In the realm of woodworking, precision and efficiency are paramount. A clear understanding of the intricate arrangements within these mechanical wonders is essential for both maintenance and optimal performance. By exploring the internal configurations, users can enhance their familiarity with functionality and troubleshooting.

When engaging with such tools, one must grasp the significance of each individual element and how they contribute to the overall operation. Recognizing how various sections interconnect enables a deeper appreciation of the machinery’s design and purpose. This insight not only aids in repairs but also elevates the user’s skill set.

Furthermore, diving into the specific components involved allows enthusiasts to tailor their usage, ensuring that each project is executed with the utmost care. Whether you’re a novice or an experienced craftsman, knowledge of these layouts can ultimately lead to improved results and longevity of your equipment.

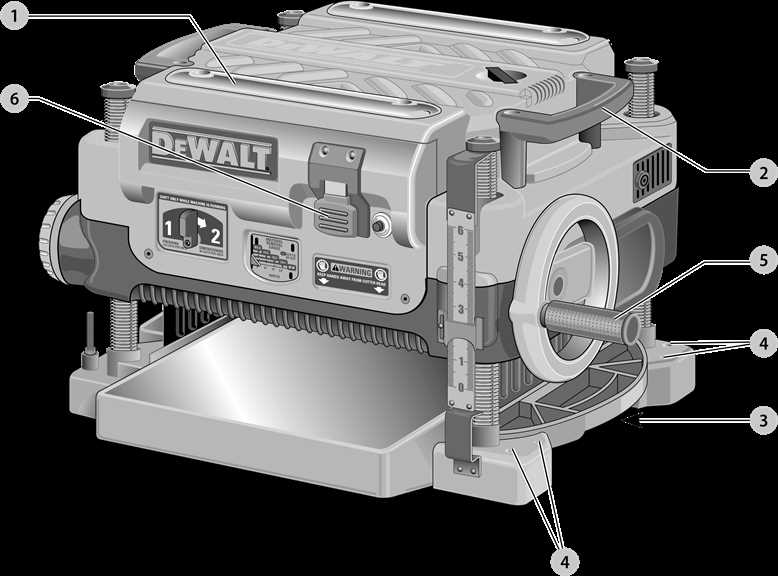

Understanding the DW735 Parts Diagram

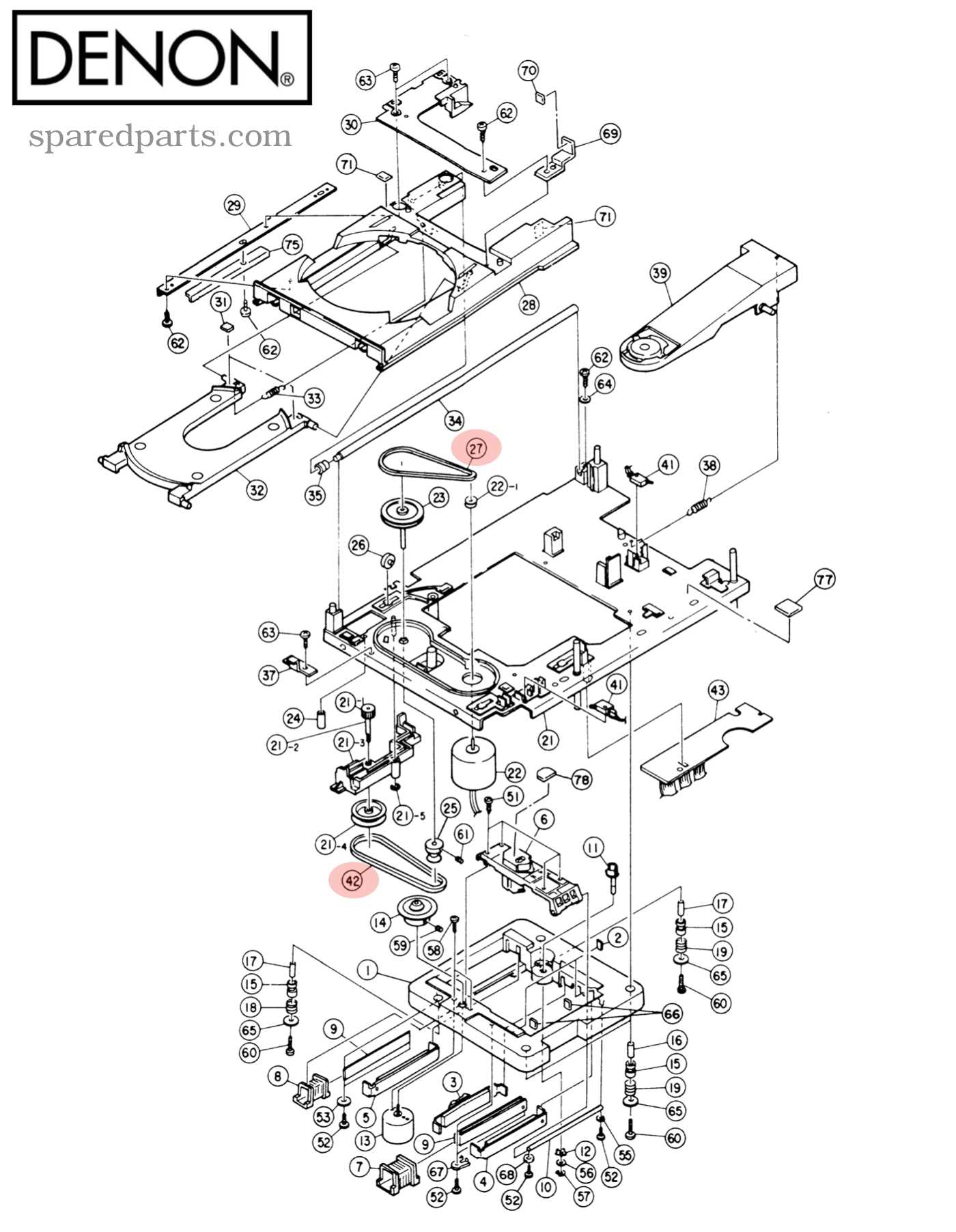

Comprehending the intricate layout of a tool’s components is essential for effective maintenance and repair. A well-structured visual representation allows users to identify individual elements and their functions, facilitating smoother troubleshooting and restoration processes. This understanding enhances the overall experience, ensuring longevity and optimal performance of the equipment.

Key Components Overview

Familiarity with the main elements is crucial. Each part plays a vital role in the machinery’s operation, contributing to its efficiency and reliability. Recognizing these features can prevent unnecessary errors during repairs.

| Component | Description |

|---|---|

| Motor | Powers the entire unit, driving the cutting mechanism. |

| Cutter Head | Houses the blades and is responsible for the actual cutting action. |

| Table | Supports the material being worked on and ensures stability. |

| Feed Rollers | Helps in advancing the material smoothly through the cutting area. |

Maintenance Tips

Regular inspection of these key components is vital to prevent wear and tear. Keeping the motor clean, checking blade sharpness, and ensuring the table is level can significantly improve performance. Understanding how these parts interact is essential for successful upkeep.

Overview of Advanced Features in DW735 Model

In this section, we explore the innovative characteristics of the DW735 model, highlighting its advanced functionalities and unique design elements. This planer exemplifies cutting-edge engineering with its array of integrated features, tailored to meet the demands of precision woodworking.

| Enhanced Cutting Capacity | The DW735 boasts expanded cutting capacity, allowing for more substantial material throughput compared to traditional models. |

| Three-Knife Cutterhead | Equipped with a sophisticated three-knife cutterhead mechanism, this model ensures smoother finishes and reduced noise levels during operation. |

| Automatic Depth Adjustment | Featuring an automatic depth adjustment mechanism, the DW735 simplifies setup and enhances accuracy, optimizing workflow efficiency. |

| Material Removal Gauge | A built-in material removal gauge provides precise measurement control, enabling users to achieve consistent results with each pass. |

| Integrated Fan-Assisted Chip Ejection | The inclusion of a fan-assisted chip ejection system ensures a cleaner workspace and minimizes downtime due to clogging, enhancing user productivity. |

These features collectively distinguish the DW735 as a superior choice for professionals and enthusiasts alike, setting new standards in performance and reliability within the woodworking industry.

Importance of Accurate Parts Identification

Proper identification of components is crucial for maintaining the efficiency and longevity of machinery. When each element is correctly recognized, it ensures that maintenance and repairs can be conducted effectively, minimizing downtime and enhancing overall performance.

Precision in identifying each element prevents the use of incorrect replacements, which can lead to further damage and increased costs. Additionally, understanding the specific characteristics of each component allows for better compatibility and functionality within the system.

Moreover, accurate identification aids in streamlining the ordering process. When technicians are able to specify the exact requirements, suppliers can provide the correct items swiftly, reducing delays in operational tasks. This not only improves workflow but also fosters a more efficient service cycle.

In conclusion, ensuring precise recognition of each element is fundamental for effective maintenance strategies. It enhances reliability, reduces operational risks, and ultimately contributes to the successful management of machinery.

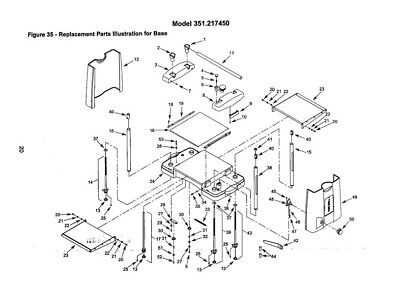

Common Replacement Components for the DW735 Planer

In maintaining your DW735 planer, it’s essential to be prepared with the necessary components that ensure smooth operation and longevity. This section highlights key elements frequently replaced due to wear and tear or as part of routine maintenance.

Cutting Blades

- Blade Set

- Planer Knives

- Rotating Cutters

Feeding Mechanism

- Feed Rollers

- Drive Belt

- Gear Assembly

These components play crucial roles in the planer’s functionality, impacting the precision and efficiency of wood processing tasks. Ensuring their timely replacement maintains optimal performance, reducing downtime and enhancing overall woodworking results.

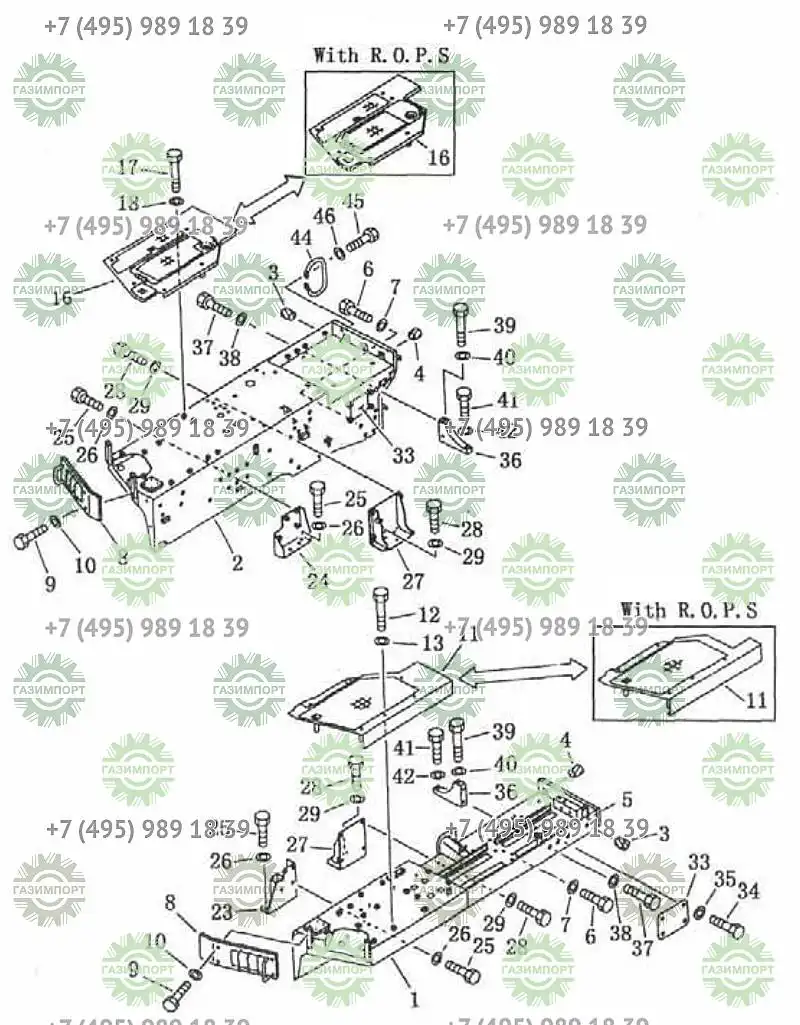

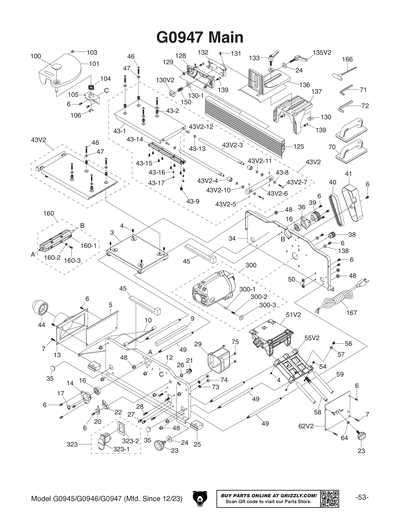

How to Use the Parts Diagram

Understanding the visual representation of components can significantly enhance your ability to perform maintenance and repairs. This guide will help you navigate the illustrations effectively, enabling you to identify and locate essential pieces with ease.

Identifying Components

Start by familiarizing yourself with the various sections of the visual guide. Each area typically represents different parts of the equipment. Pay attention to the labels and numbering systems used, as they will be crucial for your reference.

- Locate the key that explains symbols and terminology.

- Examine the layout to understand the relationship between components.

- Take note of any notes or warnings related to specific parts.

Ordering and Replacing Parts

Once you’ve identified the necessary components, you can proceed to acquire replacements or perform repairs. Following these steps will streamline the process:

- Make a list of the components you need to replace.

- Use the reference numbers to search for the correct items from suppliers.

- Consult the visual guide again during installation to ensure proper placement.

Utilizing this visual reference not only simplifies the process but also ensures that your repairs are done accurately and efficiently.

Tools Required for DW735 Maintenance

Ensuring the smooth operation of your equipment over time requires the right set of instruments. Regular upkeep not only extends the life of the machine but also improves its performance. Understanding which tools are essential for maintenance can make a significant difference in the overall process.

Wrenches are crucial for adjusting bolts and screws, ensuring that every component is securely fastened. Keeping them tight helps prevent mechanical issues that may arise from loose connections.

An air compressor or a simple air blower can be very useful for clearing dust and debris from hard-to-reach areas. Clean components function more efficiently and minimize wear over time.

Additionally, having a set of screwdrivers on hand is essential. Whether it’s for tightening or removing screws during routine checks, these are indispensable for regular maintenance tasks.

Lastly, lubricants are necessary to keep moving parts in optimal condition. Applying lubrication reduces friction, ensuring smooth operation and reducing the risk of premature wear.

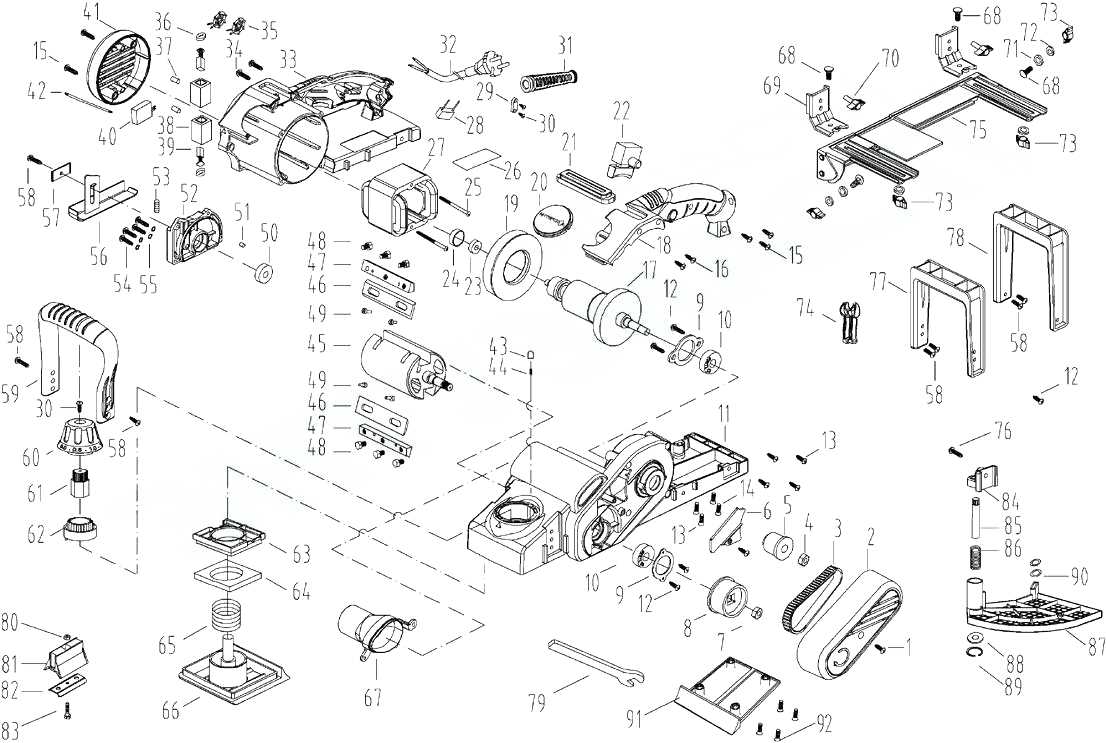

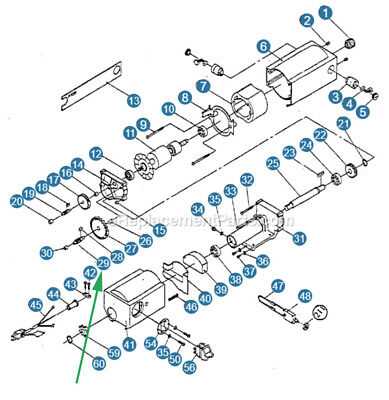

Step-by-Step Guide to Disassembly

When working with complex mechanical tools, proper disassembly is essential for maintenance, repairs, or replacements. This guide outlines the necessary actions to carefully dismantle the device, ensuring no components are damaged and everything is correctly organized for reassembly later.

- Prepare your workspace: Ensure the area is clean, well-lit, and free of clutter. Gather all necessary tools such as screwdrivers and wrenches.

- Disconnect the power: Before starting, ensure the device is completely unplugged or powered down to avoid accidents.

- Remove outer casing: Begin by unscrewing and carefully lifting off the exterior panels to expose the internal mechanisms.

- Label components: As you remove each piece, label it or place it in a marked container for easy identification during reassembly.

- Handle delicate parts: Be gentle with smaller or more fragile elements, avoiding excessive force that could cause damage.

- Keep a record: Take notes or photos of each step to simplify the reassembly process and avoid confusion.

Repairing Common DW735 Issues

When working with mechanical equipment, certain challenges can arise over time, impacting performance. These problems are often related to wear and tear, improper usage, or external factors. Understanding these common issues helps in maintaining optimal efficiency and avoiding more serious breakdowns.

The most frequent issues typically include irregularities in operation, reduced functionality, or unusual noises during use. Addressing these problems usually involves careful inspection and replacement of malfunctioning components, ensuring the machine continues to operate smoothly.

Proper maintenance and timely repairs can significantly extend the lifespan of equipment, preventing the need for costly replacements. Regular checkups and addressing issues early on are key strategies for ensuring reliable performance.

Where to Purchase Replacement Parts

When looking for compatible components for your equipment, it’s important to know where to find reliable sources. A wide range of options exists, from physical stores to online platforms, each offering different advantages depending on your needs.

| Source | Benefits |

|---|---|

| Authorized Dealers | Guarantee of genuine components, often backed by manufacturer warranties. |

| Online Marketplaces | Convenience of home delivery and wide selection, though attention to seller reputation is necessary. |

| Specialty Stores | In-person assistance and immediate availability, with expert advice on hand. |

Comparison with Other Planer Models

When evaluating different woodworking machines, it is essential to consider their performance, design, and features. Understanding how various models differ can help you make an informed decision, ensuring the tool meets your project needs.

Here are some key points of comparison between different planers:

- Cutting capacity: The maximum width and depth of cut vary across models, influencing the type of wood and project sizes they can handle.

- Motor power: Machines offer different horsepower levels, impacting their efficiency and ability to process dense materials.

- Speed options: Some models include adjustable feed rates, providing flexibility for smoother or faster passes depending on the material.

- Build quality: Construction materials and overall durability play a significant role in the longevity and performance of the equipment.

- Additional features: Some devices come with extra functionalities like dust collection systems, noise reduction, and ease of maintenance.

By comparing these characteristics, you can determine which model offers the best combination of performance and features for your woodworking tasks.

Maintenance Tips for Longevity

To ensure the continued efficiency and durability of any mechanical equipment, regular upkeep is essential. Proper care extends the working life of the machinery, allowing it to function smoothly and with minimal issues over time.

By following a few key maintenance practices, you can help avoid unnecessary wear and ensure the longevity of your equipment. Regular checks, cleaning, and timely lubrication are among the most important steps to keep everything in optimal condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Lubrication of moving parts | Every 3 months | Apply suitable grease to reduce friction and prevent wear. |

| Cleaning | Monthly | Remove dust and debris to avoid blockages and overheating. |

| Inspection of key components | Every 6 months | Check for signs of damage or fatigue and replace as necessary. |

| Tightening of fasteners | Quarterly | Ensure screws and bolts are secure to maintain structural integrity. |

Upgrades and Accessories for DW735

Enhancing the functionality and performance of your tool can significantly improve your woodworking experience. Various upgrades and additional components are available to optimize its capabilities, providing greater efficiency and versatility.

Consider the following enhancements to elevate your device:

- Replacement Blades: Investing in high-quality, durable blades can ensure cleaner cuts and extended tool life.

- Dust Collection Systems: Adding a dust extraction accessory can maintain a cleaner workspace, reducing debris and improving visibility.

- Support Tables: Auxiliary tables offer additional support for larger workpieces, enhancing stability and accuracy during operations.

- Speed Control Devices: Adjustable speed options allow for tailored cutting conditions, accommodating different materials and preferences.

Moreover, integrating compatible attachments can transform the original capabilities into a multifunctional tool. Explore options such as:

- Edge guides for precision cutting.

- Feeder systems to maintain consistent feed rates.

- Rail systems to facilitate smoother operations on longer materials.

By considering these upgrades and accessories, users can maximize the potential of their equipment and achieve superior results in their projects.

User Experiences and Recommendations

This section explores the insights and suggestions shared by individuals who have engaged with this specific tool. Their experiences shed light on the practical aspects of usage, addressing common challenges and providing valuable advice for both novice and seasoned users.

Insights from Users

Many users highlight the importance of understanding the machine’s components to maximize efficiency and minimize potential issues. A thorough grasp of the equipment’s inner workings allows for better maintenance and a smoother operational experience. Feedback indicates that those who invest time in familiarizing themselves with the apparatus often encounter fewer difficulties during their projects.

Helpful Suggestions

Several enthusiasts recommend keeping a close eye on wear and tear. Regular inspections can prevent minor problems from escalating into major repairs. Moreover, they emphasize the value of following the manufacturer’s guidelines for maintenance and operation. By adhering to these recommendations, users can enhance the lifespan of the equipment and achieve optimal performance.