When exploring the intricacies of heavy equipment, a comprehensive overview of the various elements is essential. This section aims to provide a clear representation of how different parts interact within complex systems, facilitating a deeper understanding of their functionality and significance.

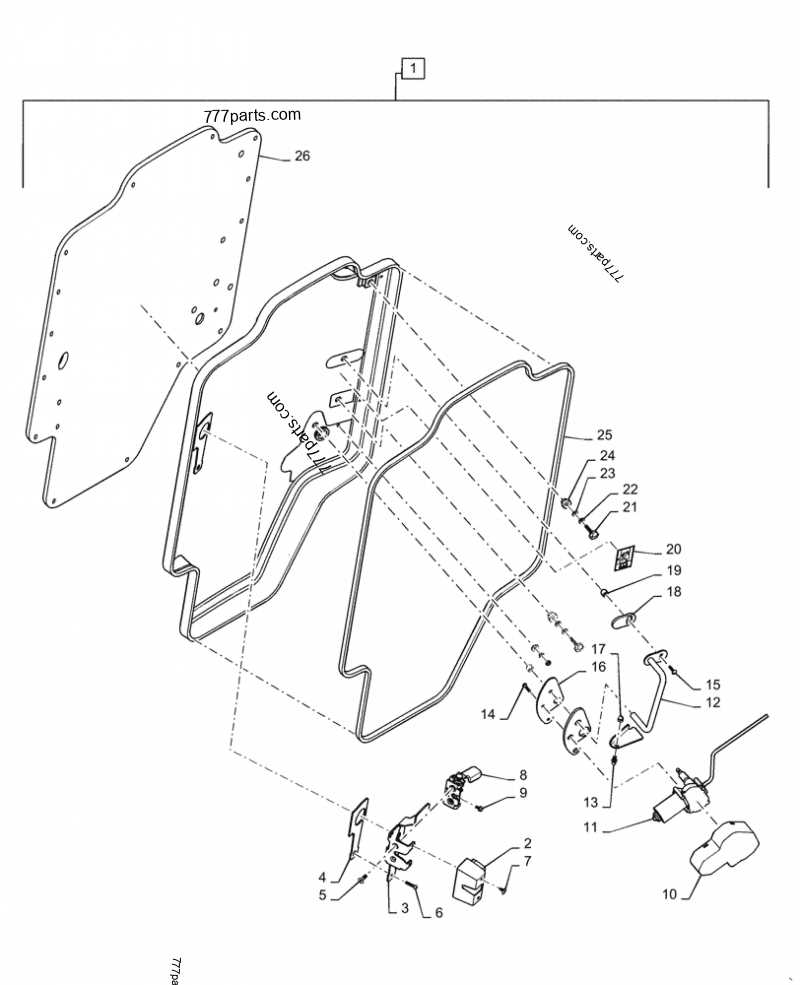

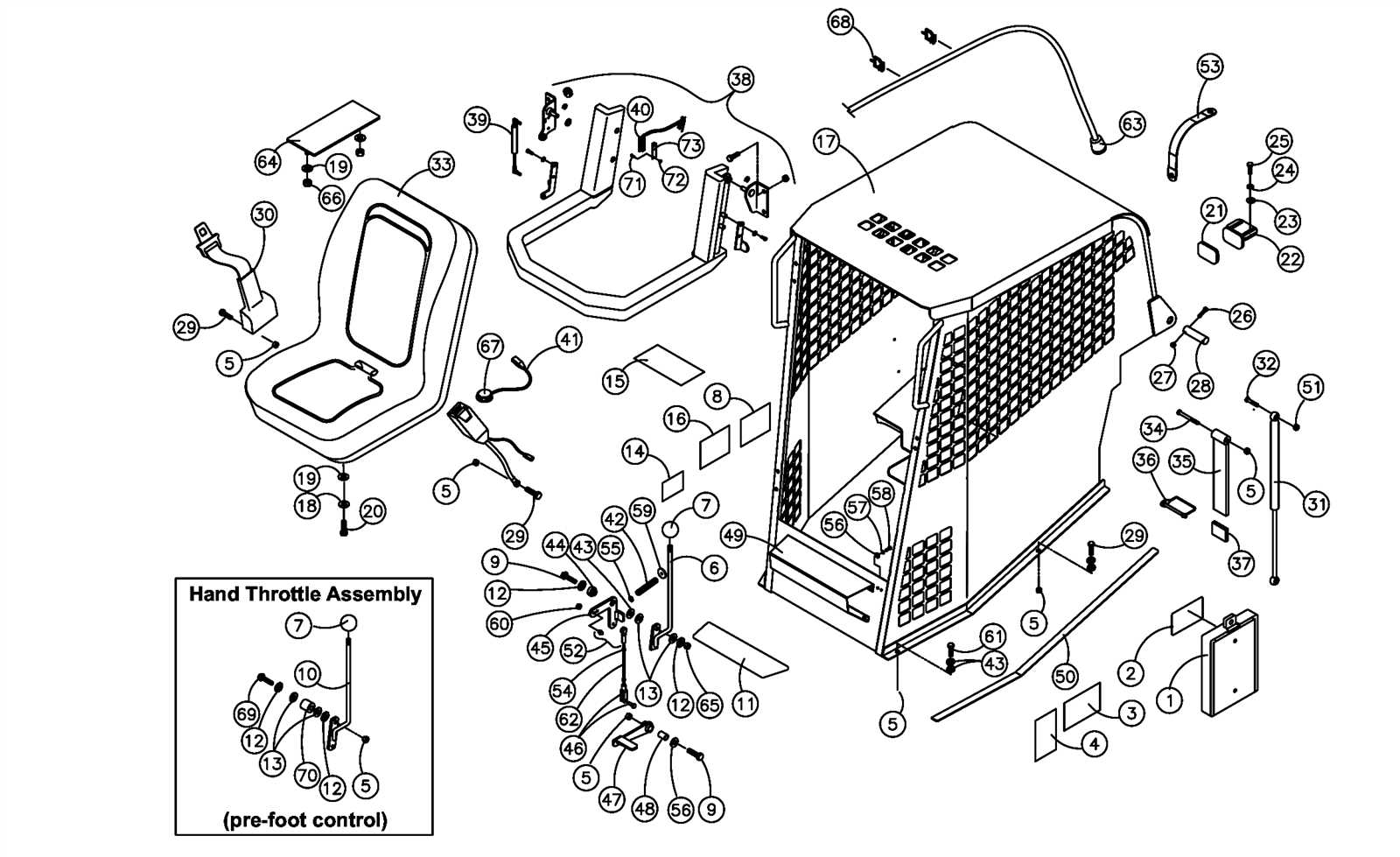

Visual aids play a critical role in grasping the relationships among these components. By examining detailed illustrations, one can identify the unique features and roles of each segment, enhancing both knowledge and maintenance capabilities.

In this exploration, we will delve into the ultimate layout of machinery, providing insights into assembly, disassembly, and repair processes. Understanding these aspects not only supports effective troubleshooting but also contributes to the longevity and efficiency of the equipment.

Understanding the TV380 Model

The model in focus is a versatile piece of machinery renowned for its efficiency and robustness. This equipment plays a vital role in various industries, offering reliable performance and adaptability across numerous applications. A thorough understanding of its structure and components is essential for maximizing its potential and ensuring longevity.

Key Features

- Exceptional maneuverability for tight spaces

- Powerful engine performance for demanding tasks

- Durable construction designed for heavy use

- User-friendly controls for enhanced operation

Components Overview

A comprehensive look at the essential components reveals the intricate design that contributes to its efficiency. Each part plays a specific role in the overall functionality:

- Hydraulic System: Enables powerful lifting and digging capabilities.

- Drive Train: Ensures smooth movement and traction on various terrains.

- Cab Structure: Provides operator comfort and visibility.

- Attachment Options: Offers flexibility for different tasks through interchangeable tools.

Understanding these elements allows operators and maintenance personnel to optimize the machine’s performance and address any potential issues proactively.

Key Components of the TV380

This section explores the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these components provides insight into their roles and interconnections, ultimately enhancing the user experience and maintenance practices.

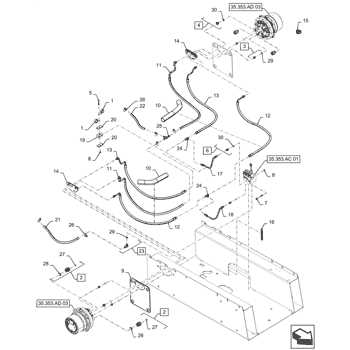

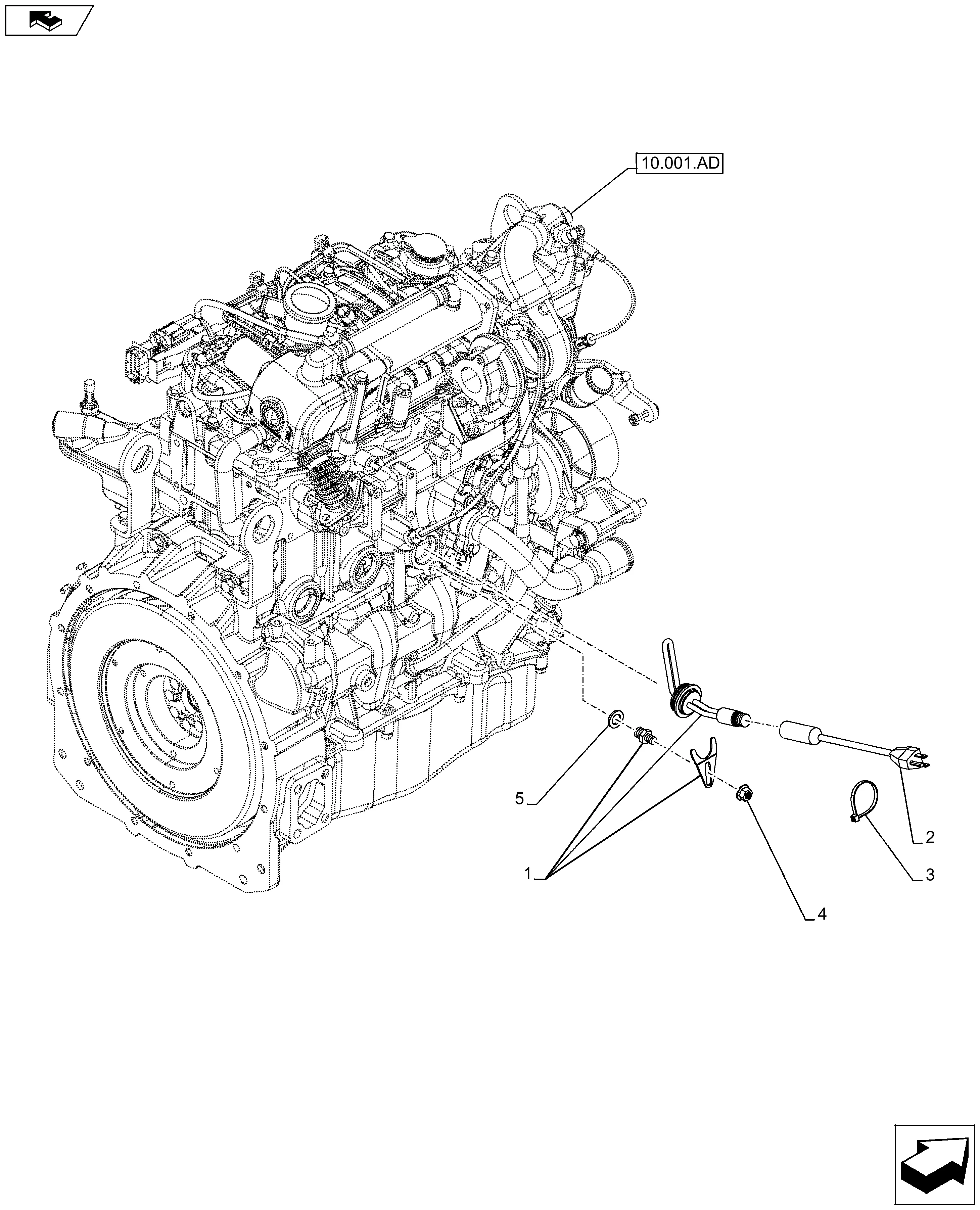

Hydraulic System

The hydraulic system is crucial for powering various functions. It enables smooth operation of the implements, ensuring optimal performance in diverse tasks. Regular checks and maintenance are vital to prevent issues and ensure longevity.

Engine and Transmission

The heart of any machine lies within its engine and transmission. This assembly not only delivers power but also affects speed and torque. Proper maintenance can significantly improve efficiency and extend the equipment’s lifespan.

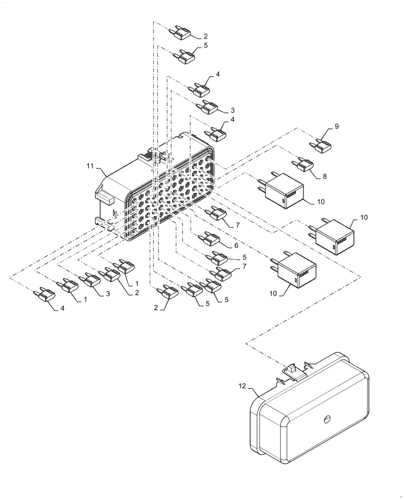

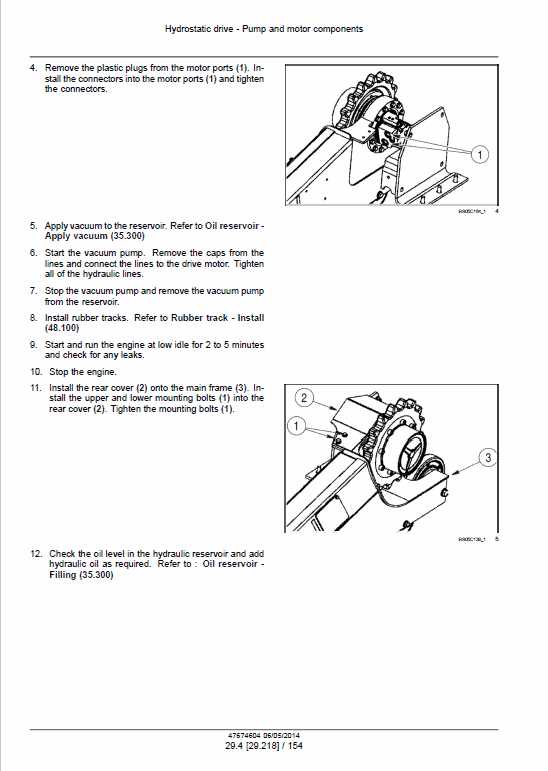

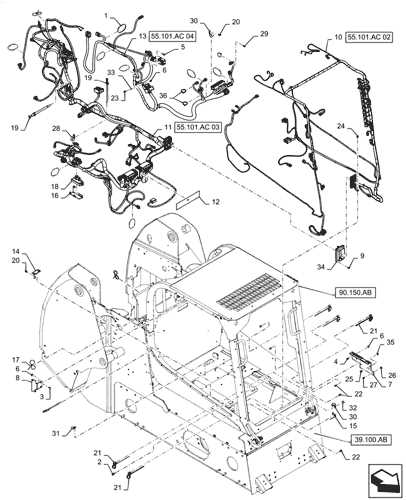

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that break down complex systems into manageable components, allowing users to identify and address issues more efficiently.

Clarity is one of the primary benefits of these visual aids. By illustrating the relationship between different elements, they help technicians and operators grasp how various pieces work together, enhancing overall comprehension of the equipment.

Furthermore, such illustrations facilitate effective communication. They provide a common reference point for discussions among team members, suppliers, and support personnel, reducing the likelihood of misunderstandings and errors during the repair process.

Moreover, these resources are invaluable for training purposes. New employees or inexperienced technicians can quickly familiarize themselves with the layout and functionality of the machinery, accelerating their learning curve and boosting productivity.

In addition, having a detailed visual guide promotes accurate ordering of components. When individuals can precisely identify required items, it minimizes the risk of acquiring incorrect parts, thus saving time and resources.

How to Read Parts Diagrams

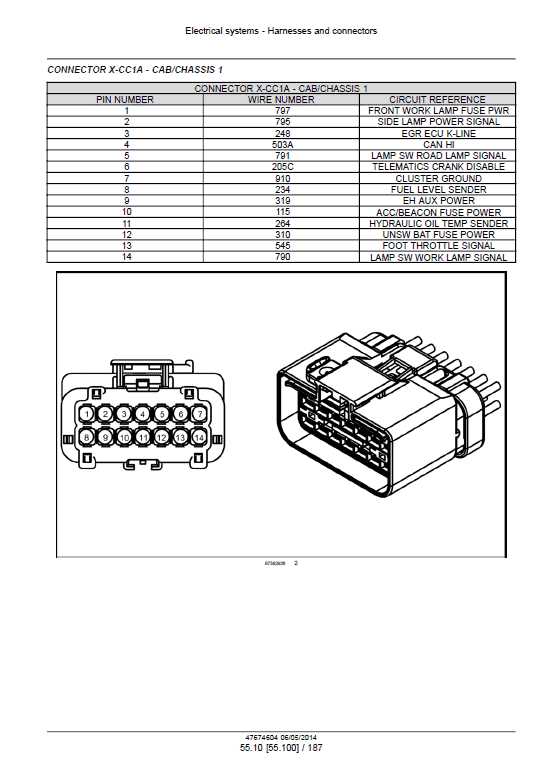

Understanding the visual representations of components can significantly enhance your ability to identify and locate essential elements within machinery. These illustrations serve as a crucial reference, allowing users to navigate complex systems with ease. Grasping the fundamentals of these visuals can lead to more effective repairs and maintenance.

Firstly, familiarize yourself with the symbols and notations used. Each icon often corresponds to a specific element, and recognizing these will aid in quickly deciphering the layout. Additionally, pay attention to the labeling, as descriptions provide essential details about each part’s function and specifications.

Next, notice the hierarchical structure of the illustration. Components are typically organized in a way that showcases their relationships and assemblies. Understanding this hierarchy is vital for effective disassembly and reassembly during servicing tasks.

Lastly, take your time to cross-reference the visual with any accompanying documentation. This can offer additional insights and clarify any ambiguities present in the imagery. Ultimately, mastering this skill will streamline your workflow and improve overall efficiency in handling equipment.

Common Issues with TV380 Parts

Maintenance and functionality can often be challenged by specific components in heavy machinery. Understanding frequent malfunctions can enhance performance and prolong the lifespan of the equipment. Below are some prevalent concerns that operators might encounter.

Frequent Problems

- Wear and Tear: Regular usage can lead to degradation, particularly in high-friction areas.

- Fluid Leaks: Hydraulic systems may experience leaks, impacting efficiency and safety.

- Electrical Failures: Wiring issues or faulty sensors can result in operational disruptions.

- Overheating: Insufficient cooling can cause critical components to overheat, leading to failure.

Preventive Measures

- Regular Inspections: Conduct thorough checks to identify early signs of damage.

- Timely Replacements: Swap out worn components before they lead to larger issues.

- Proper Lubrication: Ensure all moving parts are adequately lubricated to reduce friction.

- Training Operators: Educate users on best practices to minimize misuse and accidents.

Identifying Replacement Parts

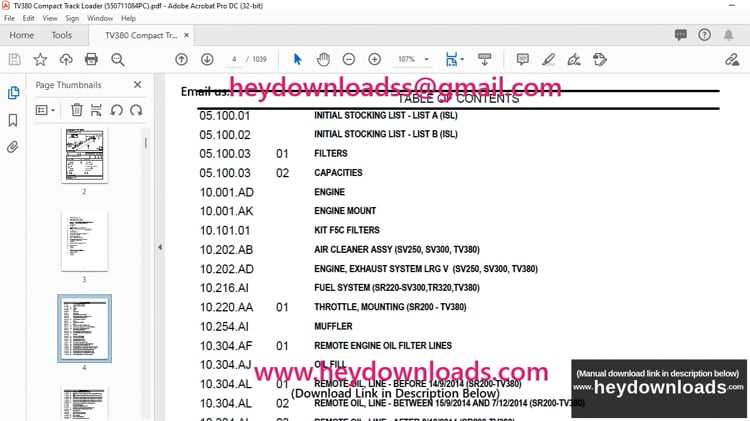

Understanding how to find suitable components for machinery is essential for maintaining optimal performance. Accurate identification of these elements ensures that equipment operates efficiently and minimizes downtime. Whether for repair or enhancement, knowing where to look and what to consider can significantly streamline the process.

Start by examining the specific model and its unique features. Familiarize yourself with the various assemblies and their functions, as this knowledge is crucial for recognizing compatible replacements. Utilizing resources like user manuals or manufacturer websites can provide invaluable information about specifications and alternatives.

Another effective approach is to consult with professionals or fellow operators who have experience with similar machinery. Their insights can guide you towards trusted suppliers and help you navigate any potential pitfalls. Additionally, online forums and communities can be a great asset for gathering feedback on various options.

Finally, keeping a detailed record of the components you need and any previous replacements can assist in future identification tasks. This organized approach not only enhances efficiency but also aids in developing a comprehensive understanding of your equipment’s requirements over time.

Where to Find OEM Parts

Locating original equipment components can be crucial for ensuring the longevity and performance of your machinery. Genuine parts are designed specifically for your equipment, providing reliability and optimal functionality. Understanding where to source these items is essential for maintenance and repairs.

Authorized Dealers

One of the best avenues for acquiring authentic components is through authorized dealers. These establishments are certified by the manufacturer and offer a wide selection of genuine items. They often provide expert advice and support, ensuring that you choose the correct pieces for your machinery.

Online Retailers

In the digital age, many reputable online retailers specialize in OEM items. These platforms often feature comprehensive catalogs and user-friendly interfaces, allowing you to quickly find the specific components you need. Always verify the credibility of the website to ensure you receive high-quality products.

Aftermarket vs. Original Components

The choice between alternative and manufacturer-specific components can significantly impact equipment performance and longevity. Each option presents distinct advantages and considerations that users must evaluate based on their needs and circumstances.

- Cost: Alternative components often come at a lower price point, making them appealing for budget-conscious consumers.

- Quality: Manufacturer-specific items are typically designed to meet precise specifications, ensuring compatibility and reliability.

- Availability: Aftermarket options may provide a wider range of choices, especially for older models.

- Warranty: Original parts often come with a warranty, offering peace of mind regarding durability.

Ultimately, the decision hinges on factors such as performance expectations, budget constraints, and personal preferences. A careful evaluation can help determine the most suitable route for each individual situation.

Maintenance Tips for TV380

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By following specific guidelines, you can prevent potential issues and enhance the efficiency of your equipment.

Check Fluid Levels: Regularly inspect and top off hydraulic fluids, engine oil, and coolant to maintain proper functionality. Low levels can lead to overheating and mechanical failure.

Inspect Filters: Clean or replace air and fuel filters periodically to ensure a steady flow and optimal combustion. This simple step can significantly improve performance.

Monitor Tire Condition: Keep an eye on tire pressure and tread wear. Properly inflated tires enhance stability and fuel efficiency while extending tire life.

Conduct Routine Inspections: Regularly examine belts, hoses, and electrical connections for wear and damage. Early detection can prevent costly repairs down the line.

Clean the Exterior: Keeping the machine free of dirt and debris not only improves aesthetics but also prevents corrosion and allows for better heat dissipation.

Follow Manufacturer’s Guidelines: Adhere to the recommended maintenance schedule provided in the user manual to ensure your equipment remains in peak condition.

Tools Needed for Repairs

Effective maintenance requires the right assortment of instruments to ensure optimal functionality and longevity of equipment. Having the proper tools at hand not only streamlines the repair process but also enhances safety and efficiency.

- Wrenches: Essential for loosening or tightening bolts and nuts.

- Screwdrivers: Necessary for adjusting or removing screws in various components.

- Socket Set: Provides versatility for different sizes of fasteners.

- Pliers: Useful for gripping, bending, and cutting wires or small parts.

- Jack Stands: Critical for safely elevating equipment during repairs.

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Diagnostic Tools: Essential for identifying issues and monitoring performance.

By gathering these essential instruments, you will be well-prepared to tackle any maintenance challenge effectively.

Benefits of Regular Maintenance

Consistent upkeep of machinery is crucial for optimal performance and longevity. Regular inspections and servicing can prevent minor issues from escalating into significant problems, ultimately saving time and resources. This proactive approach not only enhances reliability but also ensures safety for operators and equipment.

| Benefit | Description |

|---|---|

| Increased Lifespan | Routine care helps extend the operational life of equipment by addressing wear and tear early. |

| Cost Savings | Preventative maintenance reduces unexpected repair costs and downtime. |

| Improved Efficiency | Well-maintained machinery operates more efficiently, enhancing overall productivity. |

| Safety Assurance | Regular checks can identify safety hazards, ensuring a safer working environment. |