In the realm of farming machinery, comprehending the intricate layout of various elements is crucial for effective maintenance and repair. Each component plays a pivotal role in ensuring optimal performance, and having a clear visual representation can significantly simplify troubleshooting and servicing tasks.

Familiarizing oneself with the structure and functionality of these elements not only aids in the longevity of the equipment but also enhances overall efficiency in agricultural operations. A well-organized reference can serve as a valuable tool for both seasoned professionals and newcomers in the industry.

By delving into the specific arrangements and connections of these components, operators can better appreciate how each part contributes to the machine’s overall operation. This knowledge empowers users to make informed decisions, whether it’s for upgrades, replacements, or routine inspections.

Understanding Ford 6600 Tractor Components

The intricacies of agricultural machinery involve a variety of crucial elements that work in unison to ensure optimal performance. Each component plays a vital role in the overall functionality, contributing to efficiency and durability in demanding environments. A comprehensive understanding of these parts is essential for maintenance and operation.

Key Elements of the Machinery

Among the various components, the engine serves as the powerhouse, driving all operations. Coupled with the transmission system, it facilitates movement and power transfer. Other important parts include the hydraulic system, which enhances maneuverability and implements versatility, and the electrical system, ensuring reliable ignition and operation of essential functions.

Importance of Maintenance

Regular upkeep of these elements not only prolongs the lifespan of the equipment but also enhances its performance. Identifying wear and tear in specific components allows for timely interventions, ensuring that the machinery operates at its ultimate efficiency. Investing in proper care is key to achieving long-term success in agricultural tasks.

Importance of Accurate Parts Diagrams

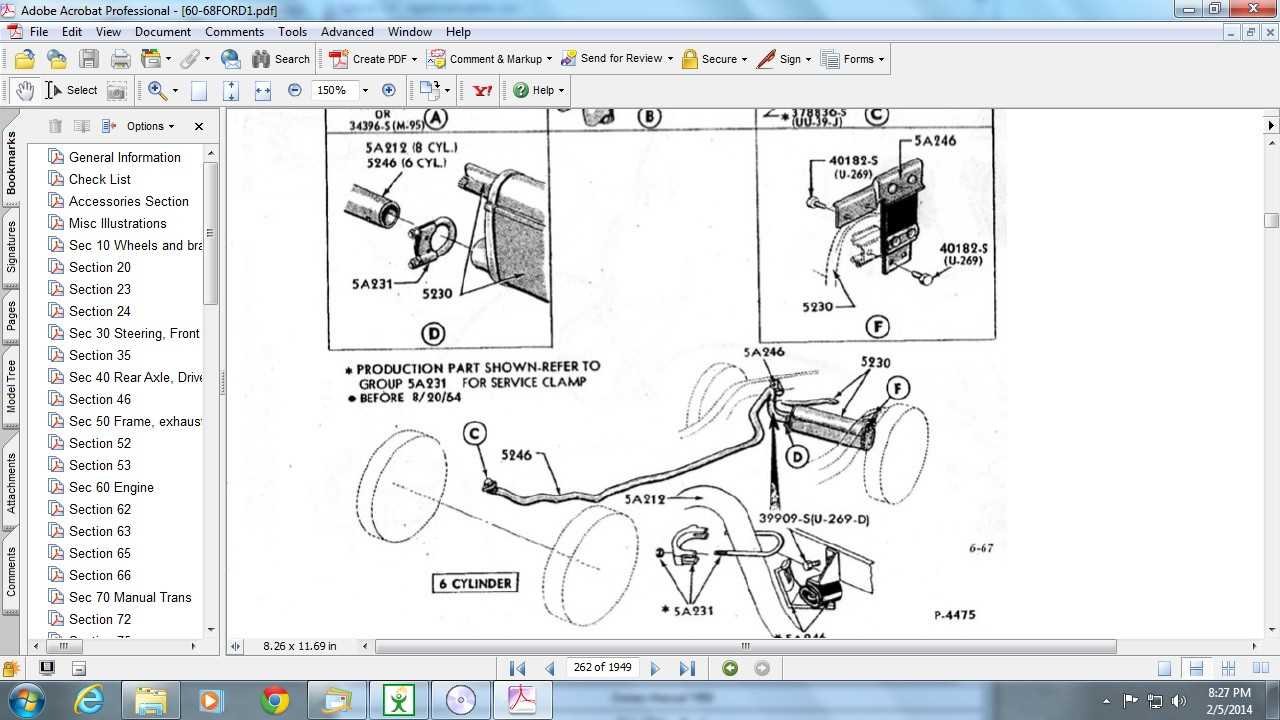

Precise visual representations of components are essential for efficient maintenance and repair of machinery. They serve as a vital reference, ensuring that every piece is correctly identified and installed, which ultimately enhances the functionality and longevity of the equipment.

Inaccuracies in these illustrations can lead to improper assembly, costly errors, and potential safety hazards. Therefore, having a reliable source of information is crucial for both professionals and enthusiasts alike.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp the assembly and functionality of each component. |

| Time Efficiency | Accurate references reduce time spent searching for the right elements. |

| Cost Reduction | Minimizing mistakes leads to savings on repairs and replacements. |

| Improved Safety | Proper assembly mitigates risks associated with equipment malfunction. |

Key Features of the Ford 6600

This section explores the remarkable attributes of a renowned agricultural machine known for its efficiency and versatility. Understanding these characteristics helps users appreciate its capabilities in various farming tasks.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that provides excellent torque and performance. |

| Durable Build | Constructed with high-quality materials, ensuring longevity and reliability under demanding conditions. |

| User-Friendly Controls | Designed with intuitive controls, facilitating ease of use for operators of all experience levels. |

| Versatile Attachments | Compatible with a wide range of attachments, enhancing functionality across different tasks. |

| Efficient Fuel Consumption | Engineered for optimal fuel efficiency, reducing operational costs during extensive use. |

Common Issues with Ford 6600 Parts

When dealing with machinery, several common challenges often arise that can affect performance and efficiency. Understanding these issues is crucial for maintenance and longevity. Identifying potential problems early can save time and resources in the long run.

Frequent Malfunctions

Several components may encounter wear and tear, leading to operational difficulties. Regular inspection can help in detecting these issues before they escalate.

Replacement Considerations

Choosing the right replacements is vital. Compatibility and quality can greatly influence the performance of the equipment.

| Component | Common Issue | Solution |

|---|---|---|

| Engine | Overheating | Check coolant levels and radiator functionality. |

| Hydraulic System | Leaks | Inspect hoses and seals for wear. |

| Transmission | Slipping Gears | Regularly check fluid levels and condition. |

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Whether you require specific items for maintenance or upgrades, a variety of sources can provide what you need. Below are some reliable options for sourcing these essentials.

- Authorized Dealers: Start by checking with official dealerships. They often carry a comprehensive selection of original components that guarantee compatibility and quality.

- Online Retailers: Numerous e-commerce platforms specialize in machinery supplies. Websites like Amazon, eBay, and specialized machinery sites can be treasure troves for various items.

- Local Suppliers: Visit nearby agricultural supply stores or hardware outlets. Many of these retailers stock common components and can order specific items if they’re not readily available.

- Salvage Yards: Consider visiting salvage or junk yards that specialize in machinery. You may find used parts at a fraction of the cost, often in good condition.

- Forums and Online Communities: Engage with online forums or social media groups focused on machinery. Members often share where to find hard-to-source items or even sell them directly.

By exploring these avenues, you can efficiently find the necessary components to keep your equipment running smoothly.

Maintaining Your Ford 6600 Tractor

Regular upkeep is essential for ensuring the longevity and efficiency of your agricultural machinery. By adhering to a consistent maintenance schedule, you can prevent breakdowns, enhance performance, and ultimately protect your investment. This section will outline key practices that contribute to the smooth operation of your equipment.

Routine Inspections

Conducting frequent assessments is vital. Check fluid levels, including engine oil, coolant, and hydraulic fluids, to ensure they are within recommended ranges. Look for any signs of wear or damage in belts, hoses, and tires. Addressing minor issues promptly can save you from costly repairs down the line.

Cleaning and Lubrication

Keeping your machinery clean is crucial for optimal performance. Remove dirt, debris, and grease from components to prevent corrosion and overheating. Additionally, apply lubricant to moving parts as recommended in the owner’s manual to reduce friction and wear. This practice will not only extend the lifespan of your equipment but also improve its overall efficiency.

Step-by-Step Repair Guide

This section provides a detailed approach to effectively addressing mechanical issues in agricultural machinery. Following a structured method ensures a thorough and efficient resolution, allowing operators to maintain optimal performance.

Tools and Materials Needed

- Socket set

- Wrenches

- Screwdrivers

- Replacement components

- Lubricants and sealants

- Safety gear (gloves, goggles)

Repair Steps

- Begin by disconnecting the power source to ensure safety during the repair process.

- Identify the specific issue by conducting a thorough inspection of the machinery.

- Refer to the technical manual for guidance on the assembly and disassembly of components.

- Carefully remove the faulty component using the appropriate tools.

- Inspect surrounding parts for any additional wear or damage.

- Install the new or repaired component, ensuring it is secure and properly aligned.

- Reassemble any removed parts, making sure to follow the reverse order of disassembly.

- Reconnect the power source and perform a test run to verify the repair.

By following these steps, operators can enhance the longevity and reliability of their machinery, ensuring that it operates at peak efficiency.

Comparing Aftermarket and OEM Parts

When it comes to machinery components, the choice between original equipment and alternative options can significantly impact performance and longevity. Understanding the differences can aid in making informed decisions that affect maintenance and operational efficiency.

Original equipment manufacturer (OEM) items are designed to meet the exact specifications set by the original creators, ensuring compatibility and reliability. These components often come with warranties and have undergone rigorous testing, providing peace of mind to users.

On the other hand, aftermarket alternatives may offer cost savings and a wider variety of choices. While they can be engineered to fit similar functions, quality and performance can vary widely among manufacturers. Investing in these options requires careful consideration of brand reputation and customer reviews.

Ultimately, the decision hinges on balancing cost, quality, and performance needs, allowing users to tailor their choices to their specific requirements and budget constraints.

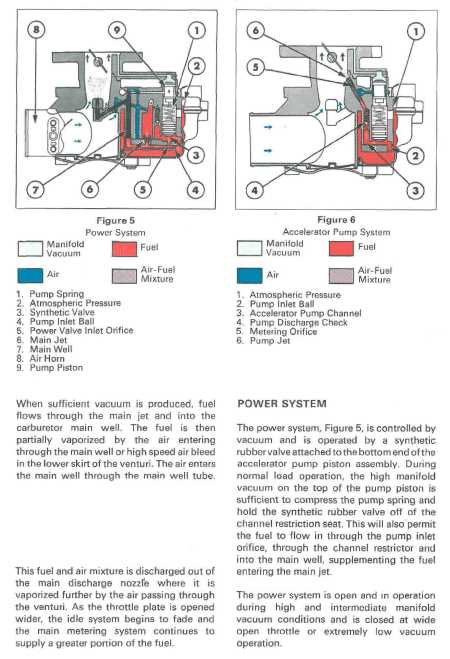

Using Diagrams for Efficient Repairs

Utilizing visual representations during maintenance tasks significantly enhances understanding and execution. These illustrations serve as valuable guides, providing clear insights into the assembly and functioning of various components.

Accurate schematics streamline the repair process by minimizing confusion and reducing the likelihood of errors. Technicians can easily identify parts and their respective placements, ensuring a smooth workflow.

Moreover, comprehending complex systems becomes more manageable with these resources, allowing for quicker diagnostics and targeted interventions. This ultimately leads to improved efficiency and cost-effectiveness in maintenance operations.

Tips for Identifying Components

Understanding the various elements of machinery can greatly enhance your ability to maintain and repair it effectively. Here are some strategies to help you recognize and differentiate between the different parts.

- Consult Manuals: Always refer to the manufacturer’s manuals for detailed descriptions and images.

- Visual Inspection: Carefully examine each component for labels, serial numbers, or distinctive shapes.

- Group Similar Parts: Categorize elements into groups based on function, which can aid in identification.

- Use Online Resources: Take advantage of forums and websites dedicated to machinery to find additional information.

- Ask Experts: Don’t hesitate to reach out to professionals who can provide insight into specific components.

By following these tips, you can ultimately improve your ability to identify and understand the elements that make up your machinery.

Benefits of Regular Maintenance Checks

Conducting routine inspections is essential for ensuring the longevity and efficiency of machinery. Regular upkeep helps identify potential issues before they escalate, promoting optimal performance and reliability.

Enhanced Performance

- Improves operational efficiency.

- Reduces the likelihood of breakdowns.

- Ensures all components function at their best.

Cost Savings

- Prevents costly repairs by catching problems early.

- Extends the lifespan of equipment.

- Optimizes fuel consumption and resource usage.

Expert Resources for Ford 6600 Owners

Owning a robust agricultural machine requires access to a variety of specialized resources. From maintenance guides to community forums, having the right information at hand can significantly enhance the ownership experience. This section aims to provide valuable references that will assist owners in optimizing performance and troubleshooting any issues that may arise.

Online Communities and Forums

Engaging with fellow enthusiasts through online platforms can be incredibly beneficial. These communities often share firsthand experiences, solutions to common problems, and maintenance tips. Joining forums dedicated to machinery enthusiasts can foster a sense of camaraderie and provide instant access to a wealth of knowledge.

Official Manuals and Guides

Accessing official documentation is crucial for understanding the specifications and operational procedures of your machine. Comprehensive manuals often include detailed instructions for routine maintenance, troubleshooting, and safety guidelines. These resources ensure that owners are well-informed and equipped to keep their equipment in optimal condition.

Community Forums and Support Groups

Engaging with online communities can significantly enhance your understanding and maintenance of agricultural machinery. These platforms provide a space for enthusiasts and professionals to share knowledge, experiences, and solutions to common challenges.

Joining a support group allows individuals to delve into discussions about specific issues, seek advice, and exchange tips on efficient upkeep. Members often share diagrams, manuals, and personal anecdotes that can guide newcomers through complex repairs.

Participating in these forums not only fosters a sense of community but also serves as a valuable resource for anyone seeking the ultimate knowledge and support in machinery management.