When maintaining your equipment, having a clear visual representation of its components can greatly enhance the repair process. This overview serves to simplify the identification of various elements, ensuring that you can address any issues effectively.

Detailed illustrations provide a roadmap to understanding the intricate workings of your device. By exploring these visual guides, you can easily pinpoint what needs attention or replacement, ultimately streamlining your maintenance efforts.

In this section, we will delve into the essential aspects of your machinery, highlighting key features and offering insights into how each element interacts. This knowledge not only aids in repairs but also enriches your overall understanding of the equipment’s functionality.

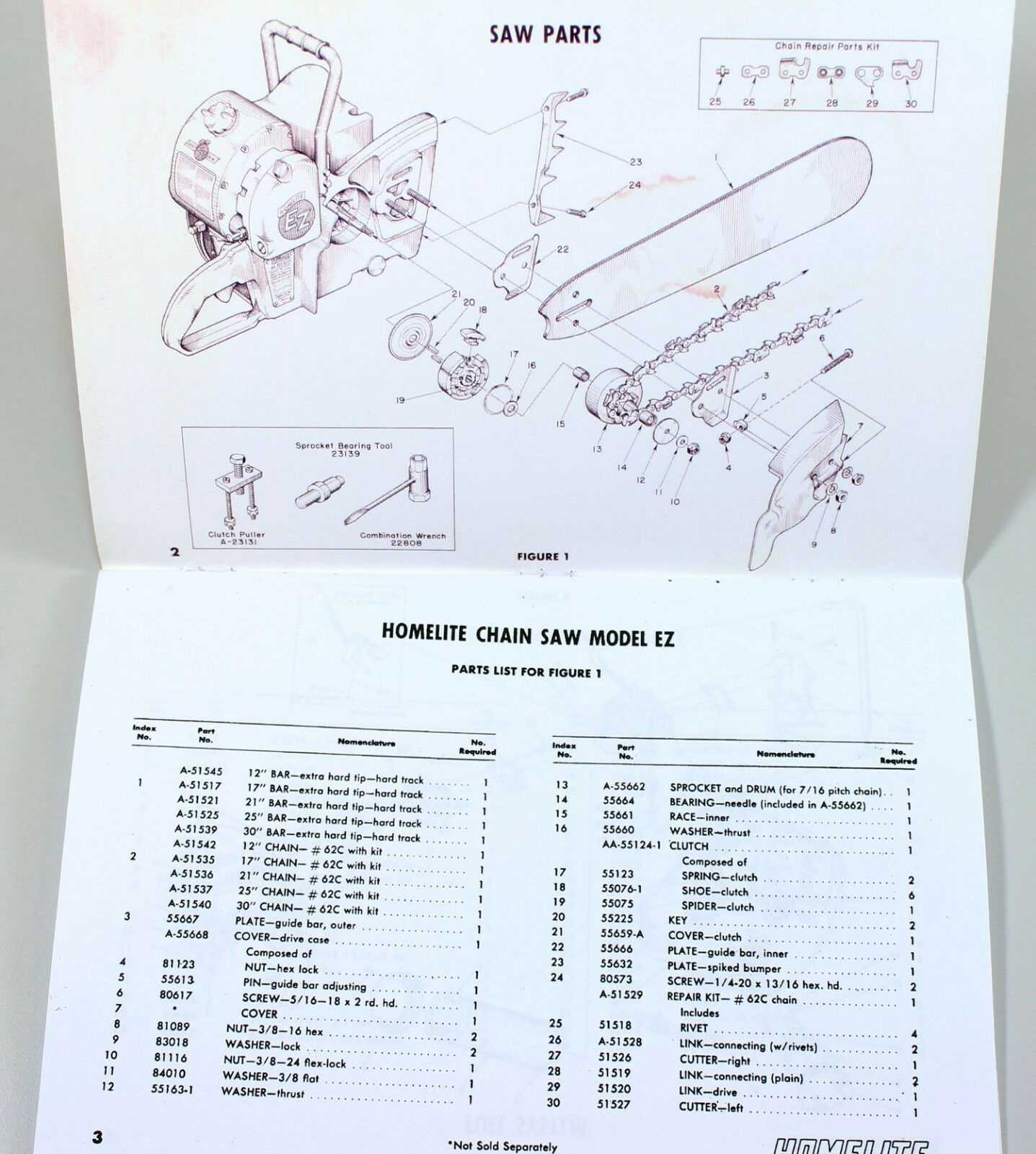

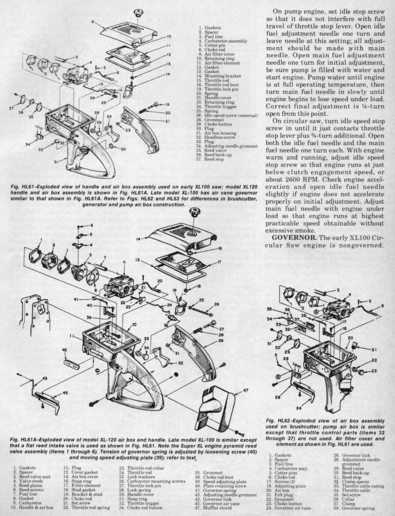

Understanding Homelite Super XL Components

In this section, we will explore the various elements that contribute to the functionality and performance of a popular model. Each component plays a crucial role, ensuring optimal operation and longevity. By examining these parts, one can gain insight into how they work together harmoniously.

Engine: The heart of the machine, responsible for power generation. Its efficiency directly impacts performance and reliability.

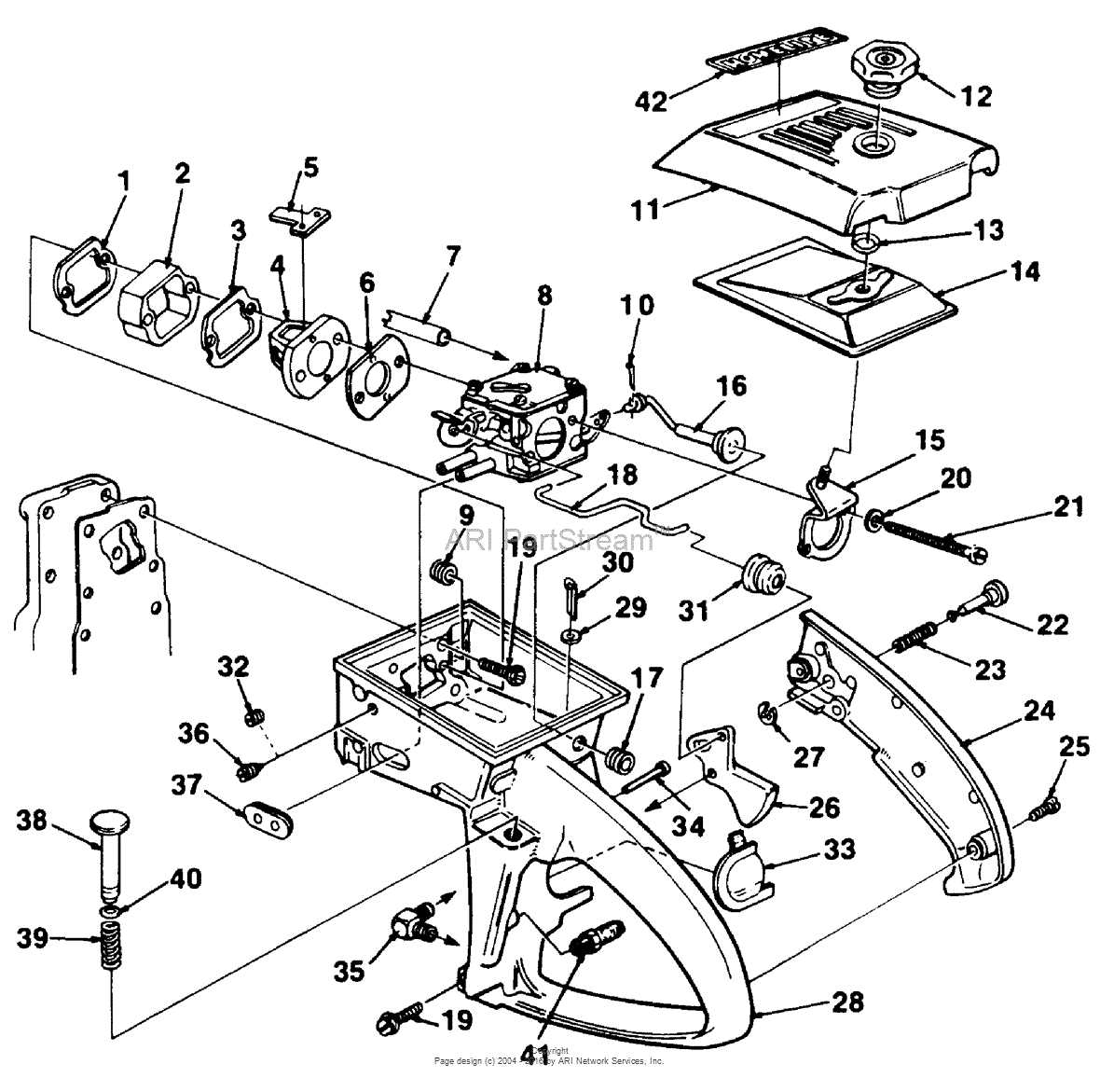

Fuel System: This includes the tank, lines, and carburetor, which work collectively to deliver the right mixture of air and fuel for combustion.

Ignition: The ignition system is vital for starting the engine, utilizing a spark plug and coil to ignite the fuel-air mixture.

Bar and Chain: Essential for cutting, the bar supports the chain, which must be well-maintained for optimal cutting efficiency.

Handle and Controls: These components ensure user safety and comfort, allowing for precise maneuvering and operation.

By understanding these essential parts, one can effectively maintain and troubleshoot any issues that may arise, ultimately enhancing the lifespan and performance of the equipment.

Key Features of the Homelite Super XL

This section explores the essential characteristics that make this chainsaw model stand out in its category. With a combination of power, efficiency, and ease of use, it caters to both casual users and professionals alike.

Powerful Engine Performance

The robust engine delivers remarkable cutting capabilities, ensuring quick and effective performance during various tasks. This strength allows for seamless operation, making it suitable for both light and heavy-duty applications.

User-Friendly Design

Engineered with convenience in mind, the ergonomic handle provides a comfortable grip, reducing fatigue during prolonged use. Additionally, the lightweight construction enhances maneuverability, allowing for effortless handling.

Importance of a Parts Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. A visual representation not only simplifies the identification of each element but also enhances the overall comprehension of how they interact within the system. This knowledge is invaluable for both seasoned technicians and novices alike.

Facilitating Repairs

Having a visual reference can significantly streamline the repair process. When individuals can easily locate and recognize each component, it reduces the risk of errors and accelerates troubleshooting. Time efficiency leads to quicker resolutions and less downtime.

Enhancing Knowledge

Beyond immediate fixes, a visual guide promotes a deeper understanding of the machinery’s design and functionality. This insight empowers users to make informed decisions about upgrades or modifications, ultimately leading to improved performance. Knowledge is the ultimate tool for anyone involved in maintenance.

How to Access Parts Diagrams

Finding specific illustrations for equipment components can greatly enhance your repair and maintenance experience. These visuals provide crucial insights into the assembly and functionality of various elements.

To successfully locate these resources, follow these steps:

- Visit the manufacturer’s official website for reliable information.

- Navigate to the support or resources section, where you can often find links to technical documents.

- Utilize online forums and communities dedicated to equipment repair for shared resources.

- Search for authorized dealers or distributors who may offer detailed manuals.

By exploring these avenues, you can effectively delve into the intricacies of your equipment, ensuring the ultimate repair experience.

Common Issues with Super XL Models

When dealing with these popular chainsaws, users often encounter a variety of challenges that can affect performance and reliability. Understanding the typical problems can help in both troubleshooting and preventative maintenance, ensuring optimal functionality over time.

Fuel System Problems: One of the most prevalent issues arises from the fuel system. Users may experience difficulties with the engine starting or running smoothly, often due to clogged filters or stale fuel. Regularly inspecting and replacing the fuel lines can mitigate these problems.

Ignition Difficulties: Another common concern is related to the ignition system. Difficulty in starting the chainsaw can often be traced back to faulty spark plugs or ignition coils. Ensuring these components are in good condition is crucial for reliable operation.

Chain Tensioning: Improper chain tension can lead to poor cutting performance and increased wear on the bar. It is essential to check and adjust the tension regularly, as a loose or overly tight chain can cause damage to both the chain and the equipment.

Oiling System Issues: The automatic oiler may fail to deliver adequate lubrication, resulting in overheating and excessive wear on the chain and bar. Monitoring the oil level and inspecting the oiler for blockages or malfunctions is vital for longevity.

Vibration and Noise: Excessive vibration or noise can indicate underlying mechanical issues. Checking for loose screws, worn parts, or misalignment can help address these concerns, improving comfort and safety during operation.

By being aware of these common challenges, users can take proactive steps to maintain their equipment, ensuring it remains in good working order for years to come.

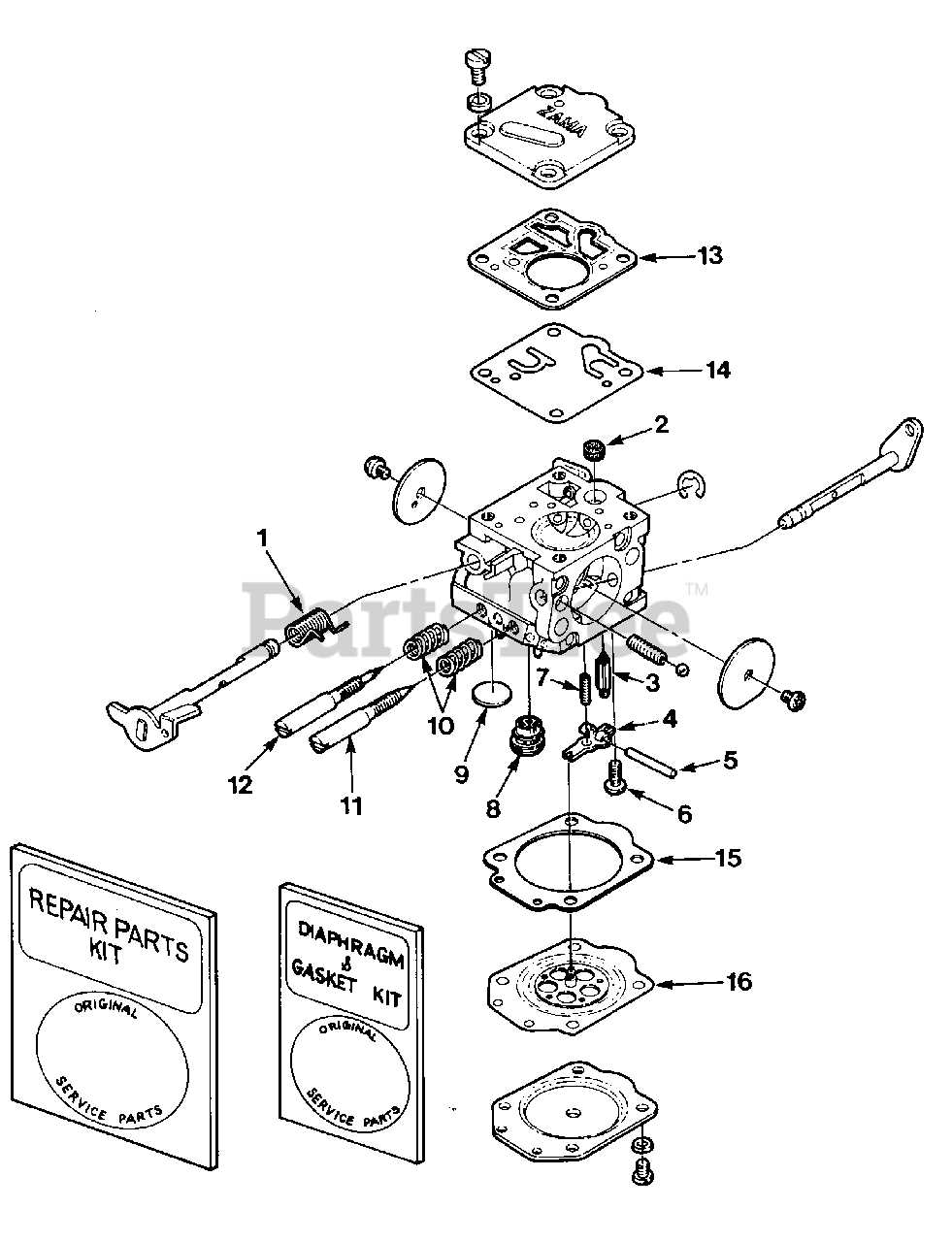

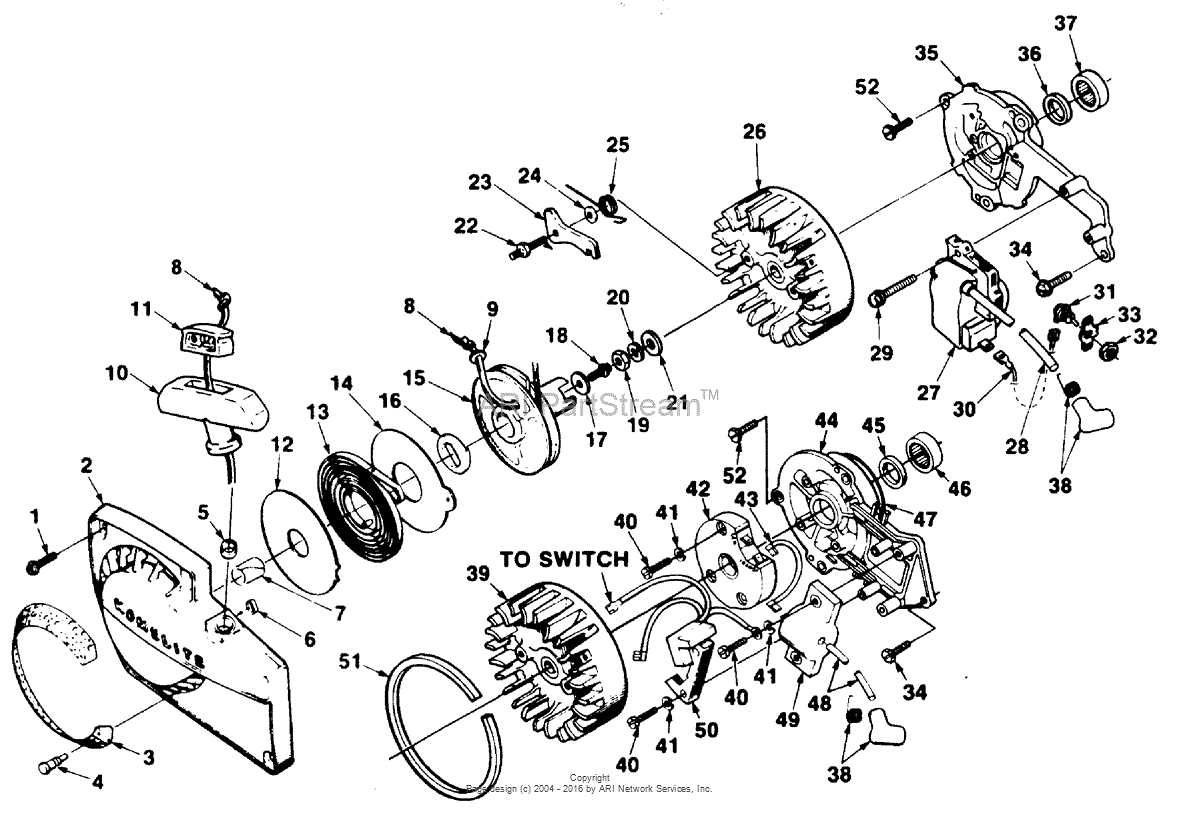

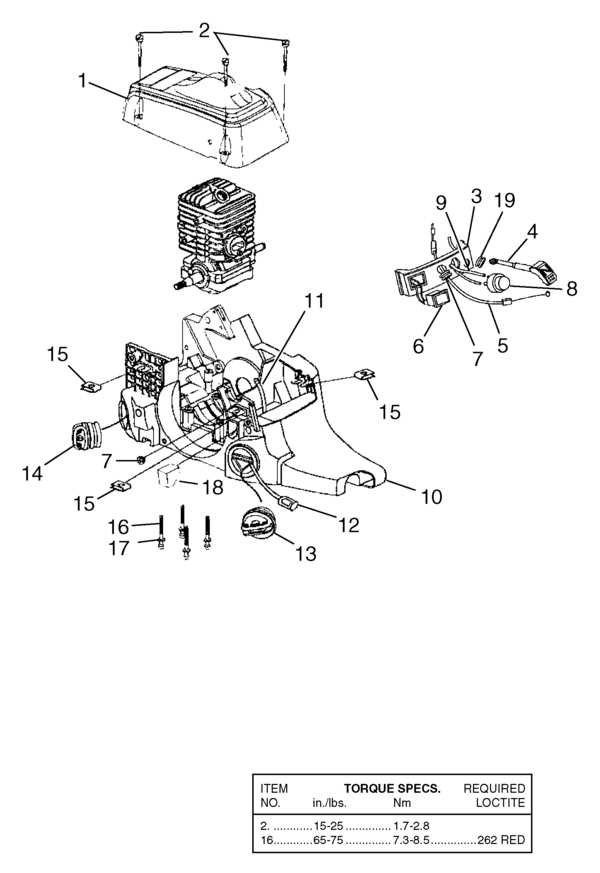

Identifying Parts in the Diagram

Understanding the components of a machinery layout is essential for effective maintenance and repair. Each section represents specific elements crucial for optimal performance. Familiarity with these components allows users to diagnose issues and carry out necessary replacements efficiently.

To assist in the identification process, follow these guidelines:

- Study the Layout: Begin by examining the overall structure. Take note of how components are arranged and grouped.

- Label Key Elements: Identify major sections, such as the engine, fuel system, and ignition. These labels will help you focus on specific areas during troubleshooting.

- Refer to Manuals: Utilize repair manuals or online resources that provide detailed descriptions of each part and its function.

- Use Visual Aids: Consider cross-referencing images or videos that showcase the components in action. This can enhance your understanding of how they interact.

By following these steps, you can gain a clearer insight into the machinery and its essential elements, facilitating smoother repairs and maintenance procedures.

Ordering Replacement Parts Online

Acquiring components for your equipment has become significantly easier with the advent of online shopping. This method offers convenience and accessibility, allowing you to find the necessary items without leaving your home. Whether you are looking for specific replacements or general maintenance supplies, the internet provides a wide array of options to meet your needs.

When navigating the online marketplace, it is essential to follow a few steps to ensure a smooth purchasing experience. Here’s a guide to help you through the process:

| Step | Description |

|---|---|

| 1. Identify Your Requirements | Determine the specific items you need, including model numbers or other identifying features. |

| 2. Research Reputable Suppliers | Look for online retailers with positive reviews and a reliable reputation in the industry. |

| 3. Compare Prices | Check multiple sources to ensure you are getting the best deal on the components. |

| 4. Check Return Policies | Understand the return and exchange policies in case the items do not meet your expectations. |

| 5. Place Your Order | Follow the checkout process carefully, ensuring all information is correct before finalizing your purchase. |

By following these steps, you can confidently order the necessary components online, ensuring that your equipment remains in optimal working condition.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the life of your equipment. By following a few key practices, you can ensure optimal performance and prevent premature wear and tear.

Regular Cleaning

- Remove debris and dirt after each use.

- Inspect and clean filters regularly to maintain airflow.

- Use a soft brush or cloth to avoid scratching surfaces.

Routine Checks

- Examine the oil levels and replace as needed.

- Inspect spark plugs for wear and replace them periodically.

- Check for loose screws or connections to ensure stability.

Tools Needed for Repairs

Proper maintenance and repairs require a variety of tools to ensure efficiency and accuracy. Having the right equipment on hand not only streamlines the process but also helps to prevent damage to the components being worked on. Below is a list of essential tools that will aid in effectively carrying out repairs.

Essential Hand Tools

Hand tools are fundamental for any repair task. These tools provide the necessary leverage and precision to perform various actions, from tightening screws to disassembling parts. Here are some of the most commonly used hand tools:

| Tool | Function |

|---|---|

| Screwdriver Set | Used for driving screws in and out. |

| Wrench Set | Ideal for loosening or tightening nuts and bolts. |

| Pliers | Helpful for gripping, bending, and cutting wires. |

| Utility Knife | Used for cutting materials or components. |

Power Tools and Equipment

For more demanding tasks, power tools can significantly enhance efficiency and reduce the physical effort required. Utilizing the correct power equipment ensures quicker and cleaner repairs. Below are key power tools you might consider:

| Tool | Function |

|---|---|

| Drill | Used for creating holes and driving fasteners. |

| Impact Wrench | Provides high torque output for loosening tough fasteners. |

| Angle Grinder | Useful for cutting, grinding, and polishing various materials. |

| Saw | Essential for making precise cuts in wood or metal. |

Comparing Super XL with Other Models

This section explores the distinctions and similarities between a particular high-performance saw and other models in its category. By examining features, specifications, and overall functionality, we can better understand how this tool stands out or aligns with its counterparts in the market.

Performance Metrics

When evaluating performance, it is essential to consider factors such as power output, cutting efficiency, and user experience. The examined model boasts a robust engine that enhances its ability to tackle various tasks. In comparison, other units may prioritize lightweight design or fuel efficiency, catering to different user preferences.

Durability and Maintenance

Durability is another crucial aspect that can influence user satisfaction. This particular model is designed with high-quality materials that ensure longevity, even under rigorous use. In contrast, some alternatives may require more frequent maintenance or have components that are prone to wear. Understanding these differences can help users make informed decisions based on their specific needs.

DIY Repair Techniques Explained

Understanding how to fix tools can empower individuals to maintain their equipment efficiently. By mastering a few essential methods, anyone can tackle repairs with confidence and save on costs.

- Assessment: Begin by examining the tool to identify issues.

- Gathering Tools: Collect necessary instruments and replacement components before starting.

- Disassembly: Carefully take apart the device, noting each step for reassembly.

- Cleaning: Remove dirt and debris to ensure smooth operation.

- Replacement: Swap out any damaged parts with compatible alternatives.

- Reassembly: Follow your notes to put everything back together correctly.

- Testing: Run the tool to confirm it functions properly.

By applying these techniques, DIY enthusiasts can enhance their skills and prolong the life of their tools.

Expert Advice on Troubleshooting

When dealing with mechanical equipment, encountering issues can be frustrating. Understanding how to identify and resolve common problems can save time and improve performance. This section provides valuable insights and practical tips for effectively diagnosing and fixing your device.

Identifying Common Issues

Begin by observing the symptoms. Unusual noises, reduced power, or failure to start can indicate specific malfunctions. Visual inspections are crucial; check for signs of wear, damage, or loose connections. Maintaining a systematic approach helps in isolating the problem.

Effective Solutions and Maintenance

Once you’ve pinpointed the issue, consider simple fixes first, such as tightening loose screws or replacing worn parts. Regular maintenance is key to preventing future problems; ensure that all components are clean and lubricated as needed. If a problem persists, consulting a professional may be necessary to avoid further complications.

Community Resources and Support Groups

Engaging with local communities and support networks can significantly enhance one’s experience and knowledge in any field. These resources often provide valuable insights, troubleshooting advice, and a sense of belonging among like-minded individuals. By connecting with others, enthusiasts can share tips, access specialized knowledge, and find solutions to common challenges.

Numerous online forums and social media groups are dedicated to fostering discussions and sharing experiences. Participants can ask questions, post photos, and receive feedback, creating a collaborative environment. Additionally, local clubs and workshops offer hands-on opportunities to learn and grow, allowing individuals to work together on projects and share resources.

Furthermore, many organizations host events, such as meetups and educational seminars, where members can gain new skills and stay updated on the latest trends. These gatherings not only provide learning opportunities but also promote camaraderie among participants, reinforcing the sense of community.

Ultimately, utilizing these resources can empower individuals, making their journey more fulfilling and enjoyable. Connecting with others who share similar interests can lead to lasting friendships and enhanced expertise, creating a supportive network that benefits everyone involved.