When it comes to mastering power equipment, having a comprehensive grasp of its individual elements is essential for efficient operation and maintenance. This knowledge not only enhances performance but also empowers users to troubleshoot and replace any worn or damaged components effectively.

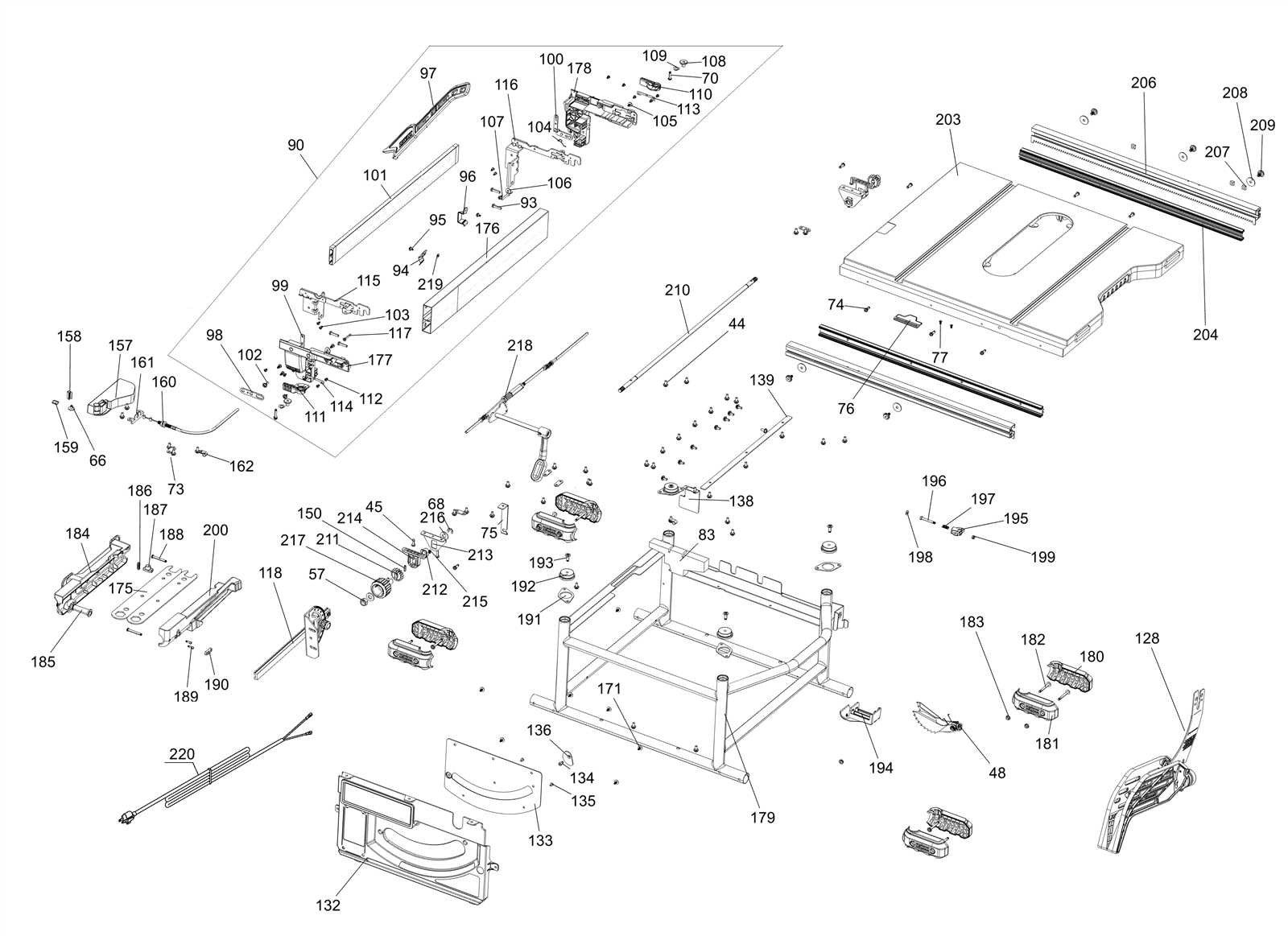

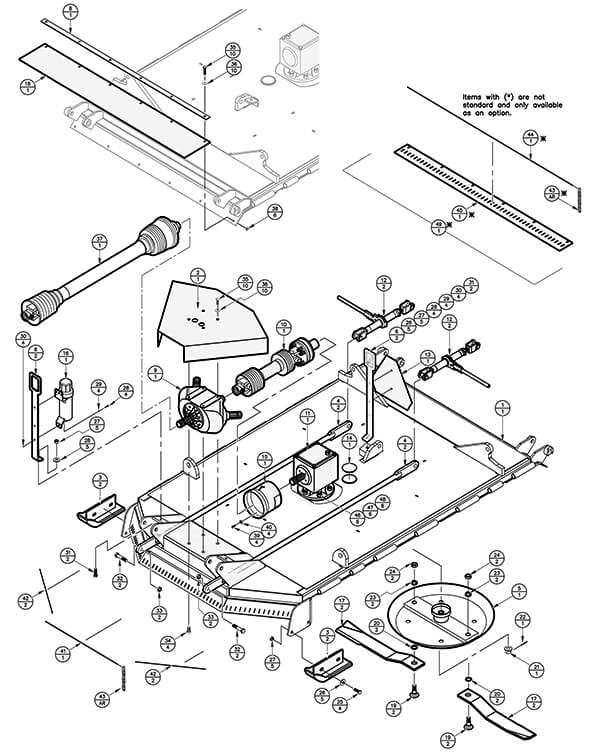

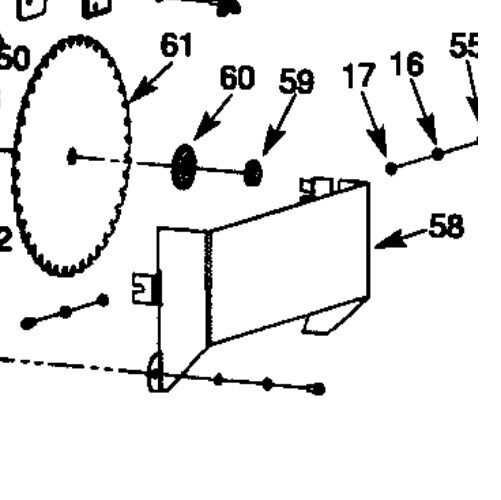

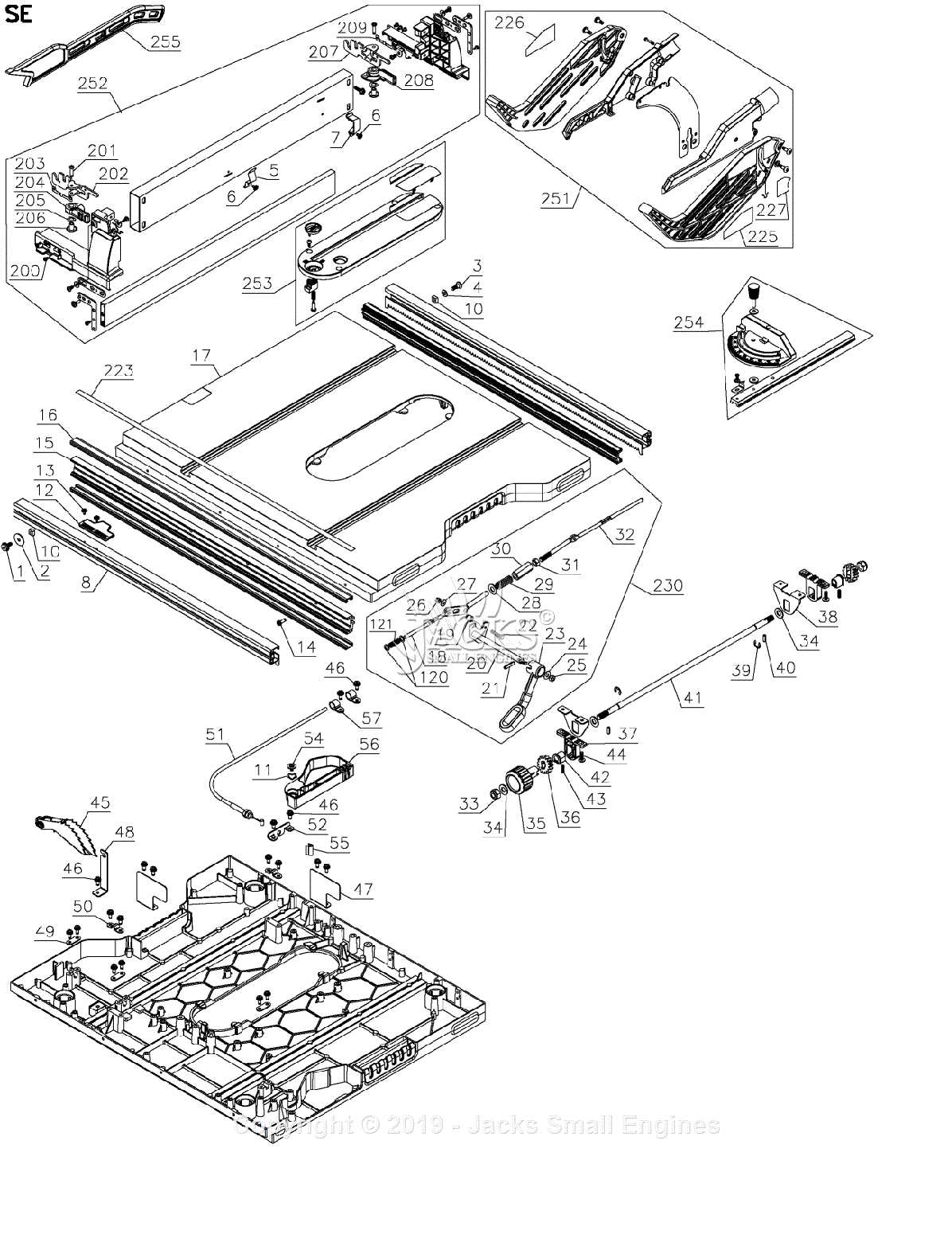

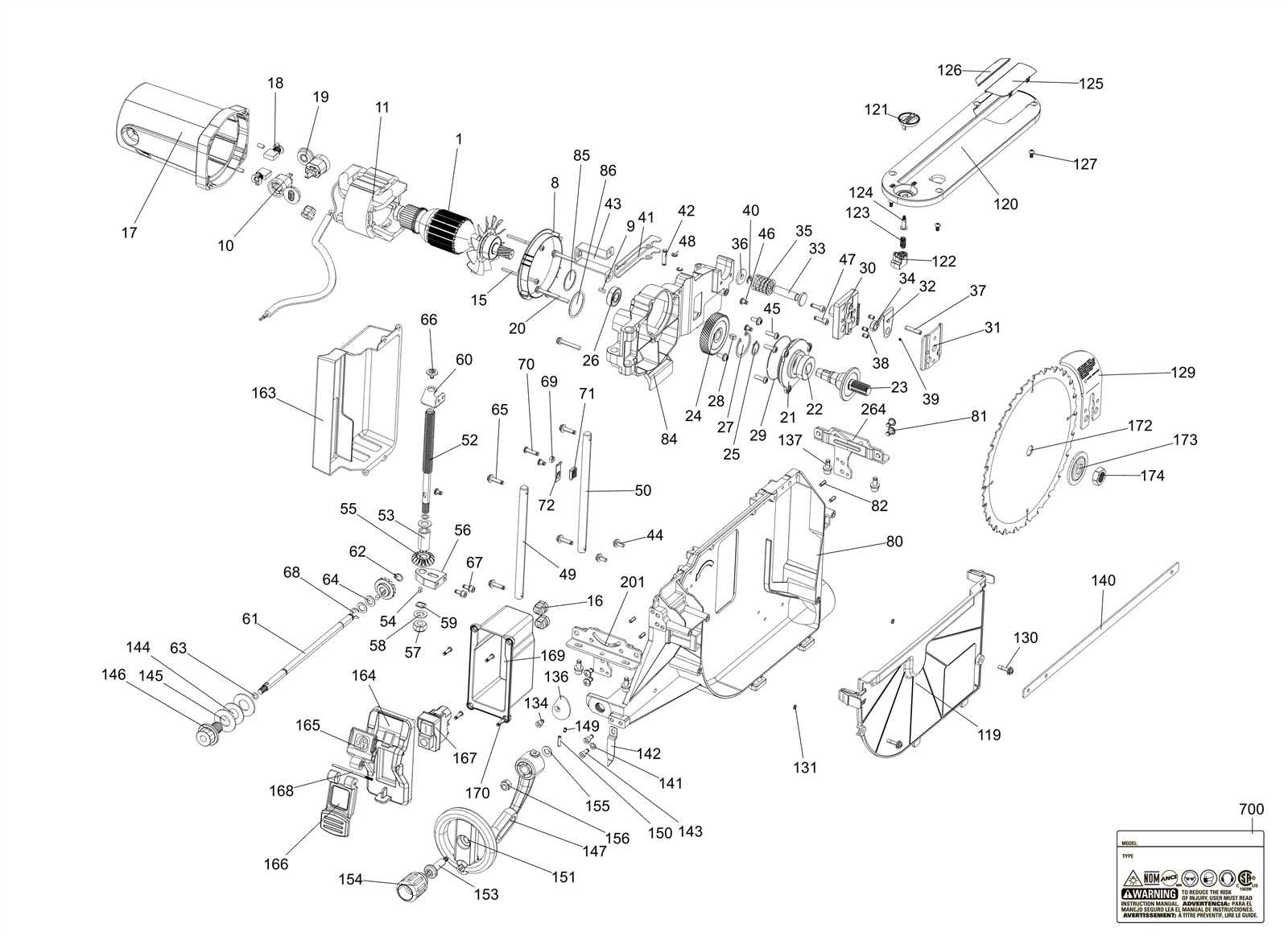

For those looking to optimize their machinery, a clear visual representation of each constituent part can serve as a valuable reference. By examining the intricate relationships between various segments, users can delve deeper into the mechanics of their tools, ultimately ensuring longevity and reliability.

In this section, we will explore a detailed overview of the various components involved, highlighting their functions and interconnections. Understanding these aspects will equip you with the ultimate insights necessary for effective tool management and enhancement.

Dwe7491rs Parts Overview

This section provides a comprehensive look at the essential components that make up this specific tool, highlighting their roles and significance in overall functionality. Understanding these elements can enhance your maintenance skills and improve performance.

Each component is designed to work in harmony, ensuring efficiency and safety during operation. Familiarizing yourself with these pieces can help identify potential issues early, leading to timely repairs.

Ultimately, knowing the details of these elements not only aids in troubleshooting but also empowers users to maximize the longevity and effectiveness of their equipment.

Key Components of Dwe7491rs

Understanding the essential elements of this equipment is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring performance and longevity. Below are the primary elements that contribute to its functionality.

- Motor: The heart of the machine, providing the necessary power for cutting tasks.

- Table: A robust surface that supports the workpiece, often featuring precise measurements for accuracy.

- Blade: The cutting instrument, available in various types to suit different materials and applications.

- Fence: An adjustable guide that ensures straight cuts and enhances safety.

- Base: The sturdy foundation that provides stability and reduces vibrations during operation.

Each of these components is designed to work in harmony, contributing to the overall effectiveness and user experience of the tool. Proper care and understanding of these parts can lead to optimal results and extended service life.

Importance of a Parts Diagram

A visual representation of components is crucial for understanding how different elements of a tool interact and function together. Such illustrations facilitate troubleshooting, maintenance, and repairs, ensuring users can easily identify and replace any faulty items.

Enhancing Understanding

Clear visual aids help users grasp complex systems more intuitively. They serve various purposes:

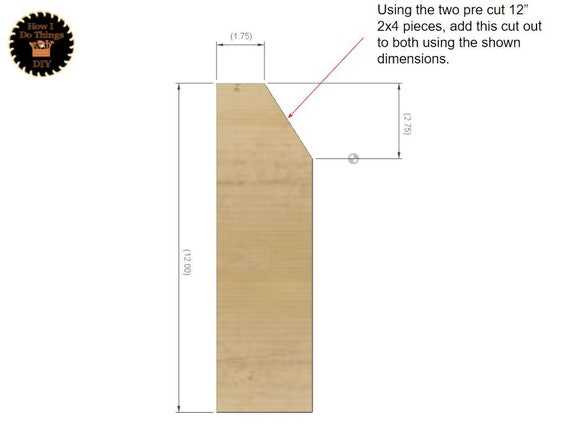

- Provide a reference for assembling and disassembling

- Clarify the location and function of each element

- Assist in recognizing compatible components

Streamlining Maintenance

Utilizing these illustrations can lead to more efficient upkeep:

- Identify wear and tear on specific parts

- Plan for timely replacements to avoid breakdowns

- Minimize downtime by ensuring quick access to necessary components

How to Read the Diagram

Understanding the visual representation of components is crucial for effective assembly and maintenance. By familiarizing yourself with the layout and symbols, you can streamline the process of identifying each element and its function.

- Familiarize with Symbols: Start by learning the various icons used in the illustration. Each symbol typically corresponds to a specific piece.

- Identify Connections: Pay attention to the lines or arrows that indicate how different parts are linked together. This will help you understand the flow and interaction.

- Use a Legend: If available, refer to the legend or key that explains the symbols and terms. This can clarify any confusion regarding unfamiliar representations.

With practice, interpreting these visuals becomes easier, enabling you to tackle tasks with confidence and precision.

Common Replacement Parts Explained

When it comes to maintaining and repairing power tools, understanding the essential components is crucial for optimal performance. Familiarity with frequently needed items can save time and enhance efficiency during the restoration process.

Below are some of the most commonly replaced elements, along with a brief description of their functions:

- Blades: These cutting tools are fundamental for various applications. Regular replacement ensures precision and safety during use.

- Motors: The heart of any tool, motors can wear out over time. Replacing a faulty motor can restore functionality and power.

- Switches: A vital safety feature, switches may fail due to overuse. A new switch can improve reliability and ease of operation.

- Bearings: These components facilitate smooth movement. Worn bearings can lead to increased friction and noise, necessitating replacement.

- Cases: Protective casings may crack or break, compromising the tool’s integrity. A sturdy case is essential for durability.

By staying informed about these key components, users can make timely replacements, ensuring that their tools function efficiently and safely over time.

Finding Authentic Replacement Parts

When seeking out genuine components for your tools, ensuring quality and compatibility is crucial. Authentic replacements not only maintain the performance of your equipment but also enhance its longevity. Knowing where and how to source these essential items can significantly impact your experience and satisfaction.

Identifying Reliable Sources

Start by exploring authorized retailers or manufacturer websites. These platforms often guarantee the authenticity of their offerings and provide detailed information about each item. Additionally, consider reading customer reviews to gauge the reliability of various suppliers.

Benefits of Genuine Components

Opting for original items can prevent potential issues that may arise from using substandard alternatives. Quality assurance is a major advantage, as authentic pieces are designed to fit and function seamlessly with your equipment. Furthermore, using genuine components often keeps your warranty intact, safeguarding your investment over time. Investing in the right replacements pays off in performance and peace of mind.

Maintenance Tips for Longevity

To ensure the prolonged performance and reliability of your equipment, regular upkeep is essential. By implementing simple yet effective practices, you can significantly extend the lifespan of your machinery and enhance its efficiency. Prioritizing maintenance not only safeguards your investment but also optimizes its operation.

Routine Cleaning

Regularly removing dust and debris from surfaces and components is crucial. This prevents buildup that can cause wear and tear, ensuring smooth functionality. Make it a habit to inspect and clean your device after each use.

Periodic Inspections

Conducting scheduled checks allows you to identify potential issues before they escalate. Look for signs of wear, loose connections, or any irregularities that could affect performance. Addressing minor concerns promptly can save you time and money in the long run.

Identifying Wear and Tear Signs

Recognizing signs of deterioration is crucial for maintaining the longevity and performance of your equipment. Over time, various components may exhibit wear that can affect functionality and safety. By understanding how to identify these indicators, you can take proactive measures to ensure optimal operation.

Common Indicators of Deterioration

Several signs can signal that parts may need attention or replacement. Here are some of the most frequently observed:

| Indicator | Description |

|---|---|

| Cracks | Visible fractures that may compromise structural integrity. |

| Excessive Wear | Noticeable thinning or rounding of edges, indicating frequent use. |

| Discoloration | Changes in color can indicate heat exposure or chemical damage. |

| Looseness | Parts that do not fit securely may lead to operational issues. |

Monitoring and Maintenance Tips

Regular inspections can help catch wear early. Keep an eye on high-friction areas and consider implementing a routine maintenance schedule to address any issues before they escalate. Noting any unusual noises or performance drops can also be key in identifying problematic components.

Upgrading Components for Better Performance

Enhancing the functionality of your tools can significantly improve their efficiency and longevity. By carefully selecting and replacing specific elements, users can achieve greater precision, increased power, and a more enjoyable experience. This section explores various options for upgrading essential components to unlock the full potential of your equipment.

Key Components for Enhancement

Identifying which parts to upgrade can make a considerable difference. Focus on elements that directly impact performance, such as motors, blades, and controls. Here’s a brief overview of the most impactful upgrades:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Motor | High-performance or brushless | Improved power and efficiency |

| Blades | Specialized or carbide-tipped | Enhanced cutting ability and longevity |

| Control System | Upgraded electronic controls | Smoother operation and greater precision |

Considerations Before Upgrading

Before proceeding with any enhancements, it’s vital to assess compatibility with existing equipment. Ensure that new components align with the specifications and operational standards of your tools. Additionally, research and consult expert opinions to make informed decisions regarding the best upgrades for your needs.

Where to Purchase Parts Online

Finding the right components for your equipment can often feel daunting, especially when seeking reliable sources. Fortunately, the internet offers a plethora of options to explore, allowing you to acquire essential items with just a few clicks. This section will guide you through various online platforms where you can confidently obtain the necessary supplies for your tools.

Trusted Retailers

When it comes to reliability, established retailers are often the best choice. These vendors typically provide a wide selection of items, along with customer reviews and support, ensuring a seamless purchasing experience.

Specialty Stores

Specialty shops focus on particular brands or types of equipment. They often stock hard-to-find items and provide expert advice, making them valuable resources for specific needs.

| Website | Description |

|---|---|

| Amazon | A vast marketplace with a wide range of tools and accessories. |

| eBay | An auction site where you can find new and used components. |

| ToolpartsPro | Specializes in a variety of equipment and offers competitive pricing. |

| Home Depot | A major home improvement retailer with an extensive online catalog. |

Customer Reviews on Replacement Parts

In the world of power tools, feedback from users is invaluable, especially when it comes to sourcing new components. Insights from fellow users can illuminate the quality, reliability, and overall performance of these essential items, guiding potential buyers in their decisions.

Quality Matters: Many customers emphasize the importance of quality in replacement items. Reviews often highlight that higher-quality alternatives not only enhance performance but also extend the lifespan of the tools.

Ease of Installation: Users frequently mention how straightforward or complicated the installation process can be. Clear instructions and compatibility with existing equipment play a significant role in user satisfaction.

Value for Money: Price is a recurring theme, with many reviewers comparing affordability against durability. Positive experiences often stem from items that offer a balance between cost and longevity.

Customer Service: A number of testimonials discuss the importance of responsive customer support when issues arise. Reliable assistance can make a significant difference in the overall experience of sourcing replacements.

FAQs About Dwe7491rs Parts

This section addresses common inquiries regarding components and accessories related to the specific model of equipment. Understanding these elements is essential for maintenance and optimal performance. Below are some frequently asked questions that can help clarify concerns users may have.

What should I do if I need to replace a component?

If you find that a certain element is worn out or malfunctioning, it’s advisable to consult the manufacturer’s manual for guidance on replacement. Ensure you obtain genuine replacements to maintain the integrity and functionality of your equipment.