When it comes to maintaining and repairing household equipment, a clear understanding of the various elements that contribute to its functionality is crucial. Each component plays a significant role in ensuring that the machine operates efficiently and effectively. Familiarizing yourself with these individual pieces can save both time and resources during maintenance tasks.

In this section, we will explore a comprehensive overview of essential elements used in modern appliances. By delving into their arrangements and relationships, users can gain insight into how these components interact, leading to a deeper appreciation for the technology at hand. This knowledge is not only beneficial for troubleshooting issues but also for optimizing performance.

Moreover, having a visual reference can significantly enhance your understanding. With an organized representation of the elements, you can easily identify specific parts and their functions, making the process of repair and maintenance much more straightforward. By equipping yourself with this information, you can achieve the ultimate goal of seamless appliance operation.

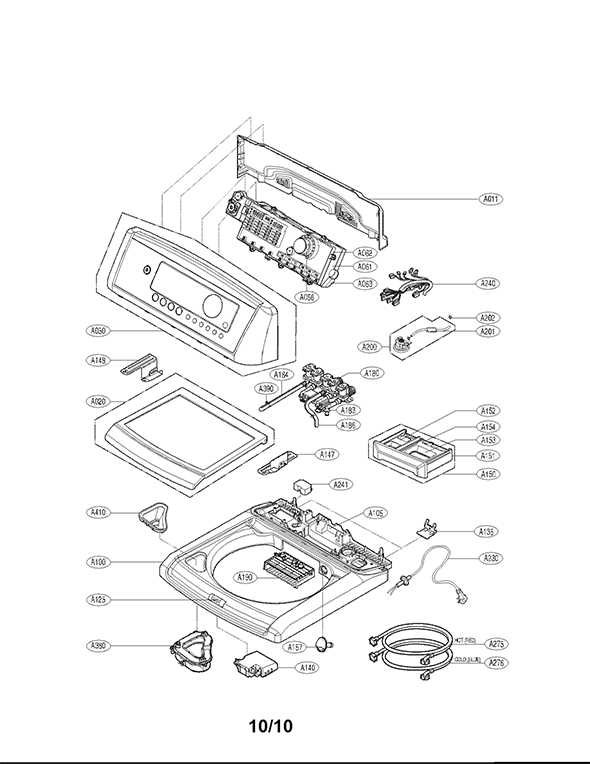

Moffat Washer Overview

This section provides insights into a popular appliance designed for cleaning textiles. Known for its efficiency and reliability, this equipment is essential in both commercial and residential settings.

Key features include:

- Robust construction for long-term use

- Advanced technology for optimal performance

- Energy-saving capabilities

Understanding its components can enhance maintenance and troubleshooting efforts:

- Drum assembly

- Motor and drive system

- Control panel functionalities

- Water inlet and drainage systems

Familiarity with these elements ensures effective operation and extends the lifespan of the appliance.

Key Components of Moffat Washers

This section explores the essential elements that contribute to the efficient functioning of commercial cleaning machines. Understanding these components is crucial for maintenance and optimal performance.

- Drum: The primary container where items are loaded for cleaning.

- Motor: Powers the movement of the drum, facilitating thorough cleaning.

- Control Panel: User interface for selecting cleaning cycles and settings.

- Heating Element: Increases water temperature to enhance cleaning efficiency.

- Drainage System: Removes used water after cleaning cycles.

Each of these elements plays a vital role in ensuring that the cleaning process is effective and reliable, making them indispensable for any operational setting.

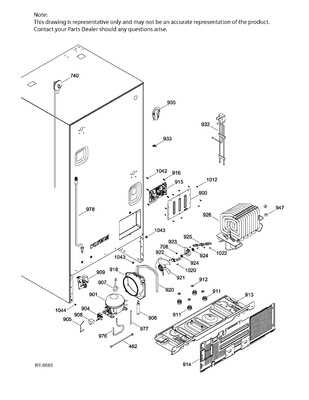

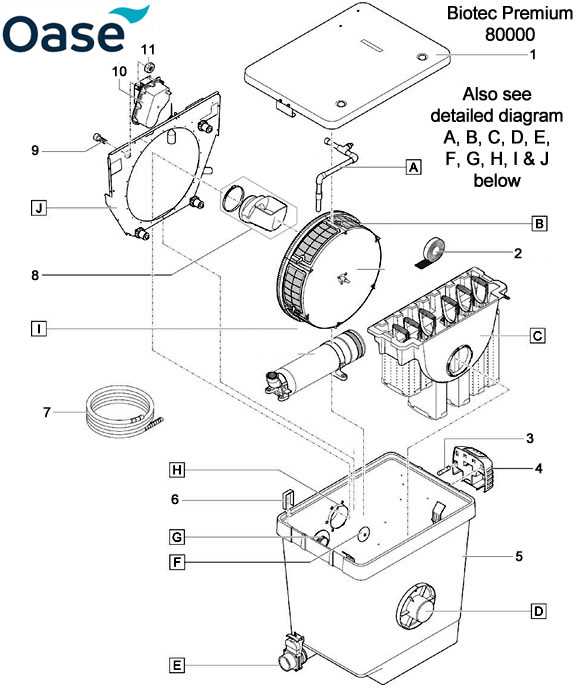

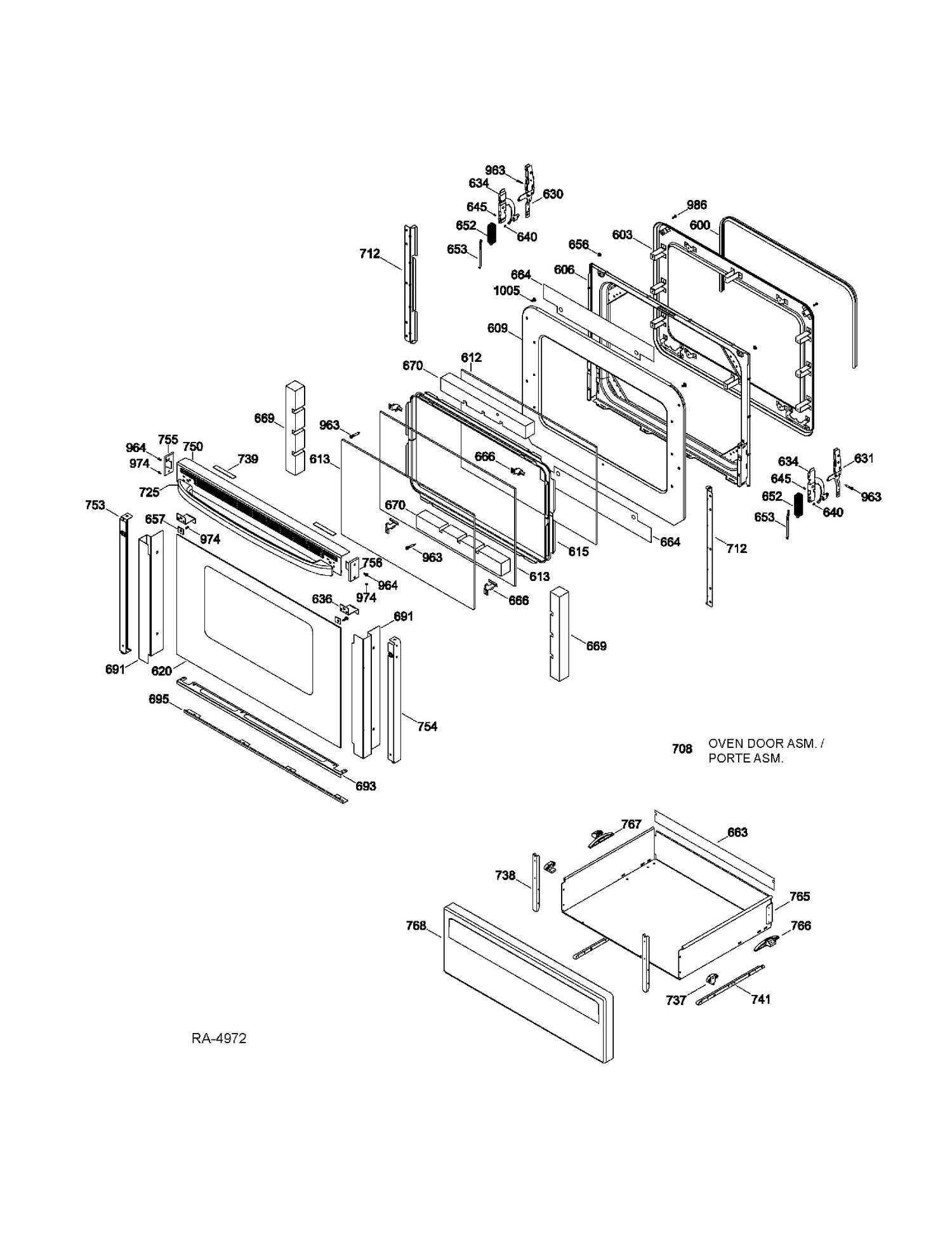

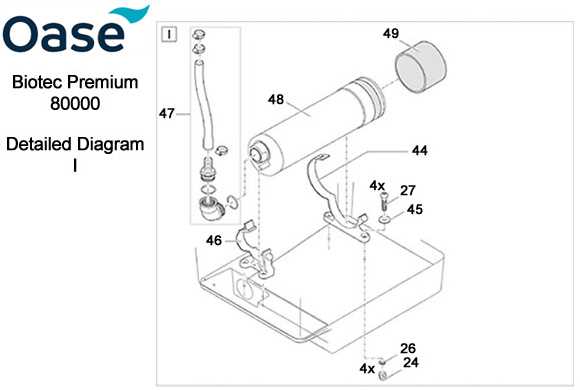

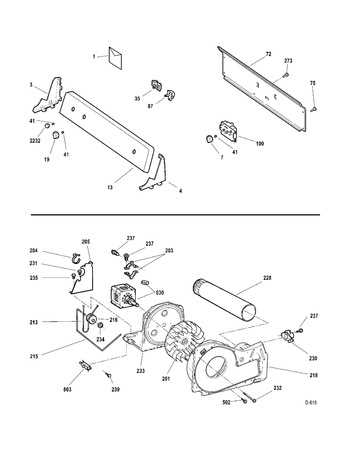

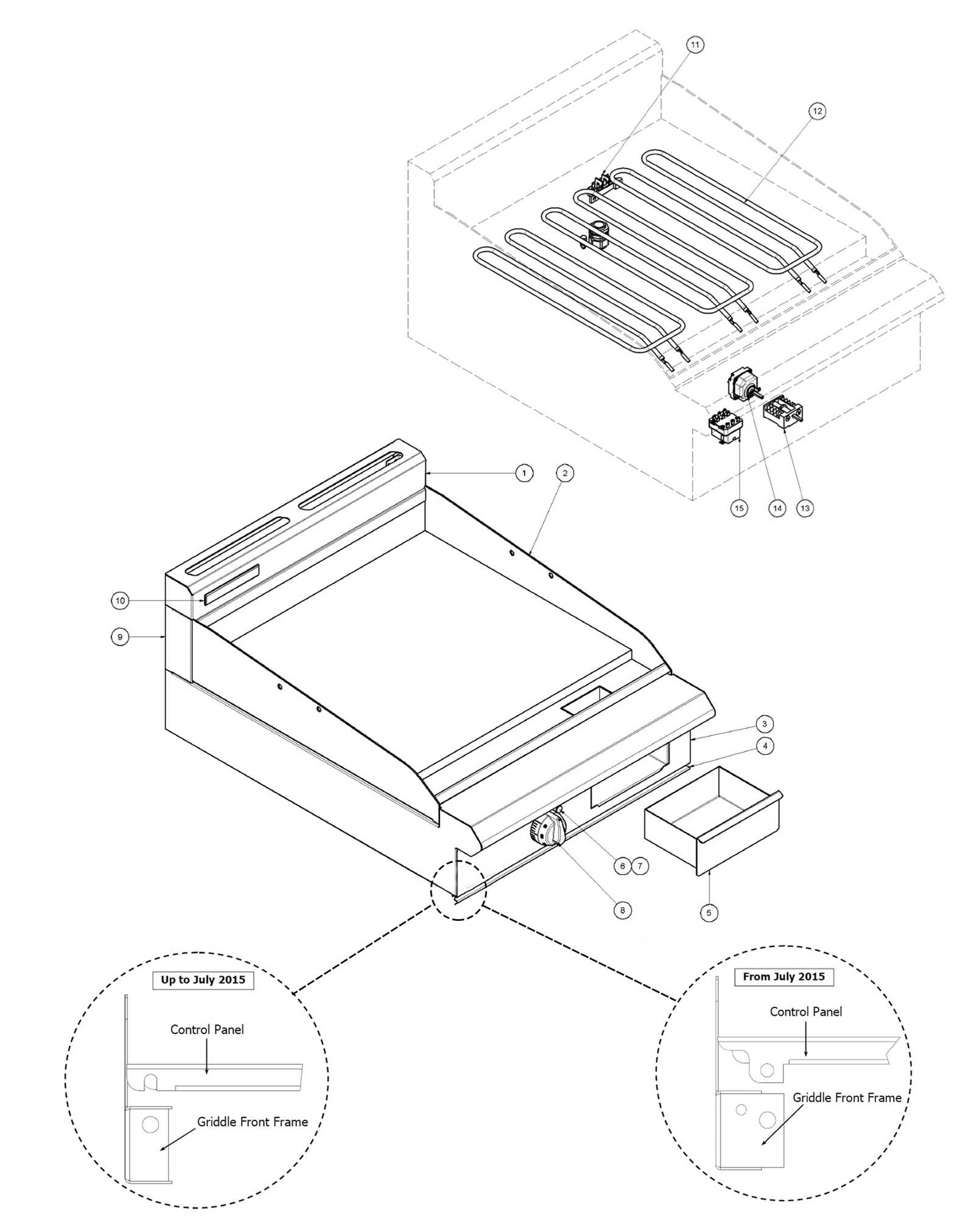

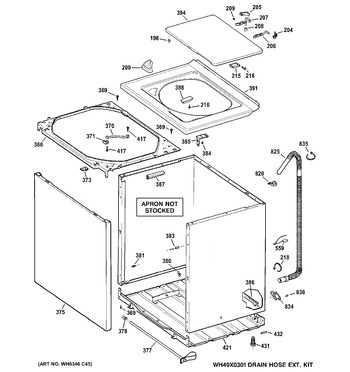

Understanding the Parts Diagram

Comprehending the illustration of components is essential for effective maintenance and troubleshooting. This visual representation serves as a guide, simplifying the complexities of assembly and aiding in the identification of individual elements. By familiarizing yourself with each section, you can enhance your ability to address issues promptly and efficiently.

The layout typically includes various labels and numbers corresponding to specific items, allowing for quick reference during repairs. Recognizing these identifiers streamlines the process of obtaining replacements or making adjustments.

| Label | Description | Function |

|---|---|---|

| 1 | Component A | Provides structural support |

| 2 | Component B | Facilitates movement |

| 3 | Component C | Ensures proper sealing |

| 4 | Component D | Regulates flow |

Utilizing this visual tool not only promotes better understanding but also empowers individuals to tackle maintenance tasks with confidence, minimizing downtime and enhancing overall efficiency.

Common Issues with Washer Parts

Understanding frequent problems that can arise in laundry appliances is essential for maintaining their efficiency and longevity. Many users encounter similar challenges, often related to performance, noise, and leaks. Identifying these issues early can prevent more significant breakdowns and costly repairs.

One of the most prevalent concerns is unusual sounds during operation. These can indicate loose components or worn bearings, which require prompt attention. Additionally, leaks are a common issue, often stemming from damaged seals or improper installation, leading to water damage and inefficiency.

Another significant problem involves failure to start or complete cycles. This may be due to electrical faults, clogged filters, or malfunctioning sensors. Regular maintenance checks can help in diagnosing these issues before they escalate, ensuring smooth operation.

Lastly, inconsistent cleaning results can point to various factors, including ineffective detergent use or blocked jets. Regular cleaning and inspection of these areas can enhance performance and ensure that fabrics are thoroughly cleaned.

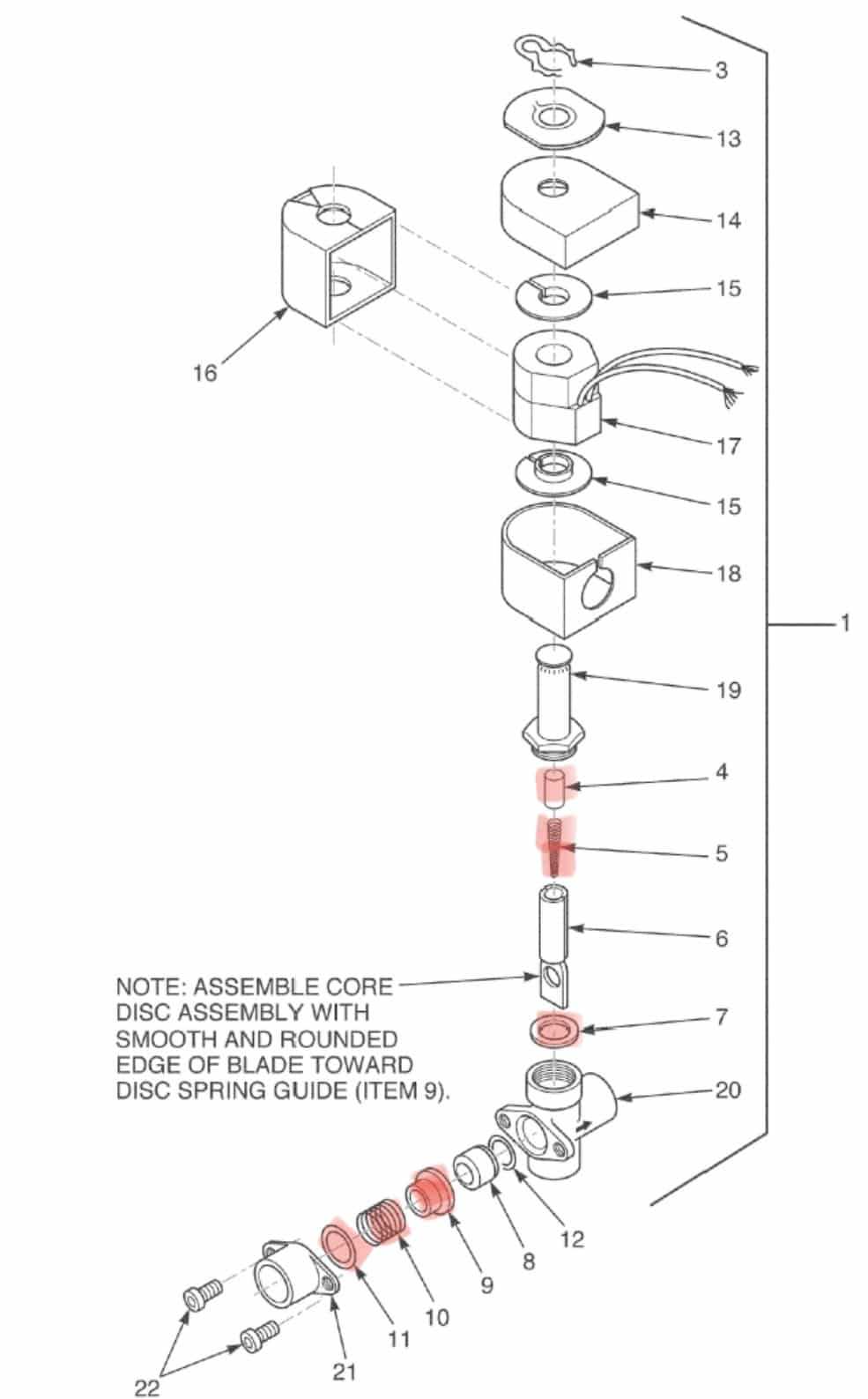

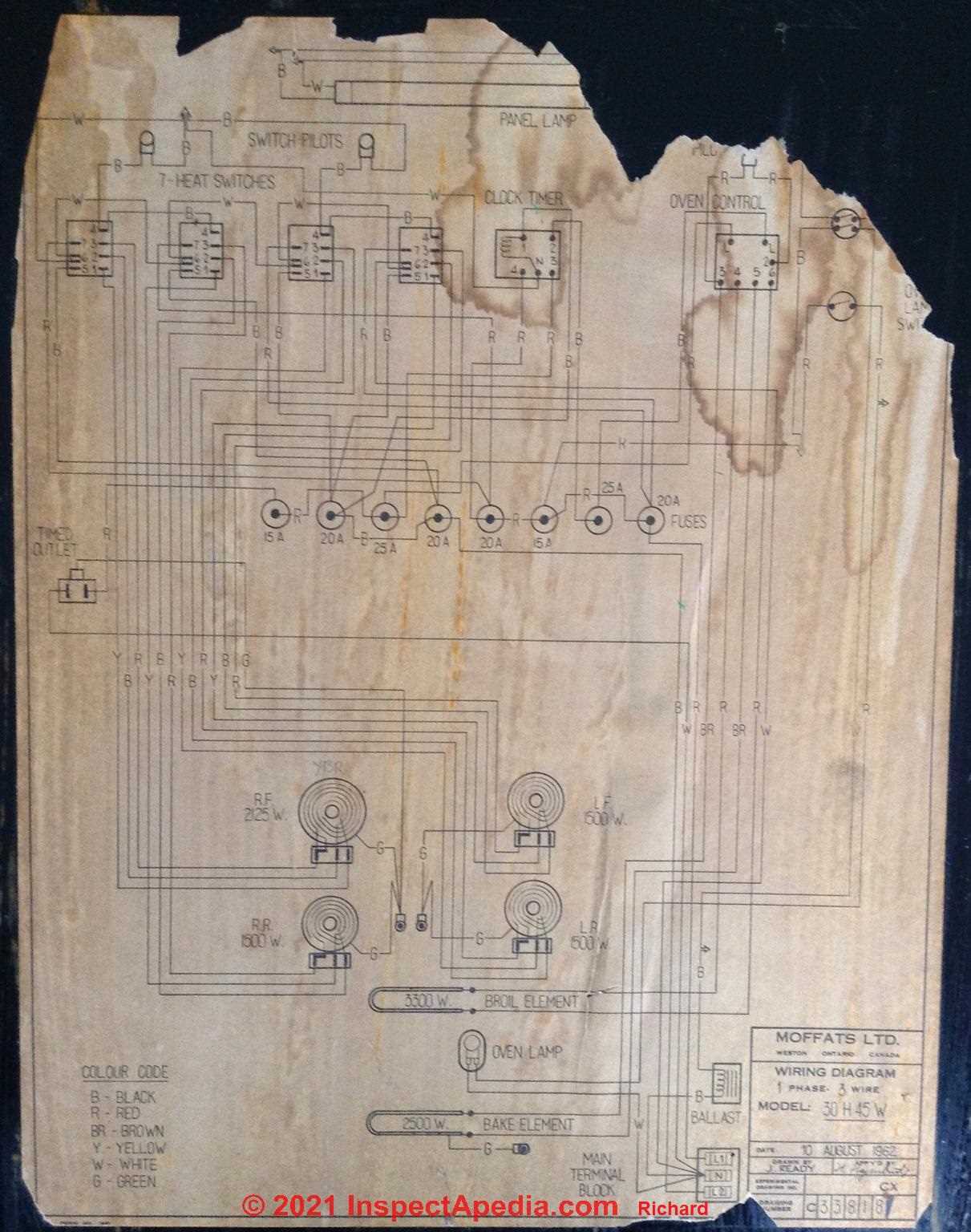

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repair. These illustrations provide a visual breakdown of various elements, helping users identify and locate each piece within a system. A clear grasp of this visual aid allows for smoother troubleshooting and more informed decision-making.

Familiarize yourself with the symbols used in the illustration. Each graphic typically represents a specific item or function, often accompanied by a label or code. Recognizing these symbols will streamline the process of locating parts and understanding their roles.

Pay attention to the layout. The arrangement of components often reflects their physical placement in the equipment. This spatial organization can reveal how parts interact with one another, highlighting essential connections and dependencies that might affect overall functionality.

Additionally, check the accompanying legend or key. This section usually provides definitions and explanations of the symbols, aiding in accurate interpretation. It may also include crucial information regarding part numbers and specifications, ensuring that replacements can be sourced correctly.

Lastly, take note of any annotations or notes included in the illustration. These can offer insights into assembly sequences, special instructions, or common issues related to specific components, enhancing your understanding of the entire system.

Identifying Wear and Tear

Recognizing the signs of deterioration is crucial for maintaining optimal functionality. Components can suffer from various forms of damage over time, which may lead to inefficiencies or complete failure. By carefully inspecting these elements, one can ensure longevity and performance.

Common Indicators

Look for fraying, cracks, or discoloration as primary signs of wear. These indicators often suggest that an item is approaching the end of its effective lifespan and may require immediate attention.

Maintenance Tips

Regular inspections and prompt replacement of worn elements can significantly enhance efficiency. Keeping a close eye on the functionality and appearance of each component is the ultimate way to prevent costly repairs and ensure optimal operation.

Replacement Parts Availability

Access to essential components is crucial for maintaining optimal functionality of your equipment. Knowing where to find reliable replacements ensures longevity and efficiency, ultimately enhancing performance.

Sources for Components

Various suppliers offer a range of solutions, from original manufacturers to third-party vendors. It’s important to consider quality and compatibility when selecting where to purchase.

Ordering Process

Most retailers provide online platforms for easy ordering. Verification of stock levels and delivery options is advisable to ensure timely receipt.

| Supplier | Availability | Delivery Time |

|---|---|---|

| Supplier A | In Stock | 2-3 Days |

| Supplier B | Limited Stock | 5-7 Days |

| Supplier C | Out of Stock | N/A |

Maintenance Tips for Moffat Washers

Regular upkeep is essential for ensuring optimal performance and longevity of your appliances. Adopting a routine maintenance schedule can prevent unexpected breakdowns and enhance efficiency, ultimately saving time and money.

Start by inspecting seals and gaskets for wear and tear, as these components are crucial for preventing leaks. Clean any residue or debris that may accumulate, particularly around the door and detergent compartments. This not only helps in maintaining hygiene but also ensures proper functioning.

Next, check the hoses for any signs of cracking or damage. Replace them if necessary, as compromised hoses can lead to significant issues. Additionally, ensure that all connections are secure to avoid any potential leaks.

Periodically, run a cycle with a cleaning agent designed for your specific model. This will help in removing any buildup that could affect performance. Always refer to the user manual for recommendations on cleaning products and methods.

Lastly, consider scheduling professional inspections annually. This proactive approach can identify potential problems before they escalate, providing peace of mind and ensuring your equipment operates at its best.

Installation Guide for New Parts

This section provides a comprehensive approach to replacing essential components in your appliance. Proper installation is crucial for optimal performance and longevity, ensuring that your equipment functions efficiently after the upgrade.

Before you begin, make sure you have all the necessary tools and components at hand. Here’s a brief overview of the steps involved in the process:

- Gather the required tools, including a screwdriver, pliers, and any specialty items needed for your specific model.

- Ensure you have the correct replacements that match the specifications of your appliance.

- Unplug the appliance from the power source to guarantee safety during installation.

Follow these detailed steps for the installation:

- Remove the old components:

- Identify and carefully detach the existing pieces, taking care to avoid damaging surrounding areas.

- Store screws and small parts in a container to prevent loss.

- Prepare the new components:

- Inspect the replacements for any damage before installation.

- Refer to the instruction manual for any specific guidelines related to your model.

- Install the new components:

- Position the new items in place, ensuring a secure fit.

- Tighten screws and connectors without over-tightening to avoid damage.

- Test the installation:

- Reconnect the appliance to the power source.

- Run a test cycle to ensure everything is functioning as intended.

Following these instructions will help ensure a smooth installation process, restoring your appliance to full working order.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety should be a top priority. Proper precautions can prevent accidents and injuries, creating a secure environment for both the technician and the equipment. Awareness and preparation are key to a successful repair process.

Essential Safety Measures

- Always disconnect power sources before beginning any work to avoid electric shock.

- Use appropriate personal protective equipment (PPE), such as gloves and goggles, to protect against potential hazards.

- Ensure the work area is well-lit and free of clutter to minimize risks of trips or falls.

Handling Tools and Materials

- Inspect tools before use to ensure they are in good condition.

- Store tools safely when not in use to prevent accidents.

- Follow manufacturer instructions for handling and disposing of materials and components.

Comparing Models and Their Parts

This section explores the nuances among different units, emphasizing their unique components and functionalities. Understanding these variations is crucial for making informed decisions when selecting the right equipment for specific needs.

Key Variations in Design

Each model showcases distinctive attributes that cater to various operational requirements. Durability and efficiency are often prioritized, influencing the choice of materials and construction methods.

Component Functionality

While many units share similar mechanisms, the ultimate performance can vary significantly. Features such as control systems and user interfaces may differ, affecting overall usability and satisfaction.

Frequently Asked Questions

This section aims to address common inquiries related to the components and their assembly in various machinery. Here, you will find answers that clarify doubts and provide insights for effective maintenance and understanding.

-

What are the essential components involved in the assembly?

The main elements typically include seals, springs, and various fastening devices. Each plays a critical role in ensuring optimal functionality.

-

How do I identify a specific component?

Components can usually be recognized by their shapes and sizes. Referencing detailed guides or schematics can aid in accurate identification.

-

What are common issues that may arise?

- Wear and tear over time

- Incorrect installation

- Material degradation due to environmental factors

-

How can I ensure proper maintenance?

Regular inspections, cleaning, and timely replacements of worn items can significantly extend the lifespan of the machinery.

-

Where can I find replacement components?

Replacement items are often available through specialized suppliers or authorized distributors. Online marketplaces also provide a wide range of options.