In the realm of outdoor machinery, having a thorough grasp of the individual elements that comprise a powerful cutting device is essential. Each component plays a vital role in ensuring optimal performance and efficiency, making it crucial for users to be familiar with their arrangement and function. This understanding not only aids in effective maintenance but also enhances the overall experience of using such equipment.

For those engaged in woodworking or landscaping, recognizing how various segments interact can prevent potential issues and extend the lifespan of the tool. From the engine assembly to the cutting mechanism, each piece contributes to the functionality and reliability of the device. Moreover, being knowledgeable about these components empowers users to troubleshoot common problems more effectively.

By exploring the layout and relationships between these essential parts, enthusiasts and professionals alike can optimize their usage and care practices. This journey into the intricacies of machinery not only demystifies the tool but also fosters a deeper appreciation for the technology that supports outdoor craftsmanship.

Understanding Husqvarna 365 Components

Exploring the intricate elements of a powerful cutting tool reveals a fascinating network of components that work in harmony to achieve optimal performance. Each part plays a crucial role, ensuring efficiency and durability during operation. A thorough understanding of these elements can enhance maintenance and troubleshooting efforts.

Key Elements of the Tool

The primary assembly includes the engine, which provides the necessary power, and the cutting mechanism that executes the task. Additionally, the fuel system ensures proper combustion, while the ignition system initiates the engine’s operation. Regular inspection of these elements can prevent unexpected failures and prolong the lifespan of the equipment.

Maintenance and Care

To ensure longevity, routine maintenance is essential. This includes checking the air filter, sharpening the blade, and inspecting the fuel lines. Understanding each component’s function allows for more effective care, ultimately leading to better performance and safety during use.

Key Features of the Chainsaw

This powerful tool is designed for efficiency and ease of use, catering to both professionals and enthusiasts alike. Its robust construction ensures durability, while innovative technologies enhance performance and safety, making it an essential asset for various cutting tasks.

One of the standout characteristics is its high-performance engine, delivering exceptional power for demanding applications. The lightweight design facilitates maneuverability, allowing users to operate for extended periods without excessive fatigue. Additionally, an ergonomic handle provides comfort and control, ensuring precision during operation.

Safety features are paramount, with advanced mechanisms that minimize the risk of accidents. Quick-release systems enable swift maintenance, while the automatic lubrication system ensures optimal chain function and longevity. These attributes collectively make this tool a reliable choice for effective and safe wood cutting.

Importance of Original Replacement Parts

Using authentic components for machinery maintenance is crucial for ensuring optimal performance and longevity. These elements are specifically designed to fit seamlessly and function effectively, providing peace of mind and reliability.

Benefits of Authentic Components

- Enhanced Durability: Genuine items are crafted from high-quality materials, reducing wear and tear.

- Improved Performance: Original replacements maintain the intended functionality, ensuring efficient operation.

- Safety Assurance: Authentic parts are rigorously tested, minimizing the risk of malfunctions.

Consequences of Using Imitations

- Increased Repair Costs: Inferior components can lead to more frequent breakdowns and costly repairs.

- Decreased Efficiency: Non-genuine parts may disrupt the overall performance of the equipment.

- Warranty Issues: Using unverified replacements can void manufacturer warranties, leaving users unprotected.

Common Issues with Husqvarna 365

Every tool comes with its own set of challenges that users may encounter over time. Understanding these common difficulties can help maintain performance and extend the lifespan of the equipment.

Frequent Problems

- Starting Issues: Difficulty in ignition can stem from fuel problems or ignition components.

- Overheating: Insufficient lubrication or clogged air filters may cause excessive heat during operation.

- Chain Stalling: A dull blade or improper tension can lead to interruptions in cutting.

Maintenance Tips

- Regularly check and replace the spark plug.

- Ensure the air filter is clean to promote proper airflow.

- Sharpen the blade frequently to maintain cutting efficiency.

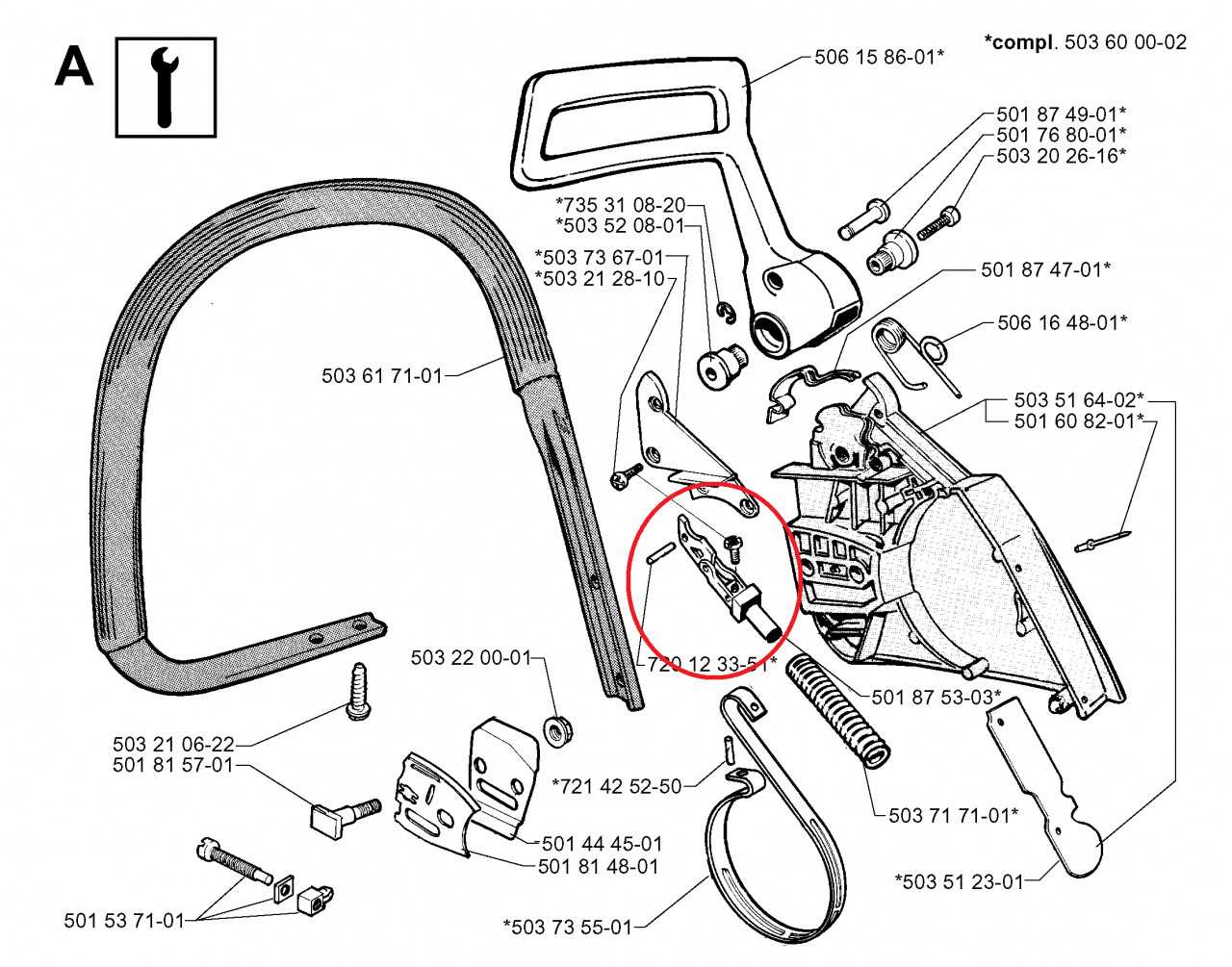

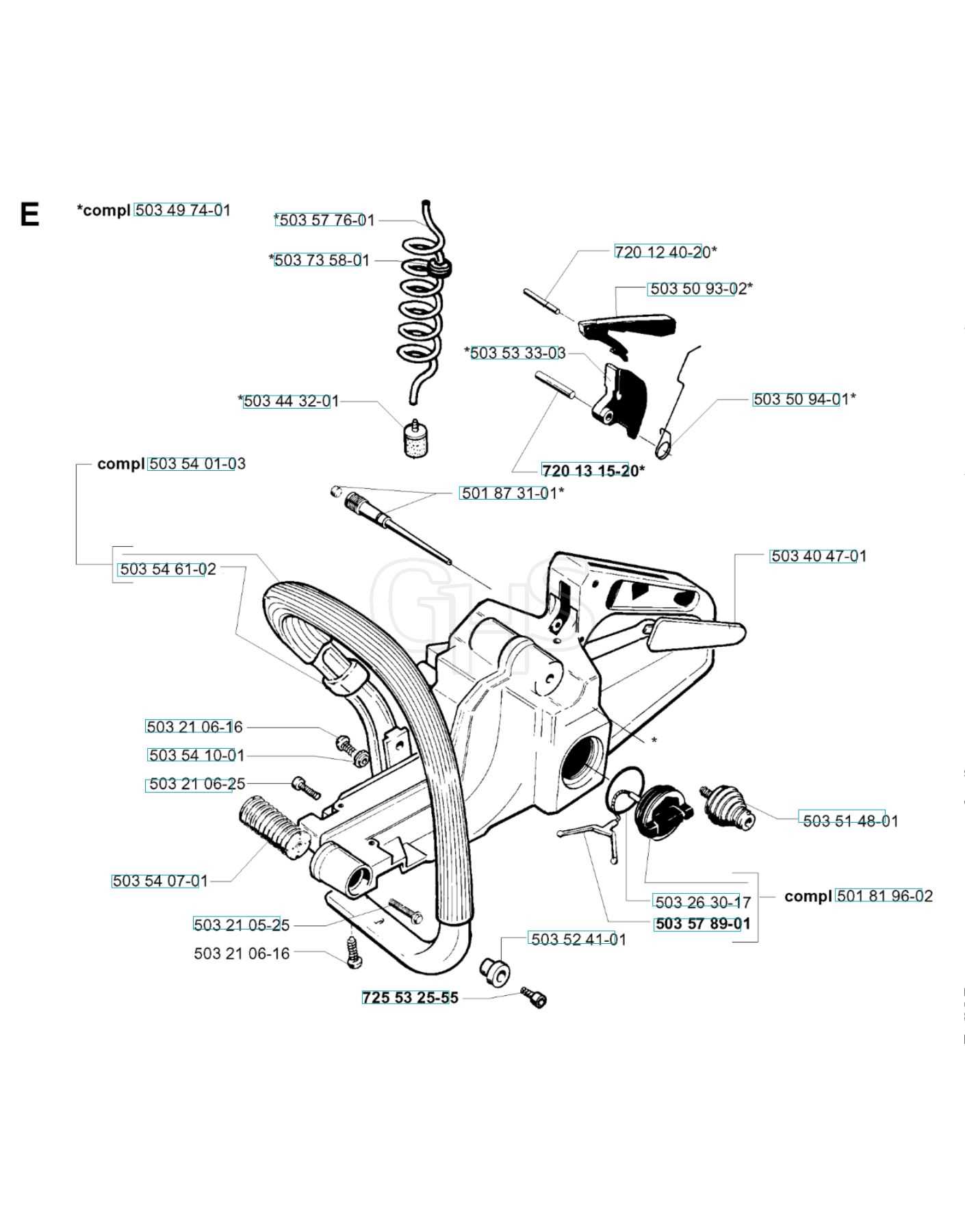

How to Identify Parts Easily

Recognizing components of equipment can often seem daunting, yet it becomes manageable with the right approach. Familiarizing oneself with the structure and function of each element can streamline the identification process, making repairs and maintenance more efficient.

Utilize Online Resources

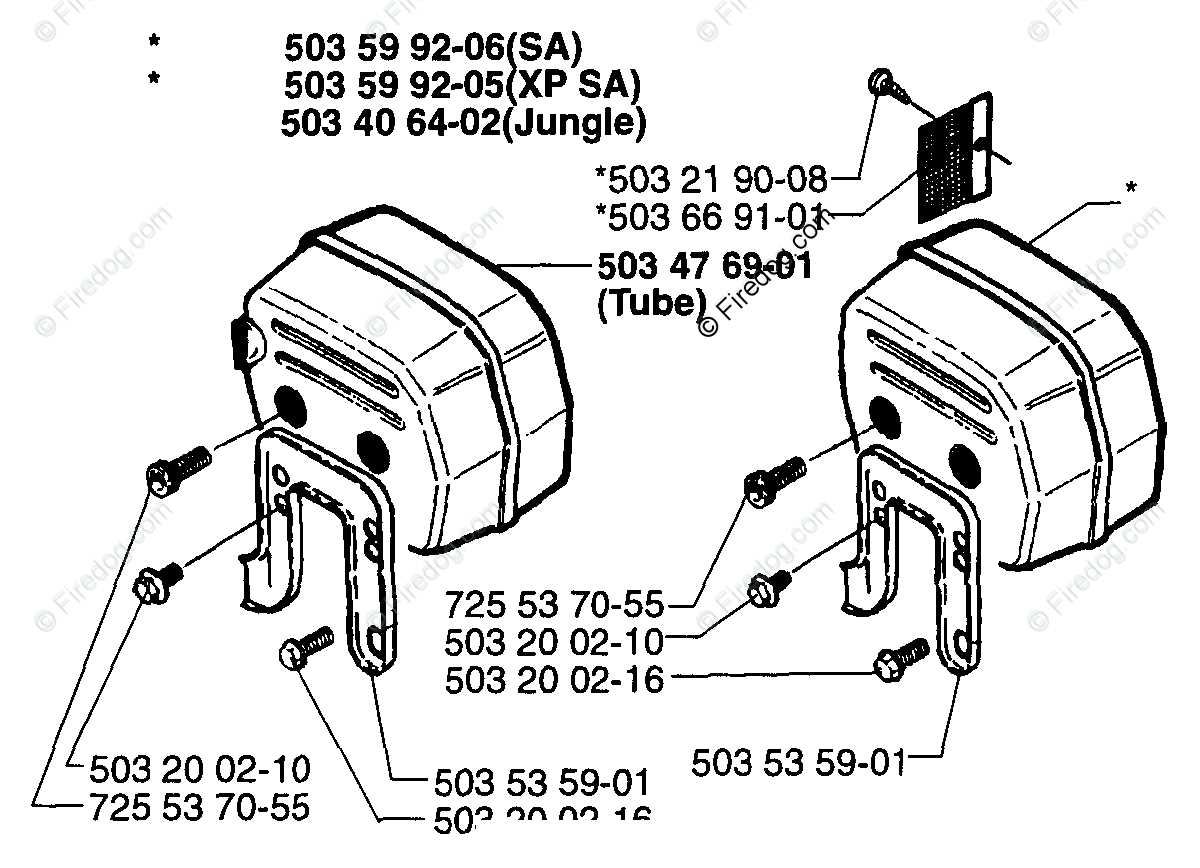

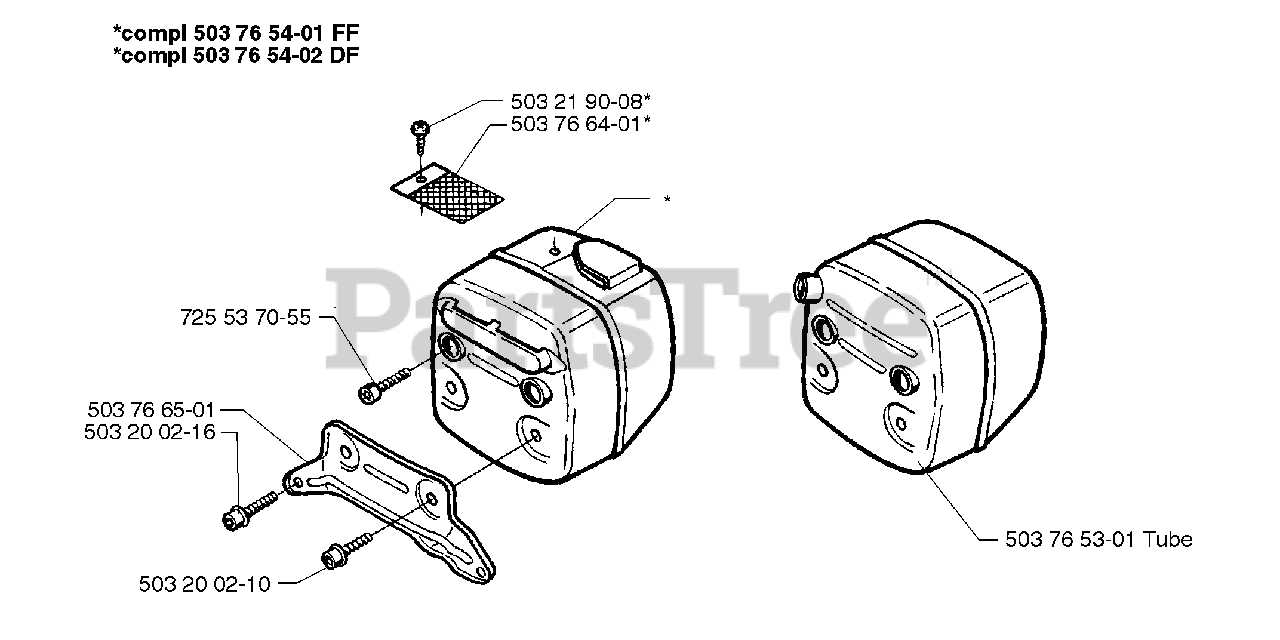

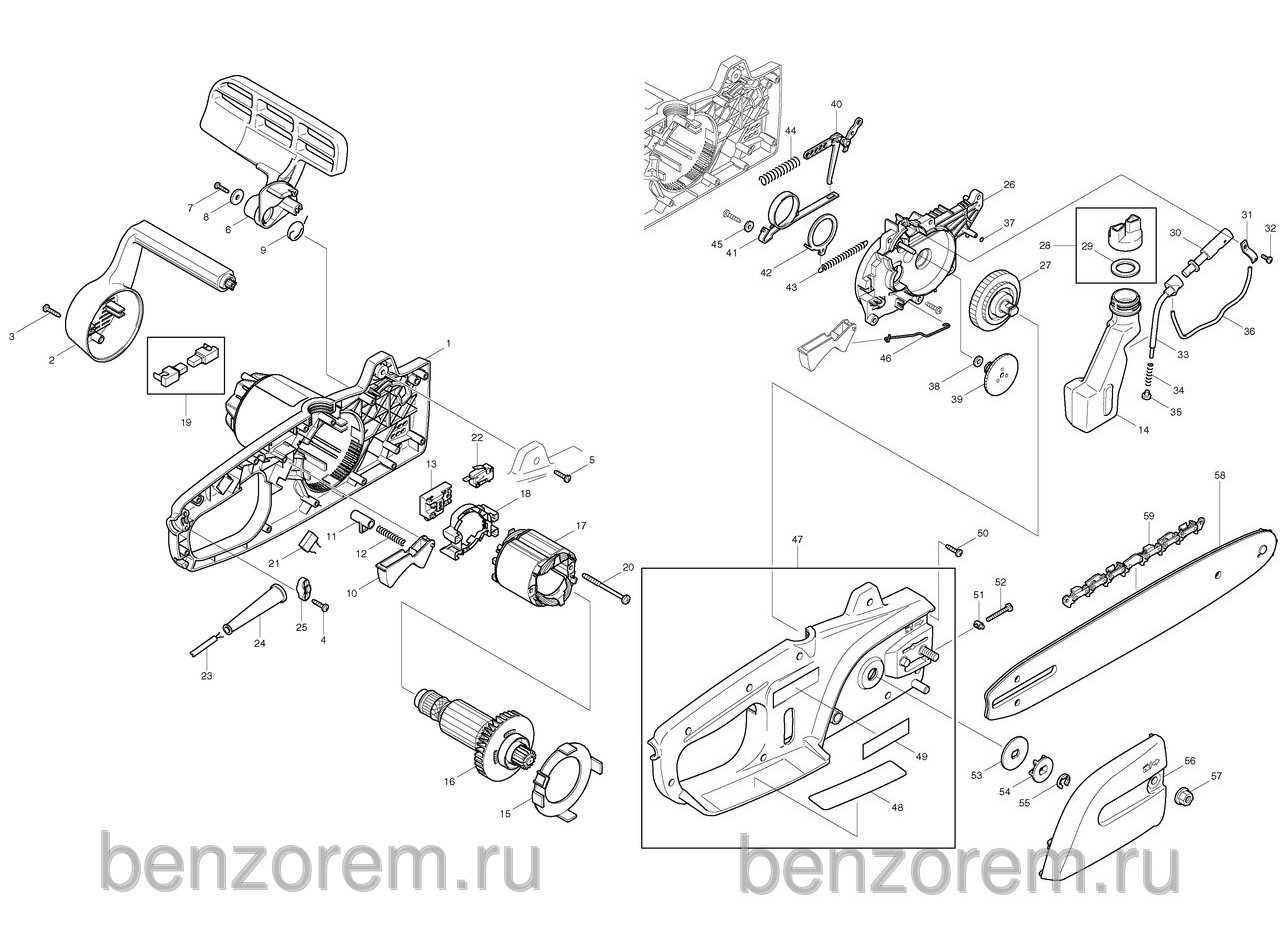

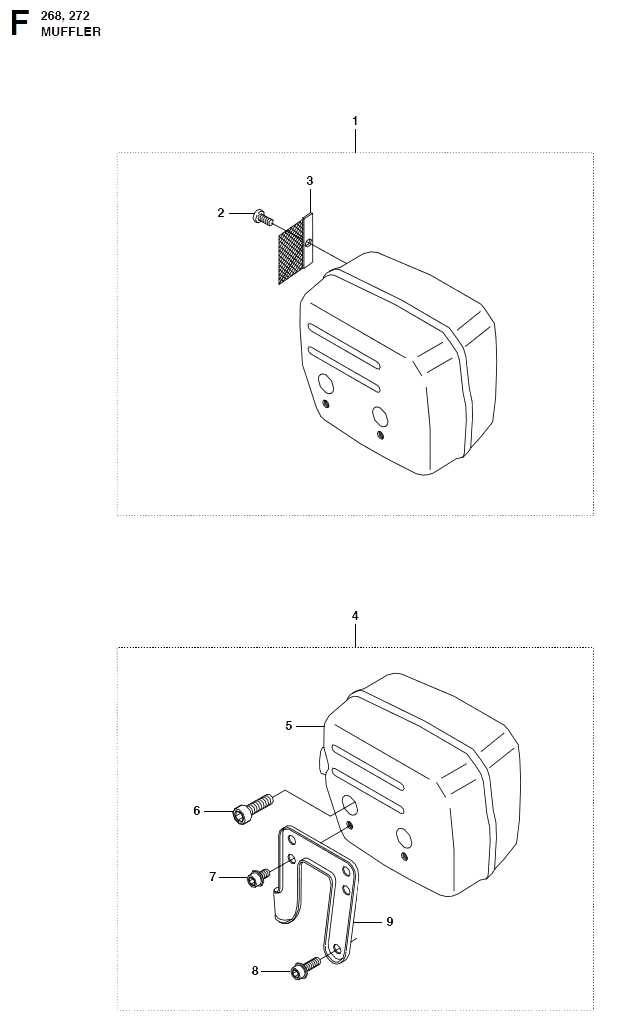

Many manufacturers offer comprehensive guides and interactive platforms where you can explore various components. Using these tools allows for a visual representation, helping to pinpoint each piece accurately.

Consult the Manual

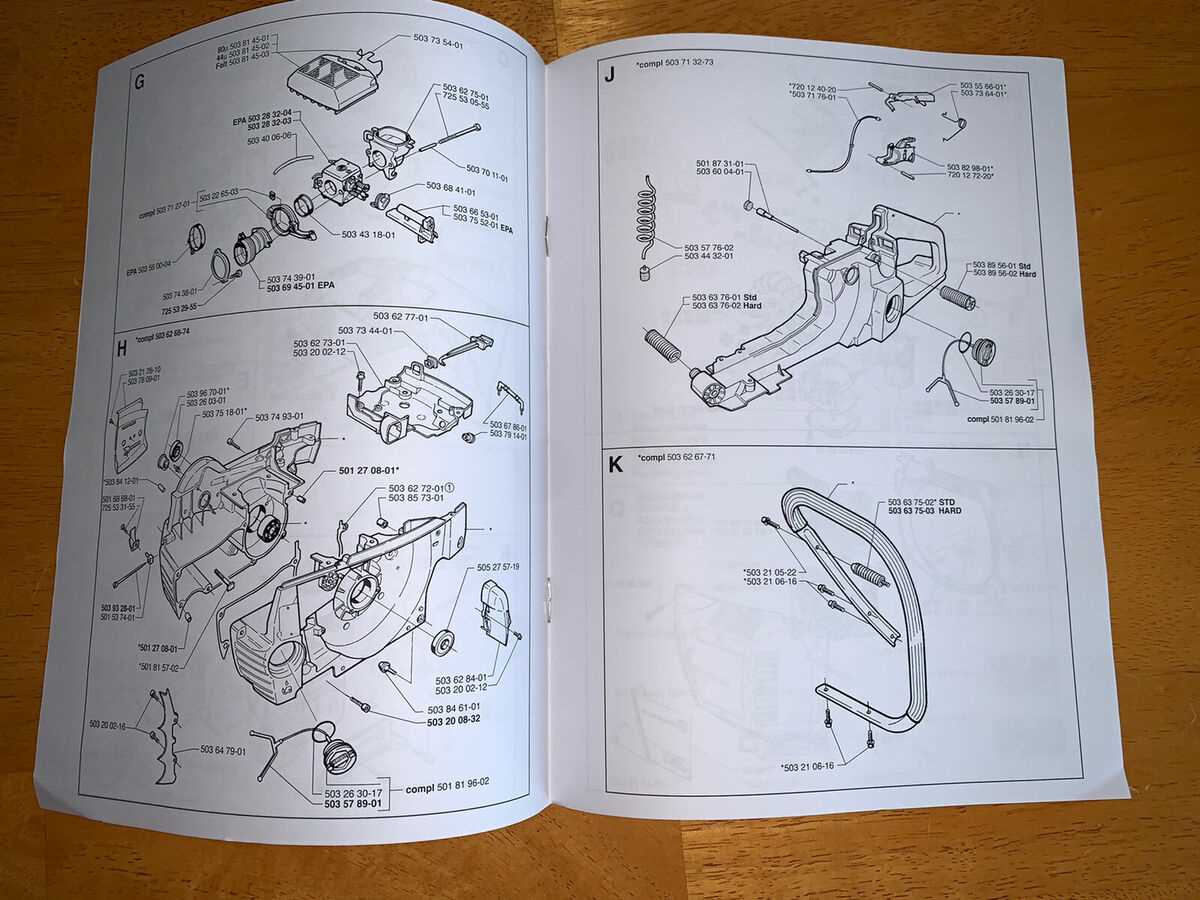

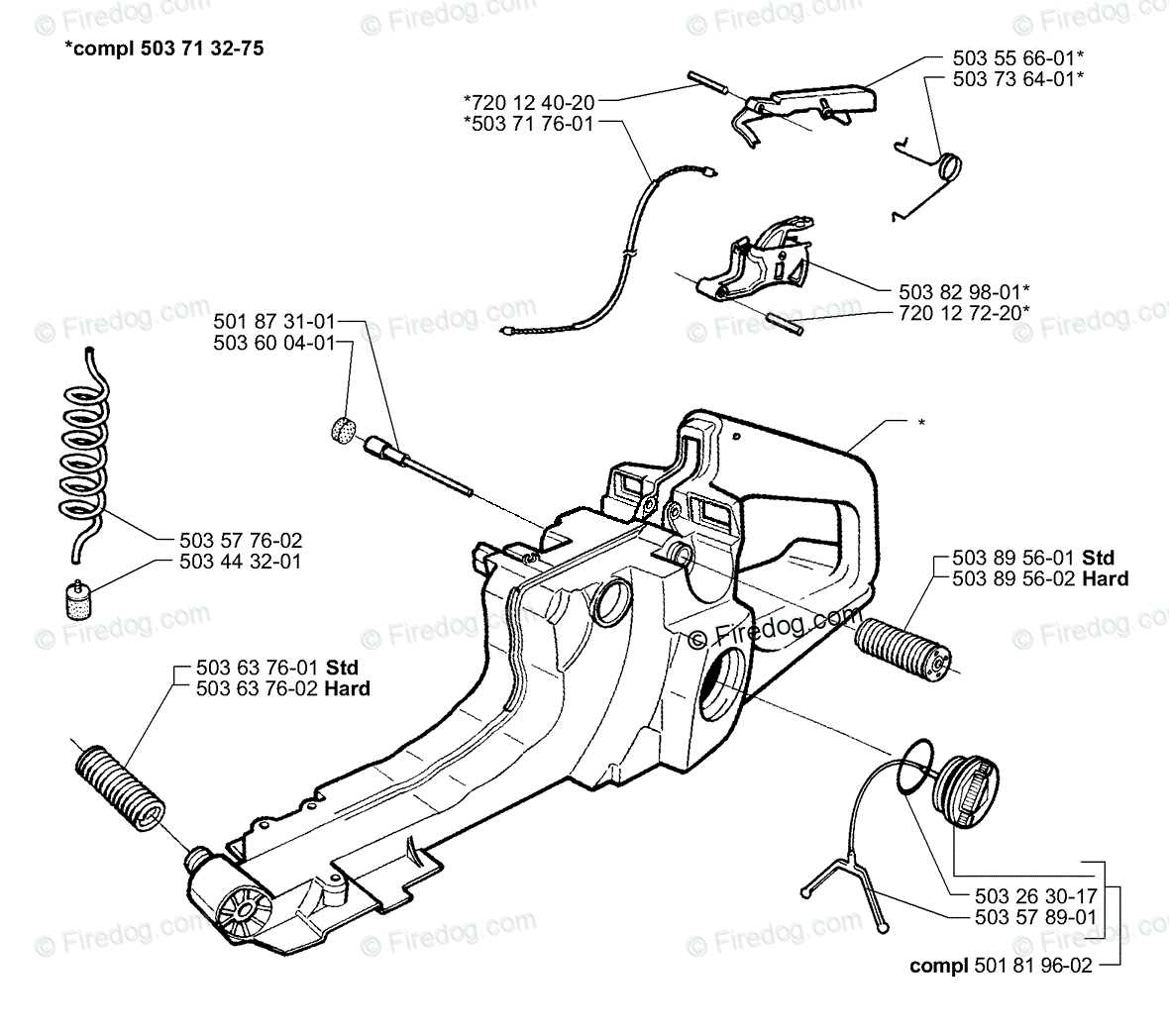

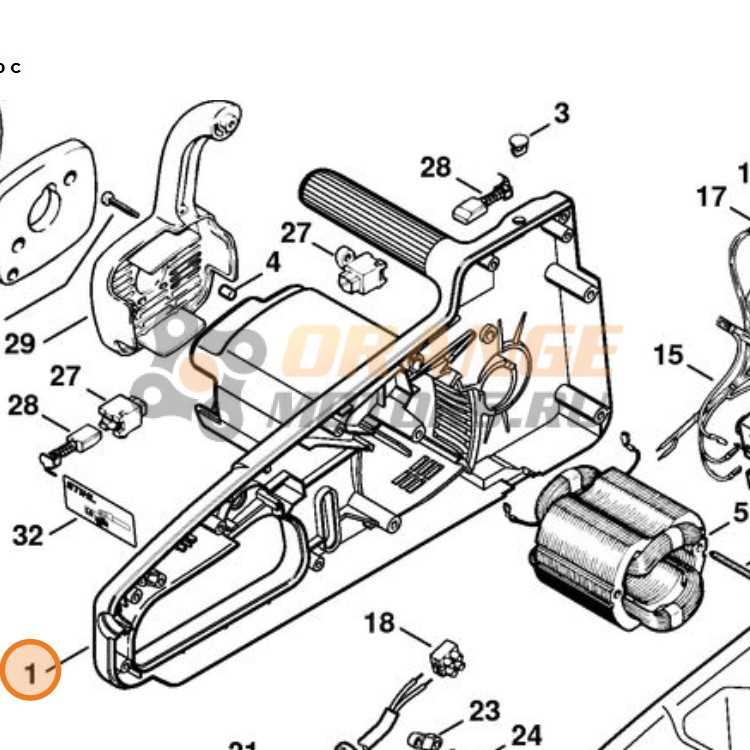

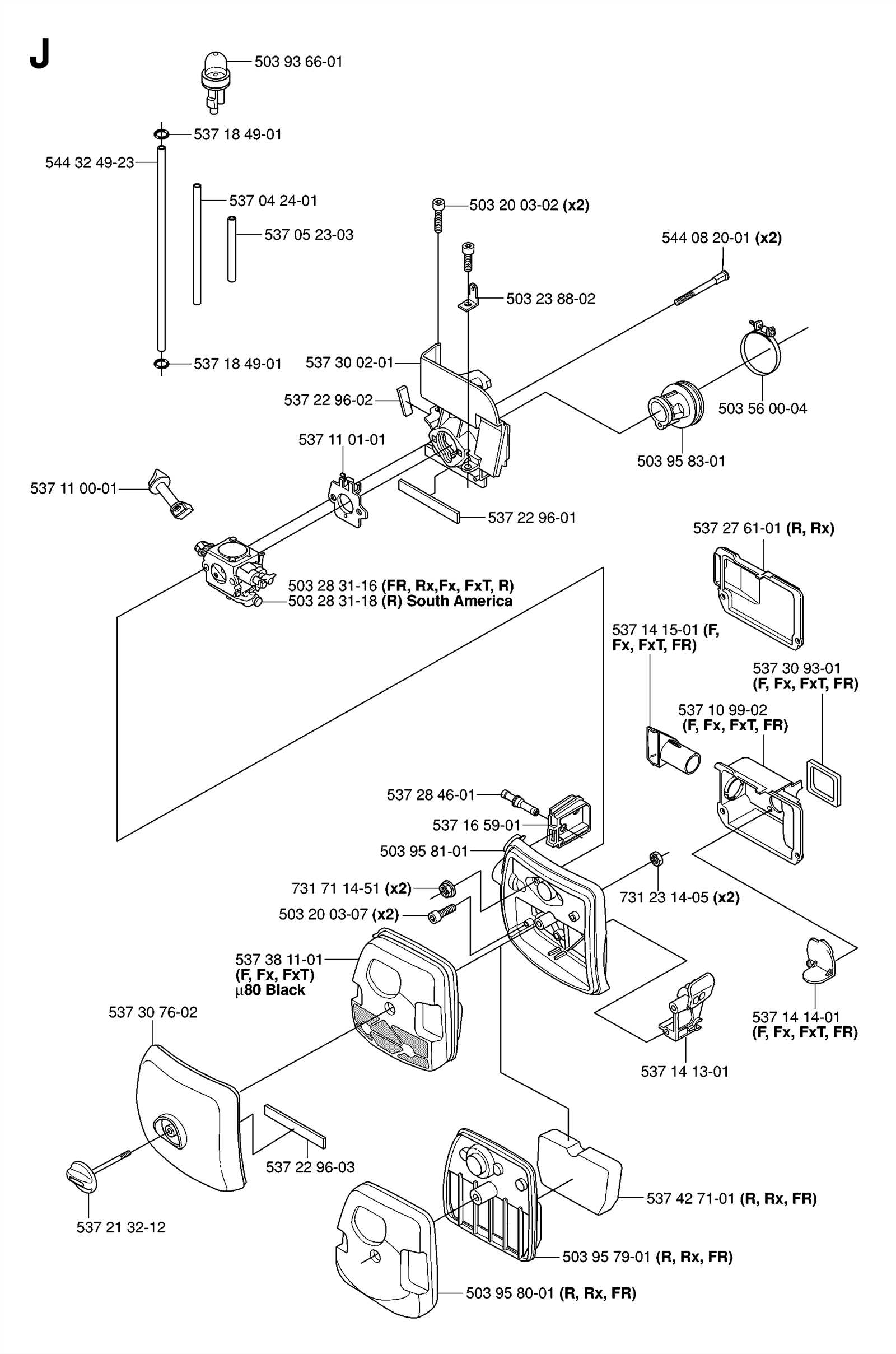

Having the operational guide handy is invaluable. It typically includes detailed illustrations and descriptions, which can significantly enhance your understanding. Pay attention to diagrams within the manual to connect visual cues with actual parts.

Step-by-Step Assembly Guide

This section provides a comprehensive guide to assembling your tool effectively and efficiently. By following each step carefully, you will ensure that all components fit together seamlessly, enhancing performance and safety during use.

Gather Your Tools

Before starting the assembly process, ensure you have all necessary tools at hand. Having everything ready will streamline your workflow and minimize interruptions.

Assembly Instructions

Begin by aligning the primary components according to the provided schematic. Secure each piece with the appropriate fasteners, ensuring they are tightened properly. Check connections periodically to confirm stability as you proceed, allowing for adjustments if necessary.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your outdoor equipment. Regular maintenance not only extends the life of your tools but also enhances their efficiency and safety. By following a few straightforward practices, you can keep your machinery in excellent working condition for years to come.

Routine Care Practices

- Clean the exterior regularly to prevent debris buildup.

- Inspect all components for wear and tear before each use.

- Ensure proper lubrication of moving parts to reduce friction.

- Sharpen blades periodically for optimal cutting performance.

Seasonal Checks

- At the start of each season, perform a thorough inspection of all essential components.

- Replace any worn-out or damaged parts immediately to avoid further issues.

- Store equipment in a dry, temperature-controlled environment to prevent rust and degradation.

- Run the engine to keep internal parts lubricated and functioning smoothly during long storage periods.

Where to Find Diagrams Online

When searching for detailed visuals and components for your machinery, the internet offers a plethora of resources. Many websites provide comprehensive illustrations that can assist in identifying and understanding each element of your tool.

Manufacturer Websites: Often, the official sites of manufacturers include sections dedicated to service manuals and illustrations. These resources are reliable and frequently updated.

Online Forums and Communities: Engaging with enthusiasts and professionals in dedicated forums can yield valuable insights. Members often share links to useful visuals or upload their own diagrams.

Retail and Parts Supplier Websites: Numerous online retailers specialize in equipment and often have detailed breakdowns available. These can help you locate specific items and understand how they fit together.

Video Tutorials: Platforms like YouTube feature many instructional videos. These can be particularly helpful, as they often showcase step-by-step processes alongside visual aids.

Exploring these avenues can ultimately enhance your understanding and maintenance of your equipment.

Tools Needed for Repairs

Performing maintenance and fixing mechanical devices requires a specific set of instruments to ensure efficiency and precision. Having the right tools on hand not only facilitates smoother repairs but also enhances safety during the process. Below is a list of essential items that will aid in conducting repairs effectively.

- Wrenches: Adjustable and fixed types are crucial for loosening and tightening various components.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help tackle screws of different types.

- Replacement Parts: Always keep a stock of commonly worn components to minimize downtime.

- Oil and Lubricants: Proper maintenance requires suitable fluids to ensure optimal performance and longevity.

- Protective Gear: Safety glasses, gloves, and hearing protection are essential for safe operation.

With these tools, you will be well-equipped to address various issues that may arise, ensuring that your equipment remains in excellent working condition.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the repairs but also safeguard those nearby. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and hearing protection to minimize exposure to hazards. |

| Work Area Organization | Keep the workspace tidy and free of clutter to prevent trips and falls during the repair process. |

| Tool Inspection | Examine tools for any damage before use, ensuring they are in good working condition to avoid malfunction. |

| Electrical Safety | Disconnect any power sources to prevent accidental starts while working on the machinery. |

| Emergency Preparedness | Have a first aid kit accessible and be aware of emergency procedures in case of an accident. |

Upgrading Your Chainsaw Performance

Enhancing the efficiency and capability of your cutting tool can significantly impact your outdoor projects. By focusing on key areas of improvement, you can achieve greater power, speed, and durability, ultimately leading to a more satisfying experience. This section explores various upgrades to consider for optimizing your equipment.

| Upgrade Type | Description |

|---|---|

| High-Performance Bar | Using a longer or thicker bar can increase cutting depth and stability. |

| Premium Chain | Opt for a chain designed for faster cutting and better durability. |

| Enhanced Air Filter | Upgrading to a high-flow air filter can improve engine performance. |

| Powerful Engine Modifications | Consider tuning the engine for increased horsepower and torque. |

| Vibration Dampeners | Install dampeners to reduce fatigue and improve handling. |

Investing in these enhancements not only boosts performance but also prolongs the lifespan of your equipment, ensuring it meets the demands of even the toughest tasks.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the performance and reliability of various outdoor power tools. Real-life experiences can provide insights into the functionality, ease of use, and durability of equipment, helping potential buyers make informed decisions.

Many customers have shared their thoughts on how their tools have met their expectations or exceeded them. Here are some common themes from user reviews:

- Performance: Users frequently praise the efficiency and cutting power of their equipment, noting how it handles different types of tasks.

- Durability: Many reviews highlight the long-lasting nature of these tools, with several users mentioning that they have performed reliably for years.

- Ease of Use: Customers often appreciate the straightforward operation and ergonomic design, making it accessible for both beginners and experienced users.

- Maintenance: Feedback indicates that regular upkeep is manageable, with users providing tips on simplifying maintenance processes.

Additionally, some reviews detail specific challenges faced during usage. Here are a few notable points:

- Occasional difficulties in finding replacement components.

- Specific models may require more frequent adjustments than others.

- Initial learning curve for those new to operating similar tools.

Overall, user experiences reveal a strong satisfaction with the capabilities and longevity of these outdoor power tools, although it’s important to consider individual needs and preferences when choosing the right model.