Understanding the intricate design and functionality of various essential elements in modern fixtures is crucial for effective maintenance and repair. This section delves into the fundamental structure of crucial mechanisms found in everyday applications, shedding light on how these elements work together to ensure smooth operation.

The ability to identify individual components within a complex system is invaluable when troubleshooting or replacing worn-out parts. By exploring each part in detail, one gains a deeper appreciation of how different elements contribute to the overall functionality of a well-designed system.

In this guide, we will provide a clear breakdown of each component, offering insights into their roles and interactions within the larger mechanism. Whether you’re repairing, replacing, or simply curious about the internal workings, this detailed explanation will give you a comprehensive understanding of the system’s anatomy.

Overview of Delta Monitor 1500 Series

Understanding the functionality and structure of this particular model involves exploring its core mechanisms and key features. The unit is designed to deliver a combination of performance and durability, making it a reliable choice for users seeking efficiency and long-lasting service. By examining its internal components and overall system, you gain insight into how it operates and what makes it stand out in its category.

Key Functional Features

This model is engineered to provide optimal control over temperature and water flow, ensuring a comfortable and consistent experience. Its internal setup includes a balanced mechanism that regulates pressure, allowing smooth transitions between settings. The thoughtful arrangement of parts contributes to the product’s overall reliability and user satisfaction.

Durability and Maintenance

Built with high-quality materials, this unit is made to withstand daily wear and tear. Routine maintenance is straightforward, with components that are easily accessible and replaceable. Its design supports longevity, reducing the need for frequent repairs and ensuring that the system remains functional over time.

Key Components in the Delta Monitor System

The system in question relies on several critical elements that work together to ensure proper functionality and efficiency. Understanding the structure and role of these components is essential for effective maintenance and troubleshooting. Each part contributes uniquely to the overall performance, ensuring reliable operation under various conditions.

- Control Valve: This central unit regulates the flow, adjusting levels based on user preferences and conditions. It is crucial for managing pressure and maintaining balance.

- Cartridge Assembly: Acting as the heart of the system, this component enables smooth adjustments and is responsible for sealing and preventing unwanted leakage.

- Temperature Regulator: A vital safety mechanism, this element ensures that the output remains within safe temperature limits, preventing overheating or abrupt temperature changes.

- Trim Kit: This set of external pieces not only provides aesthetic value but also serves as an interface for controlling the various internal components. It allows easy access and adjustments.

- Seals and Gaskets: These small but essential items create tight seals, preventing water from escaping and ensuring the system remains leak-free.

Each of these elements plays a pivotal role in ensuring the system functions efficiently and safely. Regular inspection and maintenance of these parts

Understanding the Functionality of Cartridges

Cartridges play a pivotal role in controlling water flow and temperature in modern plumbing systems. Their design allows for seamless operation, ensuring that the user can adjust both temperature and water pressure with ease. The mechanism inside the cartridge regulates how hot and cold water are mixed, providing consistent performance and preventing sudden changes in water temperature.

The key to understanding cartridges lies in the interaction between their internal components. They consist of various seals, springs, and balancing mechanisms that work together to maintain a steady flow of water. This functionality makes them crucial for both safety and comfort in everyday use.

| Component | Function |

|---|---|

| Seals | Prevent water leakage and maintain pressure. |

| Springs | Ensure smooth movement and pressure adjustment. |

| Mixing Chamber | Combines hot and cold water to the desired temperature. |

| Balancing Mechanism | Regulates temperature to avoid scalding or cold shocks. |

Exploring Valve and Handle Mechanisms

The internal systems that control water flow and temperature are designed to provide seamless operation, ensuring comfort and reliability in everyday use. Understanding how these components work together can give valuable insights into their function and help with troubleshooting or maintenance tasks. The mechanisms involved in managing water pressure and temperature blending are fundamental to achieving the desired performance in any bathroom setup.

Valve Functionality

The core of the mechanism relies on a well-engineered valve that regulates the flow of water. This part is crucial for maintaining balance between hot and cold water streams. Depending on the design, the valve may include features that prevent scalding or provide a smooth transition between water temperatures. It often incorporates advanced engineering techniques to ensure durability and precision in water management.

Handle Operations

The handle system is another essential component, allowing users to adjust water flow with ease. This part is designed to interface seamlessly with the internal control mechanisms. Whether it operates through rotational or vertical motion, the handle system is engineered to respond accurately to user inputs, making it easy to fine-tune both pressure and temperature with minimal effort. Attention to ergonomics and material quality ensures long-lasting, smooth operation.

Showerhead Design and Flow Control

The design of a showerhead plays a crucial role in determining the quality of the water flow and the overall showering experience. The structure, shape, and internal mechanisms all contribute to how water is dispersed, impacting both efficiency and comfort. Understanding how these elements work together helps in optimizing water usage while ensuring a satisfying shower experience.

Flow control is another essential aspect, regulating how much water is released and at what pressure. Proper flow control mechanisms allow users to adjust the intensity of the water, balancing between water conservation and comfort. Efficient designs incorporate adjustable settings that can cater to different preferences, ensuring versatility in use.

Pressure Balance Mechanism Explained

The pressure balance mechanism is a critical element in regulating the flow of water, ensuring that the temperature remains stable despite fluctuations in water pressure. This system operates by responding to changes in the water supply, maintaining an even distribution of pressure between hot and cold water streams. The key function is to prevent sudden temperature shifts that could lead to discomfort or even injury, particularly in shower systems.

Essentially, the mechanism acts as a safeguard, continuously adjusting the flow of hot and cold water to keep the desired temperature consistent. It works by balancing the forces exerted by the incoming water, allowing the system to react swiftly to any changes in pressure from external factors like additional water usage in other areas of the home. This ensures a steady, safe, and comfortable experience during water usage.

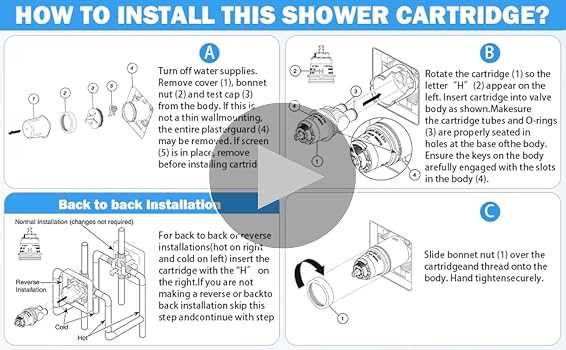

Installation Guide for Delta 1500 Parts

Proper installation of components is crucial for ensuring optimal performance and longevity of your equipment. This guide provides step-by-step instructions for assembling various elements of the system. By following these instructions, you can guarantee that all connections are made securely and function efficiently, minimizing potential issues during operation.

Preparation Before Installation

Before beginning the installation, ensure you have all necessary tools and components. Proper planning will save time and help avoid mistakes during assembly. Here’s a list of essential preparations:

- Verify that all components are available and in good condition.

- Gather necessary tools such as screwdrivers, pliers, and a multimeter.

- Ensure that the workspace is clean and free from any obstructions.

- Read through the assembly instructions carefully to understand the process.

Step-by-Step Assembly Instructions

Follow these steps to successfully assemble the various components. Be sure to secure each part as per the guidelines to ensure everything functions smoothly:

- Start by securing the base element of the system to the intended location.

- Next, connect the primary electrical inputs, ensuring the wiring is properly insulated and positioned.

- Install the interface components and secure them with the appropriate fasteners.

- Once all connections are complete, perform a system check to ensure everything is correctly installed and connected.

- Finally, power up the system and conduct a final operational test to verify proper function.

Maintenance Tips for Longevity

To ensure the long-term performance and reliability of your device, regular upkeep is essential. Taking the time to maintain key components not only helps in preventing potential malfunctions but also maximizes efficiency over time. Following a structured maintenance routine can reduce wear and tear, enhance durability, and ultimately extend the lifespan of your equipment.

1. Keep Surfaces Clean: Regularly wiping down surfaces and internal areas prevents dust and debris buildup. This simple task can reduce the risk of overheating and enhance air circulation within the device.

2. Check Connections: Ensure all cables and connectors are firmly attached and free from corrosion. Loose or damaged connections can lead to poor performance or complete failure over time.

3. Proper Storage: When not in use, store your equipment in a cool, dry place. Exposure to excessive humidity or high temperatures can damage internal components and shorten its lifespan.

4. Update Firmware: Keep the software up to date to ensure your device operates with the latest security patches and performance enhancements. Regular updates can fix bugs and improve system stability.

5. Inspect for Wear: Periodically check for signs of wear, such as frayed wires or degraded parts. Early detection can prevent more serious issues from developing and reduce the need for costly repairs.

Common Issues and Their Solutions

When working with complex display units, several common problems may arise, often related to functionality or performance. Addressing these issues requires a clear understanding of their root causes and practical solutions. This section covers some of the frequent challenges encountered and provides helpful advice for resolving them effectively.

Flickering or Dim Screen

A flickering or dim display can hinder visibility and affect user experience. This issue may be caused by electrical inconsistencies, connectivity problems, or internal component malfunctions.

- Check the power supply and cables for any loose connections or damage.

- Verify the brightness settings are correctly adjusted to optimal levels.

- Inspect internal components for signs of wear or failure and replace them if necessary.

No Display or Dead Screen

If there is no image on the screen, it could indicate a severe issue such as a failure in the internal circuitry or a malfunction in the video signal reception.

- Ensure that the unit is properly powered on and all connections are secure.

- Test the video cables and input sources to confirm they are functioning correctly.

- Consider checking or replacing the internal components responsible for signal processing if the issue persists.

Comparing the 1500 Series with Other Models

When assessing the performance and features of different devices in the same category, it is essential to consider their unique characteristics and how they align with user needs. By looking at various models, we can evaluate their strengths and weaknesses, ensuring that each option delivers the right balance of functionality and efficiency. While one model might excel in energy consumption, another could offer enhanced flexibility or better user interface options.

The core difference lies in the specific features that each model offers. Some options might prioritize compact design and ease of integration into smaller setups, while others focus on robustness and higher capacity for more demanding applications. Key considerations often revolve around performance speed, connectivity features, and adaptability in different environments.

Furthermore, examining the user experience across these models reveals how intuitive the interface is and how each device responds to different user requirements. This comparison allows potential users to make informed decisions based on both technical specifications and practical usability.

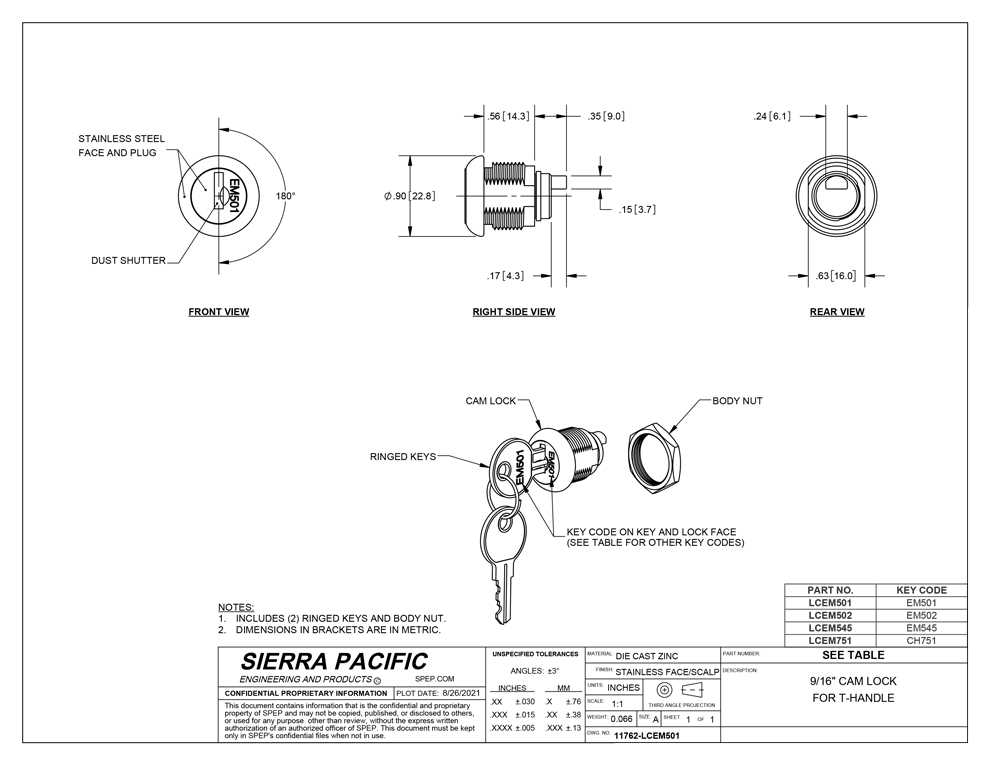

Replacement Parts Compatibility and Availability

Ensuring the correct fit and functionality of components is essential when seeking out replacements for any system. Compatibility between new and existing elements can significantly impact performance and longevity. It’s important to verify specifications and consult available resources to ensure the chosen components will integrate seamlessly with the existing setup.

Finding suitable replacements can be straightforward if you have access to reliable suppliers and documentation. Various platforms offer detailed guidance on the types of components that are compatible with the system in question. However, care must be taken to confirm that the specifications align with your requirements to avoid potential operational issues.