Every machine relies on a complex arrangement of components that work together to ensure optimal performance. A comprehensive overview of these individual pieces can greatly enhance your ability to maintain and repair your tools effectively. Familiarizing yourself with the layout of these elements is essential for troubleshooting and replacing any malfunctioning parts.

By delving into the intricate design of your equipment, you can identify how each element interacts within the overall structure. This knowledge empowers you to make informed decisions during maintenance and upgrades, ultimately extending the lifespan of your device. Whether you’re a seasoned technician or a novice user, understanding the assembly is crucial for any hands-on work.

In this exploration, we will break down the various components, illustrating their functions and relationships within the machine. With clear visuals and detailed descriptions, you will gain valuable insights that make your repair tasks simpler and more efficient. Embrace the opportunity to enhance your understanding and improve your equipment’s performance.

Understanding the Homelite 26B

In this section, we will explore the intricacies of a popular outdoor power tool, focusing on its design and functionality. This machine is known for its reliability and effectiveness in handling various tasks, making it a preferred choice for many users. By examining its components and how they work together, one can appreciate the engineering behind its performance.

Key aspects to consider include the engine’s specifications, the arrangement of its mechanisms, and the overall user experience. Each element plays a crucial role in ensuring the tool operates smoothly and efficiently. Understanding these features allows users to maximize their experience and maintain the tool effectively.

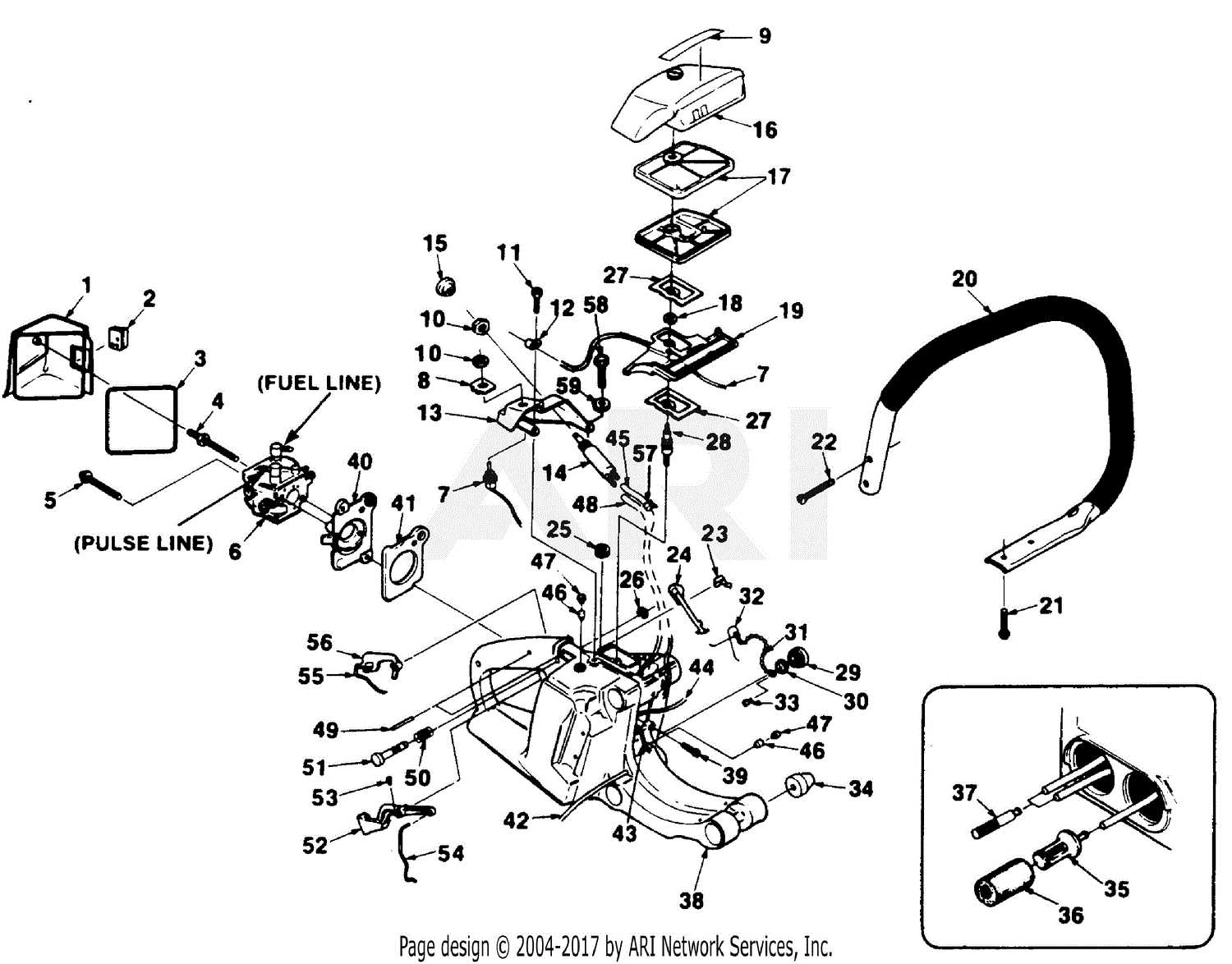

Key Components of the 26B Model

This section focuses on the essential elements that contribute to the functionality and performance of the model. Understanding these components is crucial for effective maintenance and operation.

Essential Elements

- Engine Assembly

- Fuel System

- Ignition Module

- Cutting Head

Supportive Parts

- Handlebar

- Throttle Control

- Safety Guard

- Power Transmission System

Each of these components plays a vital role in ensuring optimal performance and longevity, allowing users to tackle various tasks efficiently.

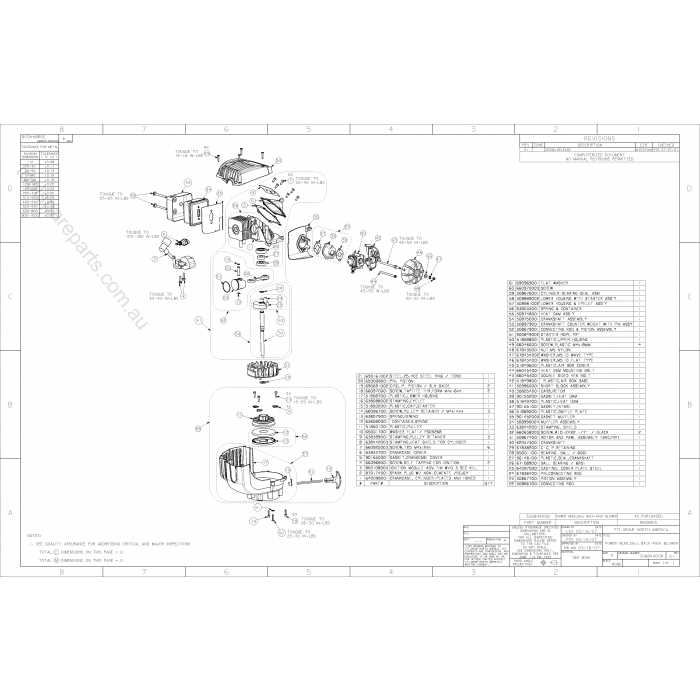

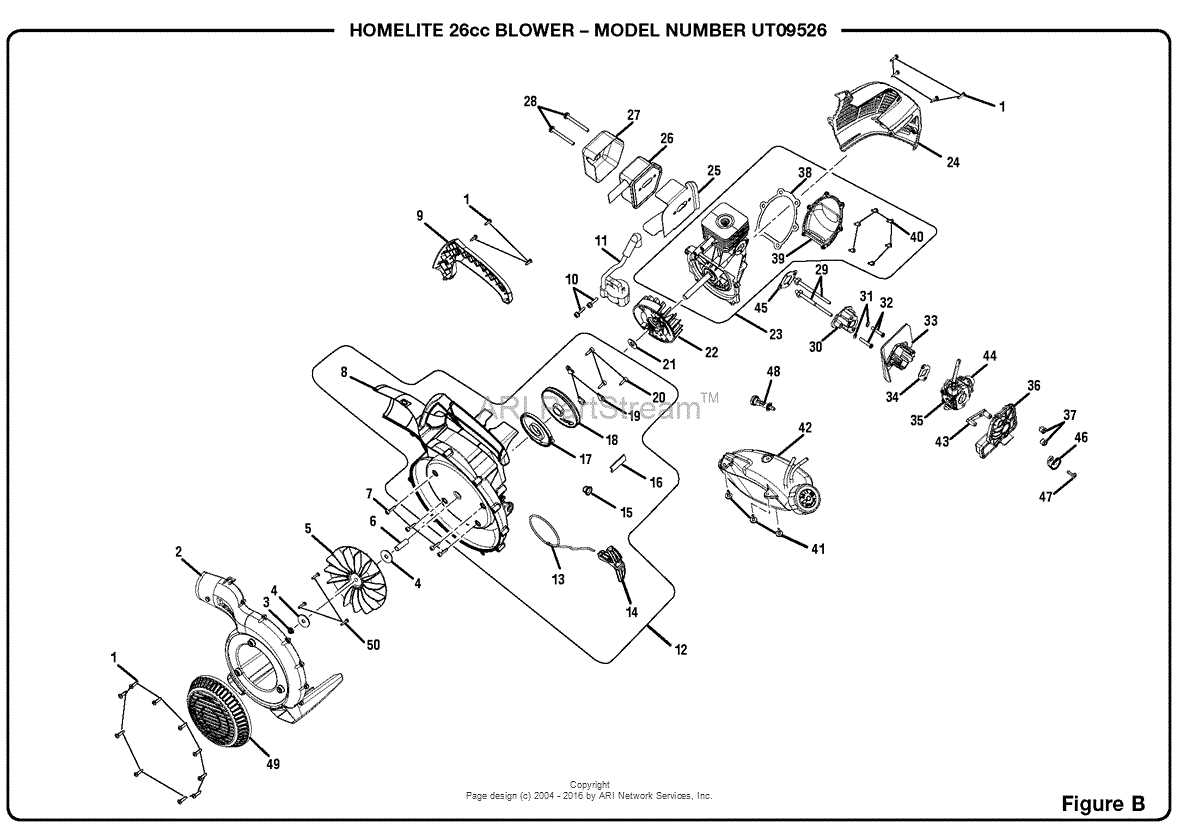

How to Read Parts Diagrams

Understanding visual schematics can significantly enhance your ability to identify components and their relationships within machinery. These illustrations serve as crucial guides for maintenance, repairs, and replacements, allowing users to quickly locate necessary items.

Key Elements to Observe

- Labels: Each component usually has a label indicating its name or number.

- Connections: Look for lines or arrows showing how parts connect or interact.

- Groupings: Components may be clustered based on function or location, aiding in comprehension.

Steps to Efficiently Navigate

- Start by familiarizing yourself with the overall layout of the schematic.

- Identify key sections and focus on one area at a time.

- Cross-reference any unfamiliar terms or components with a glossary or resource.

Common Issues with Homelite 26B

Various challenges can arise with outdoor power tools that may hinder their performance and efficiency. Understanding these issues can help users diagnose problems quickly and maintain their equipment effectively. This section outlines some frequent concerns encountered with these machines and offers insights into potential solutions.

Fuel System Problems

One of the most prevalent issues is related to the fuel system. Users may experience difficulty starting the engine or a noticeable decrease in power during operation. This can often be traced back to stale fuel, clogged filters, or malfunctioning fuel lines. Regularly replacing fuel and ensuring clean lines can mitigate these problems.

Ignition Failures

Ignition issues can also plague users, resulting in inconsistent starts or complete failure to ignite. Common culprits include worn spark plugs or faulty ignition coils. Routine inspections and timely replacements of these components can enhance reliability and performance.

Replacing Worn-Out Parts

Maintaining your equipment is essential for optimal performance. Over time, components can degrade, affecting functionality and efficiency. Identifying and substituting these diminished elements can extend the lifespan of your machine and enhance its operation.

Identifying Signs of Wear

Common indicators of degradation include unusual noises, decreased performance, and visible damage. Regular inspections can help you pinpoint which components need attention, ensuring timely replacements.

Replacement Process

Once you’ve identified the worn elements, follow these steps for a successful replacement:

| Step | Description |

|---|---|

| 1 | Disconnect power to ensure safety. |

| 2 | Carefully remove the damaged component. |

| 3 | Install the new part, ensuring proper alignment. |

| 4 | Reconnect power and test for functionality. |

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous resources are available to help you locate the necessary items to keep your machine running smoothly.

Online Retailers

Many websites specialize in providing a wide range of components. These platforms often feature user-friendly search tools that allow you to filter by model or type, ensuring you find exactly what you need.

Local Hardware Stores

Your nearby hardware stores might carry essential components, offering the advantage of immediate purchase and local support. It’s always a good idea to call ahead to check availability.

| Source | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, often competitive prices |

| Local Hardware Stores | Immediate access, local assistance, no shipping costs |

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires regular care and attention. By implementing a few essential practices, you can significantly extend the lifespan of your machinery and maintain its optimal functioning. Below are some key maintenance tips to help you achieve this goal.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep your device free from dirt and debris to prevent clogging and overheating. |

| Check and Replace Filters | Inspect filters regularly and replace them as needed to ensure proper airflow and efficiency. |

| Lubricate Moving Parts | Apply appropriate lubricants to reduce friction and wear on moving components. |

| Inspect for Wear | Regularly check for signs of wear and tear, and replace any damaged parts promptly. |

| Follow Operating Guidelines | Adhere to the manufacturer’s recommendations for operation and maintenance to avoid unnecessary strain. |

| Store Properly | When not in use, store equipment in a clean, dry place to protect it from environmental damage. |

Tools Needed for Repairs

Effective maintenance requires a variety of instruments to ensure a successful outcome. Having the right tools at your disposal not only simplifies the process but also enhances the quality of the repairs, ultimately extending the lifespan of your equipment.

Essential Instruments

Here are some fundamental tools you should consider having on hand:

| Tool | Purpose |

|---|---|

| Screwdrivers | For tightening or loosening screws. |

| Wrenches | For gripping and turning nuts and bolts. |

| Pliers | For gripping, twisting, or cutting materials. |

| Socket Set | For fastening and loosening fasteners. |

| Utility Knife | For cutting various materials with precision. |

Additional Supplies

In addition to tools, having the right supplies can significantly aid in the repair process. Items such as lubricants, adhesives, and cleaning agents are invaluable for ensuring everything operates smoothly.

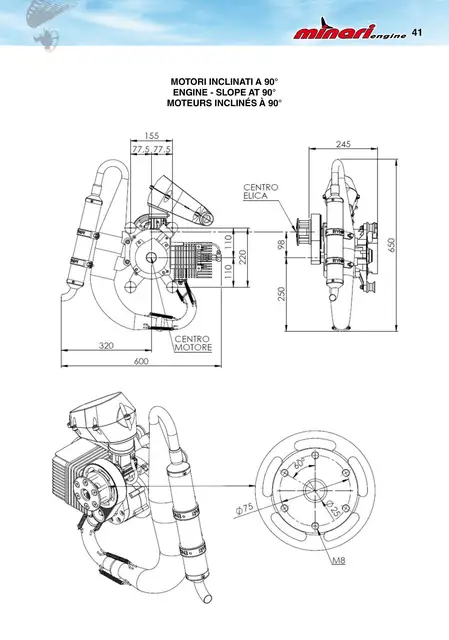

Comparing Homelite Models

When evaluating different models within a brand, it’s essential to explore their unique features and performance capabilities. Each variation offers distinct advantages tailored to specific tasks, appealing to a diverse range of users.

Performance: The efficiency of each model can vary significantly, affecting overall productivity. Users should consider horsepower and cutting capacity to determine which option suits their needs best.

Design: Ergonomics play a vital role in user experience. Some models are designed for comfort and ease of use, while others may focus on durability and ruggedness.

Maintenance: Analyzing the maintenance requirements is crucial. Certain models may demand more frequent servicing, while others are engineered for minimal upkeep.

Ultimately, understanding these differences allows consumers to make informed decisions, ensuring they select the model that aligns perfectly with their specific requirements.

Upgrading Your Equipment Effectively

Enhancing your tools can significantly improve performance and efficiency. By focusing on key components and making informed choices, you can ensure that your setup meets your specific needs while maximizing productivity. This section delves into strategies for successful upgrades.

Identifying Key Components

Start by evaluating the critical elements of your machinery. Consider which parts are essential for achieving optimal functionality. Prioritize upgrades that will have the ultimate impact on performance, ensuring that your investments yield the best results.

Research and Compatibility

Before making any purchases, conduct thorough research to understand compatibility with existing equipment. Look for reliable sources and reviews to guide your decisions. Ensuring that new additions align with your current setup will streamline the upgrading process and enhance overall efficiency.

Expert Advice on Part Selection

Selecting the right components for your equipment can significantly enhance performance and longevity. Understanding the nuances of each element is crucial for ensuring optimal functionality. Here are some essential considerations to keep in mind during your selection process.

| Factor | Importance | Recommendations |

|---|---|---|

| Compatibility | High | Always verify that the component matches the specifications of your machine. |

| Quality | High | Opt for reputable brands that guarantee durability and reliability. |

| Cost | Medium | Balance between budget and quality; cheaper options may compromise performance. |

| Availability | Medium | Ensure that the components are readily available to avoid long downtimes. |

| Warranty | High | Choose components with a warranty for peace of mind and protection against defects. |

Taking the time to evaluate these factors will lead to better choices and a smoother operation of your machinery. Always consult with experts or reference reliable resources when in doubt.