For enthusiasts of outdoor maintenance, knowing the intricacies of essential machinery is crucial. A comprehensive examination of the various elements that contribute to the functionality of lawn care tools can enhance both efficiency and longevity. This guide delves into the intricate arrangements and individual components that ensure optimal performance.

By familiarizing oneself with the schematic representation of these essential tools, users can easily identify any necessary replacements or repairs. Understanding how each component interacts fosters better maintenance practices and can ultimately lead to a more rewarding experience in managing your green spaces.

In this article, we will explore a specific model’s framework, detailing the critical components involved. By breaking down the assembly into understandable sections, readers will gain valuable insights into the mechanics that drive effective lawn care solutions.

Understanding John Deere L120 Mower Deck

This section explores the essential components and functionality of a popular lawn care equipment model, focusing on its cutting mechanism and maintenance needs. Recognizing how each element contributes to performance can enhance user experience and prolong the lifespan of the machine.

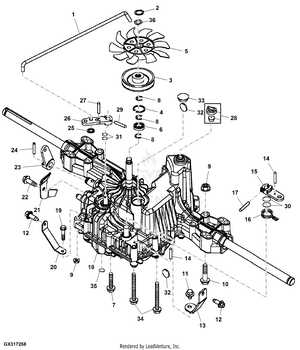

Key Components

The main elements involved in the operation of this equipment include blades, pulleys, and spindles. Each part plays a critical role in achieving a precise and efficient cut.

| Component | Function |

|---|---|

| Blades | Cut grass to the desired height. |

| Pulleys | Transfer power from the engine to the blades. |

| Spindles | Support and rotate the blades. |

Maintenance Tips

Key Components of the Mower Deck

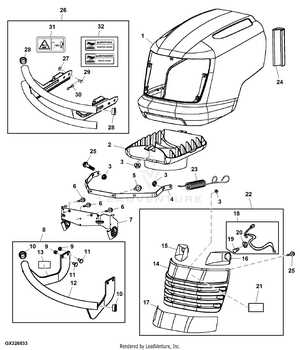

The functionality of a grass-cutting machine relies heavily on its essential elements. Understanding these components can enhance performance and maintenance, ensuring optimal operation during each use. Each part plays a specific role in the overall efficiency and effectiveness of the machine.

The cutting blade is crucial for achieving a clean and even finish on the lawn. Sharp and well-maintained blades are necessary to ensure precise cutting and to prevent grass damage. The housing encases the blade, providing protection and stability while also directing clippings to the side or rear, depending on the design.

Another important component is the spindle assembly, which supports the blade and allows it to rotate at high speeds. The bearings within this assembly reduce friction, contributing to the longevity and smooth operation of the machine. Additionally, the drive belt transfers power from the engine to the spindle, ensuring that the blade spins efficiently and effectively.

Height adjustment mechanisms allow users to customize the cutting height for different grass types and conditions. These mechanisms provide flexibility, enabling the operator to adapt to varying lawn requirements. Furthermore, the mounting brackets secure the entire assembly to the main structure, ensuring stability and proper alignment during operation.

Regular inspection and maintenance of these key components are vital for prolonging the life of the equipment and achieving the best results in lawn care. Understanding their functions aids in troubleshooting and repairs, leading to a smoother mowing experience.

Common Issues with Mower Deck Parts

When maintaining a lawn care machine, various challenges can arise related to its cutting components. Identifying and addressing these issues is crucial for optimal performance and longevity. Below are some frequent problems encountered by users.

Worn Components

Over time, certain elements can wear down, affecting efficiency. Regular inspection helps prevent significant failures.

Improper Alignment

Misalignment can lead to uneven cutting and increased wear. Ensuring correct positioning is essential for smooth operation.

| Issue | Description | Solution |

|---|---|---|

| Worn Blades | Blades may become dull or chipped. | Regular sharpening or replacement is recommended. |

| Loose Fasteners | Bolts and screws can loosen over time. | Check and tighten regularly to avoid detachment. |

| Clogging | Debris buildup can obstruct operation. | Clear away clippings and dirt after each use. |

How to Identify Worn Parts

Understanding how to spot deteriorated components is crucial for maintaining optimal performance of your equipment. Regular inspection can prevent further damage and enhance longevity.

Visual Inspection

Begin with a thorough visual examination. Look for signs of wear such as cracks, corrosion, or unusual discoloration. Any irregularities could indicate the need for replacement.

Functional Testing

Perform tests to assess the efficiency of the components. Listen for unusual noises or vibrations during operation. Any deviations from normal functioning might signal impending failure.

Regular maintenance and timely replacements are essential for keeping your machinery running smoothly.

Replacing Blades on the L120 Deck

Maintaining the cutting edges of your equipment is essential for optimal performance and a clean finish. Regularly replacing these components not only ensures efficiency but also enhances the longevity of the entire system. This section will guide you through the process of swapping out the old blades for new ones, ensuring a smooth and effective operation.

Preparation is Key

Before starting, gather all necessary tools, including a socket wrench and safety gloves. Ensure that the equipment is on a stable surface and turned off to prevent accidents. Always prioritize safety by disconnecting the battery if applicable.

Removing Old Blades

Begin by locating the securing bolts that hold the cutting edges in place. Using the socket wrench, carefully unscrew these bolts. Take your time to avoid stripping them. Once loose, gently lift the blades away from the mount, paying attention to the orientation for reinstallation.

Installing New Blades

Position the new cutting edges onto the mount, ensuring they align correctly with the holes. Reinsert the securing bolts and tighten them securely, but avoid overtightening as this could cause damage. It’s important to verify that the blades are evenly spaced and correctly oriented for optimal cutting performance.

Final Checks

After installation, perform a quick inspection of your work. Ensure that all components are secure and that nothing is loose. Reconnect the battery if it was disconnected, and test the system to confirm everything is functioning correctly. Regular maintenance will keep your equipment in peak condition and enhance its efficiency.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention not only enhances performance but also extends the lifespan of components, making maintenance a crucial aspect of ownership.

Regular Cleaning

- Remove debris after each use to prevent buildup.

- Inspect and clean air filters to ensure optimal airflow.

- Wash exterior surfaces to avoid rust and corrosion.

Routine Inspections

- Check for wear and tear on belts and blades.

- Examine fluid levels and top off as necessary.

- Look for loose or damaged fasteners and replace them promptly.

Tools Needed for Repairs

To successfully undertake maintenance or repair tasks on your equipment, it’s essential to gather the appropriate tools. Having the right instruments not only facilitates the process but also ensures safety and efficiency. Here’s a rundown of what you’ll need.

Essential Instruments

Before starting your project, make sure you have the following essential instruments on hand:

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen bolts |

| Screwdriver Set | For various screw types |

| Socket Set | To work with larger fasteners |

| Pliers | For gripping and twisting |

| Safety Goggles | To protect your eyes |

Additional Items

In addition to the basic tools, consider having these items for a more comprehensive approach:

| Item | Function |

|---|---|

| Torque Wrench | To apply precise torque settings |

| Shop Vacuum | For cleaning work area |

| Lubricant | To ensure smooth operation of moving parts |

Finding OEM Parts for the L120

Locating original equipment manufacturer components is crucial for maintaining optimal performance in your machine. Authentic parts ensure compatibility and reliability, enhancing the longevity of your equipment.

Why Choose OEM Components?

Utilizing genuine components guarantees that each piece is designed to work seamlessly with your equipment. Quality and durability are hallmarks of OEM parts, reducing the risk of malfunctions and costly repairs.

Where to Find Authentic Parts

Several reputable online retailers and local dealers specialize in OEM components. Always verify the authenticity by checking reviews and ensuring that the supplier is authorized to sell genuine parts.

Exploring Aftermarket Part Options

When it comes to maintaining outdoor equipment, the availability of high-quality alternatives can significantly enhance performance and longevity. Aftermarket components often provide a cost-effective solution without compromising on reliability. This section delves into the benefits and considerations of opting for aftermarket alternatives in your equipment upkeep.

Benefits of Aftermarket Components

One of the primary advantages of choosing aftermarket items is the potential for savings. These alternatives are frequently priced lower than original equipment manufacturer (OEM) options, allowing users to manage their budgets more effectively. Additionally, aftermarket suppliers often offer a wider variety of products, enabling users to customize their machines according to specific needs and preferences.

Considerations When Choosing Alternatives

While aftermarket components present numerous benefits, it’s essential to ensure their quality and compatibility. Researching reputable suppliers and reading customer reviews can help mitigate risks associated with inferior products. Furthermore, understanding warranty implications is crucial, as using non-OEM components may affect coverage. Balancing cost with quality will lead to a more satisfying maintenance experience.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures for assembling and disassembling essential components of your equipment. Understanding these steps ensures proper maintenance and longevity of your machine.

Preparation Steps

Before you begin, gather the necessary tools and ensure you have a clean workspace. Review the components to familiarize yourself with their arrangement and function.

Disassembly Process

Follow these steps to safely disassemble the unit:

| Step | Action |

|---|---|

| 1 | Disconnect power source to prevent accidents. |

| 2 | Remove any protective coverings or shields. |

| 3 | Loosen and remove fasteners securing components. |

| 4 | Carefully detach each part, keeping them organized. |

Follow these guidelines to ensure a smooth reassembly, which can greatly enhance your equipment’s performance and efficiency.

Benefits of Regular Deck Maintenance

- Enhanced Performance: Consistent maintenance boosts the efficiency of your machinery, allowing for a cleaner cut and improved overall results.

- Extended Lifespan: Taking care of components can significantly prolong the life of your equipment, saving you money on replacements.

- Safety Improvements: Well-maintained machinery reduces the risk of accidents, protecting both the user and bystanders.

- Cost Savings: Preventative care helps avoid costly repairs and unplanned downtime.

- Environmental Benefits: Efficiently running equipment consumes less fuel and reduces emissions.

In conclusion, regular attention to the lower assembly not only maximizes its functionality but also contributes to a safer and more sustainable lawn care experience.