Exploring the intricacies of air pressure machinery reveals a world where efficiency meets innovation. Knowing how these devices function and the roles of their various elements can significantly enhance maintenance and troubleshooting efforts. This knowledge not only empowers users but also extends the lifespan of the equipment, ensuring optimal performance over time.

In this section, we delve into the essential constituents of air compression systems. Each component plays a vital role in the overall functionality, and understanding their interconnections can illuminate the complexities of the machinery. By familiarizing oneself with these key elements, one can better appreciate the engineering behind reliable air delivery systems.

Furthermore, comprehending the layout and relationships among the different segments enables users to identify potential issues and execute repairs with confidence. Whether for personal use or professional applications, a clear grasp of the underlying structure can lead to more informed decisions and enhanced operational efficiency.

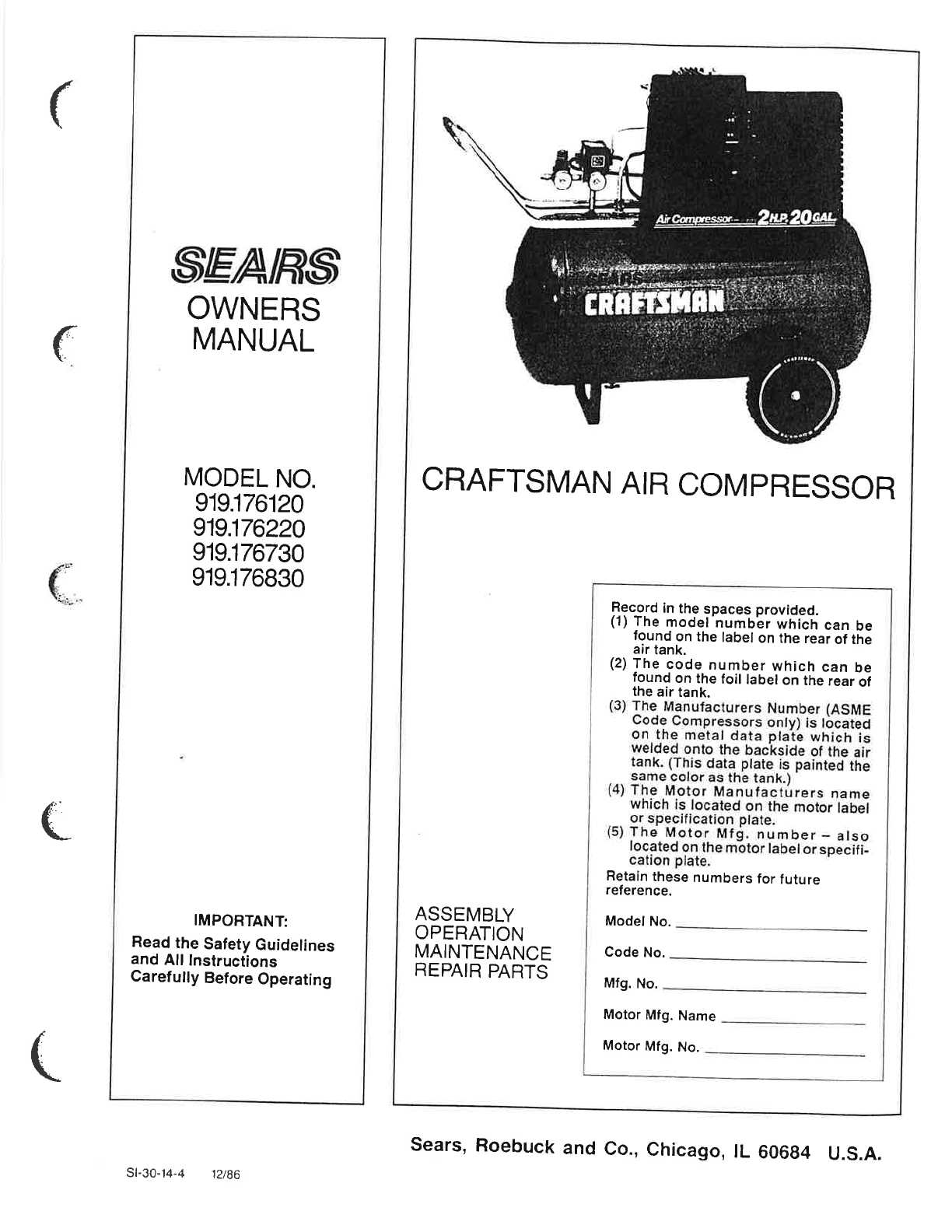

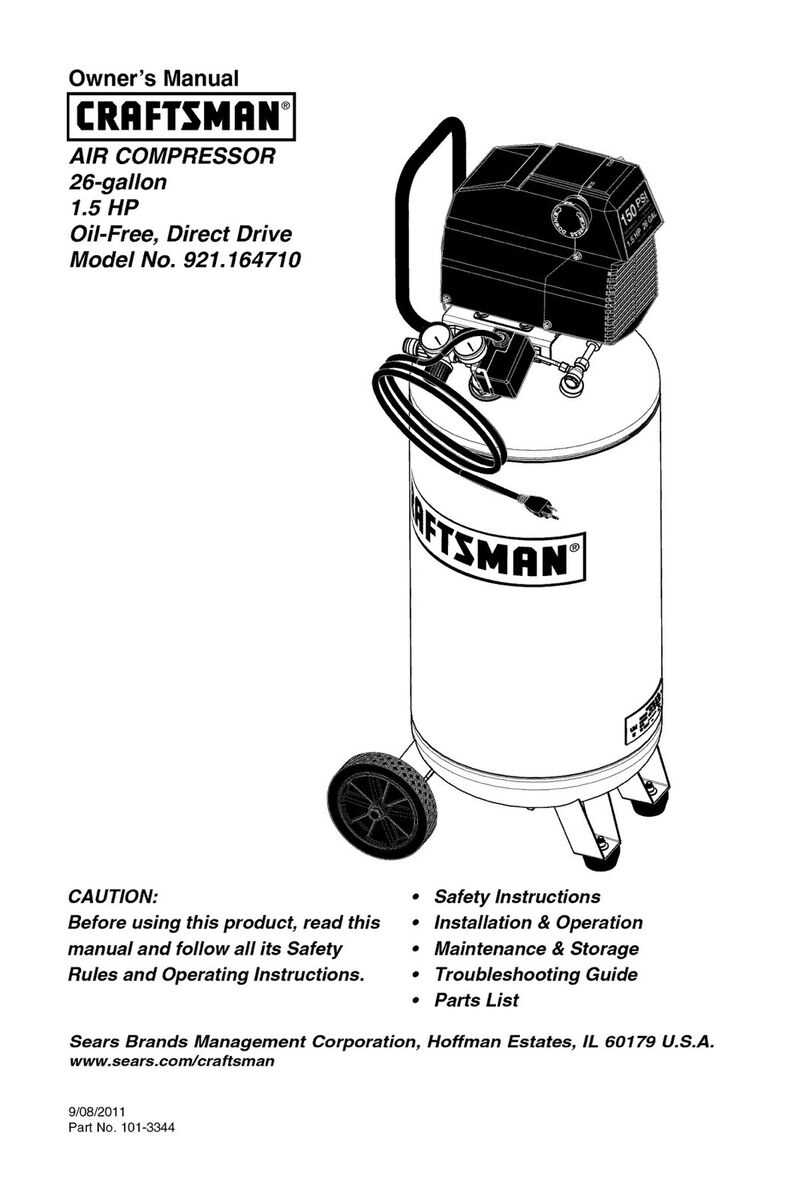

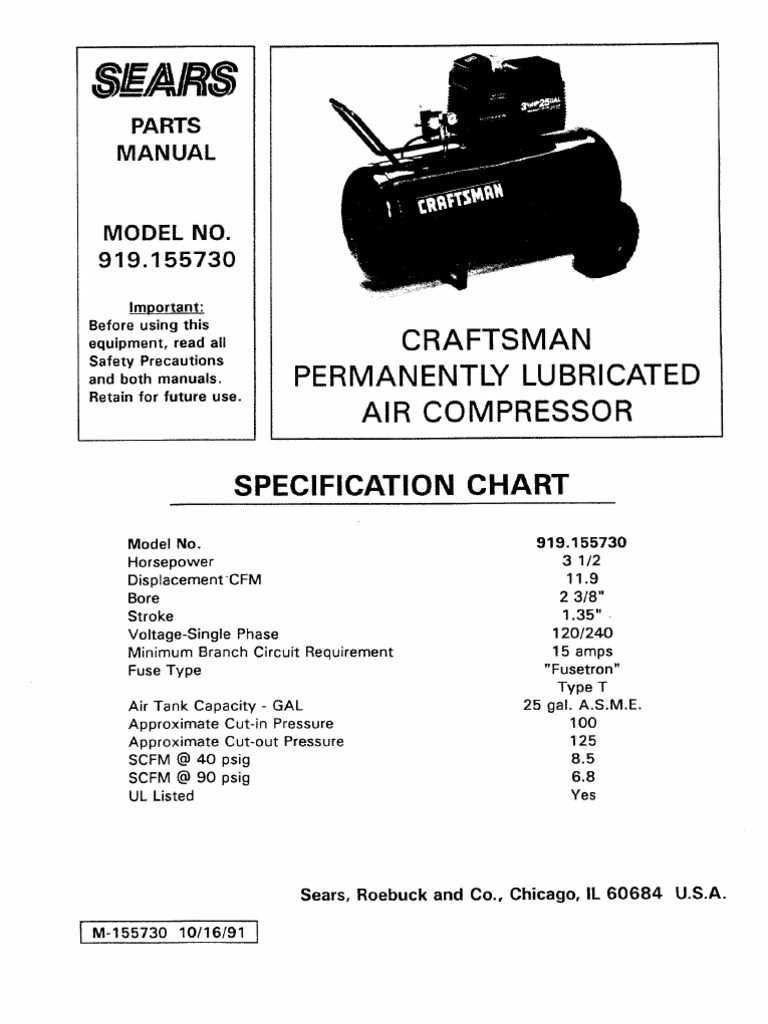

Understanding Craftsman Compressors

Air-driven tools are essential in various industries, providing power and efficiency for numerous applications. Knowing how these devices operate and their components can enhance performance and longevity. A solid grasp of their functioning mechanisms allows users to maximize productivity while minimizing potential issues.

Key Components

- Motor: Powers the unit and drives the air intake.

- Tank: Stores compressed air for immediate use.

- Regulator: Controls the pressure output for safe operation.

- Valves: Manage airflow and prevent backflow.

- Filters: Remove impurities from the air to ensure clean delivery.

Maintenance Tips

- Regularly check and replace filters to maintain air quality.

- Inspect hoses and connections for leaks and wear.

- Drain the tank frequently to prevent moisture buildup.

- Lubricate moving parts as recommended by the manufacturer.

Understanding the essential elements and maintenance requirements is crucial for anyone utilizing these powerful tools. Proper care not only enhances functionality but also extends the lifespan of the equipment.

Key Components of Craftsman Compressors

This section explores the essential elements that make up a reliable air machine, focusing on their roles and interconnections. Understanding these components is crucial for effective operation and maintenance.

- Motor: Powers the unit, converting electrical energy into mechanical energy.

- Pump: Compresses air, crucial for generating pressure.

- Tank: Stores compressed air, allowing for consistent pressure delivery.

- Pressure Switch: Regulates the air pressure within the system.

- Regulator: Controls the output pressure for various applications.

Each element plays a vital role in ensuring efficiency and performance, making knowledge of them indispensable for users.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of any machinery. By committing to a consistent maintenance schedule, users can avoid unexpected failures and enhance the overall efficiency of their equipment.

Here are key reasons why maintenance is crucial:

- Prevention of Wear: Regular checks help identify and address wear and tear before they become major issues.

- Efficiency: Well-maintained machinery operates more efficiently, saving time and resources.

- Safety: Routine maintenance ensures that all safety features are functioning properly, reducing the risk of accidents.

- Cost Savings: Investing in maintenance can prevent costly repairs and replacements in the future.

Ultimately, dedicating time and effort to maintenance not only enhances performance but also preserves the investment made in equipment.

Common Issues with Compressor Parts

In any machinery that relies on pressurized air, certain challenges frequently arise, affecting performance and efficiency. Understanding these common problems can help in troubleshooting and maintenance.

- Leaks: Air escaping from connections can lead to significant drops in efficiency.

- Wear and Tear: Over time, components may degrade, causing reduced functionality.

- Blockages: Dirt and debris can obstruct airflow, resulting in poor operation.

- Noise: Unusual sounds often indicate underlying issues, such as loose fittings.

- Pressure Drops: Inconsistent pressure can stem from various mechanical faults.

Regular inspections and proactive measures can mitigate these issues, ensuring reliable performance and longevity.

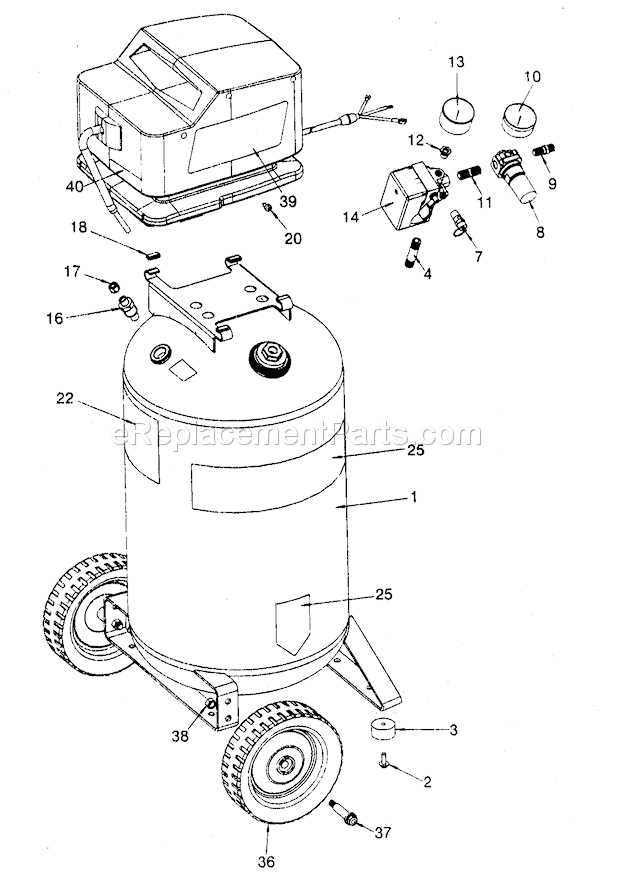

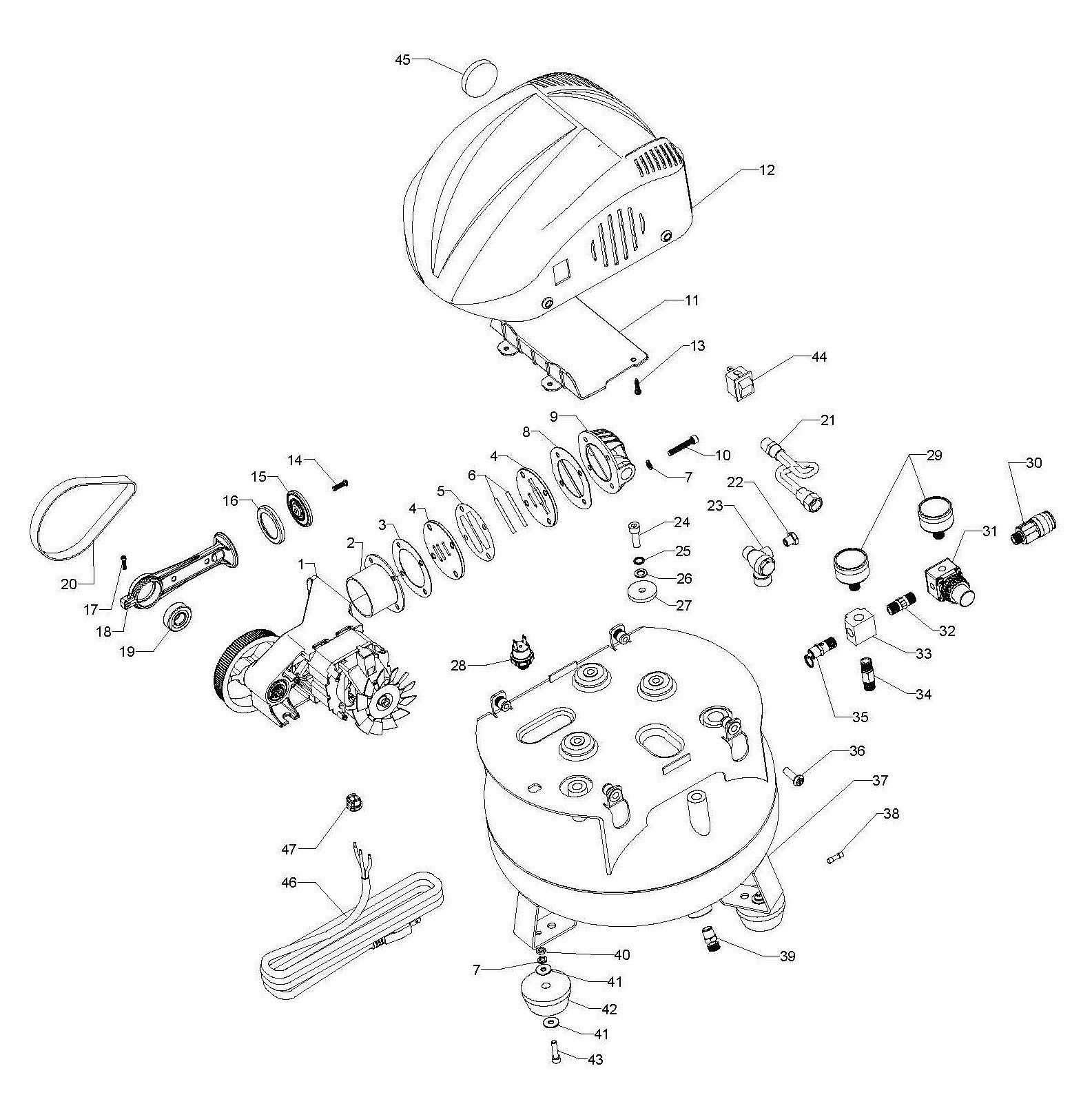

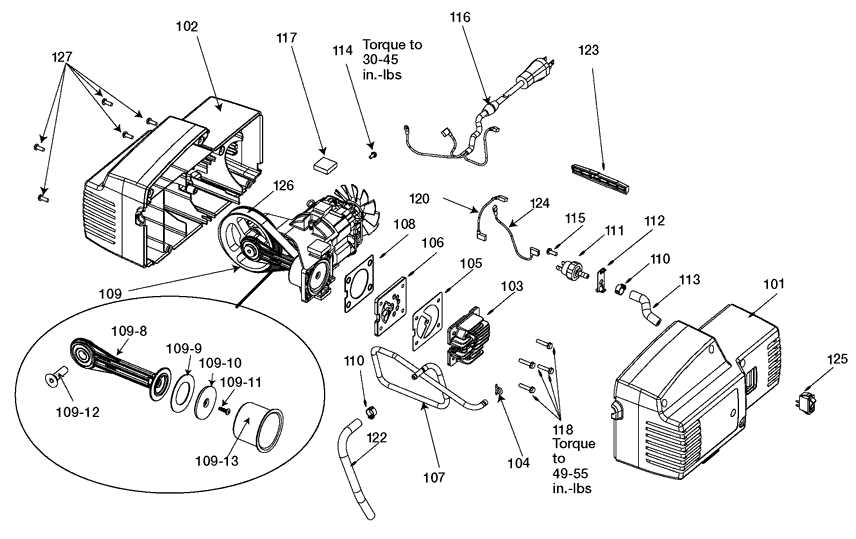

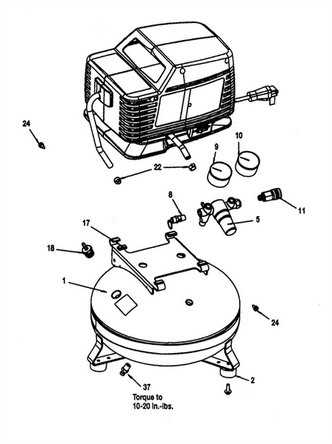

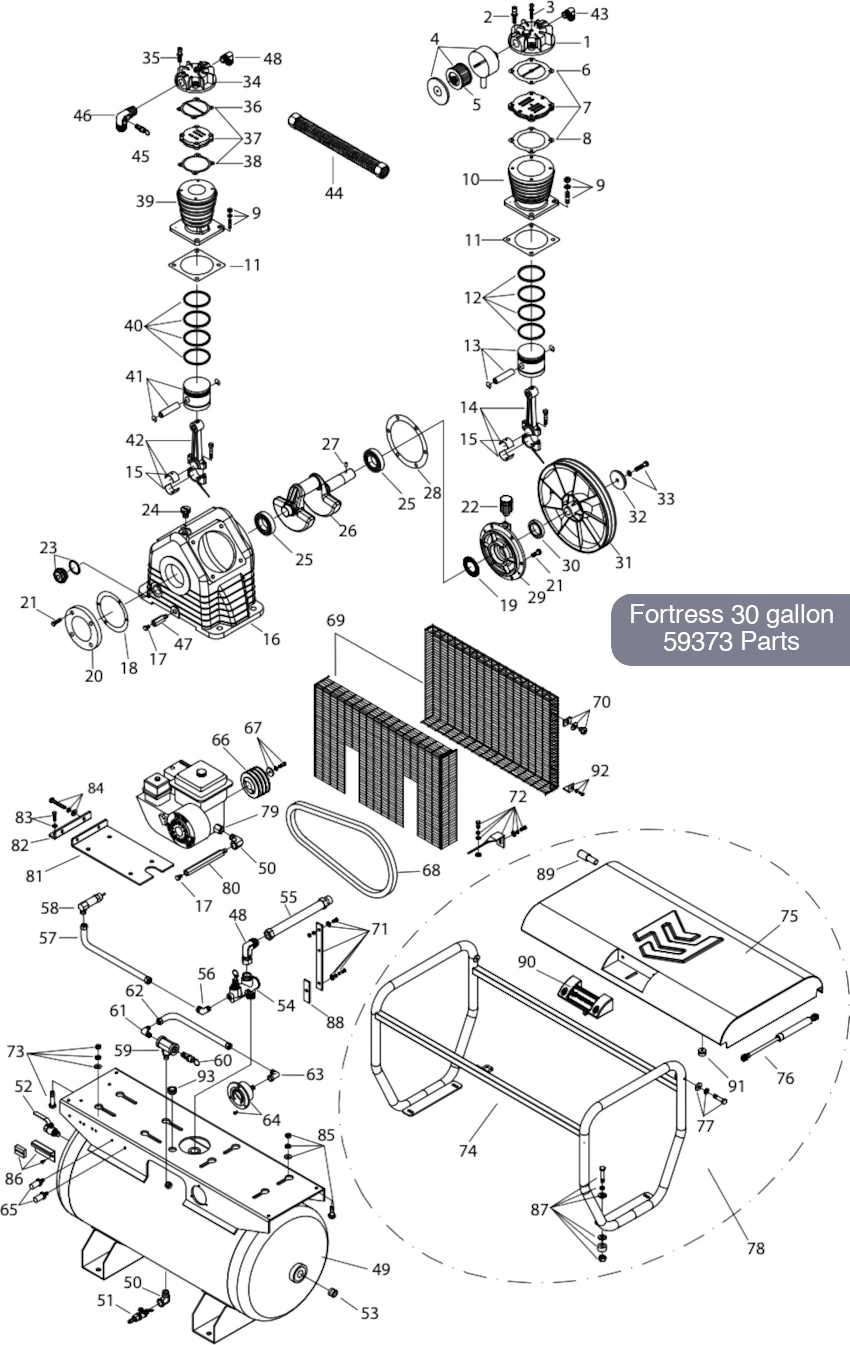

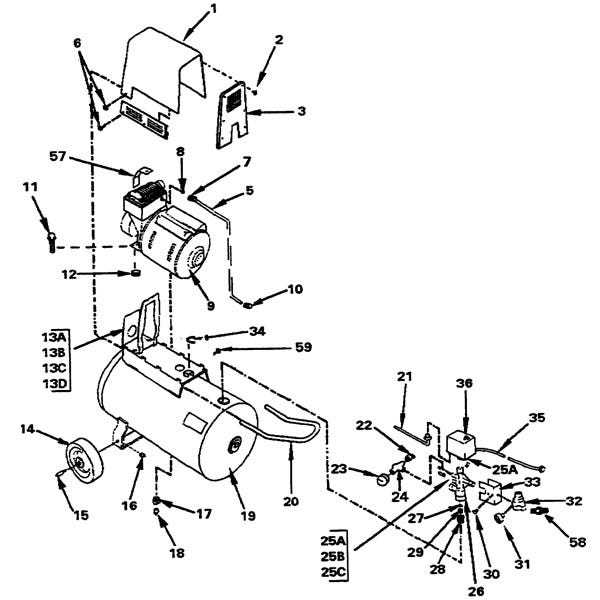

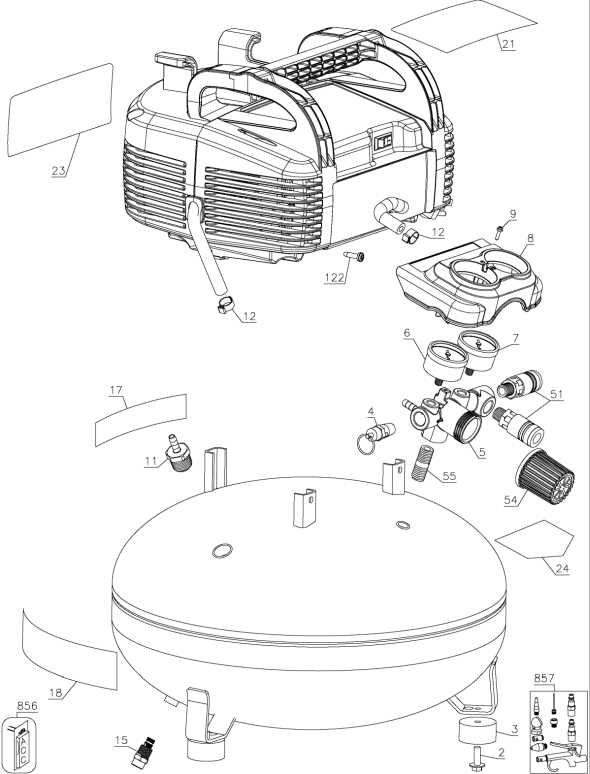

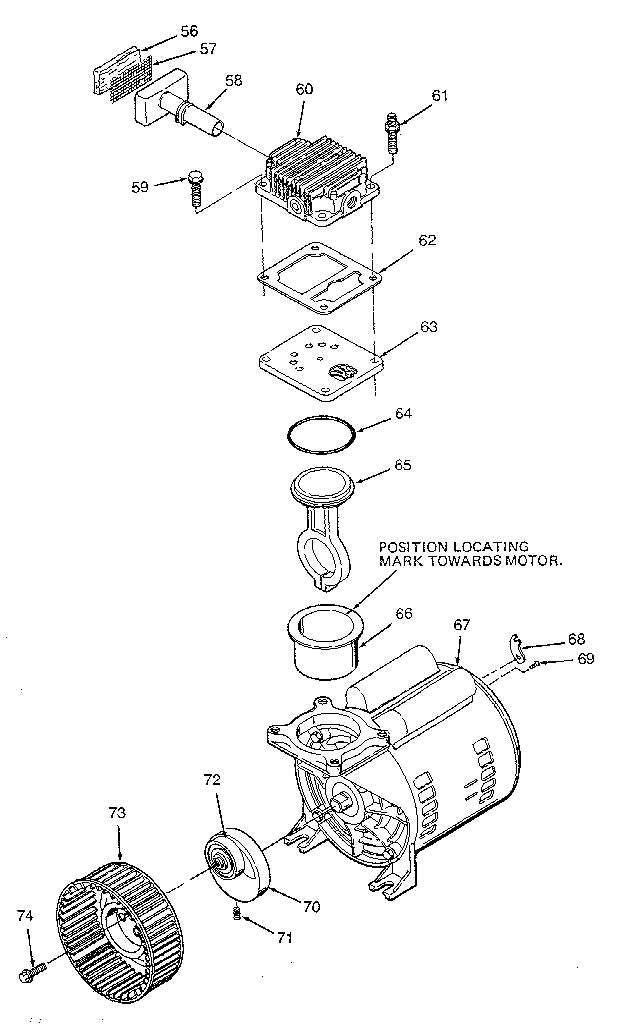

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This knowledge helps in identifying individual elements and their relationships within a larger system.

Familiarize Yourself with the Key

Most illustrations include a legend or key. This section usually provides information about symbols and markings, allowing for quick identification of various elements.

- Check for labels indicating specific functions.

- Look for color codes that signify different types of materials or components.

Identify Components and Their Connections

Once you’re familiar with the key, focus on individual elements and how they connect to one another. Understanding these relationships is crucial for troubleshooting and repairs.

- Locate major assemblies first.

- Trace lines that represent connections between components.

- Note any additional annotations that provide context.

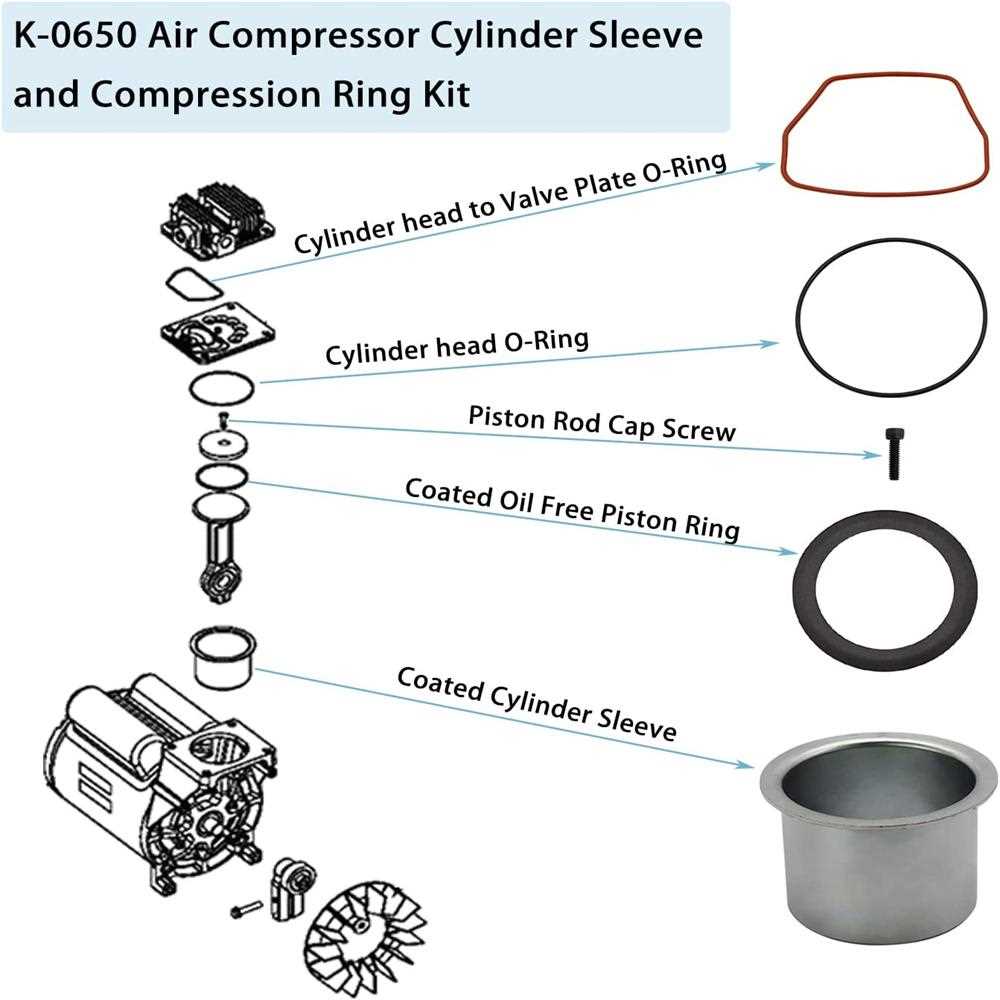

Identifying Essential Replacement Parts

Understanding the vital components of your equipment is crucial for maintaining optimal performance and longevity. Recognizing which elements require replacement can save time and enhance functionality.

Key Components to Consider

- Air Filters

- Seals and Gaskets

- Valves

- Pistons

- Pressure Switches

Tips for Identification

- Refer to the user manual for specifications.

- Look for signs of wear or damage.

- Consult online resources or forums for guidance.

- Keep a record of replaced items for future reference.

Safety Tips for Compressor Use

Operating machinery that generates pressurized air requires careful attention to safety. Understanding potential hazards and implementing proper precautions can significantly reduce the risk of accidents and injuries. Below are essential guidelines to ensure safe usage of such equipment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) when working with high-pressure systems. This includes safety goggles to protect your eyes from flying debris, gloves to ensure a firm grip, and hearing protection to guard against loud noises. Additionally, sturdy footwear can prevent injuries from falling tools or heavy components.

Maintenance and Inspection

Regular maintenance is crucial for safe operation. Inspect the machinery before each use for signs of wear or damage. Check hoses for leaks, ensure fittings are secure, and verify that safety valves are functioning properly. Keeping the equipment in good condition minimizes the risk of malfunction and enhances safety.

Best Practices for Troubleshooting Problems

Effectively addressing issues with equipment requires a systematic approach. By following established practices, users can identify and resolve malfunctions efficiently, ensuring optimal performance and longevity.

Initial Assessment

Start by conducting a thorough examination of the unit. Look for obvious signs of wear or damage, check connections, and ensure power supply is stable. Document any unusual noises or behaviors for further analysis.

Step-by-Step Diagnosis

Implement a methodical process for diagnosing issues. Break down the problem into smaller components and test each systematically. This will help isolate the root cause more accurately.

| Step | Action | Notes |

|---|---|---|

| 1 | Check power supply | Ensure the unit is receiving adequate voltage. |

| 2 | Inspect for leaks | Look for any signs of air or fluid leaks. |

| 3 | Test components | Examine individual parts for functionality. |

| 4 | Consult documentation | Reference manuals for specific troubleshooting tips. |

Where to Buy Genuine Parts

Acquiring authentic components for your equipment is essential for maintaining optimal performance and longevity. Genuine elements ensure compatibility and reliability, minimizing the risk of malfunctions. Below are some recommended sources for purchasing these essential items.

Authorized Retailers

- Visit local authorized dealers who specialize in your brand.

- Check the manufacturer’s website for a list of certified retailers.

- Explore home improvement stores that often stock original items.

Online Marketplaces

- Utilize the official website of the manufacturer for direct purchases.

- Consider reputable online platforms that offer genuine replacements.

- Search for specialized e-commerce sites that focus on quality equipment.

Always verify the authenticity of the components before making a purchase to ensure you are getting the best quality for your needs.

DIY Repairs for Common Failures

Understanding how to address frequent issues in your equipment can save you both time and money. This section will guide you through practical solutions for typical malfunctions, empowering you to tackle repairs confidently.

Identifying Common Issues

- Unusual noises

- Pressure loss

- Failure to start

Simple Repair Techniques

- Noisy Operation: Check for loose components and tighten screws as needed.

- Loss of Pressure: Inspect seals and gaskets for wear; replace if damaged.

- Won’t Start: Examine the power supply and ensure connections are secure.

By following these steps, you can effectively manage minor faults and extend the life of your machinery.

Upgrading Your Compressor Effectively

Enhancing your equipment’s performance can significantly improve efficiency and extend its lifespan. By focusing on specific components and implementing strategic improvements, you can achieve a more reliable and powerful system.

Assessing Current Performance is crucial before initiating any upgrades. Identify areas where performance lags or where enhancements could lead to greater productivity. This could involve evaluating pressure levels, flow rates, and overall functionality.

Choosing Quality Components is essential for effective enhancement. Opt for high-grade replacements that match or exceed original specifications. This investment not only improves functionality but also ensures durability, reducing the need for frequent repairs.

Regular Maintenance plays a vital role in keeping your system running smoothly. Schedule routine check-ups and cleanings to prevent wear and tear. By maintaining optimal operating conditions, you can maximize the benefits of your upgrades.

Implementing these strategies will lead to a more efficient system, allowing for increased productivity and a better overall experience in your projects.