In the realm of maintenance and cleaning, having a comprehensive grasp of your equipment’s structure is crucial for optimal performance. Each element plays a significant role in ensuring that your machine operates efficiently, delivering the results you expect. Recognizing how these components interact can enhance your ability to troubleshoot and maintain your device effectively.

Every unit consists of various intricate elements that work in unison. From the powerful motor to the intricate nozzle, understanding these individual parts is essential for both novice and seasoned users. Familiarity with the layout can empower you to make informed decisions regarding repairs and replacements.

By exploring the intricacies of these systems, you can not only improve your cleaning tasks but also prolong the lifespan of your equipment. Knowledge of the specific roles and functions of each section provides a solid foundation for anyone looking to enhance their skills in maintenance and repair. Embracing this understanding leads to more efficient and effective usage, ultimately saving time and resources.

Understanding Hotsy Pressure Washers

This section explores the essential components and functionality of high-performance cleaning equipment designed for tough tasks. These machines are engineered to deliver powerful cleaning solutions, effectively removing dirt, grime, and stubborn stains from various surfaces.

Key Features

These devices typically feature robust motors and specialized nozzles that enhance their cleaning efficiency. Users benefit from adjustable settings, allowing for tailored pressure levels suited to different applications. Durability is also a hallmark, ensuring longevity even under rigorous conditions.

Maintenance Essentials

Proper upkeep is crucial for optimal operation. Regular inspections of the internal mechanisms and ensuring all connections are secure can prolong the lifespan of the equipment. Understanding the role of each component helps in troubleshooting and maintaining peak performance.

Key Components of Pressure Washers

Understanding the essential elements of cleaning machines can greatly enhance their functionality and maintenance. Each component plays a crucial role in ensuring optimal performance and efficiency during operation.

Main Elements

- Motor: Powers the system and drives the pump.

- Pump: Pressurizes the water, providing the force needed for effective cleaning.

- Nozzle: Directs the water flow and determines the spray pattern.

- Trigger Gun: Controls water flow and pressure when in use.

- Hose: Transfers water from the machine to the nozzle.

Additional Features

- Detergent Tank: Stores cleaning solutions for enhanced results.

- Wheels: Facilitate easy maneuverability.

- Filter: Prevents debris from entering the system, ensuring longevity.

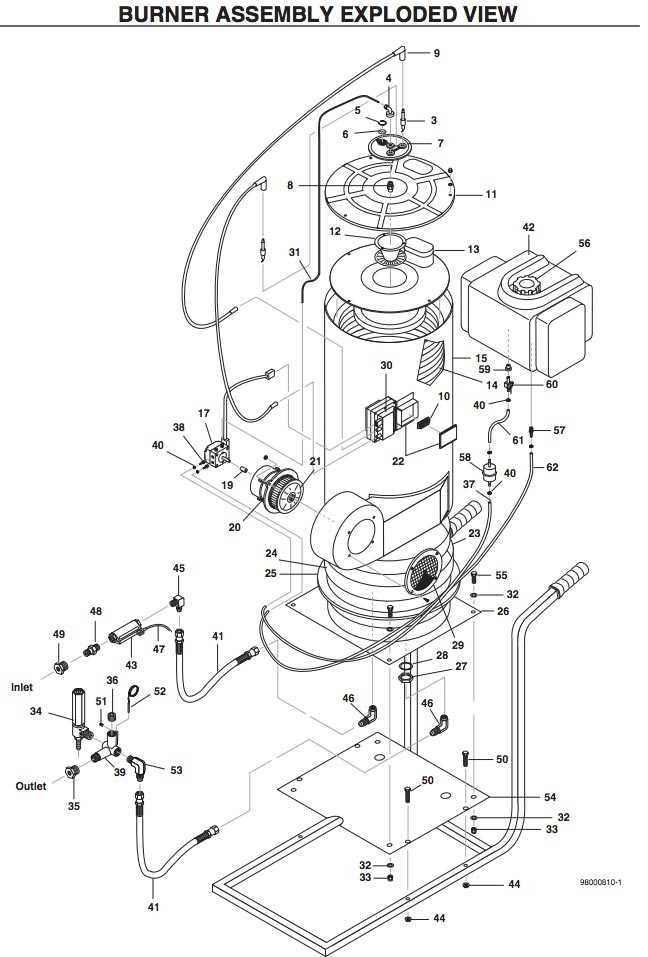

Importance of Pressure Washer Diagrams

Understanding the layout and functionality of equipment components is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, guiding users through intricate systems, enhancing comprehension, and facilitating troubleshooting. Such illustrations provide clarity, helping both novice and experienced users to grasp the essential elements of their machinery.

Benefits of Visual Guides

- Enhanced Understanding: Diagrams simplify complex information, allowing users to visualize relationships between different components.

- Efficient Repairs: Having a clear reference reduces downtime during maintenance, enabling quicker identification of issues.

- Improved Safety: Understanding the layout helps in recognizing hazards, leading to safer operation and maintenance practices.

Key Aspects to Consider

- Component Identification: Clear visuals help in identifying each part’s function and location within the system.

- Assembly Guidance: Illustrated instructions aid in the correct assembly of components, ensuring optimal performance.

- Maintenance Tips: Diagrams often include maintenance schedules and checks, promoting longevity of the equipment.

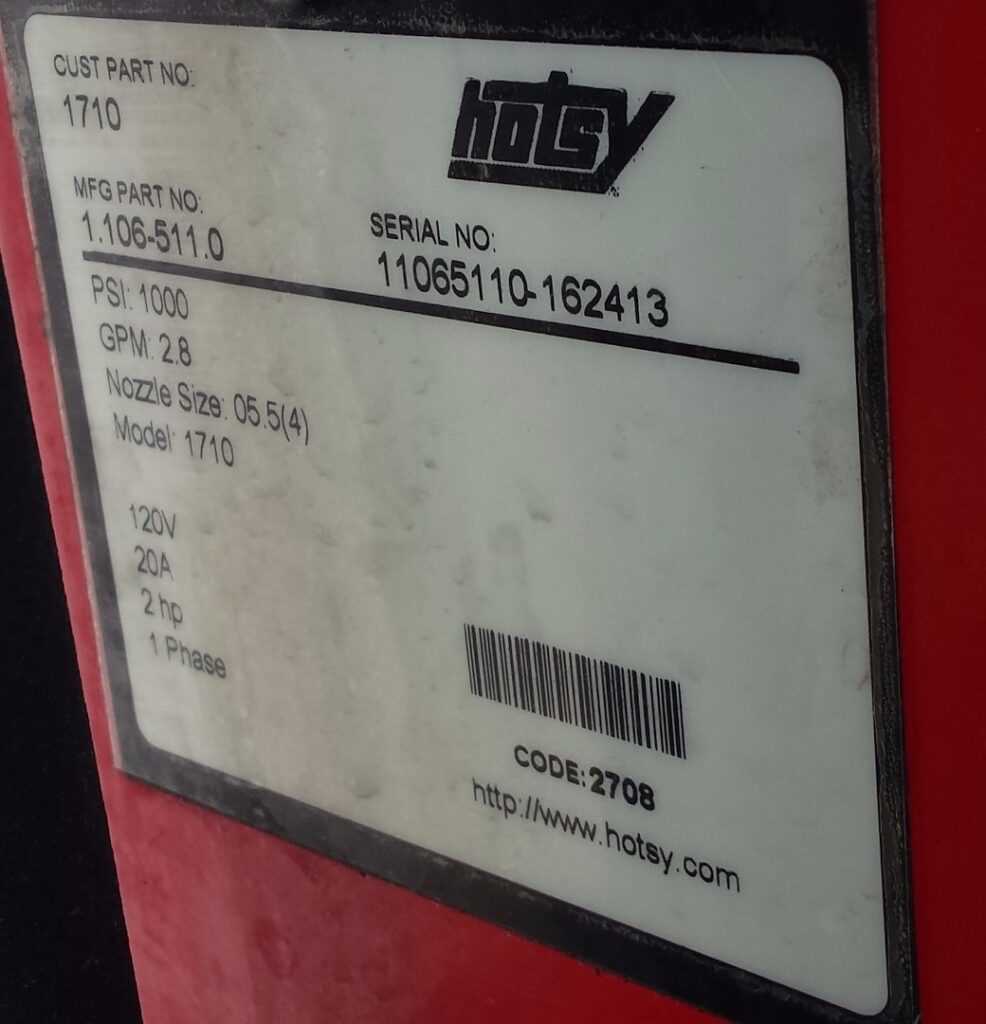

Identifying Hotsy Parts Easily

Recognizing components in your cleaning equipment can significantly enhance maintenance efficiency and ensure optimal performance. Understanding the various elements and their functions allows for quicker troubleshooting and part replacement.

Start by familiarizing yourself with the essential features of your machine. Consult the user manual, as it typically includes valuable insights into each component’s location and role. Additionally, many manufacturers provide resources online, including schematics that visually outline the structure.

Utilize online communities and forums where enthusiasts share their experiences and expertise. These platforms often have detailed discussions that can aid in identifying specific elements and their compatibility with your unit.

Consider labeling components during disassembly for easier reassembly. This method not only streamlines the process but also builds your confidence in managing repairs and replacements in the future.

Lastly, maintaining a record of any replacements made or issues encountered can prove invaluable for future reference, enabling a more efficient approach to upkeep.

Common Issues with Pressure Washer Parts

Understanding typical challenges associated with cleaning equipment can enhance performance and longevity. Various components may face wear and tear, leading to reduced efficiency or malfunction. Identifying these issues early can prevent further damage and ensure optimal operation.

Leaks are a frequent problem, often arising from worn seals or damaged hoses. These can lead to significant loss of liquid and diminished effectiveness.

Clogs in the nozzles or filters can impede the flow, resulting in a weaker stream. Regular cleaning can help mitigate this issue.

Electrical failures may occur due to faulty connections or damaged wiring, causing the motor to malfunction. Regular inspections can help catch these problems early.

Noise can indicate underlying issues such as loose parts or failing bearings. Addressing unusual sounds promptly can prevent more serious damage.

By being aware of these common complications, users can take proactive measures to maintain their equipment and achieve the best results.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. This visual tool provides a clear overview of individual elements and their interconnections, helping users identify the necessary items for their specific needs. By mastering the interpretation of these illustrations, one can streamline the repair process and ensure all components are accounted for.

Familiarize Yourself with the Legend

Most schematics include a legend that explains the symbols and notations used throughout the illustration. Taking time to review this section can save considerable effort later on. Each symbol often corresponds to a specific part, and understanding these will help you quickly locate what you need.

Follow the Flow of the Layout

As you examine the layout, pay attention to how elements are arranged. The organization often indicates the assembly sequence or functional relationship between parts. Identifying clusters of components that work together can aid in troubleshooting and replacing faulty items efficiently.

Maintenance Tips for Hotsy Washers

Proper upkeep of your cleaning equipment is essential for longevity and optimal performance. Regular maintenance can prevent breakdowns and ensure that your machine operates at peak efficiency, making your tasks easier and more effective.

Regular Inspections

Conduct frequent examinations of your unit to identify any wear or damage. Check hoses for leaks, ensure connections are secure, and inspect filters for clogs. Addressing minor issues promptly can save you from costly repairs down the line.

Cleaning and Lubrication

Keep the equipment clean by removing dirt and debris after each use. Additionally, applying appropriate lubricants to moving parts enhances functionality and reduces friction, extending the life of your machinery. Remember, a well-maintained unit is key to achieving the ultimate results in your cleaning tasks.

Replacement Parts for Optimal Performance

Ensuring the peak functionality of your equipment requires careful attention to its components. Utilizing high-quality replacements can significantly enhance efficiency and longevity. This section delves into the various essential elements that contribute to maintaining top performance.

Key Components to Consider

- Seals and Gaskets: Prevent leaks and maintain pressure.

- Filters: Ensure clean operation and protect internal mechanisms.

- Hoses: Durable connections are vital for effective fluid transfer.

- Spray Nozzles: Different designs cater to specific cleaning tasks.

- Engines and Motors: Reliable power sources ensure consistent performance.

Benefits of Quality Replacements

- Enhanced Efficiency: Quality components improve overall functionality.

- Extended Lifespan: Proper replacements reduce wear and tear.

- Cost Savings: Investing in good parts minimizes frequent repairs.

- Improved Safety: Reliable components lower the risk of malfunctions.

Prioritizing quality when selecting replacements ensures that your machinery operates smoothly and effectively, providing exceptional results for your cleaning tasks.

Where to Find Hotsy Diagrams

Finding detailed illustrations of equipment components is essential for maintenance and repairs. Whether you’re troubleshooting or upgrading your system, knowing where to locate these resources can save you time and effort.

Official Manufacturer Websites: Many manufacturers offer comprehensive resources, including detailed layouts of their products. Checking the official website is often the best starting point.

User Manuals: Often included with your equipment, manuals provide valuable insights into assembly and function. They typically feature clear visuals that can assist in identifying parts.

Online Forums and Communities: Engaging with online groups dedicated to equipment maintenance can yield shared resources and personal experiences. Members often post helpful diagrams and tips.

Retailers and Suppliers: Websites of authorized dealers may have downloadable resources. These platforms can be a treasure trove for both schematics and expert advice.

Technical Support: Don’t hesitate to reach out to customer service for assistance. They can provide or direct you to the necessary illustrations and documentation.

By exploring these avenues, you can efficiently locate the essential visuals to ensure your equipment operates at its ultimate performance.

Comparing Hotsy Models and Their Features

When evaluating different models in the realm of cleaning equipment, it’s essential to consider their unique attributes and specifications. Each variant is designed to cater to specific cleaning needs, making it crucial to delve into their performance metrics and functionalities.

Model A excels in mobility and ease of use, perfect for quick jobs in various locations. With a robust motor, it delivers a high output while maintaining efficiency.

Model B focuses on durability and longevity, featuring a reinforced chassis and components that withstand heavy usage. This option is ideal for industrial applications where reliability is paramount.

Model C offers advanced technology, incorporating smart features that enhance user experience. Its intuitive interface allows for effortless operation, making it suitable for both novice and experienced users.

By examining these distinctions, users can make informed decisions that align with their ultimate cleaning requirements.

DIY Repairs for Hotsy Pressure Washers

Home maintenance can often be a rewarding endeavor, especially when it comes to equipment upkeep. Understanding how to troubleshoot and fix common issues can save both time and money. By familiarizing yourself with the components and mechanisms of your device, you can tackle many repairs on your own. This guide will provide insights into some typical problems and solutions.

Before you start any repair work, ensure you have the right tools and safety gear. Regular maintenance checks can prevent larger issues down the line. Here’s a brief overview of common issues and how to address them:

| Common Issue | Possible Causes | Solutions |

|---|---|---|

| Low output | Clogged nozzle, dirty filter | Clean or replace the nozzle and filter |

| Noisy operation | Loose components, worn bearings | Tighten loose parts or replace bearings |

| Overheating | Insufficient water supply, blocked intake | Check water levels and clear the intake |

| Leakage | Worn seals, damaged hoses | Inspect and replace seals and hoses as needed |

Always refer to the manufacturer’s guidelines for specific instructions. Keeping a detailed log of repairs and maintenance will help you track the condition of your device and anticipate future needs. With a little patience and effort, you can extend the life of your equipment and ensure it operates efficiently.