these guidelines, users can extend the life of their cutting devices and enhance overall productivity.

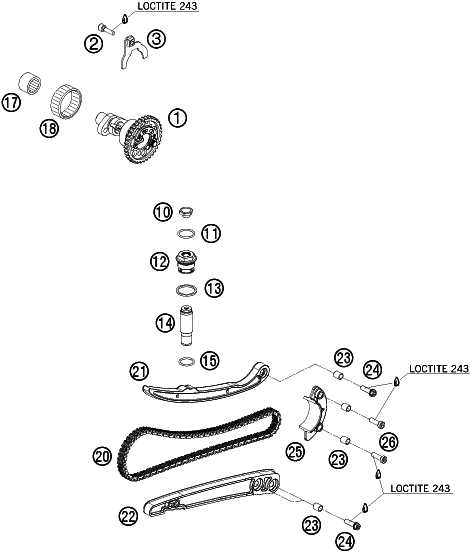

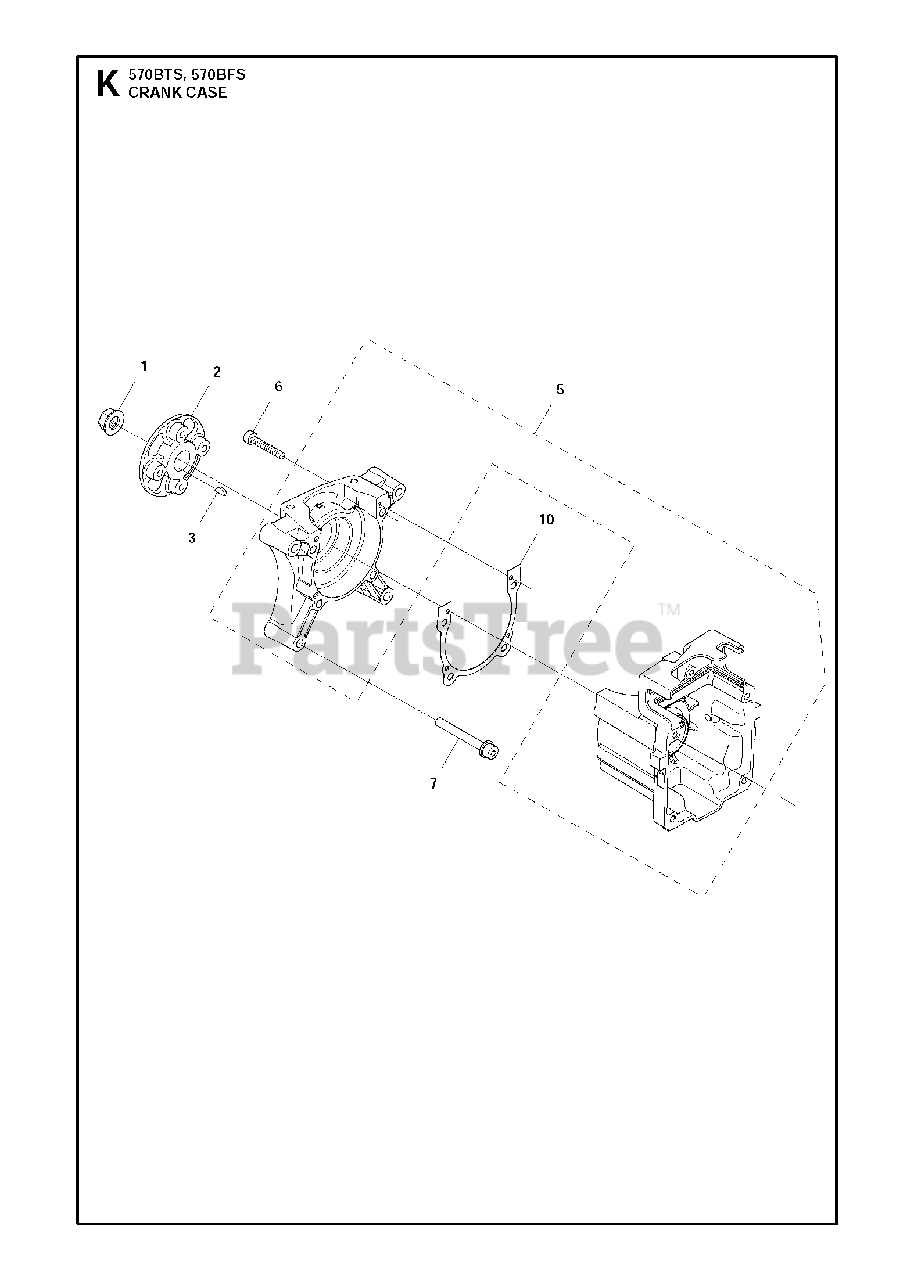

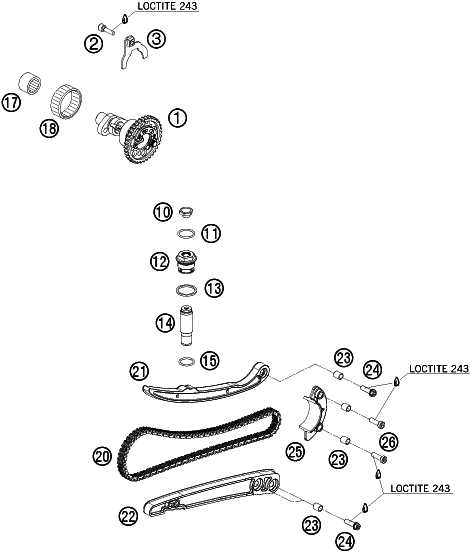

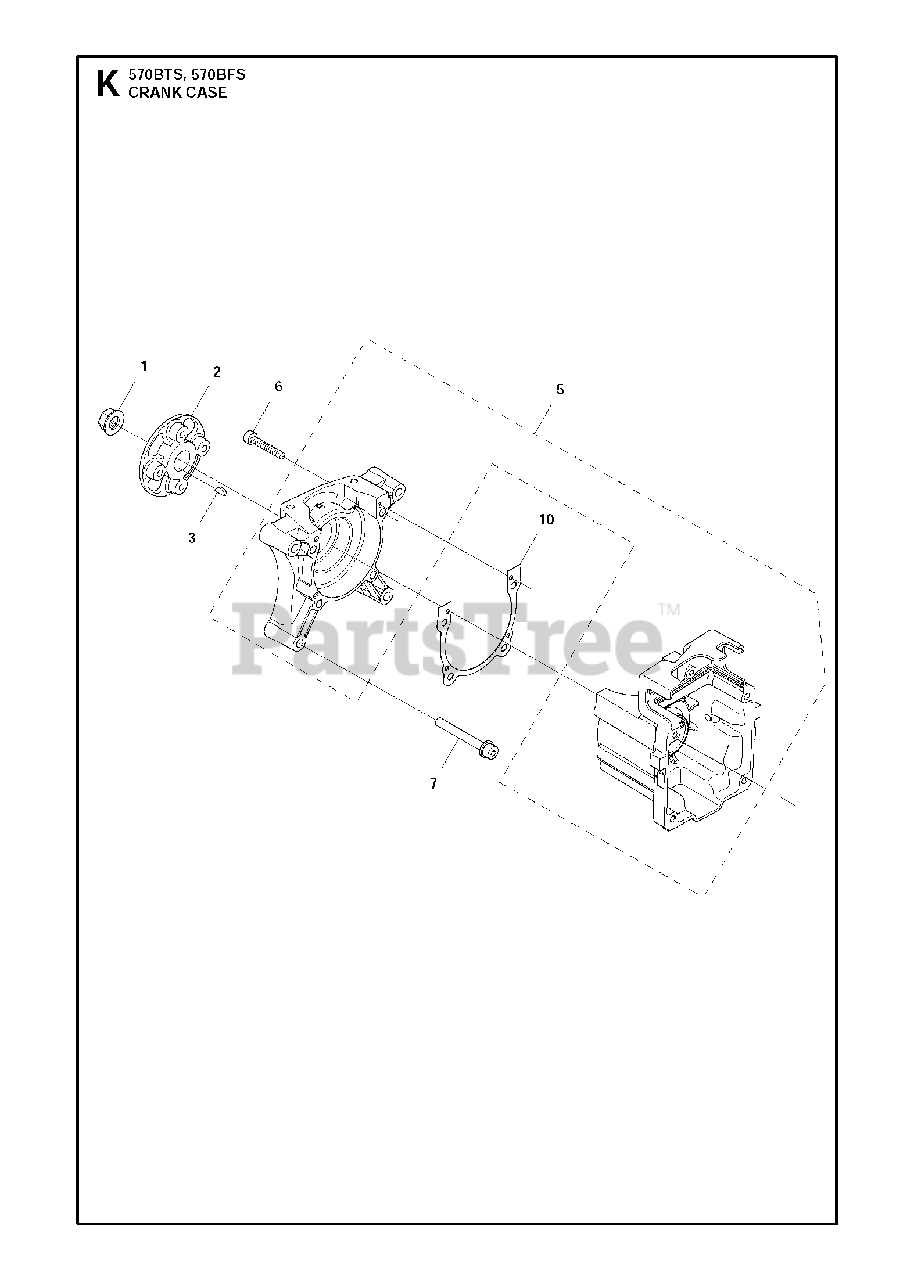

Exploring Husqvarna 570 Internal Mechanisms

This section delves into the intricate workings of a renowned outdoor power equipment model, focusing on its internal components and their roles in ensuring optimal performance. Understanding the mechanics behind this tool can enhance the user experience and facilitate better maintenance practices.

Key Internal Components

- Engine Assembly

- Crankshaft

- Piston

- Cylinder

- Fuel System

- Carburetor

- Fuel Tank

- Fuel Lines

- Ignition System

- Ignition Coil

- Spark Plug

- Flywheel

Understanding the Functionality

- The engine assembly is crucial for generating power. Each part must work seamlessly to ensure efficient combustion and energy transfer.

- The fuel system delivers the necessary mixture of air and fuel, influencing overall efficiency and responsiveness.

- The ignition system initiates combustion, with each component playing a significant role in starting and maintaining engine operation.

Where to Buy Husqvarna 570 Spare Parts

When it comes to sourcing replacement components for your equipment, knowing where to find reliable sources is essential. Various options are available for those in search of quality accessories to ensure optimal performance and longevity of their machinery.

Authorized Dealers: One of the most dependable avenues is through official distributors. They typically offer a comprehensive selection of authentic components, guaranteeing compatibility and quality.

Online Retailers: Numerous e-commerce platforms specialize in machinery accessories. These websites often provide extensive catalogs, competitive pricing, and convenient delivery options. Be sure to check reviews and ratings to ensure a positive purchasing experience.

Local Repair Shops: Neighborhood service centers frequently stock a range of components. Establishing a relationship with a local technician can also lead to helpful recommendations and possible discounts on necessary items.

Specialty Stores: Some shops focus exclusively on outdoor equipment and may carry a diverse range of accessories. These locations can provide expert advice and assistance in finding the right replacements for your machinery.

Regardless of the route chosen, it’s crucial to verify the specifications and authenticity of the items you purchase. This diligence will help maintain the efficiency and reliability of your equipment.