The complexity of small engine systems often requires a detailed exploration of their individual components. By examining these arrangements, users can gain valuable insights into the functionality and maintenance of their machines. This knowledge not only aids in repairs but also enhances overall operational efficiency.

Identifying each element’s role within the assembly allows for a more informed approach to troubleshooting. When one comprehends how different pieces interact, it becomes easier to pinpoint issues and implement effective solutions. Moreover, having a clear visual representation of the assembly can significantly streamline the repair process.

Whether you are a seasoned mechanic or a novice enthusiast, familiarizing yourself with the layout of these mechanical elements is essential. Understanding the specific functions and placements of each part can empower users to tackle maintenance tasks with confidence and precision.

This section aims to provide a comprehensive overview of the various elements that make up a small engine system, emphasizing their functionality and importance in overall operation. By delving into these components, readers can gain insights into how they work together to ensure efficient performance.

Key Components of Small Engine Systems

- Cylinder: The core of the engine where combustion occurs, facilitating the conversion of fuel into mechanical energy.

- Piston: A vital part that moves within the cylinder, compressing the fuel-air mixture for ignition.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the engine’s output.

- Fuel System: Comprises the tank, lines, and carburetor, responsible for storing and delivering the necessary fuel to the engine.

- Ignition System: Ensures reliable starting and smooth operation by providing the spark needed for combustion.

Understanding Functionality and Maintenance

- Regularly inspect and clean components to ensure optimal performance.

- Monitor fuel levels and quality to prevent issues related to combustion.

- Check the ignition system periodically to maintain starting efficiency.

- Consult technical resources for detailed information on specific components and troubleshooting tips.

Overview of Engine Functionality

The operation of a small engine revolves around the conversion of fuel into mechanical energy. This process involves several key components working in unison to ensure optimal performance. Understanding how these elements interact can provide insights into the overall efficiency and reliability of the machinery.

Core Components

At the heart of any engine are its primary elements: the cylinder, piston, and crankshaft. The cylinder houses the piston, which moves up and down, creating a vacuum that draws in air and fuel. This mixture is then compressed and ignited, resulting in a powerful explosion that forces the piston back down, turning the crankshaft. This conversion of linear motion into rotational motion drives the connected machinery.

Ignition and Fuel Systems

The ignition system plays a crucial role in engine functionality. It is responsible for initiating the combustion process at the right moment. Meanwhile, the fuel system ensures that the correct amount of fuel reaches the engine. A well-functioning fuel delivery system, combined with a reliable ignition mechanism, is essential for efficient operation and performance.

In summary, grasping the functionality of these core components and systems is vital for anyone interested in maintaining or troubleshooting small engines. Proper understanding leads to better performance and longevity of the equipment.

Identifying Key Parts

Understanding the essential components of a small engine can significantly enhance maintenance and repair efforts. Recognizing the various elements involved helps in diagnosing issues and ensuring optimal performance. This section aims to provide clarity on the critical elements that contribute to the overall functionality of such engines.

Crankshaft: The crankshaft serves as a pivotal component, converting linear motion into rotational motion. It plays a vital role in the engine’s operation and power generation.

Flywheel: Acting as a stabilizer, the flywheel helps maintain momentum during operation. Its design is crucial for the smooth functioning of the engine, allowing for a consistent output of power.

Ignition System: This system is essential for initiating the combustion process. It comprises several elements, including the spark plug and ignition coil, which work together to create the necessary spark for fuel ignition.

Fuel System: A well-functioning fuel system ensures the appropriate mixture of air and fuel is delivered to the combustion chamber. Key components include the carburetor and fuel lines, which are critical for efficient engine operation.

Oil System: The lubrication system is vital for reducing friction between moving parts. It ensures that oil circulates effectively throughout the engine, promoting longevity and performance.

By familiarizing oneself with these crucial components, operators can enhance their understanding of engine mechanics, leading to improved troubleshooting and maintenance practices.

Importance of Regular Maintenance

Consistent upkeep of outdoor power equipment is crucial for ensuring optimal performance and longevity. Neglecting routine care can lead to decreased efficiency, unexpected failures, and costly repairs. A proactive maintenance approach can significantly enhance the reliability and functionality of machinery.

Regular maintenance tasks help to:

- Identify and address potential issues before they escalate.

- Improve operational efficiency by keeping components in good condition.

- Extend the lifespan of the equipment, ensuring it serves well for years.

- Enhance safety for users by minimizing the risk of malfunctions.

- Maintain resale value by keeping the machinery in top shape.

Incorporating scheduled inspections and routine care into your operating practices will lead to a smoother, more reliable experience. Prioritizing maintenance not only benefits the equipment but also saves time and resources in the long run.

Common Replacement Components

In various machinery, certain elements frequently require replacement due to wear and tear. Understanding these components can significantly improve maintenance and prolong the lifespan of the equipment. Regularly checking and replacing these items ensures optimal performance and reduces the risk of malfunction.

Filters are essential for maintaining the efficiency of engines. Oil and air filters capture contaminants, preventing them from circulating within the system. Regular replacement helps in keeping the internal components clean and functioning properly.

Spark plugs play a crucial role in igniting the fuel-air mixture within the combustion chamber. Over time, they can become fouled or worn, leading to poor performance. Timely replacement ensures smooth operation and easy starting.

Fuel lines may deteriorate due to exposure to various elements. Cracks or leaks can lead to fuel loss and reduced efficiency. Inspecting and replacing damaged lines is vital for maintaining fuel delivery and overall engine performance.

Batteries are another common component that may need replacement. As they age, their ability to hold a charge diminishes, affecting starting capability. Regularly checking battery health can prevent unexpected failures.

By being aware of these commonly replaced components, users can effectively manage their maintenance schedules, ensuring reliable operation and enhancing the overall lifespan of their equipment.

Tools for Disassembly and Repair

Effective maintenance and repair of small engines require the right set of tools. Utilizing appropriate instruments not only simplifies the process but also ensures safety and precision. Understanding which tools are essential can significantly enhance the efficiency of your repair tasks.

Below is a list of common tools you might need for disassembling and fixing engines:

- Wrenches: A variety of sizes will be necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips head screwdrivers are essential for removing screws in various components.

- Pliers: Needle-nose and standard pliers can assist in gripping and twisting wires or small parts.

- Socket Set: A socket set can provide the necessary torque for larger fasteners, making assembly and disassembly easier.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Cleaning Tools: Brushes and cloths are crucial for maintaining cleanliness and preventing debris from affecting the engine’s performance.

- Safety Equipment: Gloves and goggles should always be worn to protect yourself from potential hazards during repairs.

Having these tools readily available will prepare you for a variety of repair tasks. Always remember to follow safety protocols and guidelines while performing maintenance.

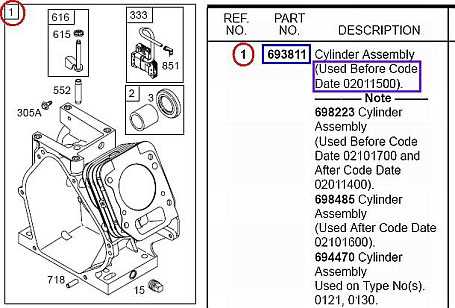

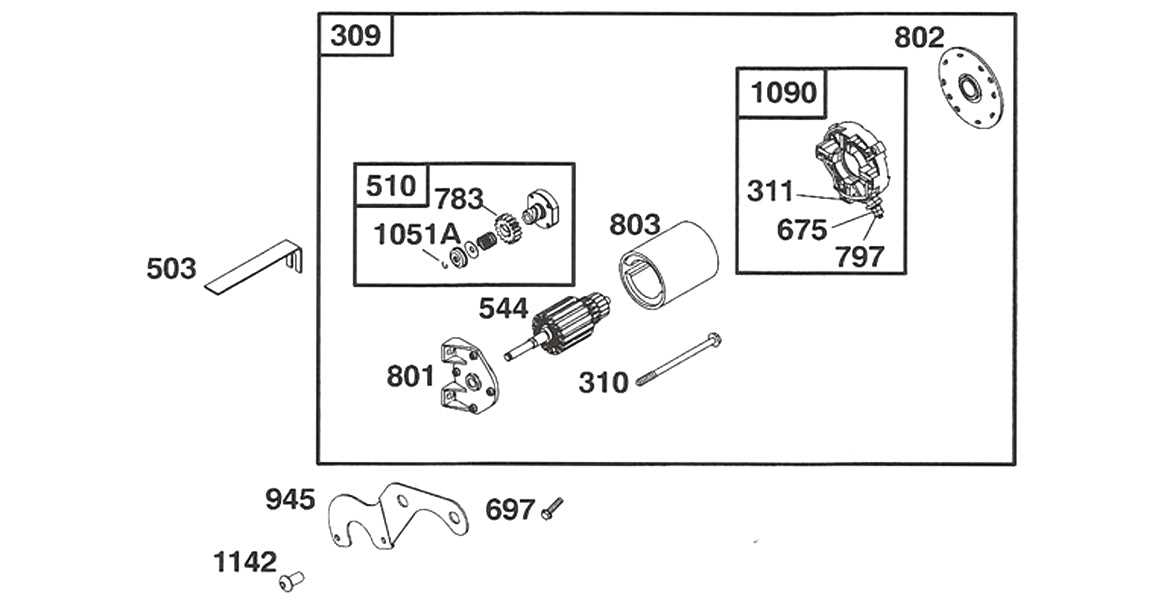

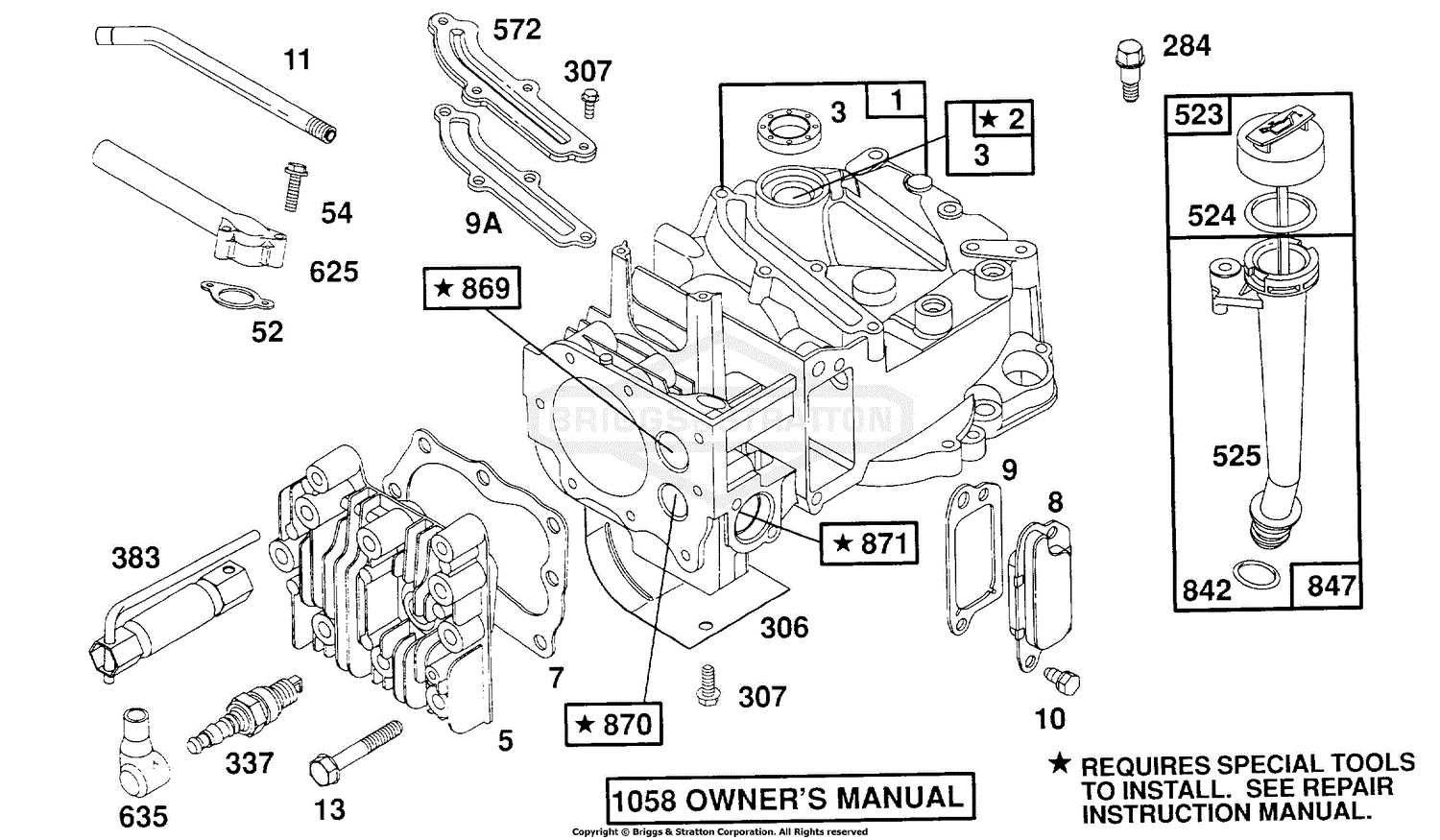

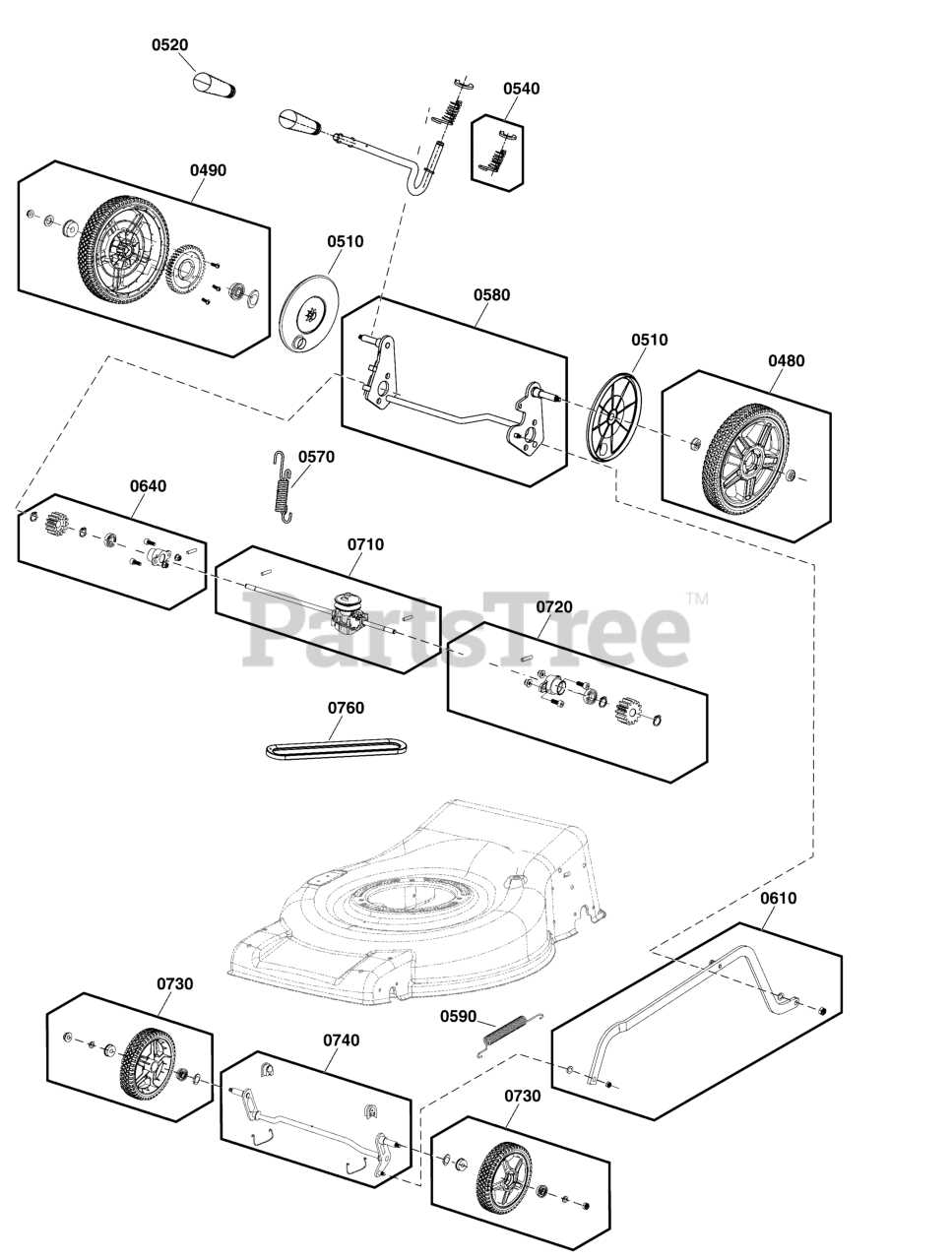

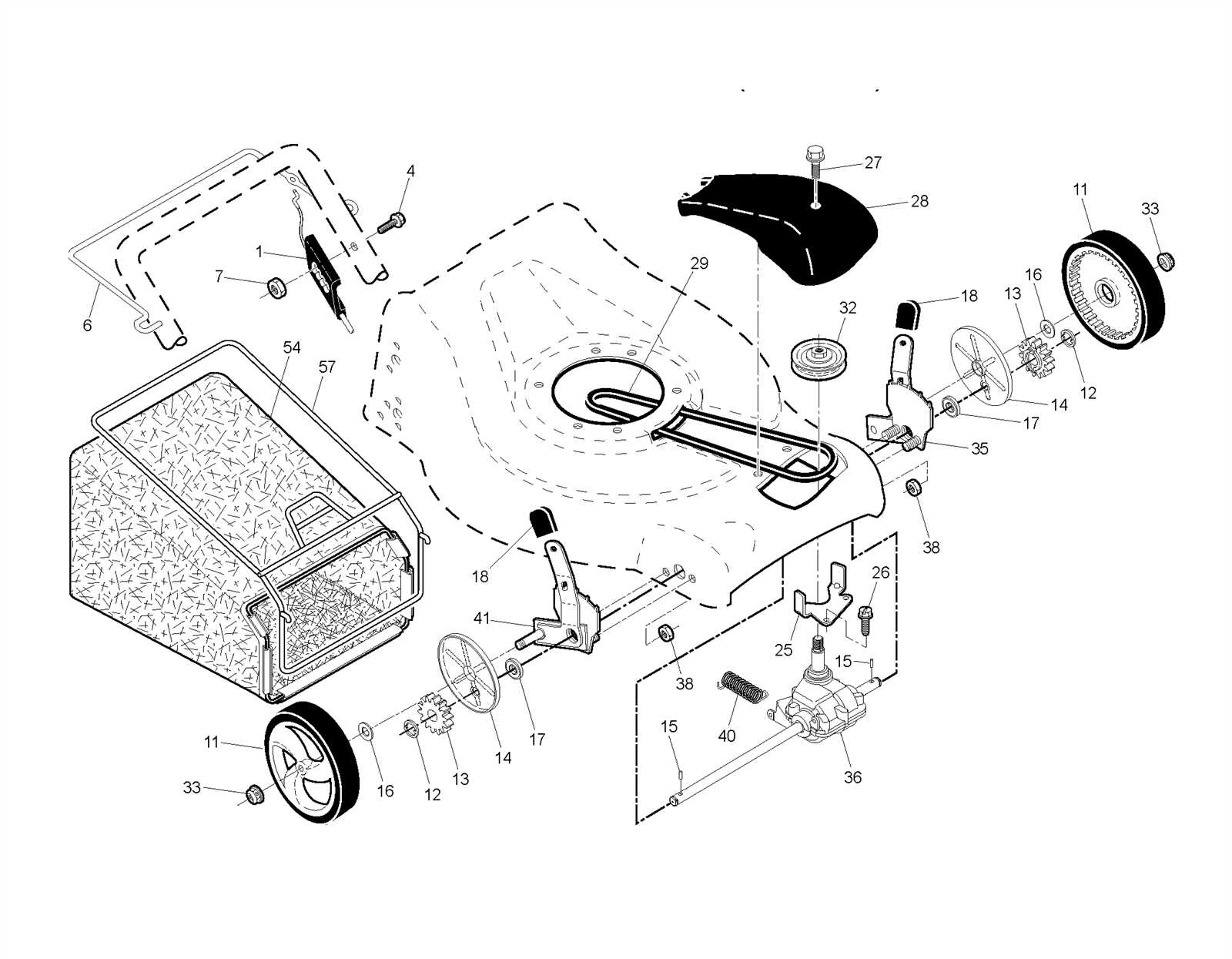

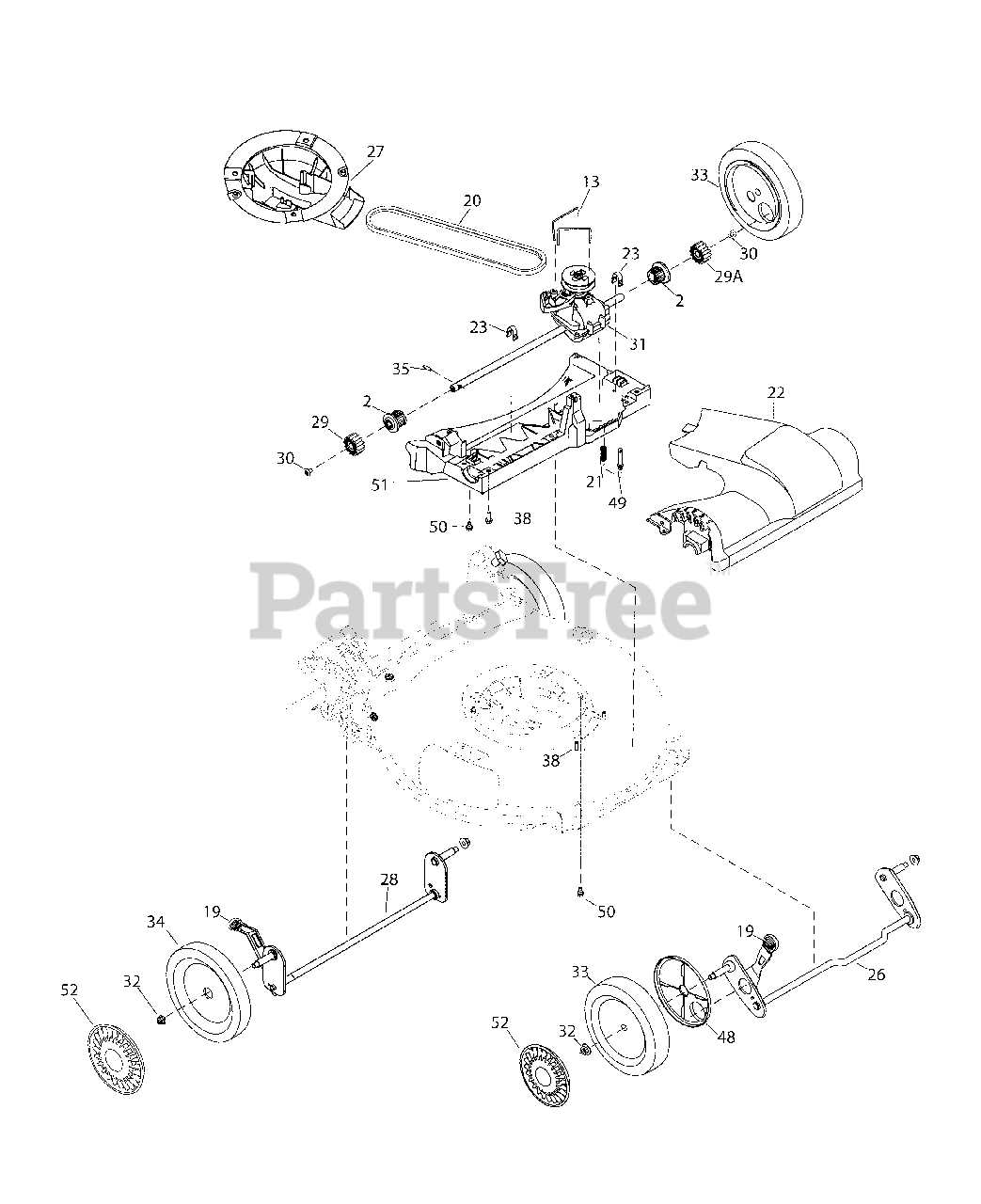

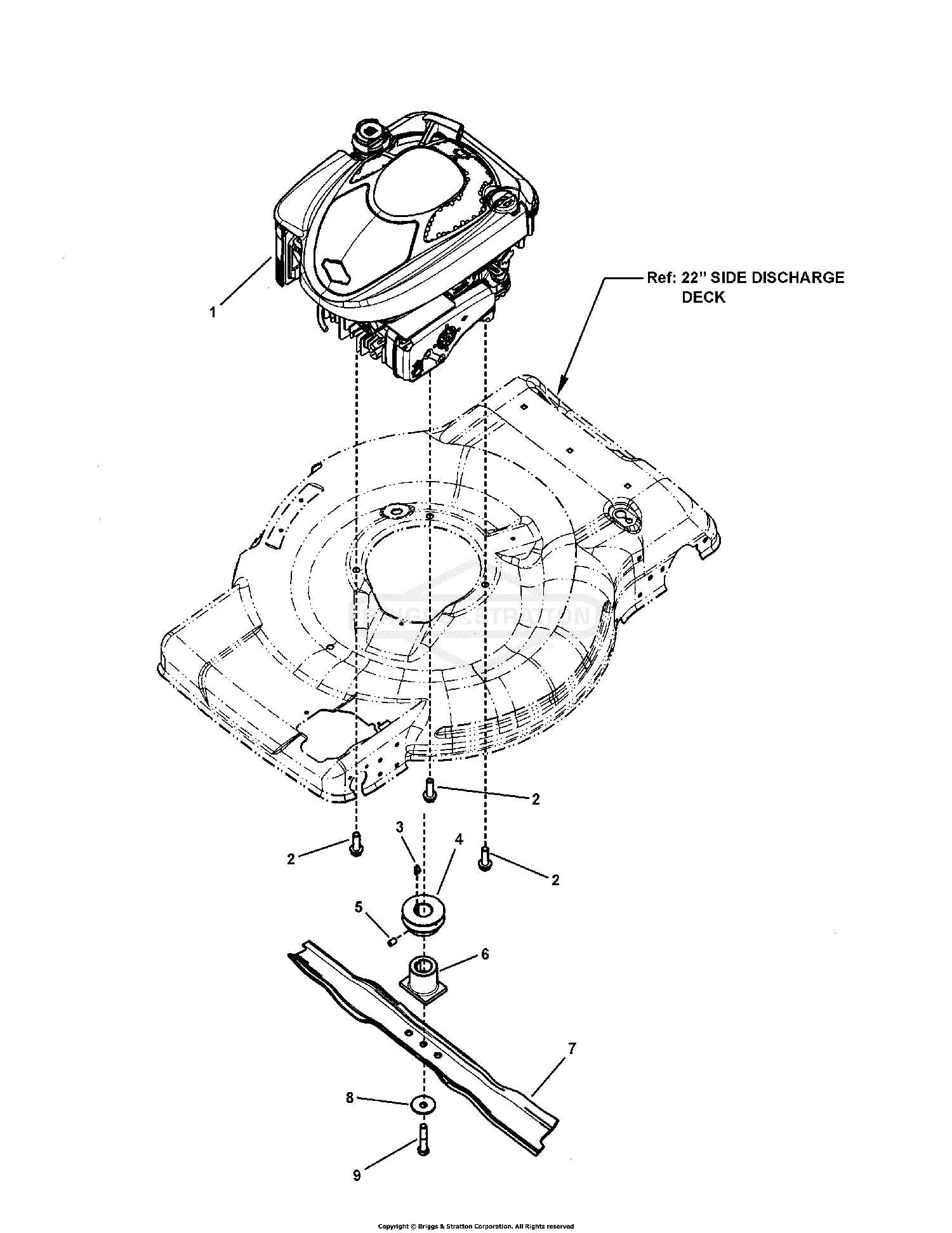

Visual Reference for Parts Diagram

This section aims to provide an insightful visual guide that showcases various components of the engine assembly. A comprehensive representation can greatly assist users in identifying individual elements and understanding their functions within the overall mechanism. Such a reference not only aids in maintenance but also enhances troubleshooting skills.

Understanding the Components

- Identifying each part and its role in the engine’s operation

- Visual cues for easier recognition during assembly or repair tasks

- Helpful illustrations for clarity on positioning and connections

Benefits of Using Visual References

- Enhances comprehension of mechanical layouts

- Simplifies the repair process for beginners and experienced users alike

- Facilitates accurate reassembly after maintenance work

Utilizing visual aids ensures that users are better equipped to handle various tasks related to their equipment, leading to more efficient and successful operations.

Step-by-Step Repair Guide

This guide aims to assist users in effectively addressing common issues encountered with their small engine equipment. By following a systematic approach, you can troubleshoot and resolve problems efficiently, ensuring optimal performance and longevity of your machinery.

Identifying the Issue

The first step in the repair process is to accurately diagnose the problem. Start by observing any unusual behaviors, such as difficulty starting, unusual noises, or decreased power output. Make notes of these symptoms, as they will be helpful in determining the necessary actions. Additionally, consult the user manual or online resources for guidance on common issues associated with your specific equipment.

Gathering Necessary Tools

Before beginning any repairs, it’s essential to assemble the required tools and materials. Commonly needed items include wrenches, screwdrivers, pliers, and replacement components. Having everything on hand will streamline the repair process and minimize downtime. Once you are fully equipped, you can proceed with the disassembly and inspection of the affected areas.

Safety Precautions During Repairs

When conducting maintenance on small engines, it is crucial to adhere to specific safety guidelines to prevent accidents and injuries. These precautions not only protect the individual performing the work but also ensure the equipment remains in optimal condition. Following established safety practices minimizes risks and contributes to a smoother repair process.

Essential Safety Measures

Prior to starting any maintenance tasks, take the time to familiarize yourself with the manufacturer’s instructions and safety recommendations. Ensure the work area is well-lit and free of clutter. Wear appropriate personal protective equipment, such as gloves and safety goggles, to shield yourself from potential hazards.

Safe Handling of Tools and Equipment

Proper handling of tools is vital for safe repairs. Always use the correct tool for each task, as using inappropriate tools can lead to accidents. Keep tools organized and within reach to prevent unnecessary movement around the work area.

| Safety Tips | Description |

|---|---|

| Disconnect Power Source | Always disconnect the power supply before starting repairs to avoid accidental starts. |

| Check for Fuel Leaks | Inspect for any fuel leaks and clean spills immediately to prevent fire hazards. |

| Use Proper Ventilation | Ensure adequate ventilation when working with fuel or cleaning agents to avoid inhalation of harmful fumes. |

Troubleshooting Common Issues

When working with small engines, encountering operational challenges is common. Understanding these issues and their potential solutions can significantly enhance performance and extend the life of the engine. This section will explore frequent problems and practical approaches to resolving them, ensuring smooth operation for your equipment.

Engine Won’t Start

If the engine fails to ignite, it may be due to fuel delivery problems or ignition system malfunctions. First, check the fuel level and ensure the mixture is fresh. Clogged filters can also prevent proper flow, so inspect and replace any blocked components. Additionally, examine the spark plug for wear or fouling, as a faulty plug can hinder ignition.

Uneven Operation

Inconsistent performance can often be traced back to issues with the air filter or carburetor. A dirty air filter restricts airflow, affecting combustion. Clean or replace the filter as needed. Moreover, ensure the carburetor is free of debris and correctly adjusted for optimal fuel-air mixture. Regular maintenance in these areas can prevent uneven operation and promote efficiency.

Where to Buy Replacement Parts

Finding suitable components for small engines can be a straightforward task when you know where to look. There are various options available that cater to different needs and preferences. Whether you are looking for original or aftermarket alternatives, understanding your choices can significantly enhance your repair experience.

Online Retailers

The internet offers a wide range of platforms for purchasing necessary components. Here are some popular options:

- Manufacturer’s Website: Official websites often provide original components directly, ensuring quality and compatibility.

- eCommerce Marketplaces: Websites like Amazon or eBay can have numerous sellers, often providing competitive prices.

- Specialty Sites: Websites dedicated to outdoor equipment or engines often stock a vast array of necessary components.

Local Stores

If you prefer to shop in person, local retailers can be a great resource:

- Hardware Stores: Many local hardware stores carry a selection of components for small engines.

- Outdoor Equipment Dealers: Shops specializing in lawn and garden equipment often have a range of items suited for maintenance.

- Automotive Parts Stores: Some automotive parts retailers may also offer a selection of engine components.

Regardless of where you choose to shop, always verify that the components are compatible with your specific engine model to ensure optimal performance.

Exploring Upgrades and Enhancements

Improving the performance and longevity of your engine can significantly enhance its efficiency and functionality. By exploring various enhancements, users can achieve better output, increased reliability, and a smoother operation. This section will delve into various options available for upgrading your machine, focusing on common enhancements that can be easily implemented.

Several approaches can be taken to boost performance:

- Upgrade the air intake system for better airflow.

- Install a high-performance spark plug to improve ignition efficiency.

- Consider a new exhaust system to enhance exhaust flow and reduce back pressure.

- Replace the carburetor with a more efficient model for better fuel delivery.

- Use synthetic oils for improved lubrication and reduced friction.

Additionally, routine maintenance plays a crucial role in the overall performance of your engine. Regular checks and replacements can prevent potential issues:

- Change the oil and replace filters at recommended intervals.

- Inspect and clean the air filter regularly to ensure optimal airflow.

- Examine fuel lines for any signs of wear or leaks.

- Keep the spark plug clean and replace it if necessary.

By integrating these enhancements and adhering to a diligent maintenance schedule, users can maximize the performance and durability of their equipment, ensuring it operates efficiently for years to come.