In the realm of power equipment, comprehending the various elements that contribute to the effective functioning of a device is crucial. This section delves into the intricate relationships between different components and how they work synergistically to ensure optimal performance. By familiarizing oneself with the layout and functionality of these elements, users can enhance their operational knowledge and troubleshooting skills.

Recognizing individual parts not only aids in maintenance but also facilitates a deeper appreciation of the tool’s design. Understanding how each segment interacts with others can lead to more informed decisions regarding repairs and upgrades. This knowledge empowers users to tackle challenges confidently and improve the longevity of their equipment.

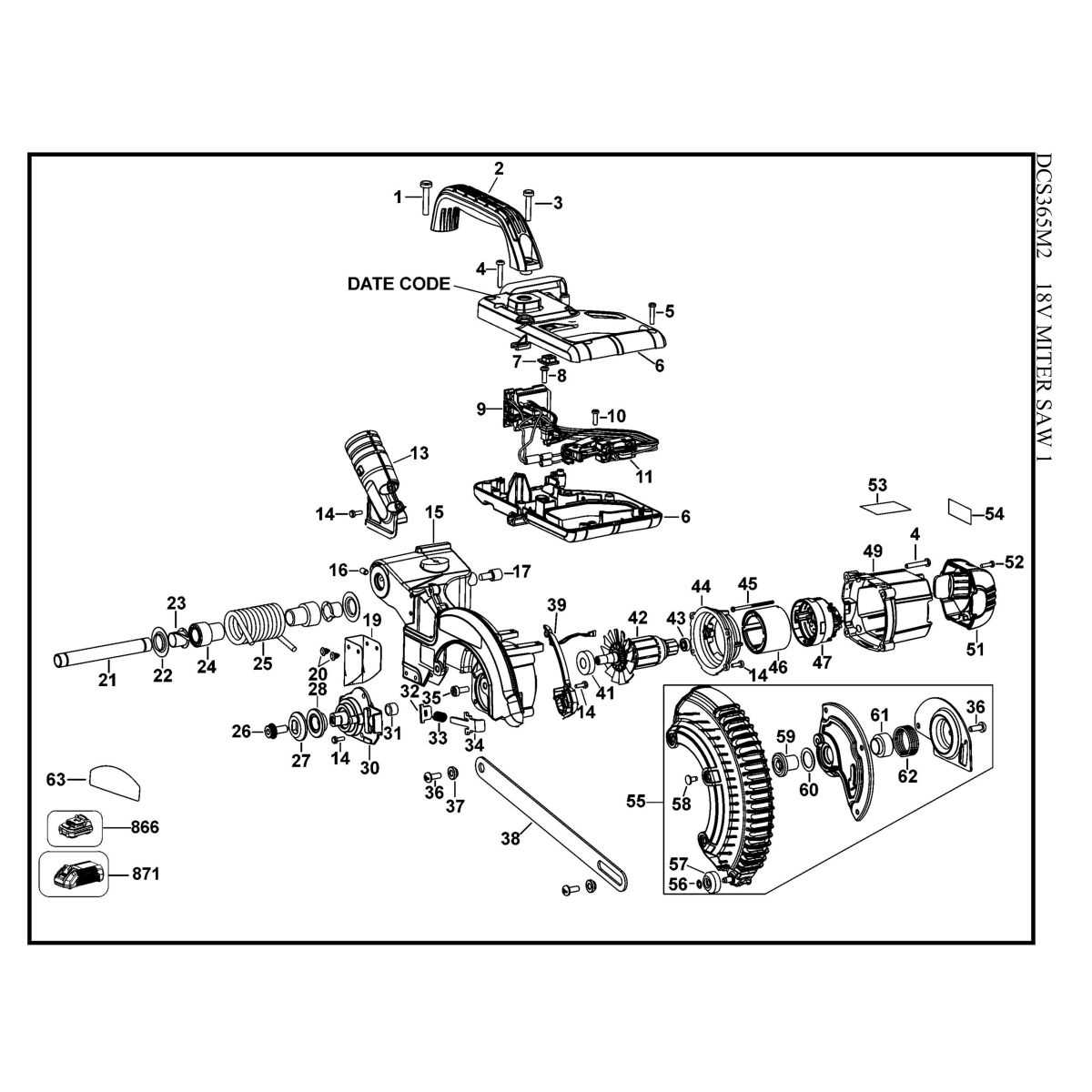

Moreover, visual aids showcasing the arrangement of various sections can serve as invaluable references. These illustrations offer clarity, allowing users to identify and understand the significance of each part effortlessly. By engaging with these resources, one can transform their approach to using and maintaining power tools.

Grasping the various elements of a power tool is essential for optimal performance and maintenance. Each component plays a significant role in the overall functionality, contributing to efficiency and durability during operation.

Key elements typically found in these machines include:

- Motor: The heart of the tool, responsible for driving the operation.

- Blade: The cutting instrument that determines the effectiveness and precision of the task.

- Guard: A protective feature that ensures user safety while using the device.

- Base Plate: The surface that stabilizes the tool and aids in accurate cutting.

- Handle: The grip that provides control and maneuverability during use.

Familiarity with these components not only enhances user experience but also aids in troubleshooting and maintenance. Understanding how each part functions together allows for better decision-making regarding repairs and upgrades.

Identifying Key Parts

Understanding the essential components of a cutting tool is crucial for optimal performance and maintenance. Familiarity with these elements not only enhances functionality but also aids in troubleshooting and repairs. Knowing each part’s role allows users to effectively manage their equipment and ensure longevity.

Primary Components

The main elements typically include the motor, blade assembly, and handle. The motor drives the tool, providing the necessary power to operate effectively. The blade assembly is responsible for the actual cutting, while the handle offers the necessary grip and control during use.

Additional Features

Beyond the primary components, various additional features can enhance usability. These may consist of safety guards, adjustment mechanisms, and dust extraction systems. Each of these features contributes to a more efficient and safe cutting experience, making it essential to recognize their importance in the overall design.

Maintenance of Each Section

Regular upkeep of individual components is crucial for optimal performance and longevity of the equipment. By ensuring that each segment is properly maintained, users can prevent unnecessary wear and enhance the overall efficiency of the tool. This section provides insights into essential maintenance practices for various parts of the device.

Cleaning and Inspection

Routine cleaning is vital to remove debris and prevent buildup that may hinder functionality. Inspect all areas for signs of damage or wear. Pay close attention to critical components, ensuring they remain free from contaminants. Use appropriate cleaning agents and tools to avoid any potential harm.

Lubrication and Adjustments

Applying lubrication to moving parts minimizes friction and prolongs the life of the equipment. Regularly check for proper alignment and make necessary adjustments to maintain precision. Following manufacturer guidelines for lubrication intervals is essential to achieve the best results.

Repair and Replacement Tips

Maintaining and restoring equipment involves careful consideration and a strategic approach to ensure longevity and optimal performance. Understanding common issues and knowing when to address them is essential for any user.

Start by regularly inspecting the tool for signs of wear or damage. Identify components that may need attention, such as blades or motors, and familiarize yourself with the process of replacing them. Keep a checklist handy to track parts that require replacement, and always prioritize using compatible items to maintain functionality.

When tackling repairs, ensure you have the right tools and safety gear at your disposal. This preparation can prevent accidents and ensure a smooth workflow. Consult the manual or reliable online resources for step-by-step guidance to avoid mistakes during the repair process.

Finally, consider investing in high-quality replacement components. While it might be tempting to opt for cheaper alternatives, using durable parts can save time and money in the long run, as they often perform better and last longer.

Common Issues with Components

When utilizing power tools, certain components may encounter frequent challenges that can affect overall functionality. Identifying these common issues is essential for maintaining optimal performance and ensuring safety during operation.

One prevalent problem involves wear and tear on moving parts, which can lead to decreased efficiency. Regular inspection is crucial to detect any signs of deterioration. Overheating is another concern, often caused by prolonged use or inadequate lubrication, resulting in potential damage to vital components.

Moreover, misalignment of parts can create operational difficulties, causing excessive vibration or inaccurate performance. Addressing these issues promptly helps prolong the lifespan of the tool and enhances its reliability.

Diagram Interpretation Guide

This section aims to enhance your understanding of visual representations used in maintenance manuals. By familiarizing yourself with these illustrations, you can more effectively identify components and their functions.

To navigate these representations successfully, consider the following key aspects:

- Component Labels: Pay attention to annotations that provide names or numbers for each part, facilitating easy reference.

- Connections: Observe lines or arrows that indicate how different elements interact or connect with each other.

- Groupings: Look for clusters of parts that are often used together, as they may represent assemblies or units.

Understanding these elements will significantly aid in troubleshooting and repair tasks. Proper interpretation of these visuals is essential for effective maintenance.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. A well-equipped toolkit not only simplifies the process but also ensures that repairs are conducted efficiently and effectively. Understanding which tools are essential can save both time and effort, making the repair experience smoother.

Common Hand Tools

Basic hand tools form the backbone of any repair kit. Items such as wrenches, screwdrivers, and pliers are fundamental for a variety of tasks. Each tool serves a specific function, enabling users to tackle different issues with ease. For instance, adjustable wrenches can accommodate various sizes of fasteners, while a set of precision screwdrivers allows for working on delicate components.

Power Tools and Accessories

In addition to hand tools, power tools are invaluable for larger projects. A reliable electric saw can significantly reduce the effort required for cutting materials. Moreover, having appropriate accessories, such as blades and drill bits, enhances the versatility of these tools, enabling them to handle a wider range of tasks. Investing in quality power tools can lead to improved performance and durability, making them a wise choice for frequent repairs.

Safety Considerations During Maintenance

Ensuring safety while performing maintenance tasks is essential to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment. This section outlines critical safety measures to adhere to during maintenance activities.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is vital for safeguarding oneself against potential hazards. The following items are commonly recommended:

| Protective Gear | Purpose |

|---|---|

| Safety Goggles | To protect eyes from debris and particles. |

| Gloves | To shield hands from sharp edges and hazardous substances. |

| Hearing Protection | To reduce noise exposure during operation. |

| Dust Masks | To prevent inhalation of harmful dust and fumes. |

Workspace Organization

Maintaining an organized workspace minimizes risks and enhances efficiency. Consider the following tips:

- Keep tools and equipment in designated areas.

- Ensure adequate lighting to improve visibility.

- Remove any tripping hazards from the work area.

- Store materials securely to prevent falling objects.

Where to Find Replacement Parts

Locating suitable components for your tool can significantly enhance its performance and longevity. Various resources are available to help you acquire the necessary items, ensuring that your equipment operates efficiently and effectively.

Authorized Retailers

One of the most reliable sources for obtaining replacements is through authorized sellers. These retailers often provide original items that guarantee compatibility with your device. Visiting the official website of these distributors can also yield information about local stores that carry the required components.

Online Marketplaces

Many individuals prefer the convenience of shopping online. Reputable e-commerce platforms offer a wide selection of components, often at competitive prices. When purchasing online, it is essential to check the reviews and ratings of sellers to ensure the quality of the items.

FAQs About Dewalt DHS790 Parts

This section aims to address common inquiries regarding the components and accessories related to a specific power tool model. Understanding these elements can enhance the overall user experience and ensure optimal functionality.

- What are the main components of the tool?

The primary elements typically include the blade assembly, motor housing, and base plate, among others.

- How can I identify the right replacement components?

Refer to the product manual or consult an authorized retailer to ensure compatibility with your specific model.

- Where can I purchase accessories?

Accessories can be acquired through official distributors, online marketplaces, or local hardware stores.

- What maintenance tips should I follow?

- Regularly inspect the blade for wear and replace as needed.

- Keep the tool clean and free from debris.

- Lubricate moving parts to ensure smooth operation.

- Is it easy to replace worn-out components?

Yes, most parts are designed for easy replacement with minimal tools required.