The intricacies of heating systems can often seem daunting, yet they are vital for efficient performance. By exploring the various elements that make up these appliances, users can gain valuable insights into their functionality and maintenance. A comprehensive overview of the individual components contributes to a better understanding of overall system operation.

Identifying specific parts and their roles allows for effective troubleshooting and replacement when necessary. This knowledge not only enhances user confidence but also promotes long-term reliability and efficiency. Ultimately, becoming familiar with each element transforms the experience of managing heating solutions.

In this section, we will delve into the essential features of a popular model, providing a detailed visual reference. This exploration aims to empower users with the ultimate resource for understanding their heating system’s framework, ensuring they can make informed decisions regarding maintenance and repairs.

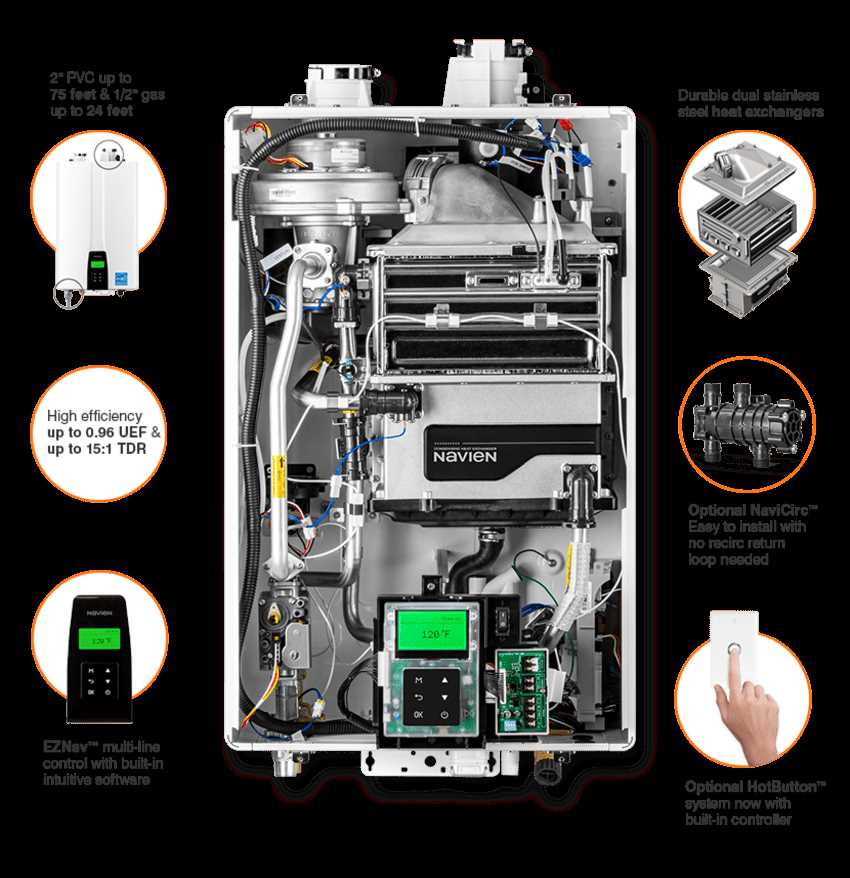

Understanding Rinnai RL75 Components

Comprehending the elements of a high-efficiency heating unit is essential for effective maintenance and optimal performance. Each component plays a vital role in ensuring that the system operates smoothly, providing reliable hot water and heating solutions. This section will delve into the main elements, highlighting their functions and significance in the overall system.

Main Components Overview

The following table outlines key components typically found in these heating systems, along with their primary functions:

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat from the combustion process to the water, ensuring efficient heating. |

| Gas Valve | Regulates the flow of gas to the burner, crucial for maintaining proper combustion. |

| Burner | Generates heat through the combustion of gas, vital for the heating process. |

| Thermostat | Monitors and controls the temperature of the water, ensuring user comfort. |

| Control Board | Coordinates the operation of various components, enabling efficient system management. |

Understanding these components is crucial not only for operation but also for regular maintenance. Ensuring that each part is functioning correctly can prevent breakdowns and prolong the lifespan of the unit. Routine checks and servicing will help identify potential issues early, leading to more efficient operation and savings on energy costs.

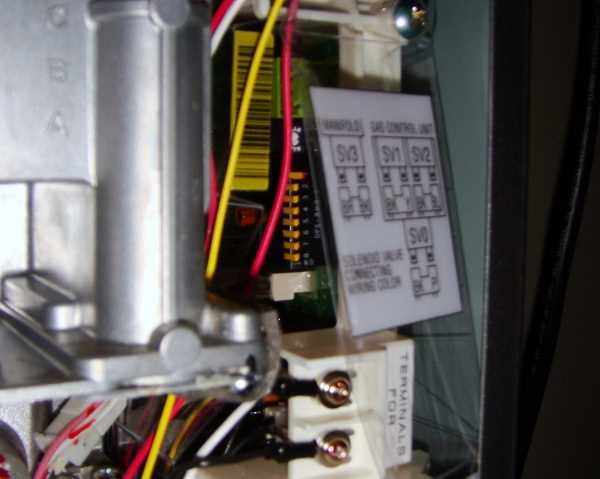

Exploring the Parts Diagram

Understanding the components of a heating unit is essential for effective maintenance and troubleshooting. This section delves into the intricate layout that illustrates each element’s function and relationship within the system.

By analyzing the visual representation, users can identify the key sections and discover how each component contributes to overall performance. This knowledge empowers owners to make informed decisions regarding repairs and replacements.

Familiarity with the schematic enhances the ability to diagnose issues quickly, ensuring optimal functionality and longevity of the equipment. A thorough grasp of these details ultimately leads to a more efficient and reliable heating experience.

Key Functions of Each Part

This section explores the essential roles of various components in a heating system, highlighting how each element contributes to overall performance and efficiency.

| Component | Function |

|---|---|

| Burner | Generates heat by combusting fuel, ensuring effective temperature regulation. |

| Heat Exchanger | Transfers heat from the combustion process to the water, maximizing energy efficiency. |

| Ignition System | Initiates the combustion process safely and reliably for consistent heating. |

| Thermostat | Monitors and controls temperature settings, optimizing comfort and energy use. |

| Flue Vent | Safely directs exhaust gases outside, maintaining indoor air quality and safety. |

Common Issues with Rinnai RL75

Many users experience challenges with their tankless water heating systems. Understanding these common problems can help in troubleshooting and maintaining optimal performance. From ignition failures to inconsistent water temperature, these issues often arise due to a variety of factors, including installation errors and regular wear and tear.

Ignition Problems

One frequent issue is the failure to ignite. This can occur due to a faulty electrical connection, a dirty flame sensor, or insufficient gas supply. Regular maintenance, including cleaning components and checking connections, can mitigate these problems.

Temperature Fluctuations

Another common concern is inconsistent water temperature. This may result from mineral buildup within the unit, affecting heat exchange efficiency. Flushing the system periodically can help maintain stable temperatures and prolong the lifespan of the heater.

Maintenance Tips for Longevity

Ensuring the durability of your heating unit requires regular upkeep and attention to detail. By following a few essential maintenance practices, you can enhance performance, reduce the likelihood of breakdowns, and extend the lifespan of your equipment.

- Regular Cleaning: Keep the exterior and accessible components clean to prevent dust and debris buildup. This helps maintain optimal airflow and efficiency.

- Inspect Connections: Periodically check gas and water connections for leaks or corrosion. Tighten any loose fittings to ensure safe operation.

- Flame Adjustment: Ensure the burner flame is blue and stable. A yellow or flickering flame may indicate a need for adjustment, which can enhance efficiency and safety.

Following these steps can significantly impact the functionality of your heating unit and help you avoid costly repairs in the future.

- Check Filters: If applicable, replace or clean filters regularly to maintain airflow and efficiency.

- Annual Professional Inspection: Schedule a professional service at least once a year. This can identify potential issues before they become major problems.

- Monitor Performance: Keep an eye on performance indicators. Unusual noises or changes in temperature can signal the need for further investigation.

By committing to these maintenance practices, you ensure reliable operation and maximize the longevity of your heating equipment.

How to Replace Parts Safely

Replacing components in your appliance can be a straightforward task if done correctly. Ensuring safety and efficiency during this process is paramount, as it prevents accidents and damage to the device.

Preparation Steps

- Turn off the power supply to avoid electrical hazards.

- Gather necessary tools and replacement items before starting.

- Consult the manual for specific instructions related to your model.

Replacement Process

- Carefully remove the outer casing, following the manual guidelines.

- Identify the faulty component and disconnect it gently.

- Install the new item by reversing the disassembly steps, ensuring secure connections.

- Double-check all connections and replace the casing properly.

- Restore power and test the appliance to confirm proper function.

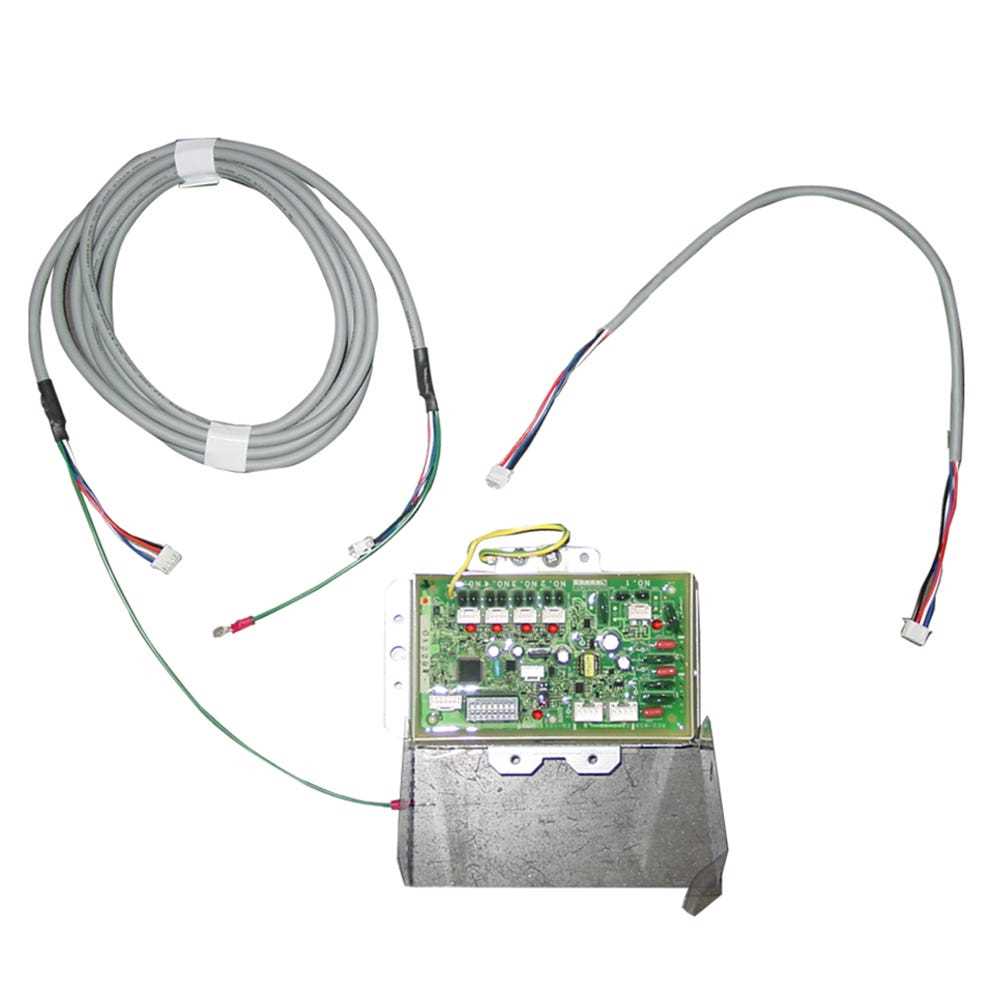

Identifying Compatible Replacement Parts

When it comes to maintaining and repairing heating systems, ensuring that you select the correct components is crucial for optimal performance. Compatibility plays a significant role in the efficiency and longevity of these devices. Understanding the specific requirements and specifications of the system will aid in identifying suitable alternatives that function seamlessly.

Researching Specifications

Start by reviewing the technical details of your system, including model numbers and manufacturer recommendations. This information will guide you in determining the exact type and size of the components needed. Additionally, consulting the user manual or official documentation can provide valuable insights into the necessary features and compatibility standards.

Consulting Professionals

For those unsure about their choices, seeking advice from qualified technicians or customer support can be beneficial. Experts can provide recommendations based on experience and knowledge of the industry, ensuring that you select components that are reliable and fit your system’s requirements. This step not only saves time but also helps prevent potential issues related to improper installation or functionality.

Diagram Analysis for Technicians

Understanding intricate schematics is crucial for technicians tasked with maintenance and repair. These visual representations serve as vital tools, providing insight into component relationships and operational flow. A detailed examination can enhance troubleshooting efficiency and ensure optimal performance of the equipment.

Identifying Key Components

By meticulously analyzing the visual layout, technicians can identify essential elements within the system. This knowledge allows for quick diagnosis of issues, facilitating timely interventions. Recognizing the purpose and function of each part is integral for effective problem resolution.

Enhancing Repair Strategies

Furthermore, a comprehensive understanding of the schematic empowers technicians to develop more effective repair strategies. By delving into the connections and interactions, they can anticipate potential failures and address them proactively. This ultimately leads to improved reliability and customer satisfaction.

Importance of Regular Inspections

Routine evaluations are crucial for ensuring the longevity and efficiency of any system. These assessments help identify potential issues before they escalate, ultimately saving time and resources. By conducting regular checks, users can maintain optimal performance and prevent unexpected failures.

Timely inspections not only enhance safety but also contribute to cost savings in the long run. When components are monitored consistently, any signs of wear or malfunction can be addressed promptly, reducing the risk of significant damage.

Moreover, regular maintenance fosters a deeper understanding of the system’s functionality. This knowledge empowers users to make informed decisions about necessary upgrades or replacements, ensuring the system operates at its best.

Customer Reviews on Rinnai RL75

Understanding user experiences can provide valuable insights into the performance and reliability of any appliance. This section compiles various testimonials from customers who have utilized this specific model, highlighting both the advantages and potential drawbacks as perceived by real users.

Positive Feedback

- Many users appreciate the consistent hot water supply, especially during peak usage times.

- Several customers noted the energy efficiency, leading to reduced utility bills.

- Installation was often described as straightforward, with clear instructions provided.

- Many reviews commend the compact design, making it suitable for smaller spaces.

Areas for Improvement

- Some users reported occasional fluctuations in water temperature during use.

- A few customers experienced difficulties with customer service during warranty claims.

- While most found it easy to install, some highlighted that professional installation is recommended for optimal performance.

Overall, user reviews reveal a generally positive sentiment towards this model, with a few areas identified for enhancement. Prospective buyers may find these insights beneficial in making an informed decision.

Installation Guide for New Users

Setting up a new heating system can be a straightforward process with the right guidance. This section aims to equip first-time users with essential steps and considerations to ensure a successful installation. Proper preparation and adherence to safety protocols are crucial for optimal performance and longevity of your equipment.

Pre-Installation Checklist

- Read the user manual thoroughly.

- Gather necessary tools and materials.

- Ensure you have all required permits and follow local regulations.

- Identify the best location for installation, considering ventilation and accessibility.

Step-by-Step Installation Process

- Turn off the main power supply and gas line before beginning.

- Secure the unit in the chosen location, ensuring it is level and stable.

- Connect the water supply lines and check for any leaks.

- Install the exhaust vent according to the manufacturer’s specifications.

- Re-establish the power supply and gas line.

- Test the system to ensure it operates correctly and safely.

By following these guidelines, new users can facilitate a smooth installation experience, setting the foundation for effective and reliable heating.

Resources for Troubleshooting Issues

When encountering challenges with heating systems, having access to reliable resources can make all the difference in diagnosing and resolving problems effectively. A variety of materials and tools are available to assist users in understanding their equipment better and identifying potential faults.

Online forums and communities dedicated to home heating solutions can be invaluable. Users often share their experiences, offering insights into common issues and their resolutions. Additionally, manufacturer websites typically provide detailed guides and manuals, outlining troubleshooting steps and maintenance tips.

Videos on platforms like YouTube can be particularly helpful, as visual demonstrations clarify complex procedures. Furthermore, consulting with certified technicians can provide expert advice tailored to specific situations, ensuring that any repairs or adjustments are performed safely and correctly.

Utilizing these resources not only aids in resolving current issues but also enhances overall knowledge about maintaining and operating heating systems efficiently.