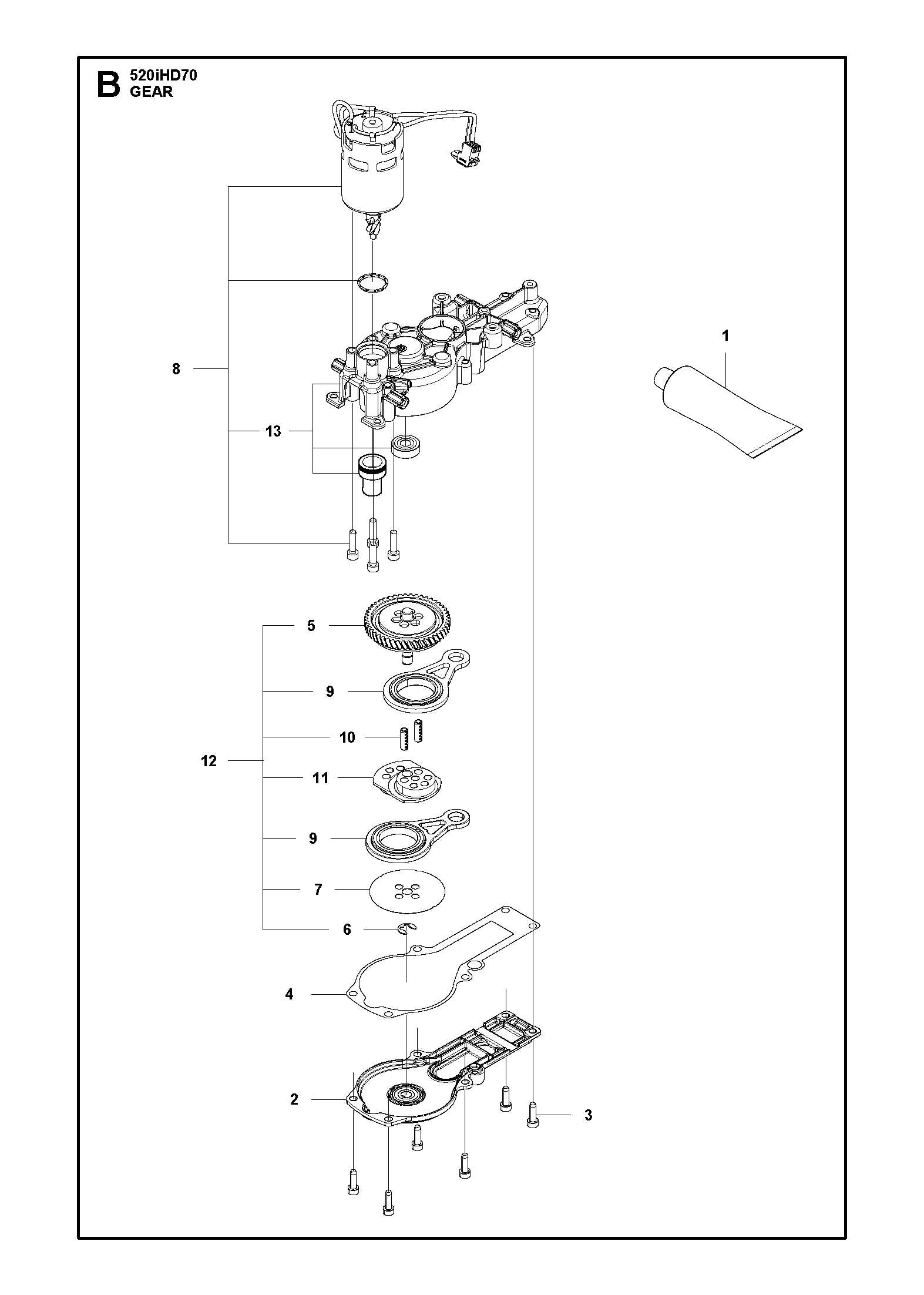

Maintaining a lush, healthy lawn often requires a reliable machine designed for precision and efficiency. Understanding the various components that contribute to the overall functionality of such equipment is essential for effective maintenance and repairs. A detailed representation of these elements can be invaluable, providing insight into their arrangement and interconnectivity.

When working on machinery, having a clear visual reference of the individual sections can significantly simplify the process of identifying issues or performing upgrades. Each part plays a crucial role in ensuring optimal performance, and knowing how they fit together allows for more informed decision-making during maintenance. This knowledge can lead to improved longevity and efficiency of the equipment.

In this article, we will explore an illustrative layout that showcases the configuration of essential elements found in various lawn care machines. By examining this schematic, users will gain a deeper understanding of how to approach repairs, replacements, and enhancements with confidence.

Kubota ZD326 Overview

This section provides an insight into a specific model known for its efficiency and versatility in landscape management. Designed for various tasks, it caters to both residential and commercial needs, offering reliable performance in maintaining outdoor spaces.

Key Features

- Powerful engine for enhanced productivity

- Durable construction suitable for tough conditions

- Ergonomic design for user comfort

- Efficient cutting capabilities for a pristine finish

Applications

- Residential lawn care

- Commercial landscaping

- Golf course maintenance

- Parks and recreational areas management

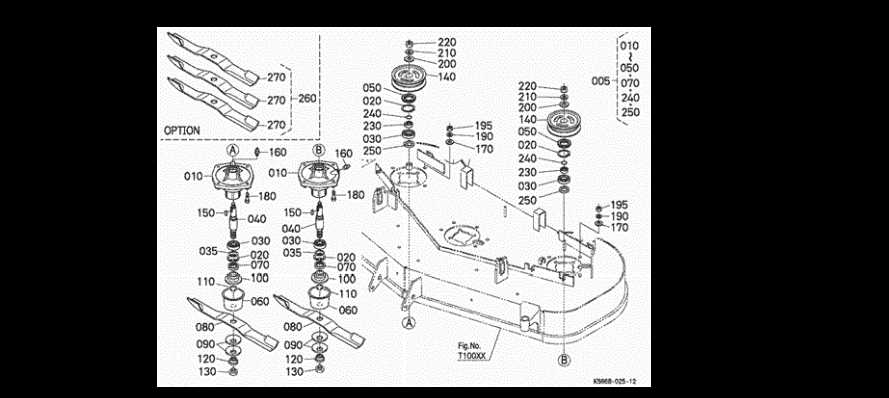

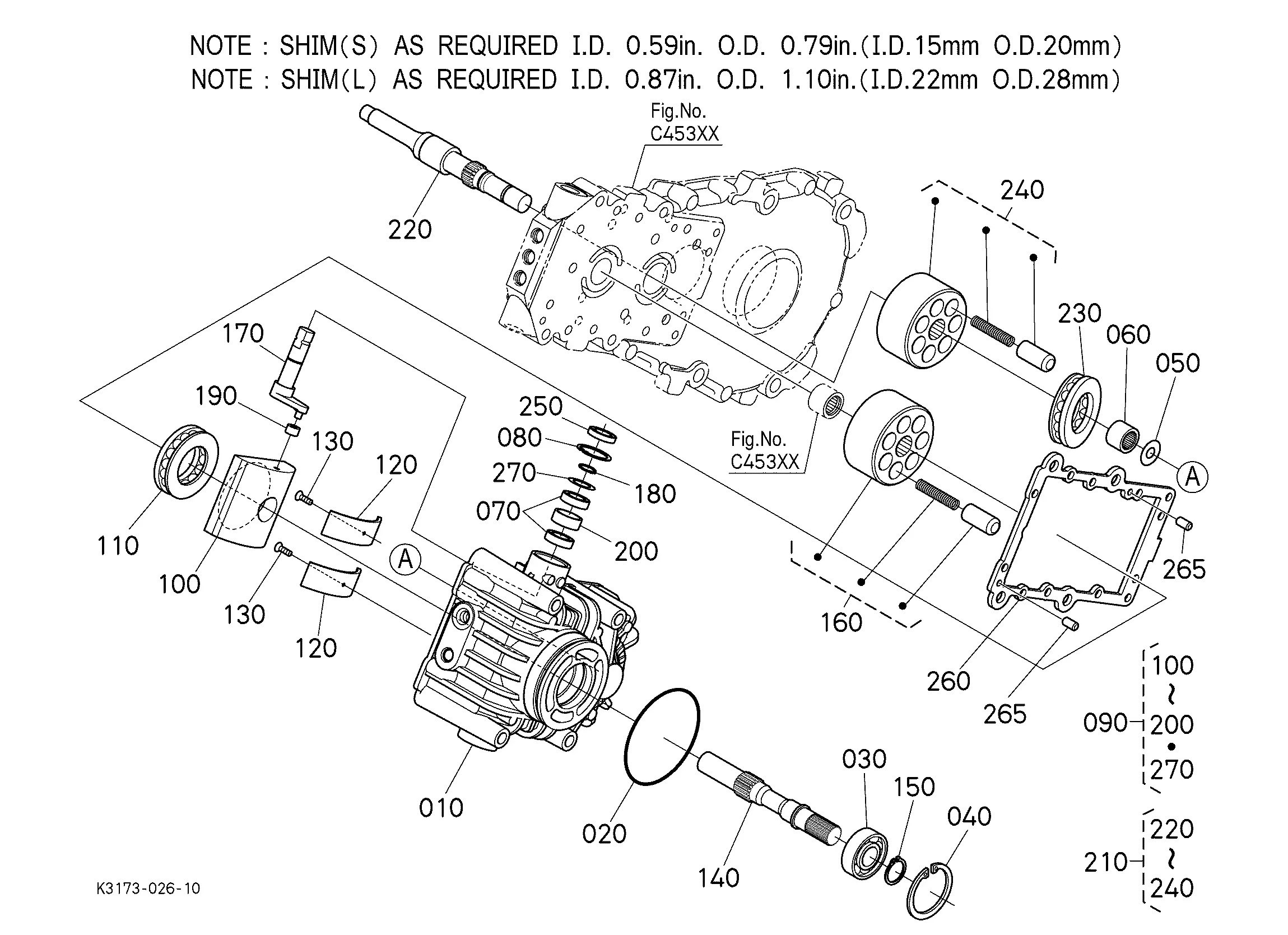

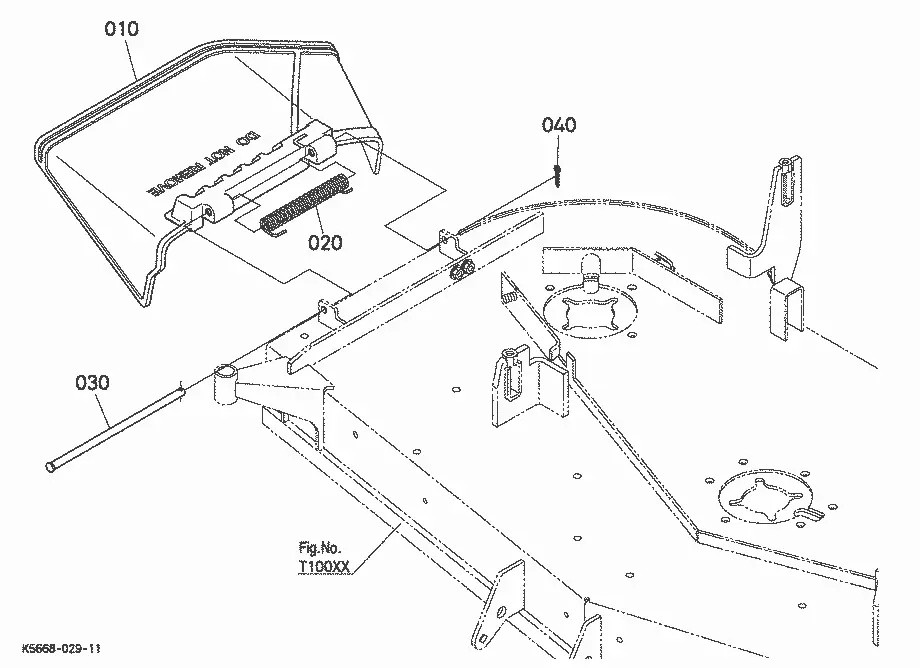

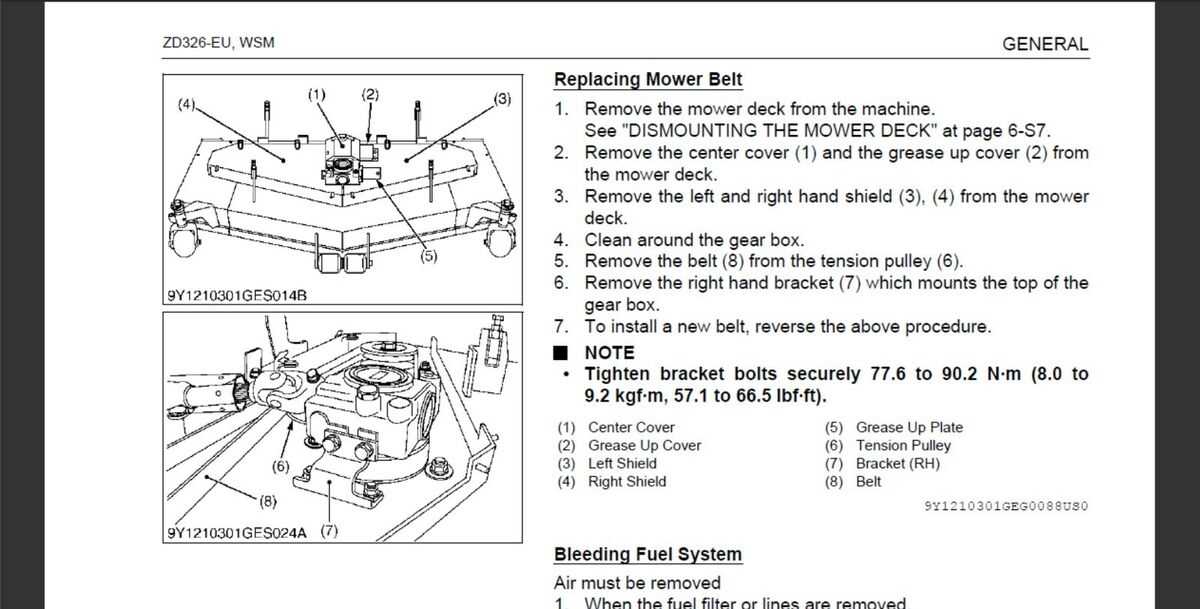

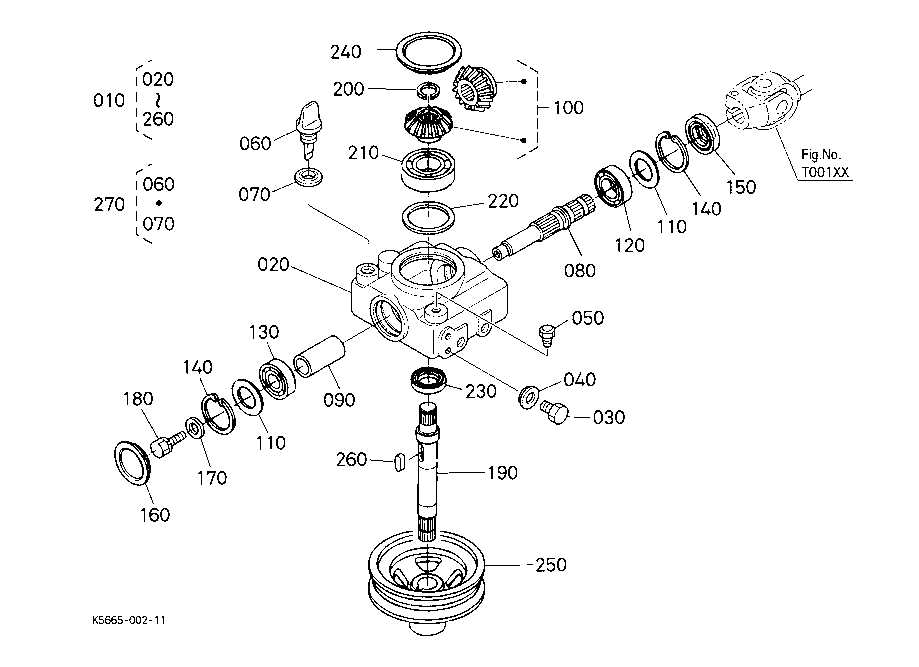

Importance of Deck Parts Diagram

A clear representation of component layout is essential for effective maintenance and repair tasks. Such visuals facilitate a deeper understanding of how individual elements interact, ensuring efficient troubleshooting and assembly. This clarity helps users avoid errors that can arise from guesswork, ultimately leading to improved performance and longevity of the machinery.

Moreover, having access to these illustrations enhances the overall user experience, allowing operators to confidently navigate complex assemblies. This not only saves time but also reduces the risk of damage during repairs. Understanding the configuration empowers users to make informed decisions regarding upgrades or replacements, optimizing functionality.

Common Issues with Kubota ZD326

When operating high-performance mowing equipment, users often encounter various challenges that can hinder efficiency and performance. Understanding these common problems is essential for maintenance and ensuring smooth operation.

Engine Performance Problems

One prevalent issue is engine performance inconsistencies, which can manifest as reduced power or difficulty starting. These symptoms may stem from fuel quality, air filter clogs, or spark plug malfunctions, all of which require timely attention to restore optimal functionality.

Cutting Quality Issues

Another frequent concern involves cutting quality. Users may notice uneven grass height or streaking patterns, typically caused by dull blades or improper leveling of the cutting unit. Regular maintenance and blade sharpening are crucial for achieving a pristine cut.

How to Access the Diagram

Accessing the visual representation of components is essential for effective maintenance and repair. Knowing how to locate and interpret this information can greatly enhance your understanding of the machinery.

Here are some steps to help you find the schematic you need:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for links related to manuals or technical documents.

- Search for the specific model or type of equipment.

- Download the appropriate documentation in PDF format.

Additionally, consider the following sources:

- Online forums and communities dedicated to machinery.

- Third-party retailers specializing in equipment parts.

- Local dealers who may provide printed resources.

By utilizing these resources, you can efficiently access the necessary visual aids for your maintenance tasks.

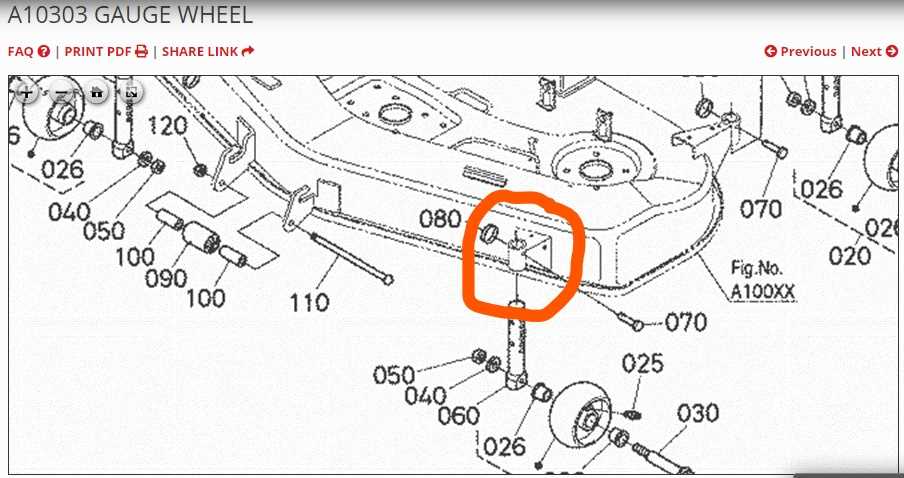

Understanding Deck Component Functions

This section explores the various elements involved in a cutting platform, focusing on their specific roles and importance in overall performance. Each component contributes uniquely to the efficiency and effectiveness of the mowing process.

- Cutting Blades: Essential for achieving a clean cut, these sharpened edges are designed to slice through grass with precision.

- Spindle Assembly: This mechanism supports the blades and ensures they rotate smoothly, contributing to uniform cutting height.

- Deck Housing: The sturdy structure that encases the blades, it provides protection and helps direct the flow of clippings.

- Anti-Scalp Wheels: Positioned to prevent the cutting edges from touching the ground, these wheels help maintain a consistent height.

- Lift Mechanism: This system allows for easy elevation and lowering of the cutting platform, providing flexibility for different mowing conditions.

Understanding these components helps users appreciate their individual contributions to overall functionality and performance.

Maintenance Tips for Deck Parts

Proper upkeep of your lawn care equipment is essential for ensuring its longevity and optimal performance. Regular attention to individual components can prevent premature wear and enhance functionality. Here are some effective strategies to maintain these critical elements of your machine.

Firstly, routinely inspect the blades for sharpness and integrity. Dull or damaged blades not only compromise cutting efficiency but can also strain the engine. Sharpen or replace them as necessary to achieve a clean, even cut.

Next, check all fasteners and connections. Vibration during operation can lead to loosening over time, which may affect stability and performance. Ensure everything is securely tightened and replace any missing or damaged fasteners to maintain safety and effectiveness.

Additionally, keep all surfaces clean and free from debris. Accumulated grass clippings and dirt can obstruct functionality and lead to rust or corrosion. A thorough cleaning after each use will help preserve the equipment’s condition.

Finally, lubricate moving parts as specified in the manufacturer’s guidelines. Regular lubrication reduces friction, which can lead to wear and tear, ensuring smooth operation and extending the lifespan of the equipment.

Identifying Replacement Parts

Understanding how to find the right components for maintenance can significantly enhance the performance and longevity of your machinery. This section aims to provide a clear guide for recognizing and selecting suitable alternatives when the need arises.

To effectively identify components, consider the following steps:

- Refer to the user manual for specific details regarding each component.

- Examine any existing labels or stamps on the items to gather information.

- Utilize online resources to access diagrams and catalogs that illustrate similar parts.

When searching for replacements, keep these tips in mind:

- Check compatibility with your specific model.

- Look for reputable suppliers to ensure quality and reliability.

- Consider aftermarket options if original components are unavailable.

Using the Diagram Effectively

Understanding a visual representation of components is crucial for efficient maintenance and repair. By leveraging this illustration, users can quickly identify individual elements and their relationships, ensuring proper functionality and longevity of the equipment.

To maximize the benefits of the illustration, follow these steps:

| Step | Action |

|---|---|

| 1 | Familiarize yourself with the layout and key features of the representation. |

| 2 | Identify the specific components you need to inspect or replace. |

| 3 | Cross-reference with your manual for detailed instructions on each part. |

| 4 | Organize your tools and parts before starting the task to streamline the process. |

| 5 | Refer back to the visual as needed during assembly or disassembly. |

By following these guidelines, you can enhance your efficiency and ensure accurate repairs, ultimately prolonging the lifespan of your machinery.

Where to Find Genuine Parts

Finding authentic components for your machinery is essential for optimal performance and longevity. Various sources can help ensure you acquire high-quality items that fit your needs perfectly.

Authorized Dealers

- Visit local distributors for reliable selections.

- Inquire about warranty and return policies.

- Check if they offer installation services.

Online Retailers

- Explore e-commerce websites specializing in machinery supplies.

- Look for customer reviews to gauge reliability.

- Verify that the site offers genuine components by checking certifications.

Tools Needed for Repairs

Effective maintenance and repair of machinery require a specific set of instruments to ensure that tasks are completed efficiently and safely. Utilizing the right tools not only simplifies the process but also enhances the quality of the work performed. Below is a list of essential tools that can aid in the repair process.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For driving screws in and out of components. |

| Socket Set | For working with various sizes of nuts and bolts. |

| Pliers | For gripping, twisting, and cutting wires or fasteners. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Diagnostic Tools | To troubleshoot and identify issues within the system. |

| Cleaning Supplies | For maintaining the cleanliness of components during repairs. |

Equipping yourself with these essential tools will ensure a smoother repair process and help maintain the longevity and efficiency of your machinery.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components for specific outdoor equipment. Understanding these elements can enhance your experience and ensure optimal performance.

-

What are the common issues faced with outdoor machinery?

Users often report problems such as uneven cutting, engine difficulties, and wear on specific components. Regular maintenance can help mitigate these issues.

-

How can I identify parts that need replacement?

Signs of wear include unusual noises, vibrations, and decreased efficiency. Regular inspections and following manufacturer guidelines can assist in identifying necessary replacements.

-

Where can I find replacement components?

Replacement items can typically be found at authorized retailers, online marketplaces, or through specialized suppliers. Ensure compatibility with your specific model before purchasing.

-

How often should maintenance be performed?

Routine checks should be done at the beginning of each season, with more frequent inspections during heavy use. Follow the recommendations in the user manual for detailed guidance.

-

Can I perform repairs myself?

Many repairs can be handled by owners with basic mechanical skills. However, for complex issues, it is advisable to consult a professional technician.