For anyone dealing with complex outdoor machinery, understanding how various components work together is essential. This knowledge can greatly enhance maintenance efforts, ensuring everything runs smoothly and efficiently. Proper insight into these mechanical systems allows for timely repairs and upgrades, extending the lifespan of the equipment.

When dealing with such equipment, it’s crucial to focus on the structure and connections between key elements. Knowing the arrangement of these elements makes it easier to troubleshoot issues and perform adjustments. A well-organized visualization can assist in identifying potential weak points, ensuring that repairs are both effective and safe.

Mechanical alignment and proper configuration of elements play a significant role in overall performance. By understanding the layout, users can enhance operational efficiency, reduce downtime, and avoid costly mistakes. This section aims to provide clarity on the connections between core components, helping users navigate through their technical needs.

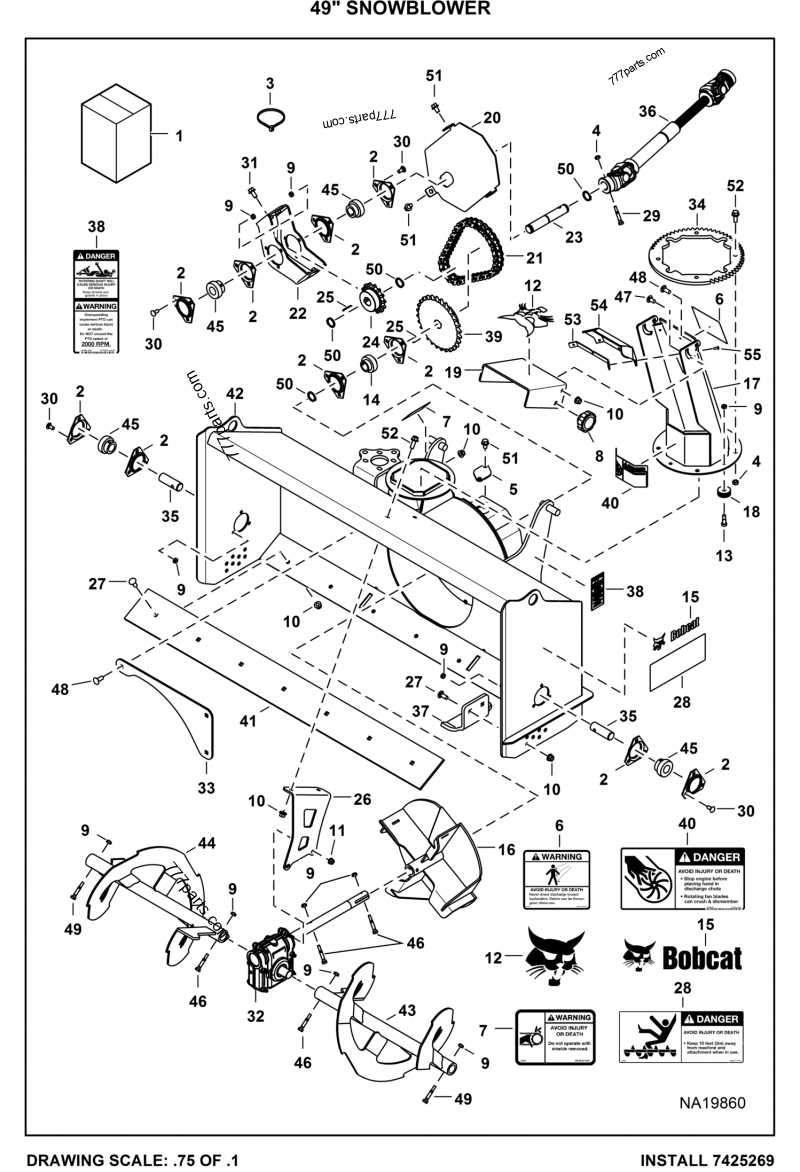

Understanding the Structure of Bobcat Attachments

The framework of machine accessories designed for moving heavy materials is built on a combination of robust components and specialized features. These tools are specifically designed to enhance the overall functionality of equipment, offering greater versatility in handling various tasks. The construction of these attachments focuses on ensuring durability and efficient operation under different conditions.

Key Components of the Framework

Each attachment consists of essential elements that contribute to its effectiveness. The base structure provides support and stability, while the mechanical parts enable the attachment to perform specific tasks. Additionally, various connecting points allow for seamless integration with machinery, ensuring a secure fit and optimal performance.

Materials and Durability

The materials used in the construction are chosen to withstand intense use. Reinforced metals and specialized alloys provide resistance to wear and tear, ensuring long-term reliability. Understanding the selection of materials and their application is crucial in assessing the longevity of these attachments in different working environments.

Essential Components for Snow Removal

Effective snow clearing requires the right set of mechanical elements, designed to handle heavy workloads and tough weather conditions. These key components work together to ensure smooth and efficient operation during winter months. By understanding how each element contributes to the overall process, you can better maintain your equipment and achieve optimal performance in challenging environments.

Power Transmission

A reliable power system is critical for converting energy into movement, driving the machinery forward while tackling compacted snow and ice. This process relies on durable belts, gears, and chains that can withstand intense use over time. Proper alignment and regular maintenance are crucial for avoiding wear and ensuring smooth operation.

Auger and Impeller

The auger and impeller play an essential role in gathering and expelling snow from the clearing path. The auger cuts through icy layers, while the impeller moves it rapidly away from the surface. For these components to function effectively, their blades must be kept sharp and free of obstructions. Regular inspection ensures maximum efficiency in snow management.

Key Features of Bobcat Snowblower Systems

Innovative mechanical systems designed for handling winter conditions are known for their reliability and efficiency. These systems integrate advanced engineering solutions that allow for effective snow clearing, even in the toughest environments. Below are some of the standout functionalities that make these machines highly sought after in cold-weather applications.

- Durable construction materials designed to withstand extreme cold and heavy-duty use.

- Efficient power transfer mechanisms that optimize performance in various snow and ice conditions.

- Precision control features that provide operators with the ability to navigate and clear paths with ease.

- Advanced safety systems to ensure smooth operation even in difficult or unpredictable terrain.

- Quick attachment capabilities that make it easy to integrate with a variety of other equipment for enhanced versatility.

These features collectively contribute to a machine’s superior performance in maintaining operational efficiency during winter months, reducing downtime, and ensuring a safe and effective work environment.

Maintenance Tips for Efficient Operation

Regular upkeep is crucial to ensure the long-term efficiency and smooth functionality of any mechanical system. Following a few essential practices can help prevent unexpected issues and extend the life of your equipment. By dedicating time to routine checks, you can maintain consistent performance and avoid the need for costly repairs.

Lubrication and Cleaning

Keeping moving components properly lubricated is one of the most effective ways to reduce friction and wear. Make sure to apply suitable oils or greases as recommended in the manual. Additionally, ensure that all areas prone to dirt buildup are cleaned regularly to prevent any obstructions or damage over time.

Regular Inspection and Tightening

Over time, nuts, bolts, and fasteners may loosen due to vibrations and continuous use. It’s important to periodically inspect the assembly and tighten any loose components. This will help maintain stability and prevent any operational inefficiencies that could arise from loose connections.

Exploring the Mechanism of Snowblower Augers

The auger system plays a pivotal role in the operation of snow clearing equipment, ensuring effective removal of accumulated material. This component is designed to break down and move large amounts of debris, pushing it towards the discharge area. Understanding the mechanism of augers can offer insight into how they function efficiently in various weather conditions.

- Rotation: The augers are built with a rotating motion that helps scoop and lift heavy materials.

- Blade Design: Curved or straight blades are commonly used to optimize movement and avoid clogging.

- Speed Variations: Adjustments to the rotation speed can be made depending on the density and volume of the material being cleared.

The interaction between these components determines how efficiently the equipment performs. By examining each feature, users can gain a better understanding of the overall efficiency of the auger system.

How to Identify Auger Issues

Recognizing problems with the cutting mechanism is crucial for maintaining optimal performance. Several indicators can help you determine if the auger is functioning correctly or if it requires attention. By being aware of these signs, you can prevent potential complications and ensure efficient operation during use.

Common Signs of Auger Malfunctions

- Insufficient Material Movement: If the device struggles to process snow or debris effectively, it may indicate a blockage or a malfunctioning auger.

- Unusual Noises: Grinding, clanking, or rattling sounds can signify worn-out components or misalignment within the cutting mechanism.

- Inconsistent Output: If the material is not being discharged uniformly, this could point to a problem with the auger blades or their rotation.

Steps to Diagnose Auger Problems

- Inspect the cutting mechanism visually for any visible damage or obstructions.

- Check the connections and ensure all fasteners are tight and secure.

- Listen for abnormal sounds during operation, noting when they occur for further troubleshooting.

- Test the performance by clearing a small area to observe any issues with material handling.

- If problems persist, consult the maintenance manual for detailed troubleshooting guidance.

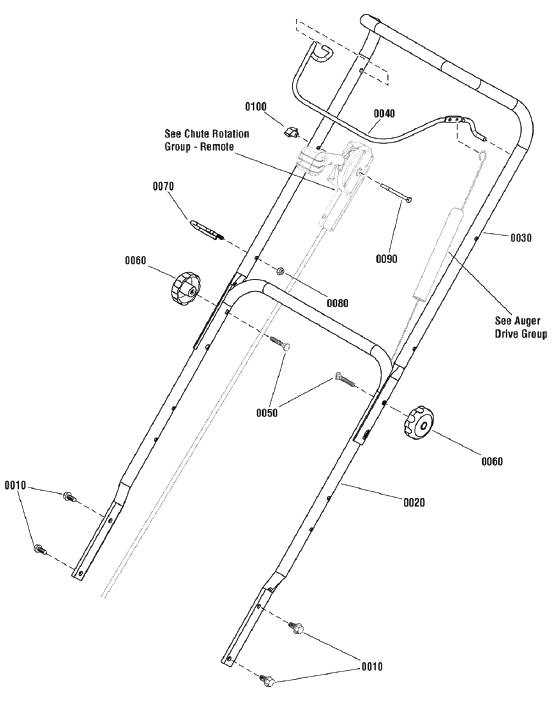

Snowblower Drive System Overview

The drive mechanism of a winter clearing machine is crucial for its effective operation, facilitating movement across various terrains and ensuring optimal performance. This system integrates several components that work in harmony to deliver power from the engine to the wheels and auger, allowing for efficient clearing of snow and ice.

Typically, the drive assembly comprises a transmission, a series of belts, and gears, all designed to convert engine power into usable motion. The transmission serves as the central unit, adjusting the torque and speed as needed. Gears play a vital role in this process by altering the mechanical advantage, enabling the machine to handle various snow conditions.

Furthermore, the system often includes clutches that allow operators to control engagement and disengagement of the drive, providing flexibility and ease of use. Understanding these elements is essential for maintaining optimal functionality and addressing any potential issues that may arise during operation.

Common Problems in Drive Systems

Drive systems are essential for the efficient functioning of machinery, enabling movement and operation. However, like any mechanical system, they can encounter issues that affect performance and reliability. Understanding these common problems can help in timely diagnosis and repair, ensuring optimal operation.

| Problem | Description | Possible Causes | Solutions |

|---|---|---|---|

| Slipping Drive | Inconsistent power transfer, resulting in loss of traction. | Worn belts, incorrect tension, or damaged components. | Inspect and replace worn parts; adjust tension settings. |

| Unresponsive Control | Inability to engage or disengage the drive mechanism. | Faulty switches or linkage issues. | Test electrical components; repair or replace as necessary. |

| Noisy Operation | Unusual sounds during operation indicating potential problems. | Lack of lubrication, misalignment, or worn bearings. | Lubricate moving parts; realign components or replace bearings. |

| Overheating | Excessive heat generation, potentially leading to component failure. | Inadequate cooling, excessive load, or friction. | Check for obstructions in cooling areas; reduce load or service parts. |

Blade Adjustment for Optimal Performance

Proper alignment of cutting elements is crucial for achieving peak efficiency during operation. When the height and angle of the blades are correctly set, it enhances the overall effectiveness, allowing for smoother handling and improved results. Regular assessment and modification of these components can significantly influence the effectiveness of the machinery.

Understanding Blade Positioning

Ensuring the correct positioning of the cutting elements helps prevent unnecessary wear and tear on the equipment. Optimal alignment not only enhances cutting efficiency but also minimizes the energy consumed during operation. Regular checks should be performed to maintain the ideal configuration, which can also prolong the lifespan of the components.

Adjusting for Different Conditions

Different environments may require adjustments to the cutting elements. Seasonal variations or varying surface types can necessitate changes in blade height and angle. For example, when working on softer terrain, a lower blade setting may be beneficial, while firmer surfaces might require a higher position. Regularly evaluating these conditions ensures the machine operates at its best, regardless of external factors.

Techniques for Effective Blade Maintenance

Maintaining the cutting edges of your equipment is crucial for ensuring optimal performance and longevity. Proper upkeep techniques not only enhance functionality but also improve safety during operation. Understanding the right practices can make a significant difference in the efficiency of your machinery.

One of the key aspects of blade care is regular inspection. This involves checking for any signs of wear or damage that may hinder performance. Keeping blades sharp is another critical technique, as dull edges can lead to inefficient cutting and increased fuel consumption. Additionally, cleaning the blades after use helps prevent the buildup of debris, which can affect performance.

| Maintenance Technique | Description |

|---|---|

| Inspection | Regularly check for wear, cracks, or chips that may compromise blade effectiveness. |

| Sharpening | Keep the edges finely honed to ensure smooth cutting and reduce strain on the engine. |

| Cleaning | Remove dirt, ice, and other debris after each use to maintain optimal performance. |

| Lubrication | Apply suitable lubricants to pivot points to minimize friction and wear. |

Incorporating these techniques into your maintenance routine will lead to better performance and a longer lifespan for your equipment. A proactive approach not only saves time and money but also ensures that your machine operates at its best when you need it most.

Hydraulic System and Power Flow in Snowblowers

The hydraulic system plays a crucial role in the operation of various outdoor equipment, enabling effective manipulation and movement of components. Understanding how power is transferred within these machines enhances the efficiency and performance of their tasks. This section explores the dynamics of hydraulic mechanisms and their contributions to functionality in snow clearing devices.

Functionality of the Hydraulic System

At the heart of hydraulic systems lies the principle of fluid mechanics, where pressurized fluid is utilized to perform work. By directing fluid to various actuators and valves, operators can control movements with precision. This system not only allows for the lifting and lowering of components but also facilitates the rotation and adjustment of angles for optimal clearing performance.

Power Flow Mechanism

The flow of power within hydraulic systems is critical for seamless operation. It involves several interconnected components that work in harmony. Below is a table illustrating the key elements and their functions:

| Component | Function |

|---|---|

| Hydraulic Pump | Generates pressurized fluid to initiate movement. |

| Hydraulic Cylinder | Converts fluid pressure into linear motion for lifting or lowering. |

| Control Valves | Regulate the flow of fluid to different parts of the system. |

| Hydraulic Reservoir | Stores hydraulic fluid and maintains system pressure. |

| Hoses and Fittings | Facilitate the movement of fluid between components. |

Ensuring Proper Fluid Pressure

Maintaining the appropriate pressure within hydraulic systems is crucial for optimal performance and longevity. This involves regular checks and adjustments to prevent issues that could lead to inefficiencies or damage. Proper fluid pressure not only enhances the overall functionality but also safeguards the integrity of various components.

Importance of Regular Monitoring

Frequent inspection of fluid pressure helps identify potential problems before they escalate. Abnormal pressure levels can indicate underlying issues, such as leaks or blockages, which may compromise operational efficiency. By ensuring that the fluid maintains the correct pressure, users can avoid costly repairs and downtime.

Adjustment Techniques

To achieve and sustain the desired pressure, several adjustment techniques can be employed. Utilizing pressure gauges allows for precise monitoring and timely interventions. Additionally, regular maintenance of seals and filters contributes to stable pressure levels. Implementing these practices ensures that the hydraulic system operates smoothly, enhancing overall performance and reliability.