In the world of machinery maintenance, having a clear visual representation of components is essential for effective repairs and upgrades. By familiarizing yourself with the various sections of your device, you can ensure optimal performance and longevity. This guide delves into the intricate details that define the structure and functionality of your equipment.

Every mechanical system comprises numerous elements, each playing a critical role in its operation. Recognizing these parts and their interconnections not only simplifies troubleshooting but also enhances your understanding of how everything works together. A comprehensive overview helps you navigate potential issues with confidence and precision.

Whether you are a seasoned technician or a curious novice, grasping the layout of essential components can significantly improve your maintenance skills. Visual aids serve as invaluable resources, allowing you to identify parts quickly and accurately, which is crucial when seeking replacements or performing upgrades.

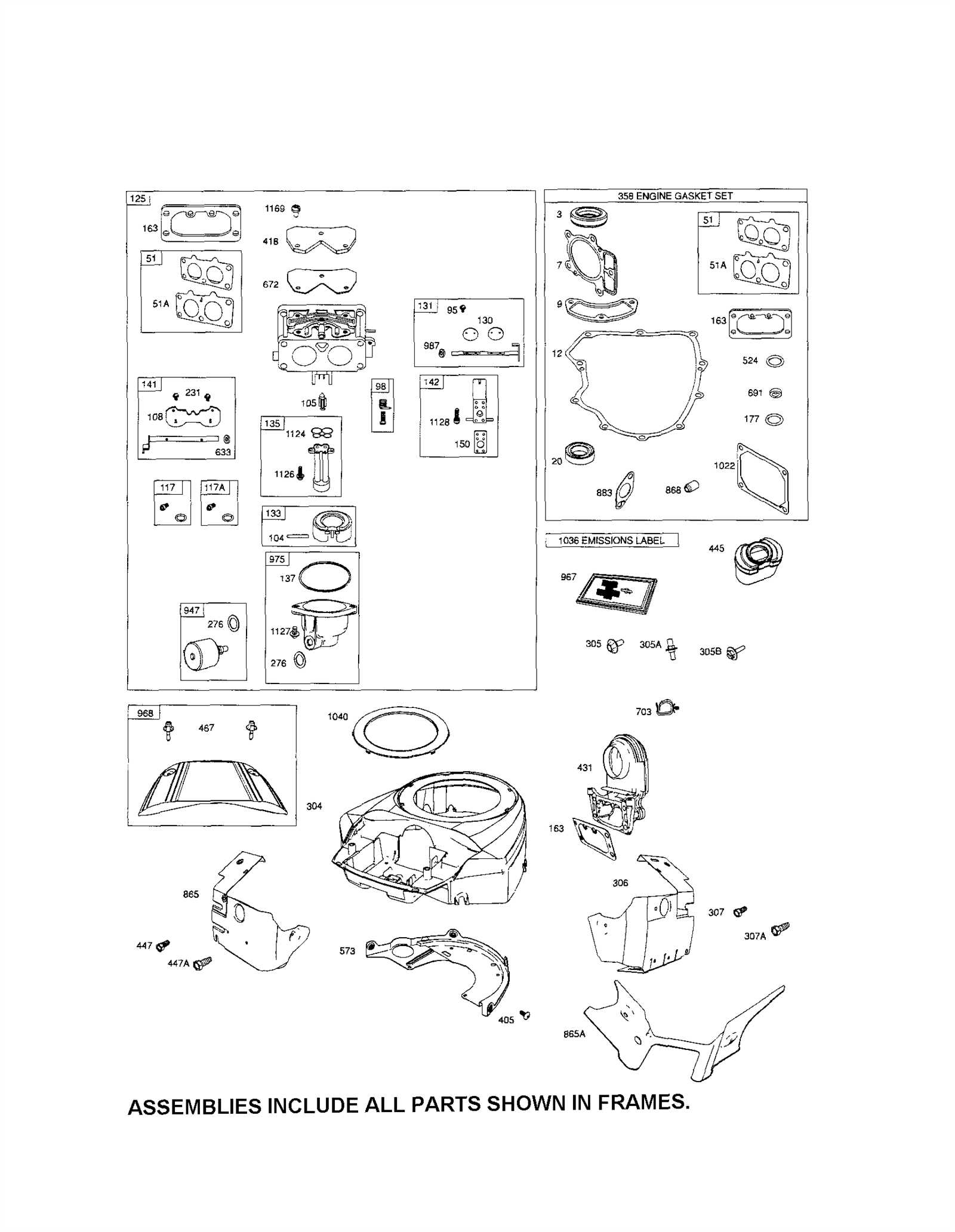

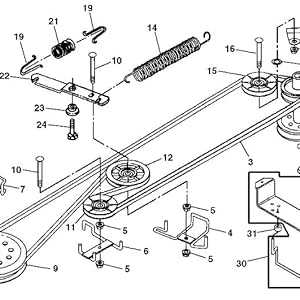

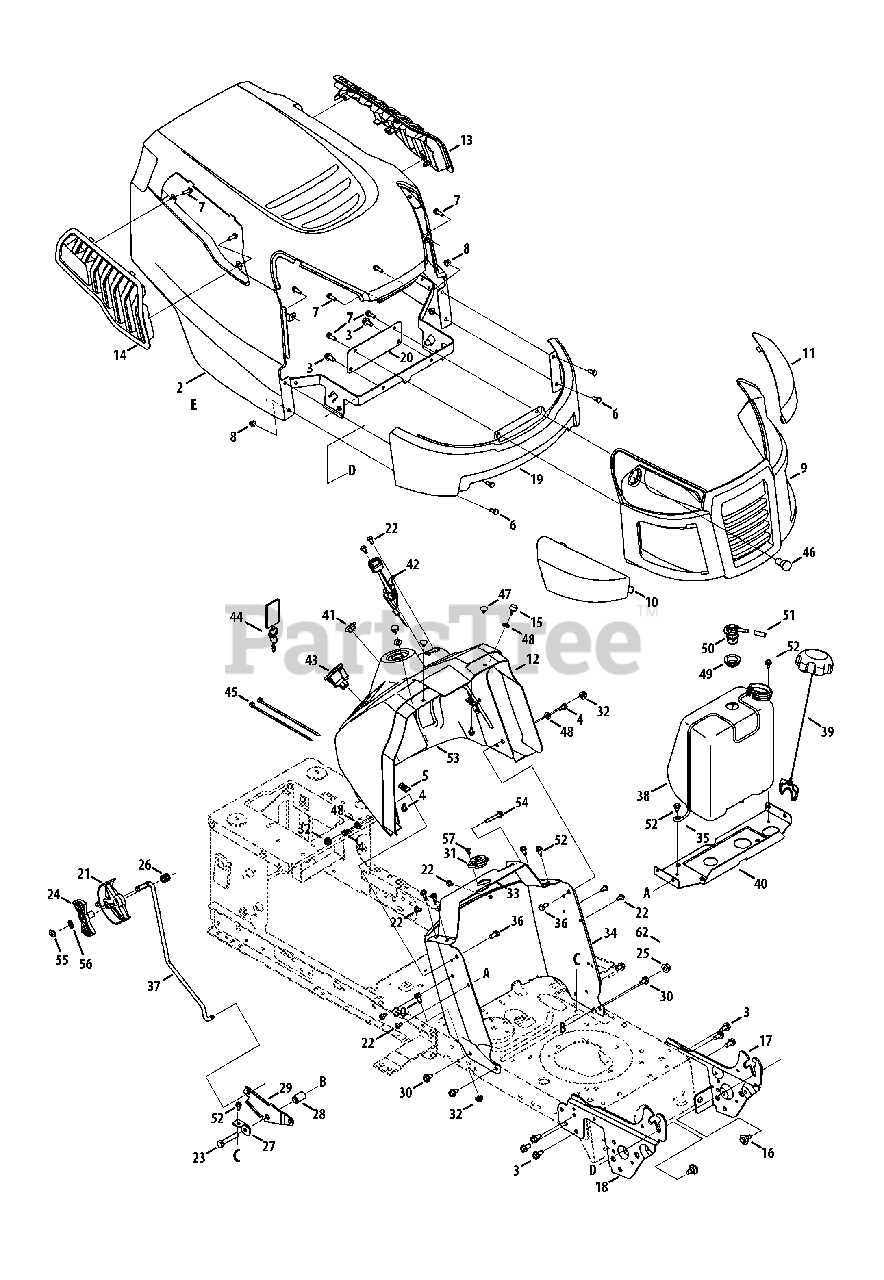

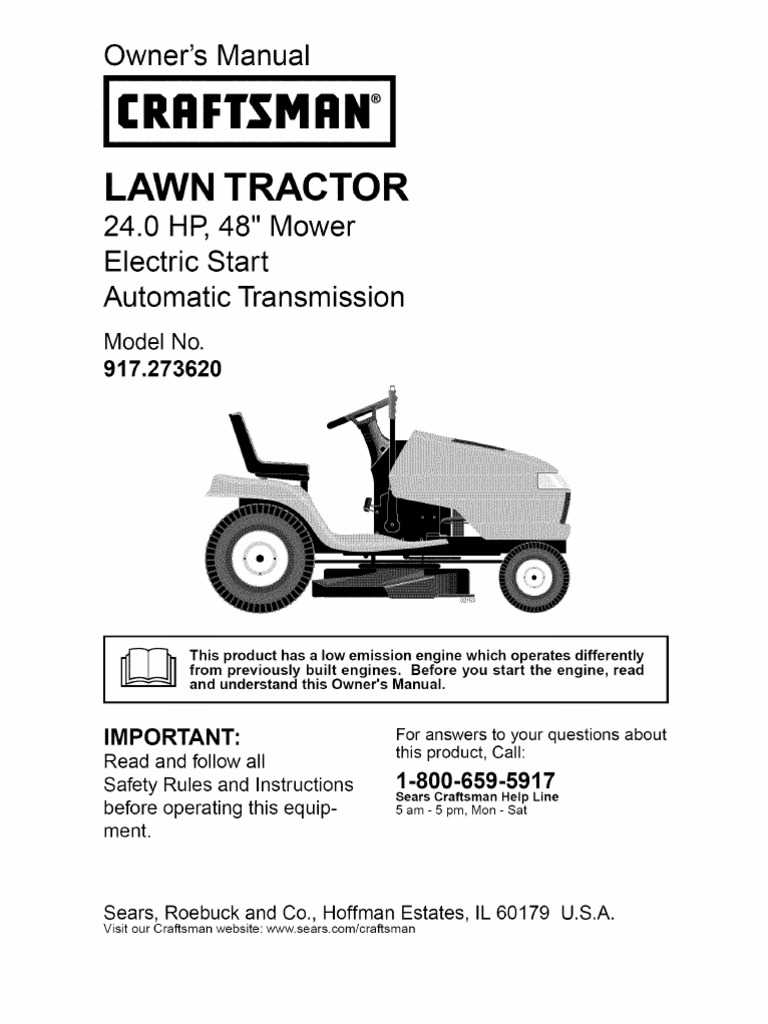

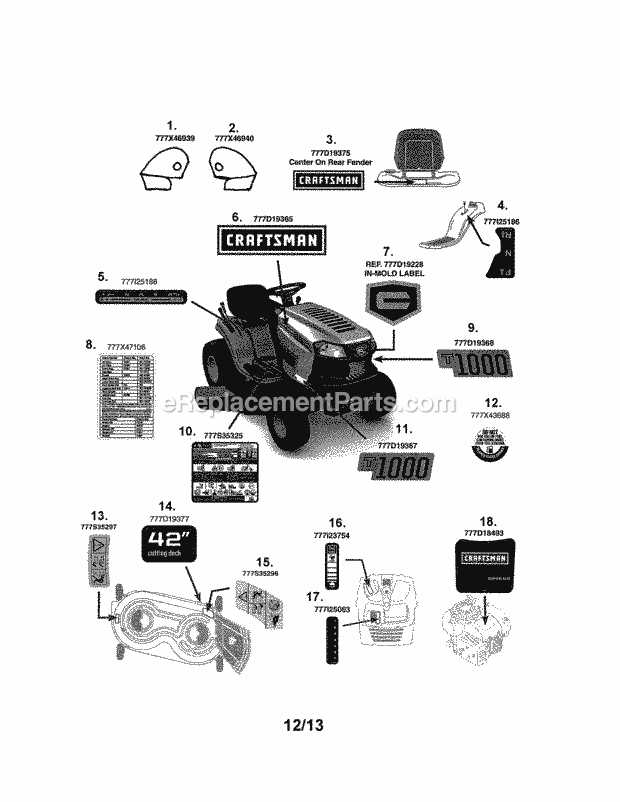

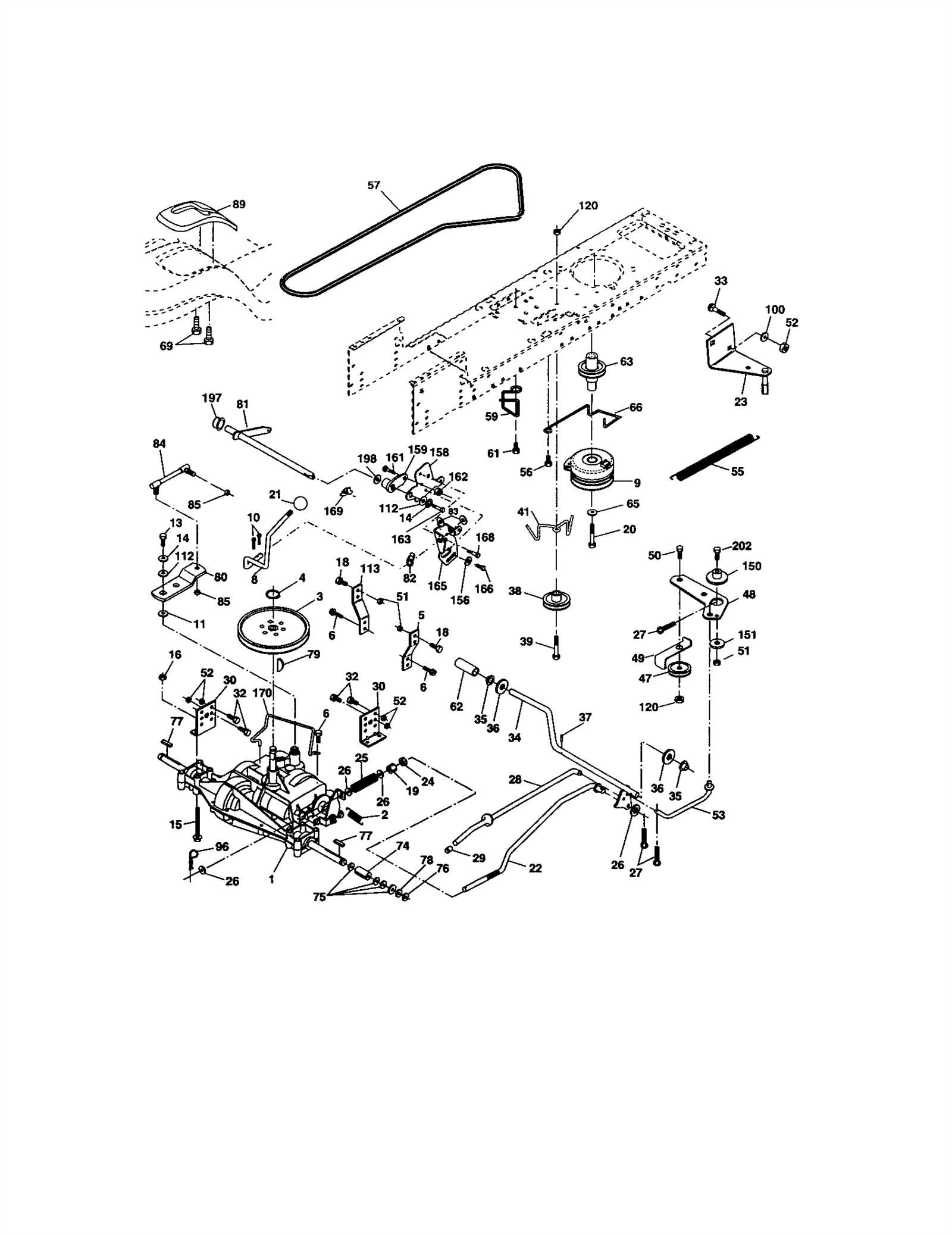

Understanding Craftsman LT4000 Components

This section explores the essential elements that contribute to the overall functionality of a specific lawn maintenance machine. Each component plays a crucial role in ensuring efficient operation and maintenance.

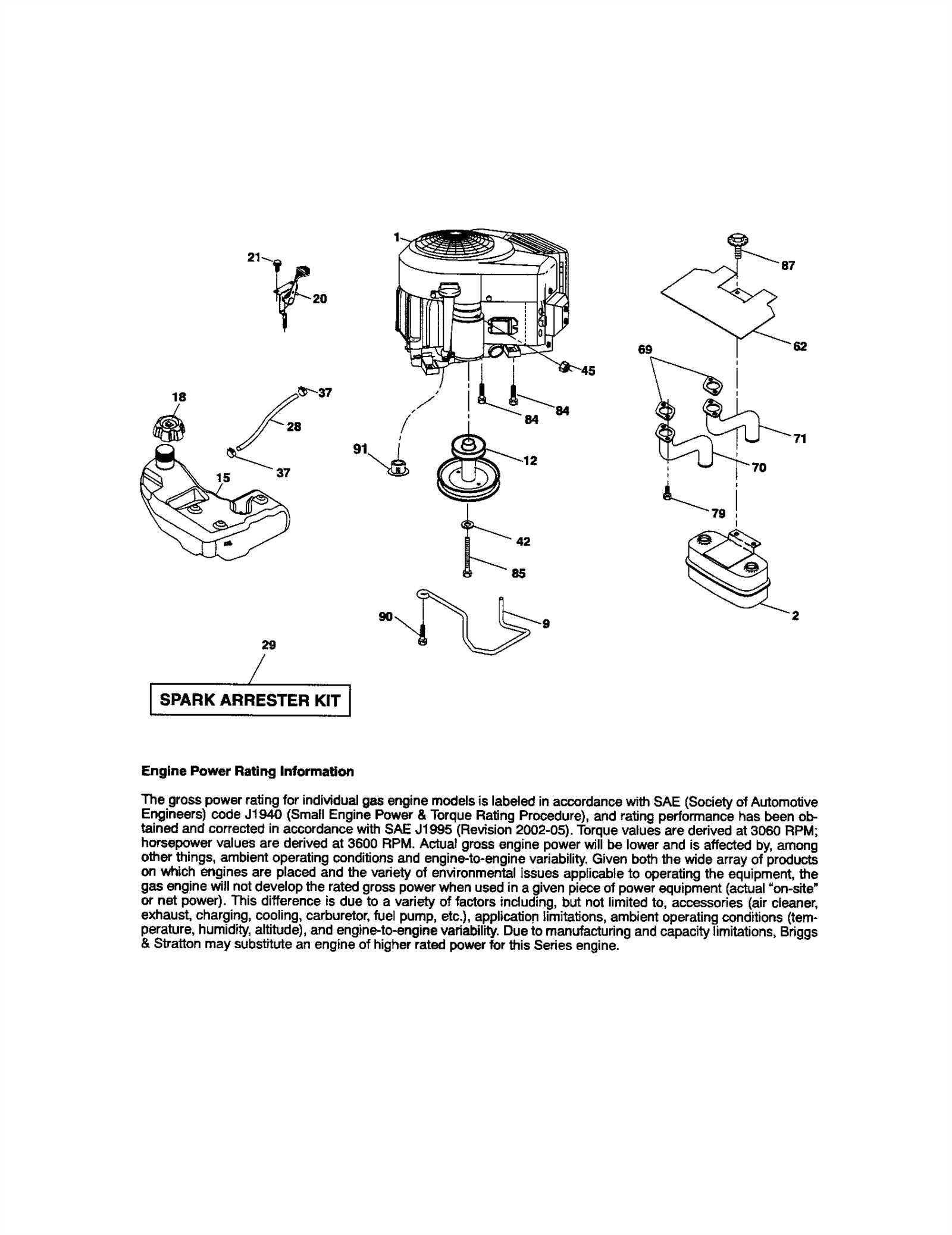

- Engine: The power source that drives the entire system.

- Transmission: Responsible for controlling speed and direction.

- Deck: The housing that contains the cutting mechanism.

- Wheels: Provide mobility and support the machine’s weight.

- Steering Mechanism: Allows precise navigation during use.

Understanding these elements helps users maintain and troubleshoot their equipment effectively.

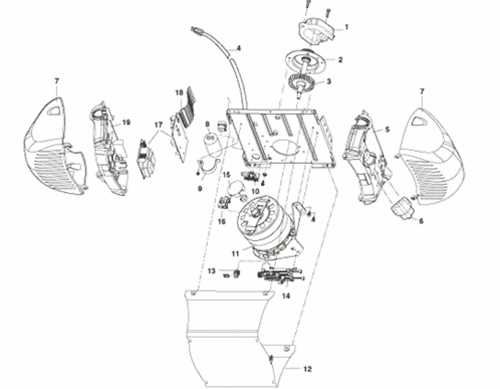

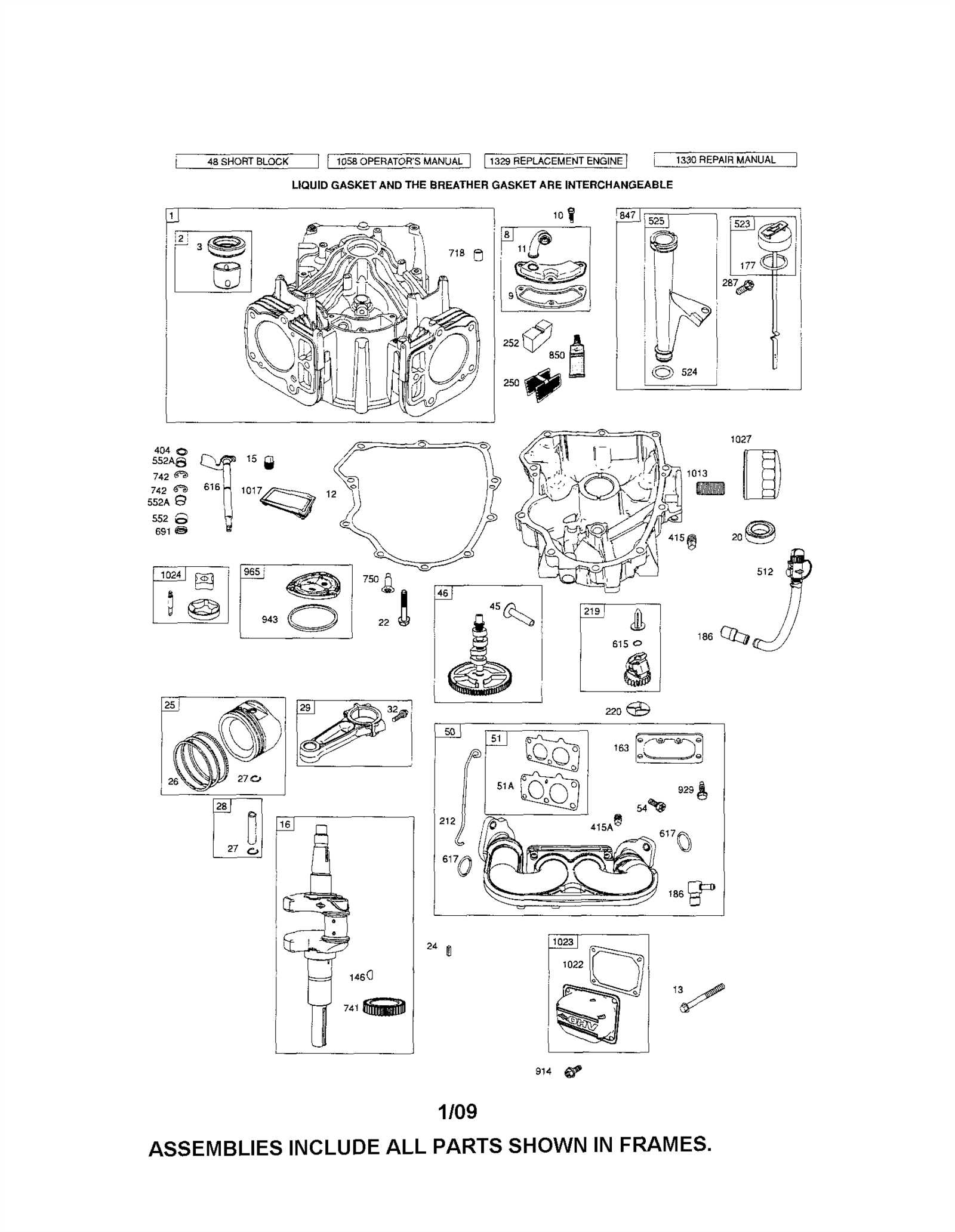

Importance of Accurate Parts Diagrams

Having precise illustrations for various components is essential in the maintenance and repair of equipment. These visual guides not only enhance understanding but also facilitate efficient assembly and disassembly processes. Accurate depictions help users identify each element’s placement and function, minimizing errors during repairs.

Enhancing Repair Efficiency

When individuals have access to well-detailed visual representations, they can streamline their workflow. This leads to quicker repairs and reduces downtime, allowing users to get their equipment back in optimal working condition swiftly. Moreover, clarity in these guides helps in preventing the misuse of components, which could result in further damage.

Improving Safety Standards

Clear illustrations also play a vital role in ensuring safety. Misidentification of parts can lead to improper handling or installation, potentially resulting in accidents or equipment failure. Accurate visuals provide critical information, aiding users in following safety protocols effectively.

| Benefits | Impact |

|---|---|

| Reduced Errors | Minimizes costly mistakes during repairs |

| Time Efficiency | Speeds up repair processes |

| Enhanced Safety | Prevents accidents and equipment mishaps |

Common Issues with LT4000 Parts

Understanding the frequent challenges encountered with components can greatly enhance maintenance and repair efforts. By identifying these common problems, users can ensure optimal performance and longevity of their machinery.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Components may degrade over time, leading to inefficiency. | Regular inspections and timely replacements can mitigate this. |

| Loose Connections | Connections may become loose, resulting in operational failures. | Tightening and securing all connections is essential. |

| Corrosion | Exposure to moisture can lead to rust and damage. | Utilizing protective coatings can prevent corrosion. |

| Overheating | Components may overheat due to lack of lubrication. | Ensuring proper lubrication is crucial for heat management. |

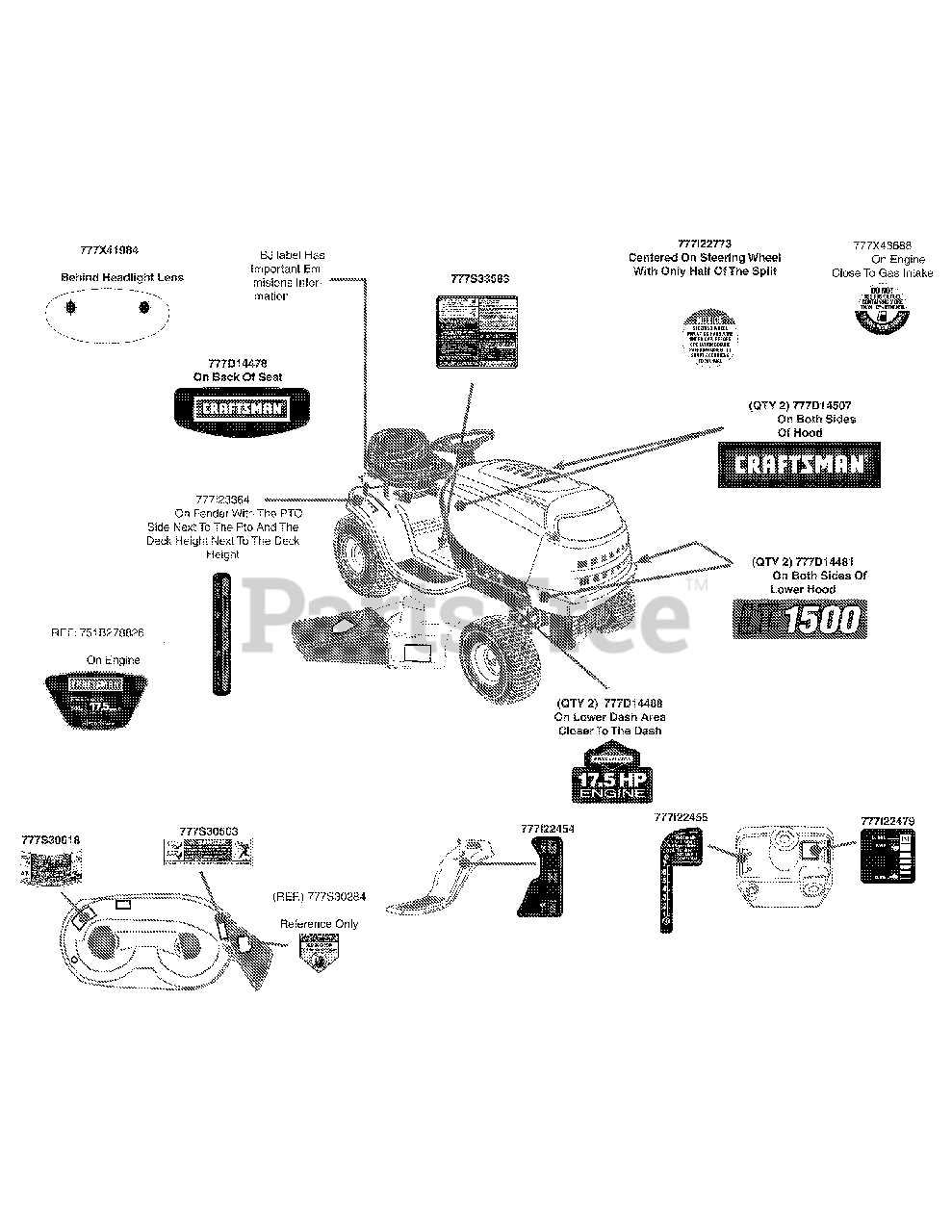

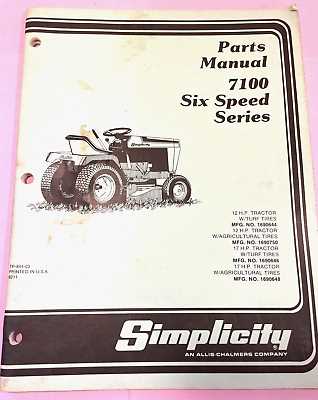

How to Identify Replacement Parts

Identifying the right components for maintenance or repair can be a crucial task. A clear understanding of what you need is essential for ensuring that your equipment operates efficiently. Here are steps to help you pinpoint the necessary items effectively.

- Consult the User Manual: Start by referring to the manual that came with your equipment. It usually contains a list of components and their specifications.

- Check Model Numbers: Locate the model number on your device. This number is vital for searching compatible components online or at local retailers.

- Examine Existing Components: If you have a damaged item, inspect it closely. Look for any part numbers or markings that can lead you to a suitable replacement.

- Online Resources: Utilize reputable websites that specialize in components. Many of these sites offer detailed information and images to assist in your search.

- Join Community Forums: Engage with online communities or forums. Fellow users often share insights and can guide you in finding the correct parts.

- Visit Local Stores: If possible, visit local hardware or specialty stores. Staff can provide assistance and may even help identify what you need.

By following these steps, you can streamline the process of finding the appropriate replacements, ensuring your equipment continues to perform optimally.

Tools Needed for LT4000 Repairs

Effective maintenance and repair require specific instruments to ensure tasks are completed efficiently and safely. Having the right tools on hand not only simplifies the process but also enhances the quality of the work.

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: A variety of types, including flathead and Phillips, are crucial for different screws.

- Socket Set: Offers versatility for reaching tight spaces and applying torque.

- Pliers: Useful for gripping, twisting, and cutting wires or components.

- Jack and Stands: Necessary for safely lifting and supporting the equipment during repairs.

- Safety Gear: Gloves and goggles are important for personal protection while working.

Collecting these tools will prepare you for any repair job and contribute to a successful maintenance routine.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. By implementing a systematic maintenance routine, you can prevent potential issues and extend the lifespan of your machinery.

Regular Inspections

- Check for loose bolts and screws monthly.

- Inspect belts and cables for wear and tear.

- Look for signs of rust or corrosion on metal components.

Cleaning and Lubrication

- Clean the machine after each use to remove dirt and debris.

- Lubricate moving parts to minimize friction.

- Use appropriate cleaning agents that won’t damage surfaces.

Where to Find OEM Parts

Locating original equipment components can significantly enhance the performance and longevity of your machinery. These authentic items ensure compatibility and reliability, making them essential for any restoration or maintenance project.

Authorized Retailers

Visiting certified dealers is one of the most reliable ways to procure genuine components. These establishments often have a wide range of items in stock and can provide expert advice on selections and compatibility.

Online Marketplaces

Numerous online platforms specialize in original parts. Reputable websites offer detailed catalogs and user reviews, facilitating informed purchasing decisions and often providing direct shipping options.

DIY Repair Techniques for LT4000

Maintaining your equipment can save time and money. Learning to perform repairs on your machinery empowers you to tackle issues effectively, ensuring smooth operation.

Here are some essential techniques for successful repairs:

- Assessment: Start by examining the machine carefully to identify any visible problems.

- Disassembly: Carefully take apart components to access the areas needing attention.

- Cleaning: Use appropriate cleaners to remove dirt and debris from internal parts.

- Replacement: Replace worn or damaged components with new, compatible parts.

- Reassembly: Ensure all pieces fit snugly before reassembling the unit.

Follow these steps, and you can effectively manage repairs, extending the lifespan of your machinery.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance tasks is crucial for both personal safety and the longevity of the equipment. Following proper guidelines can help prevent accidents and injuries while working on machinery. This section outlines essential safety measures to adopt before and during repair activities.

Essential Safety Measures

Before initiating any repair work, it is vital to prepare adequately. This involves wearing appropriate protective gear and having the right tools on hand. Additionally, ensuring the work area is clean and free from hazards can significantly reduce the risk of accidents.

Tool and Equipment Safety

Using tools correctly is fundamental for safe repairs. Always inspect equipment for any defects before use, and adhere to manufacturer guidelines regarding operation. When working with electrical components, ensure the power source is disconnected to prevent shock or other injuries.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and appropriate footwear to protect against injuries. |

| Work Area Organization | Keep tools organized and the workspace tidy to minimize risks of tripping or dropping items. |

| Tool Inspection | Check tools for damage or wear before use, ensuring they are safe to operate. |

| Disconnect Power | Always turn off and unplug equipment when performing repairs on electrical parts. |

FAQs about Craftsman LT4000 Parts

This section addresses common inquiries regarding components and maintenance essentials for outdoor machinery. Understanding these elements is crucial for ensuring optimal performance and longevity.

What should I do if a component breaks? It’s advisable to consult your user manual for specific troubleshooting steps and replacement options.

How can I find compatible replacements? Check with local retailers or online platforms that specialize in garden machinery accessories for suitable alternatives.

Is it necessary to use original equipment? While using original components is recommended for compatibility, high-quality aftermarket options can also suffice.

How often should I replace wear items? This varies based on usage, but regularly inspecting these elements will help determine the right schedule for replacements.

Where can I access repair guides? Many websites offer comprehensive repair guides and videos that can assist in DIY maintenance.

Customer Reviews and Experiences

Understanding user feedback is crucial for anyone looking to enhance their experience with a particular machine. Reviews provide insight into performance, durability, and overall satisfaction. This section explores various perspectives from users who have interacted with this equipment, highlighting both positive and negative aspects of their experiences.

Positive Feedback

Many users appreciate the reliability and ease of use of their machines. One reviewer noted, “I was pleasantly surprised by how well it handled various tasks around my yard. It’s efficient and saves me time.” Others have emphasized the quality of materials, stating that they feel confident in the longevity of their purchase. Several customers have shared that the customer service team was responsive and helpful when they needed assistance, further enhancing their overall experience.

Constructive Criticism

While many reviews are favorable, some users have voiced concerns. A few highlighted issues with assembly instructions, mentioning that clearer guidance would have been beneficial. Another reviewer expressed dissatisfaction with specific features, saying, “I expected more versatility from the attachments.” Such feedback is valuable as it provides manufacturers with insights into areas needing improvement, ensuring that future models meet user expectations more effectively.