Understanding the layout and structure of various mechanical systems can significantly improve maintenance and repairs. Having a clear visual representation of each component and its placement within the system allows for a more efficient troubleshooting process. This section focuses on providing a detailed look at the schematics involved, helping to break down even the most complex machinery into easily understandable parts.

The breakdown of mechanical structures often reveals hidden insights into how the system operates. Identifying key elements and their connections ensures a smoother approach to repair tasks. This guide emphasizes the importance of familiarizing oneself with each section and its role within the entire mechanism.

By following the outlined information, users will gain a deeper understanding of how to maintain their equipment, ensuring longer-lasting functionality and smoother operation. The visual aids provided will assist in this process, making it easier to grasp the relationships between various sections of the machine.

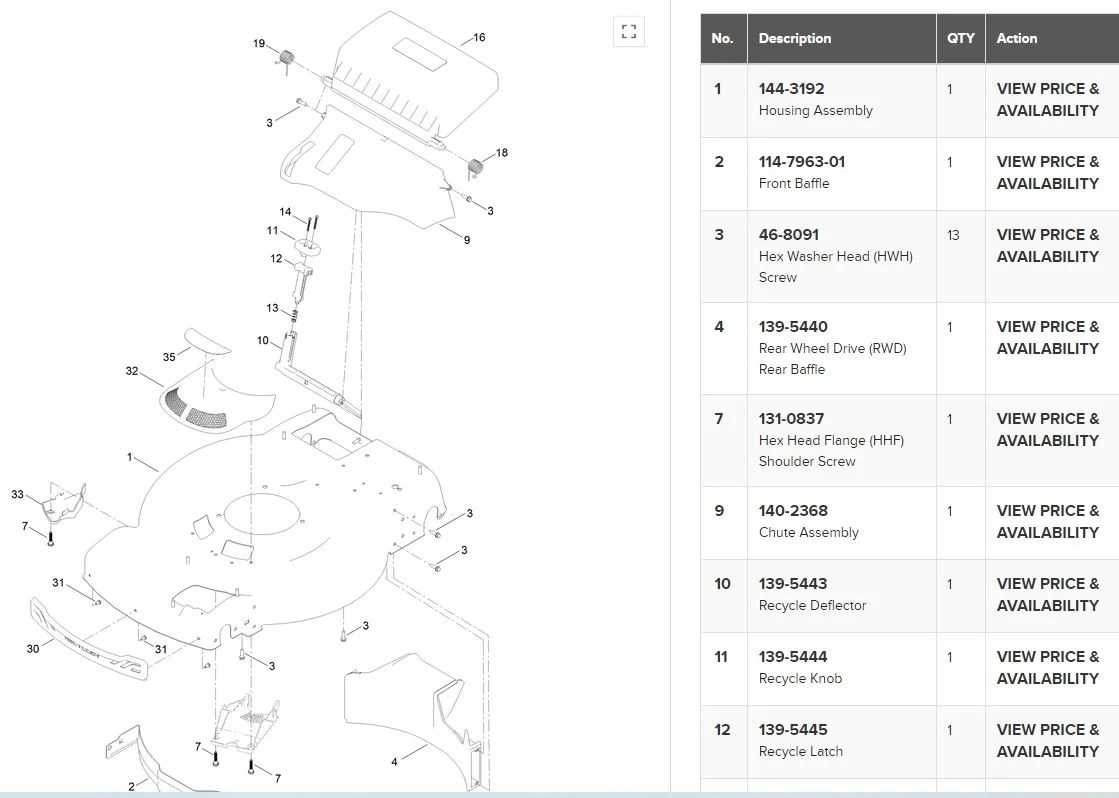

Toro 22 Recycler Parts Overview

The components of this efficient lawn mower are designed to work together seamlessly, ensuring optimal performance and durability. Each element plays a vital role in the machine’s overall operation, contributing to smooth cutting and grass collection.

Cutting Blade Assembly: The sharp and robust blade is engineered to deliver precise cuts, making lawn maintenance easier. It is constructed from durable materials to handle various grass types and withstand wear over time.

Wheel and Drive System: The set of wheels ensures stability and easy maneuverability across different terrains, while the drive mechanism helps in adjusting the speed and improving control during mowing sessions.

Grass Collection Mechanism: This section allows for efficient collection of grass clippings, keeping the lawn clean after each pass. It’s designed to minimize blockages, providing uninterrupted performance.

Maintenance and timely replacement of these elements are essential for extending the mower’s lifespan and ensuring continued efficiency.

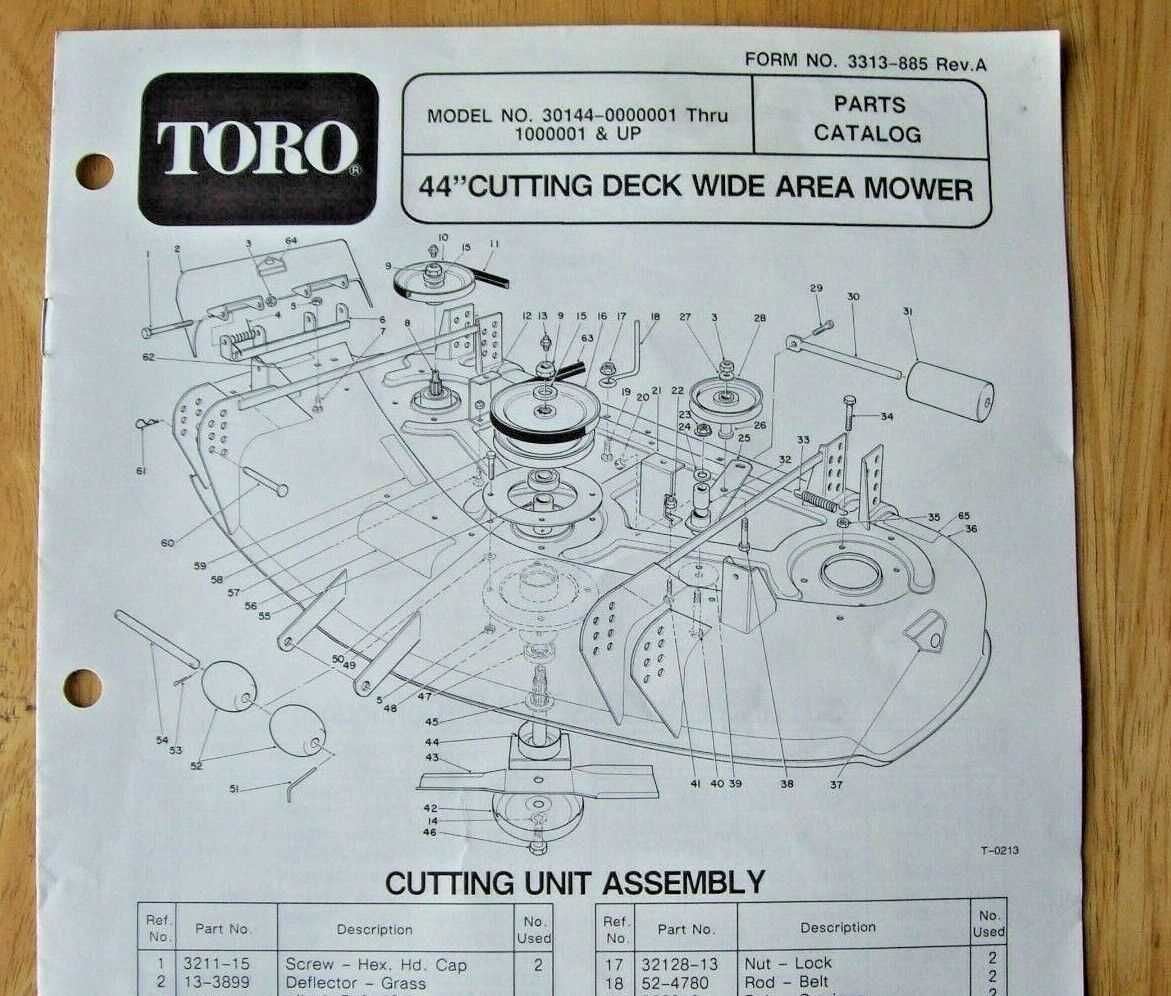

Understanding the Cutting Blade Assembly

The cutting blade assembly is a crucial part of any lawn maintenance tool, ensuring efficient grass cutting and overall machine performance. It consists of several interconnected components that work together to deliver precise and clean cuts. Proper understanding of its structure and function is essential for maintaining optimal cutting performance and ensuring the longevity of your equipment.

Main Components of the Assembly

- Blade: The sharp, rotating element responsible for cutting the grass. It requires regular sharpening and maintenance to stay effective.

- Blade Mounting Hardware: Includes bolts, washers, and nuts that secure the blade to the machine. These should be checked frequently to ensure tightness and safety.

- Blade Adapter: Connects the blade to the drive shaft, ensuring that the blade rotates correctly and efficiently.

Maintenance Tips

- Regularly inspect the blade for signs of wear and tear, such as dullness or damage.

- Sharpen the blade at least once a season to maintain cutting efficiency.

- Ensure all mounting hardware is securely fastened to avoid accidents or improper operation.

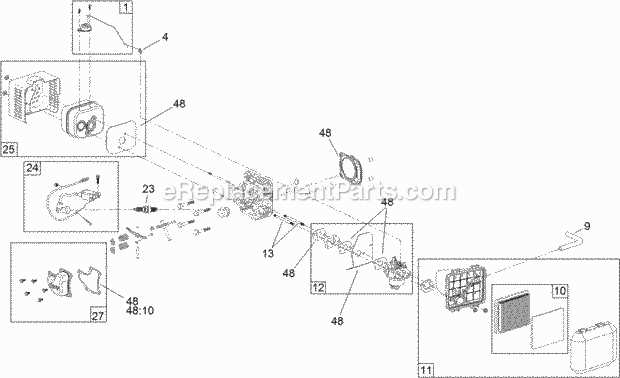

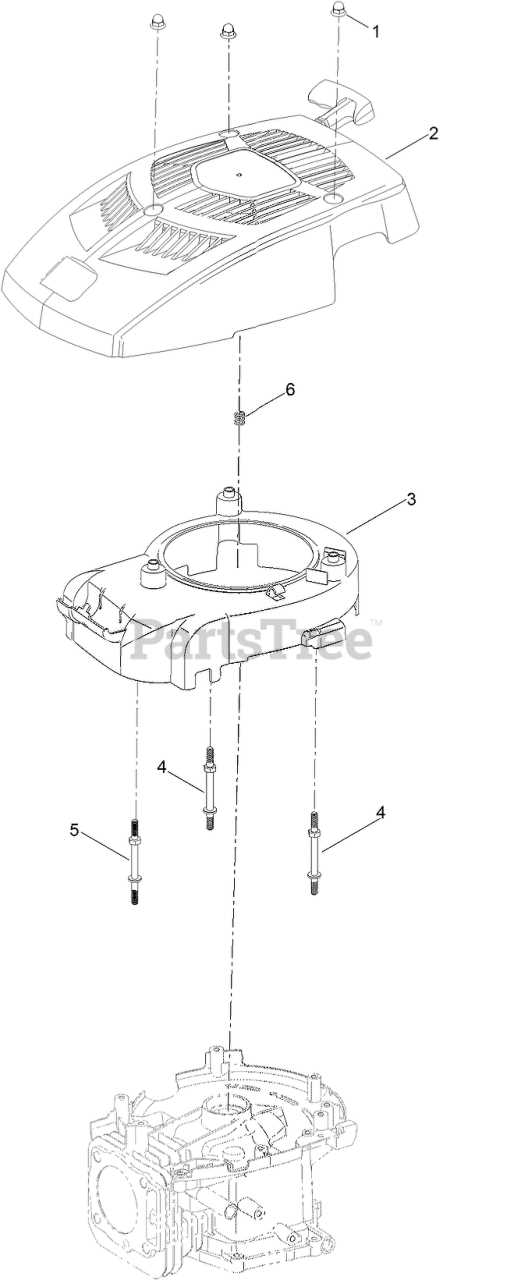

Exploring the Engine Components

The heart of any outdoor machine is its engine, which is composed of several essential elements working together to ensure proper operation. Understanding these components can help users maintain their equipment and identify potential issues early. In this section, we will break down the key parts that drive the machine’s performance, emphasizing the most vital elements of the engine’s structure.

Key Elements of the Engine

At the core of the engine lies the cylinder, responsible for housing the piston, which moves to generate power. Surrounding the cylinder are various other crucial parts, including the crankshaft and connecting rod, both of which contribute to the conversion of energy into motion. The engine’s performance also depends on the quality of the fuel system and the ignition system, ensuring consistent and efficient operation.

Supporting Components

Several supporting elements work to keep the engine running smoothly. The air filter plays an important role in preventing debris from entering the system, while the exhaust system safely directs gases away from the engine. Regular maintenance of these components ensures a longer lifespan and reduces the likelihood of malfunctions during use.

Drive System and Wheel Mechanism

The propulsion and wheel system play a crucial role in ensuring smooth movement and control of the machine. This section will explore the basic components that contribute to efficient handling and movement on various surfaces.

- Drive Belt: The belt transmits power from the engine to the wheels, ensuring the movement of the equipment across different terrains.

- Transmission: Responsible for transferring power to the wheels, the transmission allows for variable speeds and smooth operation.

- Wheels: Designed for optimal traction, the wheels maintain stability and grip on both flat and uneven surfaces, preventing slippage.

- Adjustment Levers: These allow for easy modifications to the wheel height, adapting the machine to different grass heights or ground conditions.

Understanding how these components work together ensures better maintenance and longer lifespan of the equipment. Regular checks and proper adjustments will keep the system running efficiently.

Air Filter and Maintenance Tips

Keeping the air filter clean is essential for optimal engine performance. A well-maintained filter prevents debris from entering the system, ensuring smooth operation and longevity. Regular inspections and timely replacements can enhance the overall efficiency of the machine.

How to Clean the Filter

Before beginning the cleaning process, make sure the engine is turned off and has cooled down. Gently remove the filter, avoiding any damage. For foam filters, use warm soapy water to clean out dirt and grime. Let the filter dry completely before reinstalling. For paper filters, gently tap them to remove debris or replace them if they are too dirty or damaged.

Maintenance Schedule

To ensure the machine runs efficiently, the air filter should be checked after every few uses. Cleaning or replacing the filter regularly, especially in dusty conditions, can prevent major engine issues. Always refer to the user manual for specific guidelines on filter types and maintenance intervals.

Fuel Tank and Fuel Line Guide

Maintaining the fuel system is crucial for ensuring the smooth operation of any outdoor equipment. This section provides a detailed look into how the fuel storage and delivery mechanisms function, offering tips on care and potential troubleshooting steps. A properly maintained fuel system can prevent performance issues and ensure longevity.

| Component | Description | Maintenance Tips |

|---|---|---|

| Fuel Tank | The container responsible for storing gasoline. Typically made of durable materials to prevent corrosion and leaks. | Regularly check for any cracks or signs of wear. Clean the tank periodically to remove sediment buildup. |

| Fuel Line | A flexible tube that transports fuel from the tank to the engine, ensuring steady flow for combustion. | Inspect the fuel line for cracks or clogs. Replace if damaged to avoid fuel leakage. |

| Fuel Cap | Seals the fuel tank and prevents debris from contaminating the fuel. It also maintains proper pressure inside the tank. | Ensure the cap is tightly closed after refueling. Replace if the seal is worn out. |

Handle and Control Levers Breakdown

This section provides a comprehensive overview of the various components associated with the handles and control mechanisms. Understanding these elements is crucial for proper operation and maintenance of the equipment. Each part plays a vital role in ensuring smooth functionality and user experience.

The following table outlines the key components, their descriptions, and potential replacement options:

| Component | Description | Replacement Option |

|---|---|---|

| Control Handle | Primary lever used to adjust speed and direction. | Compatible lever assembly available at authorized retailers. |

| Throttle Lever | Adjusts engine power output during operation. | Universal throttle control can be fitted. |

| Choke Control | Regulates air intake for starting and operation. | Standard choke lever compatible with most models. |

| Brake Lever | Stops the operation when engaged for safety. | Replacement brake levers can be sourced from various suppliers. |

Mulching Plug and Bagging System

The mulching mechanism and collection system are essential components for efficient lawn maintenance. These features enhance the performance of mowers by providing options for grass clippings management, ensuring a tidy and healthy lawn. Understanding how these systems work can improve both the functionality and versatility of your equipment.

Mulching Mechanism

The mulching mechanism finely chops grass clippings and redistributes them back onto the lawn. This process has several benefits:

- Promotes nutrient recycling by returning organic matter to the soil.

- Reduces the need for additional fertilizers.

- Minimizes waste and lowers disposal costs.

When utilizing the mulching feature, it’s crucial to maintain the blades regularly to ensure optimal cutting performance.

Collection System

The collection system is designed to gather grass clippings efficiently during mowing. Key aspects include:

- Easy attachment and detachment for convenience.

- Robust design for effective collection even in challenging conditions.

- Various bagging options to suit different lawn sizes and types.

Proper usage of the collection system helps keep lawns clean and reduces the risk of thatch buildup.

Deck and Housing Structure Analysis

The examination of the surface and enclosure framework is crucial for understanding the overall functionality and performance of the device. This segment focuses on the various components that contribute to the structural integrity and efficiency of the equipment.

Key elements to consider in the analysis include:

- Material Composition: The choice of materials affects durability and weight.

- Design Features: Specific shapes and contours can influence airflow and grass discharge.

- Mounting Points: Locations where components are attached can affect stability and vibration levels.

- Maintenance Access: The ease with which one can access internal parts for cleaning or repair is essential for longevity.

Each of these factors plays a significant role in ensuring that the equipment operates at its best, providing an efficient and reliable user experience.

Transmission and Drive Belt Components

This section explores the critical elements involved in the transmission system and the drive belt mechanisms essential for optimal performance of lawn care equipment. Understanding these components helps in maintaining efficiency and ensuring smooth operation.

- Drive Belt: A vital component that transfers power from the engine to the cutting blade, enabling effective grass cutting.

- Transmission Assembly: Houses gears and linkages that facilitate the conversion of engine power into motion, allowing for speed adjustments and smooth transitions.

- Idler Pulley: Plays a key role in tensioning the drive belt, ensuring it operates at the correct tension to prevent slippage.

- Gearbox: Encloses the gearing system that controls the speed and torque delivered to the drive mechanism.

- Clutch Mechanism: Engages and disengages the drive system, allowing operators to control when power is transmitted to the blades.

Regular inspection and maintenance of these components are crucial for extending the lifespan of lawn equipment and enhancing its performance.

Starter System and Ignition Parts

The starter mechanism and ignition components play a crucial role in the effective functioning of outdoor power equipment. These elements are essential for initiating the engine’s operation and ensuring smooth performance throughout its use.

Key Components

At the heart of the starting system are the electric starter and the associated ignition assembly. The electric starter is responsible for engaging the engine, while the ignition assembly generates the spark necessary for combustion. A well-functioning starter system ensures reliable starts and optimal performance during operation.

Common Issues and Solutions

Frequent problems with the starting mechanism can stem from worn-out components or electrical failures. Symptoms such as a sluggish crank or failure to start may indicate the need for maintenance. Regular inspection of the ignition system and replacement of faulty elements, such as the spark plug or ignition coil, can enhance reliability and performance.

Cleaning and Replacing the Spark Plug

Maintaining the functionality of your machine’s ignition system is essential for ensuring smooth and efficient operation. Regular care and replacement of the ignition component will prevent starting issues and maintain engine performance. It’s a simple process that doesn’t require specialized tools, but it plays a significant role in the longevity of the equipment.

To begin, locate the component near the engine and disconnect the cable attached to it. Carefully remove the plug using a wrench, being cautious not to damage surrounding parts. Inspect the plug for signs of wear or dirt buildup. If it’s dirty, clean it with a wire brush or replace it if it’s excessively worn or damaged. Once cleaned or replaced, reinstall it by hand and secure it with the wrench, then reconnect the cable. This process will ensure your engine continues to run efficiently.