Maintaining a pristine lawn requires an understanding of the various components that contribute to the effective operation of your landscaping equipment. Each element plays a crucial role in ensuring that the machine functions smoothly and delivers optimal performance. A comprehensive overview of these components not only aids in routine maintenance but also enhances the longevity of the equipment.

In this section, we will delve into the intricacies of the key components of your landscaping apparatus. From the cutting mechanism to the housing structure, every part is designed to work in harmony with the others. Familiarizing yourself with these elements will empower you to make informed decisions when it comes to repairs and upgrades, ensuring your equipment remains in peak condition.

By breaking down the essential features and their respective functions, you will gain valuable insights that can enhance your understanding of how each component contributes to the overall effectiveness of your landscaping tools. This knowledge is essential for any user aiming to optimize performance and achieve superior results in lawn care.

Overview of John Deere X300 Mowers

This section provides insights into a popular model of residential lawn care equipment, highlighting its design, features, and functionality. It is essential for homeowners seeking to maintain their lawns effectively, combining innovation with user-friendly operations.

The equipment is engineered to deliver optimal performance, ensuring efficient grass cutting while minimizing the effort required from the user. Various components work together to enhance its usability, making it a preferred choice among homeowners.

In addition, the machine is recognized for its durability and reliability, providing long-term value for those invested in maintaining their outdoor spaces. Understanding the intricate parts that contribute to its operation can further aid users in achieving the best results.

| Feature | Description |

|---|---|

| Engine Power | Robust engine designed for effective cutting and handling of diverse terrains. |

| Cutting Width | Wider cutting area for faster completion of lawn care tasks. |

| Transmission Type | Seamless operation ensuring smooth transitions while navigating. |

| Comfort Features | Ergonomic design aimed at enhancing user comfort during extended use. |

Importance of Mower Deck Components

Understanding the significance of essential elements within a cutting system is crucial for optimal performance and longevity. Each component plays a vital role in ensuring efficient operation, contributing to the overall effectiveness of the equipment.

Key Functions of Essential Elements

- Precision Cutting: Components like blades and housing are designed to deliver accurate cutting performance, ensuring a clean finish on the grass.

- Durability: High-quality materials used in these components enhance resistance to wear and tear, extending the lifespan of the entire system.

- Ease of Maintenance: Well-designed parts facilitate straightforward upkeep, making it easier for users to maintain optimal functioning.

Impact on Overall Efficiency

- Improved Grass Health: Properly functioning components contribute to a healthier lawn by preventing uneven cuts.

- Enhanced Maneuverability: Lightweight and well-balanced elements allow for better handling and control during operation.

- Fuel Efficiency: Efficient design minimizes energy consumption, resulting in lower operational costs.

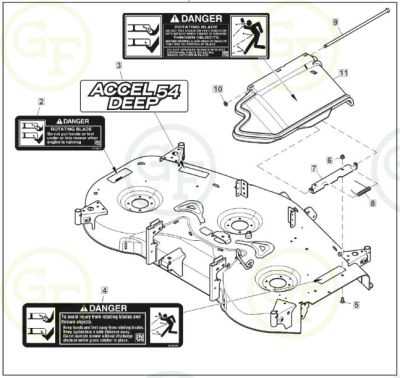

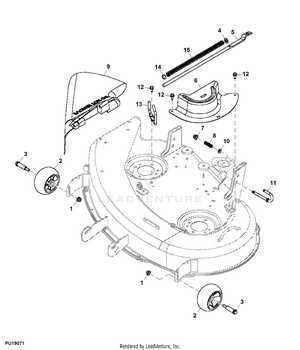

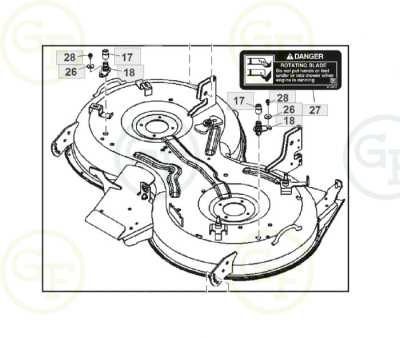

Understanding Deck Assembly Parts

The assembly of a cutting system consists of various components working in harmony to achieve optimal performance. Each element plays a crucial role in ensuring efficiency and effectiveness during operation. A thorough comprehension of these components can enhance maintenance practices and improve overall functionality.

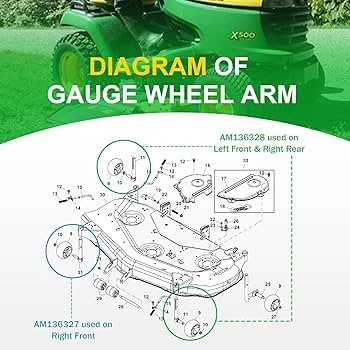

Key elements include the rotating blades, which are essential for achieving a clean cut, and the housing that provides protection and structural support. Additionally, the drive mechanisms enable the rotation of the blades, while the mounting brackets ensure secure attachment to the machine. Understanding the function and interrelation of these components is vital for troubleshooting and repairs.

Moreover, maintenance tasks such as cleaning, blade sharpening, and periodic inspections can significantly extend the lifespan of the assembly. Familiarity with the individual components and their specific roles fosters better care practices, leading to improved performance and longevity of the entire system.

Common Issues with Mower Decks

Maintaining a healthy cutting assembly is essential for optimal lawn care. Various problems can arise, leading to reduced efficiency and uneven results. Understanding these challenges is crucial for effective management and repair.

1. Uneven Cutting

One of the most frequent complaints is uneven grass cutting. This issue can stem from several factors, including:

- Improper height adjustment of the cutting blades.

- Worn or damaged blades that fail to provide a clean cut.

- Unbalanced wheels or frame components.

2. Clogging and Buildup

Another common problem is the accumulation of grass clippings and debris, which can lead to clogging. Regular maintenance can help mitigate this issue. Key points to consider include:

- Cleaning the assembly after each use to prevent buildup.

- Inspecting for any signs of rust or corrosion that may trap debris.

- Ensuring proper airflow by checking for blockages in the discharge area.

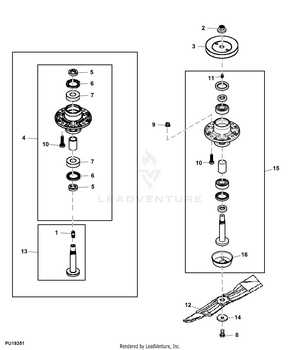

Identifying Essential Replacement Parts

When maintaining outdoor equipment, recognizing key components that may require substitution is crucial for optimal functionality. Understanding the various elements involved allows for efficient repairs and prolonged use of your machine.

Common Components in Need of Replacement

Over time, several vital elements may wear out or become damaged. These can include blades, which are essential for cutting efficiency, as well as belts that drive the machinery. Other critical items often requiring attention are spindles and pulleys, which play significant roles in the operation of the system.

Signs Indicating Replacement

It’s important to monitor performance indicators. Unusual noises, inconsistent cutting results, or visible wear can signal the need for replacements. Regular inspections can help identify these issues early, ensuring your equipment remains in peak condition.

Tools Needed for Maintenance

Proper upkeep of your equipment requires a set of essential tools to ensure optimal performance and longevity. Having the right instruments on hand not only makes the maintenance process smoother but also helps in identifying and resolving any potential issues effectively.

Below is a list of necessary tools that will assist in maintaining your machinery:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To remove and secure screws in various components. |

| Pliers | Useful for gripping, bending, and cutting wires or small parts. |

| Socket Set | For easier access to fasteners in tight spaces. |

| Grease Gun | To apply lubricant to moving parts, ensuring smooth operation. |

| Safety Goggles | To protect your eyes from debris during maintenance tasks. |

Having these tools readily available will facilitate routine checks and repairs, contributing to the overall efficiency of your equipment.

Step-by-Step Repair Instructions

This section provides comprehensive guidance for executing repairs effectively. Following these steps will help ensure that the maintenance process is smooth and efficient, enhancing the longevity and performance of your equipment.

Preparation

Before initiating any repair, gather all necessary tools and materials. Ensure that the work area is clean and organized to facilitate a safe and effective workflow.

Repair Process

Follow these steps to complete the repair:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent any accidents during the repair. |

| 2 | Remove the necessary components carefully, following the manufacturer’s guidelines. |

| 3 | Inspect each part for wear or damage, replacing any components as needed. |

| 4 | Reassemble the unit in reverse order, ensuring all connections are secure. |

| 5 | Reconnect the power source and perform a test to confirm functionality. |

Upgrades for Enhanced Performance

Improving the efficiency and capability of your cutting equipment can significantly enhance your overall experience. Upgrading certain components can lead to better cutting precision, increased durability, and overall improved performance during operation.

One effective upgrade involves enhancing the cutting blades. Opting for high-performance blades can lead to cleaner cuts and improved grass health. Additionally, utilizing sharpened or specialty blades tailored to your specific terrain can provide an edge in cutting efficiency.

Another aspect to consider is the drive system. Upgrading to a more robust transmission or enhancing the drive belts can lead to smoother operation and reduced wear over time. This ensures that the equipment runs efficiently, reducing the likelihood of mechanical issues.

Finally, consider adding accessories that boost functionality. Options such as mulching kits or side discharge systems can diversify your equipment’s capabilities, allowing for a more versatile approach to lawn care. Each upgrade contributes to a comprehensive improvement, making your cutting experience more effective and enjoyable.

Safety Guidelines for Operation

Ensuring a safe working environment while operating landscaping equipment is crucial for preventing accidents and injuries. Adhering to established safety protocols can significantly enhance the operator’s protection and promote efficient functioning of the machinery.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is essential. Operators should always don sturdy footwear, gloves, and protective eyewear to shield against potential hazards. Additionally, using hearing protection can help minimize the risk of hearing damage from prolonged exposure to loud machinery.

Pre-Operation Checks

Before starting any landscaping equipment, it is vital to perform thorough pre-operation inspections. Check for any loose components, leaks, or signs of wear and tear. Ensuring that all safety guards are in place and functioning properly can prevent malfunctions during operation.

Where to Purchase Replacement Parts

Finding the right components for your equipment is essential to ensure optimal performance and longevity. Various sources offer high-quality replacements, from authorized dealers to online retailers. Each option has its benefits, making it crucial to consider factors such as pricing, availability, and customer service when selecting a vendor.

Authorized Dealers

Authorized dealers provide genuine components, ensuring compatibility and reliability. They often have knowledgeable staff who can assist with your specific needs and answer any questions regarding installation or maintenance.

Online Retailers

Online platforms offer a wide range of options at competitive prices. Shopping online allows you to compare different vendors quickly and find customer reviews, helping you make an informed decision. Popular online retailers typically stock a comprehensive selection of components, often with user-friendly navigation.

| Source Type | Advantages | Disadvantages |

|---|---|---|

| Authorized Dealers | Genuine components, expert advice | Higher prices, limited inventory |

| Online Retailers | Competitive pricing, vast selection | Potential quality issues, delivery delays |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular care and attention. Implementing a proactive maintenance routine can significantly enhance performance and extend the lifespan of your machinery. By focusing on key practices, you can keep your device in optimal condition and ready for any task.

Regular Cleaning

Keeping the equipment clean is essential. After each use, remove grass clippings, dirt, and debris that may accumulate. Thorough cleaning prevents corrosion and buildup, which can impair functionality over time. Make use of a brush or a blower to keep all components free from obstructions.

Routine Inspections

Conducting regular inspections is vital for identifying potential issues early. Check for signs of wear and tear, such as frayed belts or loose bolts. Addressing minor problems before they escalate into major repairs can save time and money in the long run. Follow the manufacturer’s guidelines for periodic checks and recommended service intervals.