The inner workings of professional tools are often a mystery to users, but understanding the makeup of these devices can lead to more effective usage and easier maintenance. Exploring the structure of a powerful, reliable device reveals how each element contributes to its overall functionality. By gaining insight into the individual components, users can enhance their skills in handling and repairing the equipment.

In modern construction and heavy-duty applications, these devices play a crucial role. Familiarity with how various parts interact ensures that the tool remains in peak condition, providing efficiency and durability. Whether you’re looking to maintain, upgrade, or troubleshoot, having a clear grasp of the mechanics allows for better decision-making and quicker solutions.

Dewalt DCH273 Parts Diagram Overview

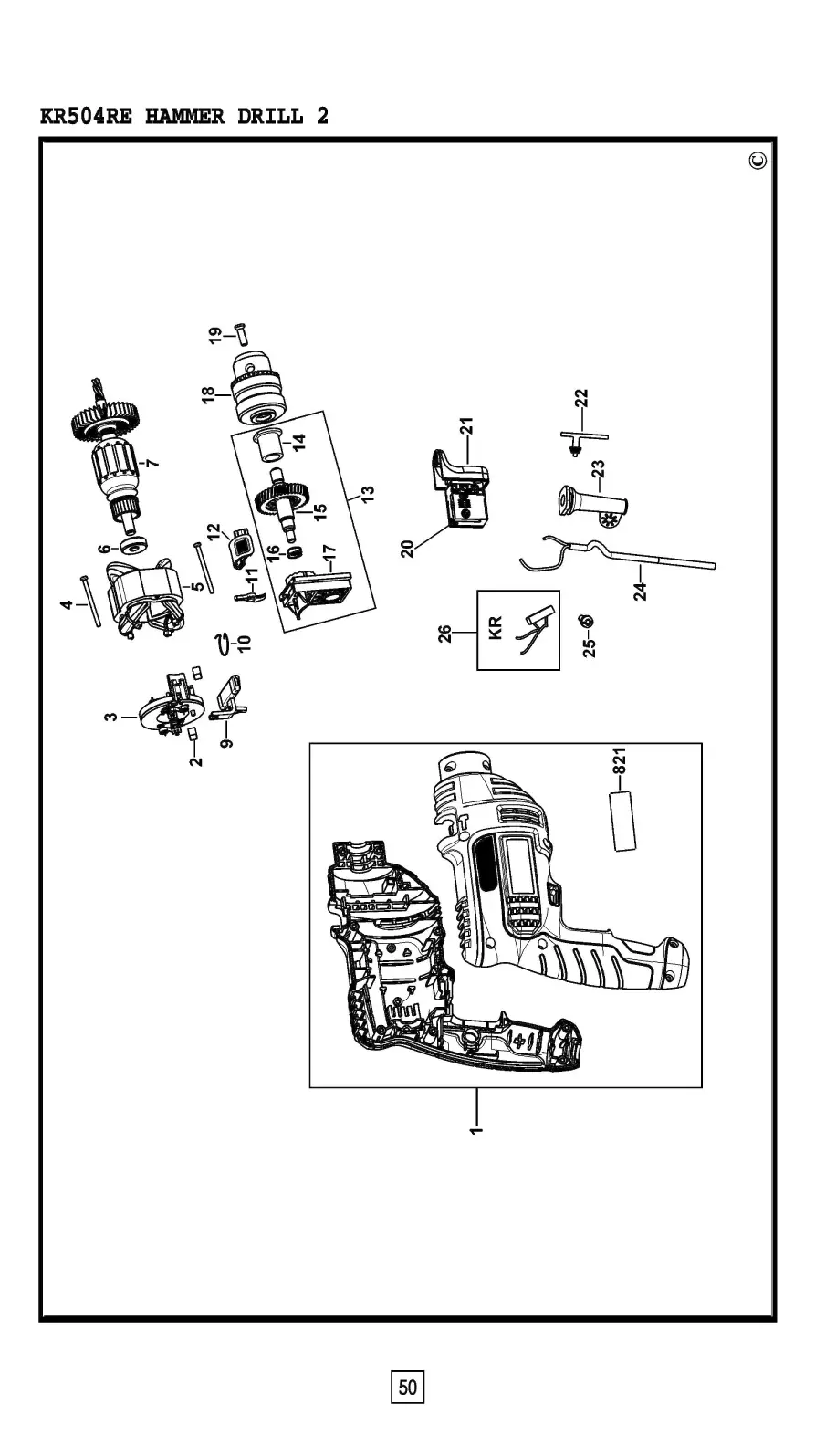

This section provides a comprehensive look at the internal structure and components of a powerful tool used for drilling and chiseling tasks. Understanding the layout of its essential elements allows for easier maintenance and repair. The following breakdown offers insight into the key segments that ensure the device operates efficiently.

- Motor assembly: The core driving force behind the tool’s performance.

- Trigger mechanism: Responsible for controlling the speed and power during operation.

- Handle components: Designed for optimal grip and vibration reduction.

- Protective casing: Shields the internal mechanisms from external damage.

- Power transmission system: Ensures efficient energy transfer between the motor and drill bit.

Each part works together to provide maximum efficiency and durability, making the device suitable for a wide range of professional applications.

Main Components of the Dewalt DCH273

This tool is designed with several key elements that ensure its efficiency and durability in various applications. Each component is engineered to provide optimal performance, enhancing the overall functionality and reliability. The arrangement of these parts allows for a seamless operation, making the tool suitable for both professional and personal use.

Core Structural Elements

- Ergonomic handle for enhanced grip and control

- Sturdy housing to protect internal mechanisms

- High-performance motor for consistent power output

Functional Features

- Advanced trigger system for precision control

- Adjustable settings for versatile operation

- Shock-absorbing mechanism to reduce vibrations

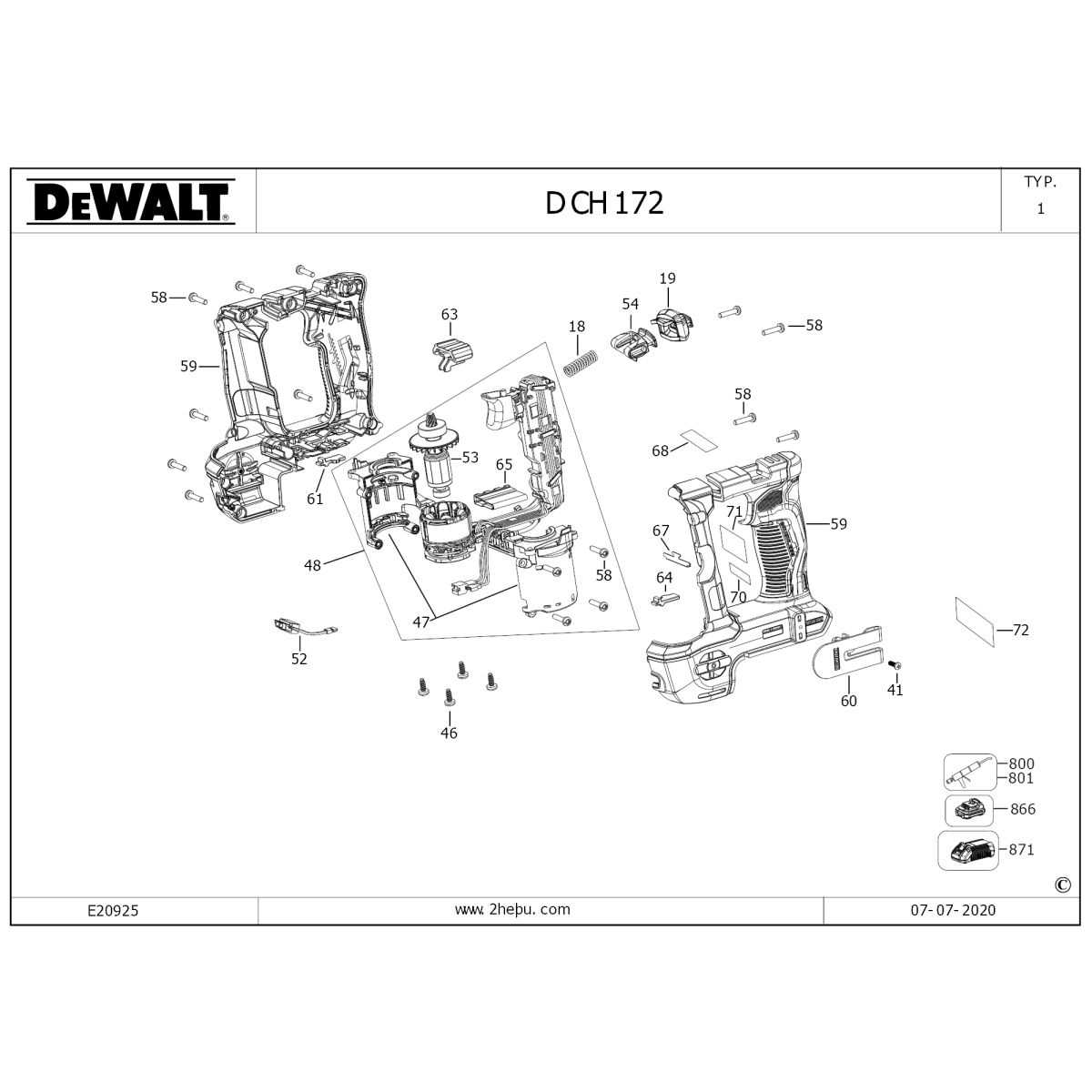

Understanding the Dewalt DCH273 Motor Assembly

The motor assembly plays a crucial role in powering the tool, ensuring consistent performance and efficiency during operation. It is composed of several interconnected components that work together to generate the necessary force for drilling and chiseling tasks. The proper alignment and functioning of these elements are essential for optimal tool performance, providing the energy needed to drive the mechanical functions smoothly.

Key internal mechanisms within the motor contribute to the overall durability and longevity, allowing it to handle demanding tasks without compromising on power output. Regular maintenance of the motor assembly ensures that these components remain in good condition, preventing potential breakdowns and prolonging the life of the equipment.

Hammer Mechanism and Its Parts

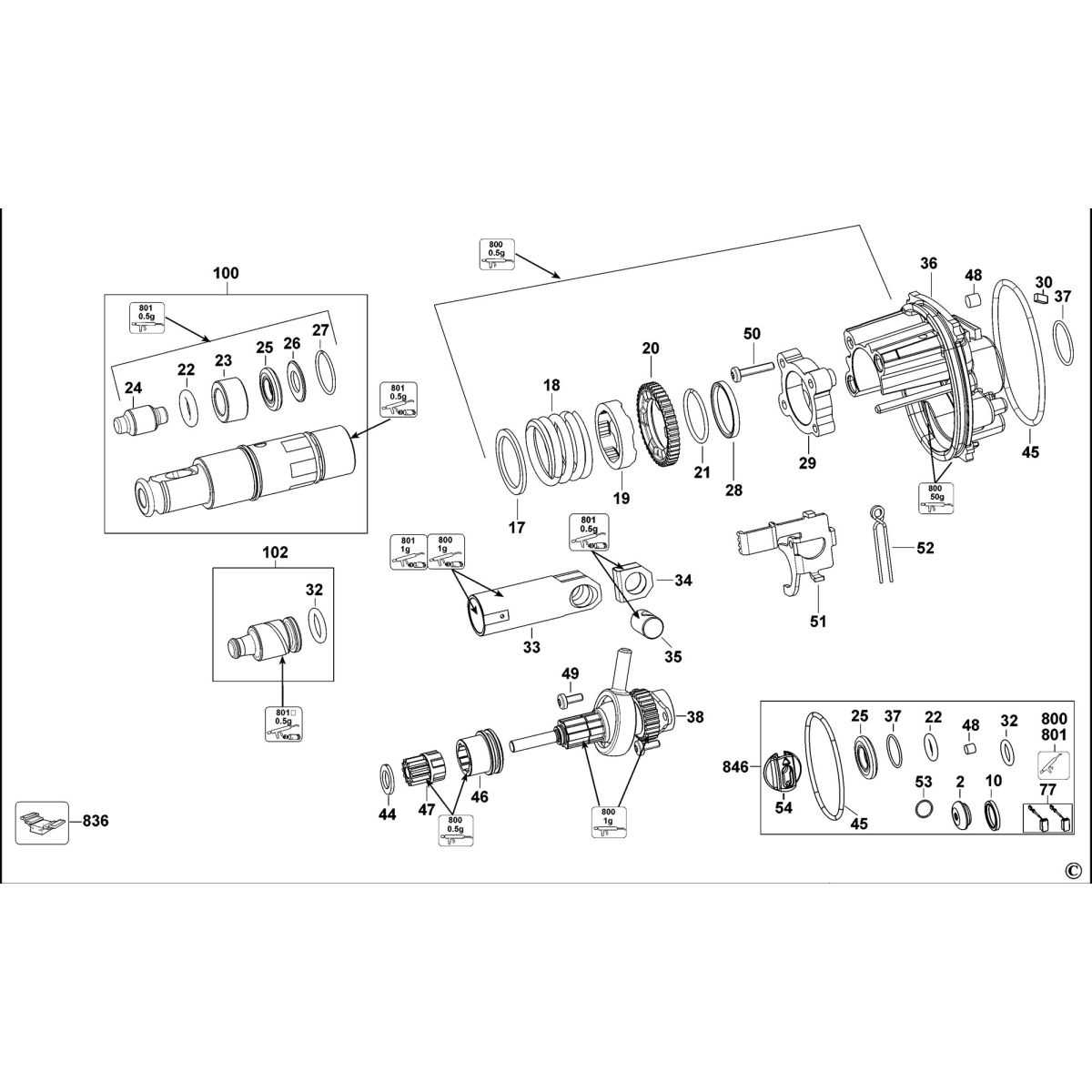

The hammer mechanism in rotary tools is a crucial component that delivers the powerful impact needed for drilling into hard materials. This system uses a series of interconnected components to create a strong force, which enables efficient penetration into concrete or masonry. Understanding how the mechanism operates can help in maintaining its efficiency and troubleshooting issues when they arise.

Main Components of the Hammer Mechanism

The system typically consists of several key elements that work together to generate the striking force. These include a driving piston, which is responsible for transferring energy, and an anvil that receives the impact. Additionally, there are seals and springs that ensure smooth operation and control the motion within the mechanism.

Functionality of Each Component

Each part of the hammer mechanism plays a specific role in converting rotational energy into impact. The piston compresses air, creating a high-pressure environment, while the anvil transfers this energy directly to the bit, resulting in a powerful strike. Proper synchronization between these components is essential for optimal performance.

Battery Compartment and Power System

The energy source and its housing are crucial for the efficient operation of any portable tool. The compartment designed for the power unit ensures a secure fit, allowing for a consistent flow of energy throughout usage. Proper design of the housing protects the energy supply from external factors while allowing quick and easy access for replacement or maintenance.

Energy Flow and Management

The system that channels energy from the source to the tool’s internal components is engineered for stability and efficiency. Power management plays a key role in maintaining optimal performance, regulating the flow to prevent overheating or power surges. This ensures longer usage times and reliable operation, even under demanding conditions.

Maintaining the Energy Unit

Regular inspection of the energy housing and connectors is essential for maintaining peak performance. Cleaning the contacts and ensuring no debris is present helps prolong the lifespan of the power unit, allowing for smoother transitions and uninterrupted work sessions.

Trigger and Speed Control Mechanism

The trigger and speed control system plays a crucial role in the operation of power tools, allowing users to regulate the tool’s performance effectively. This mechanism enables precise control over the tool’s speed and power output, ensuring optimal functionality for various tasks. Understanding how this system operates can enhance user experience and improve work efficiency.

The primary function of the trigger is to initiate the tool’s operation by providing a variable speed feature. When the user pulls the trigger, it activates the motor, which then adjusts its speed based on the amount of pressure applied. This dynamic response allows for finer control during operation, catering to different materials and job requirements.

Understanding the Chuck and Bit Holder

The chuck and bit holder are essential components of power tools that facilitate the secure attachment of drill bits and accessories. Their primary function is to ensure that these tools operate efficiently and safely, allowing for precise drilling and fastening tasks. Understanding how these parts work can enhance the user’s ability to select the right attachments for various applications.

Types of Chucks

There are different types of chucks available, each designed for specific purposes. The most common types include keyless chucks, which allow for quick bit changes without additional tools, and keyed chucks, which require a specialized key to tighten and loosen the grip on the bit. Knowing the advantages of each type can help users make informed decisions based on their needs.

Maintaining the Bit Holder

Regular maintenance of the bit holder is crucial for optimal performance. Keeping it clean and free from debris can prevent wear and ensure a secure fit for the attachments. Additionally, users should inspect the bit holder for any signs of damage or wear, as these can affect the tool’s effectiveness. Proper care can extend the lifespan of both the chuck and the bits used.

Handle and Vibration Control Parts

This section focuses on the components associated with grip and vibration management in power tools. These elements play a crucial role in enhancing user comfort and control during operation. Effective design minimizes fatigue and maximizes performance, allowing for a more efficient workflow.

Grip Features

The gripping mechanism is designed to provide a secure hold, ensuring safety while using the tool. Various materials and shapes are employed to enhance ergonomics, reducing the strain on the user’s hands.

Vibration Management Components

Components aimed at vibration reduction are essential for improving user experience. They absorb shock and minimize the transmission of vibrations, making prolonged use more comfortable and reducing the risk of injury.

| Component | Description |

|---|---|

| Handle Grip | Ergonomically designed covering for secure hold |

| Vibration Dampener | Absorbs shock to reduce vibrations felt by the user |

| Handle Base | Support structure for grip and stability |

| Control Switch | Enables easy access to tool functions |

Gearbox and Transmission System

The gearbox and transmission mechanism play a crucial role in the functionality of power tools, facilitating the transfer of energy from the motor to the working components. This system is essential for ensuring that the tool operates efficiently, providing the necessary torque and speed for various applications. Understanding its components and their arrangement can significantly enhance the performance and longevity of the equipment.

Within this assembly, several key elements contribute to the overall effectiveness:

| Component | Function |

|---|---|

| Gear Set | Transforms the speed and torque generated by the motor to meet operational requirements. |

| Clutch Mechanism | Controls the engagement and disengagement of power, protecting the motor from overload. |

| Transmission Housing | Encloses and supports the gears and related components, ensuring proper alignment and protection. |

| Bearings | Facilitate smooth rotation and reduce friction between moving parts. |

Maintaining these components is vital for optimal operation. Regular inspections and timely replacements can prevent premature wear and enhance the overall durability of the tool.

Maintaining and Replacing Dewalt DCH273 Parts

Proper upkeep and timely replacement of components are essential for optimal performance and longevity of power tools. Understanding the importance of routine maintenance can greatly enhance the efficiency of your equipment.

Regular inspection is crucial. Here are key practices to follow:

- Check for any signs of wear or damage.

- Ensure all connections are secure and free of debris.

- Clean the tool regularly to prevent dust accumulation.

When it comes to replacement, follow these steps:

- Identify the component that needs to be changed.

- Refer to the user manual for specific instructions on removal.

- Install the new component carefully, ensuring a proper fit.

- Test the tool to confirm functionality after replacement.

By adhering to these guidelines, you can maintain your tool’s performance and extend its lifespan effectively.