In the realm of power equipment, comprehending the intricacies of tool assembly is crucial for both enthusiasts and professionals. A clear visual representation of various components can significantly enhance the maintenance and repair processes, ensuring optimal performance and longevity of the devices.

By examining a detailed layout of the individual elements, users can easily identify and understand the function of each part. This knowledge not only aids in troubleshooting issues but also empowers individuals to make informed decisions when it comes to replacements or upgrades.

Whether you’re a seasoned technician or a DIY hobbyist, having access to comprehensive illustrations serves as an invaluable resource. These visuals can guide users through the assembly and disassembly processes, demystifying the workings of their tools and fostering a deeper connection with their equipment.

Understanding Milwaukee M18 Tools

This section explores the features and benefits of a popular line of battery-operated tools designed for professionals and DIY enthusiasts alike. These versatile devices are engineered to provide exceptional performance, ease of use, and reliability across various tasks.

Key characteristics of these tools include:

- Powerful battery systems that ensure prolonged usage without frequent recharging.

- A wide array of tools, including drills, saws, and impact wrenches, catering to different needs.

- Ergonomic designs that enhance comfort and reduce user fatigue during extended operations.

- Advanced technology that improves efficiency and effectiveness in various applications.

Understanding the components of these tools is essential for effective maintenance and troubleshooting. Familiarity with their structure can help users identify issues and optimize performance.

- Battery: The heart of the system, providing the necessary power.

- Motor: Converts electrical energy into mechanical energy for operation.

- Gearbox: Transmits power from the motor to the tool’s working parts.

- Housing: Protects internal components while ensuring durability.

By gaining insights into these aspects, users can maximize the lifespan and efficiency of their tools, making every project smoother and more productive.

Overview of the M18 Battery System

The innovative power system is designed to provide reliable energy for a wide range of tools, ensuring optimal performance and longevity. This technology combines advanced battery chemistry with efficient energy management to meet the demands of both professionals and DIY enthusiasts.

At the core of this system are high-capacity lithium-ion cells that deliver exceptional runtime and faster charging capabilities. The batteries are engineered to withstand rigorous use, featuring robust construction that enhances durability in various working conditions.

Additionally, the intelligent communication between the battery and tool allows for enhanced performance monitoring, providing real-time feedback on charge levels and overall health. This ensures that users can complete their tasks without interruptions, maximizing productivity on the job site.

Moreover, compatibility across a wide array of tools simplifies the user experience, enabling seamless transitions between equipment without the need for multiple power sources. This flexibility is particularly beneficial for those who require versatility in their toolkit.

Common Issues with M18 Devices

Tools powered by lithium-ion technology are widely appreciated for their efficiency and convenience. However, like any machinery, they can encounter various problems that may hinder performance. Understanding these common issues can help users maintain their devices effectively and ensure optimal operation.

- Battery Problems:

- Reduced charge capacity over time

- Inability to hold a charge

- Overheating during use or charging

- Motor Malfunctions:

- Unusual noises or vibrations

- Intermittent operation or failure to start

- Excessive wear on components

- Tool Functionality:

- Difficulty with speed settings or triggers

- Inconsistent power delivery

- Attachment compatibility issues

- Physical Damage:

- Cracks or breaks in housing

- Loose or damaged handles

- Wear on moving parts leading to malfunction

Regular maintenance and timely repairs can significantly prolong the life of these tools, minimizing the impact of these issues on performance.

Importance of Using Genuine Parts

Utilizing authentic components is crucial for maintaining the efficiency and longevity of any mechanical system. Quality and precision in manufacturing ensure that each element fits seamlessly and functions as intended, thereby preventing potential issues that could arise from inferior substitutes. When it comes to performance and reliability, opting for original products is always a wise choice.

Benefits of Authentic Components

Investing in genuine items provides numerous advantages that enhance both functionality and safety. These benefits include:

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to strict standards, ensuring optimal performance. |

| Durability | Designed to withstand wear and tear, leading to a longer lifespan. |

| Warranty Protection | Often comes with a warranty that covers defects and issues. |

| Compatibility | Perfectly fits with existing systems, reducing the risk of malfunction. |

Conclusion

In summary, choosing authentic components not only safeguards the functionality of your equipment but also enhances overall safety and reliability. The investment in quality pays off by minimizing downtime and reducing long-term costs associated with repairs and replacements.

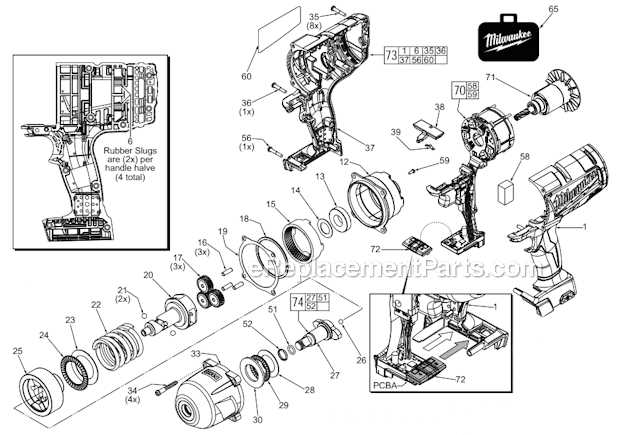

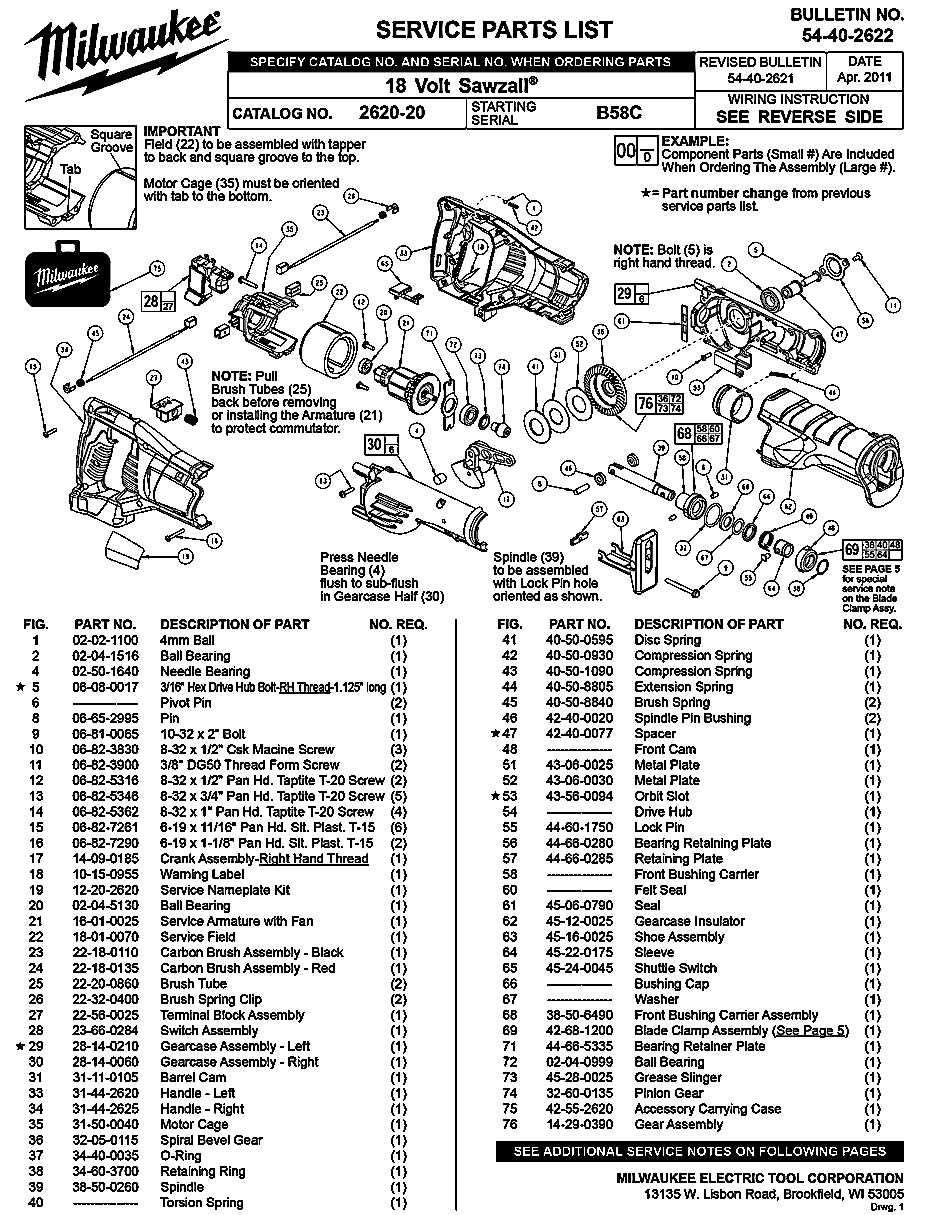

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to repair or maintain equipment. These visual guides provide a detailed view of components and their relationships, allowing users to identify specific elements quickly. Mastering the interpretation of these visuals can save time and improve efficiency in the repair process.

Key Elements of Technical Illustrations

- Symbols: Familiarize yourself with common symbols that represent different components. Each symbol usually corresponds to a specific piece of equipment.

- Labels: Pay attention to the annotations. Labels often indicate part numbers and names, which are crucial for identifying and ordering replacements.

- Connections: Observe how elements are connected. Arrows or lines may show how components interact or are assembled together.

Steps for Effective Interpretation

- Review the Legend: Always start by checking the legend or key, which explains the symbols and terms used in the illustration.

- Identify the Main Components: Locate the major elements first. This will give you a framework for understanding the rest of the illustration.

- Trace Connections: Follow the lines or arrows to see how different parts work together, ensuring you understand their relationships.

- Cross-Reference with Manuals: Use accompanying manuals or documents for additional context on how to use the illustration effectively.

By mastering these techniques, anyone can enhance their ability to read and understand technical illustrations, leading to more effective maintenance and repairs.

Identifying Key Components in M18 Tools

Understanding the essential elements of power tools is crucial for efficient operation and maintenance. Each tool consists of various parts that contribute to its overall functionality. Familiarizing oneself with these components can enhance both performance and longevity.

| Component | Description |

|---|---|

| Motor | The heart of the tool, converting electrical energy into mechanical power. |

| Battery | A rechargeable unit providing the necessary power for operation. |

| Chassis | The outer casing that protects internal components and provides structure. |

| Switch | A control mechanism that allows the user to start or stop the tool. |

| Chuck | The part that holds the bit or attachment securely in place during use. |

| Gearbox | Facilitates the transfer of power and adjusts speed and torque. |

By recognizing these crucial components, users can troubleshoot issues more effectively and ensure their tools remain in peak condition. Proper knowledge of each element aids in making informed decisions regarding repairs and upgrades.

Maintenance Tips for Longevity

Ensuring the durability of your power tools requires a systematic approach to upkeep and care. Regular maintenance not only extends the life of your equipment but also enhances performance, making your tasks easier and more efficient.

Start with routine cleaning. Dust and debris can accumulate in crevices, leading to overheating and reduced functionality. Use a soft brush or compressed air to keep the exterior and vents clear. This simple step can significantly prevent mechanical failures.

Check and tighten all fasteners periodically. Vibrations during use can loosen screws and bolts, which may cause parts to misalign or detach. A quick inspection and tightening session can save you from costly repairs down the line.

Pay attention to battery care if your tools are cordless. Avoid letting batteries fully deplete regularly; instead, aim to recharge them when they reach around 20% capacity. Additionally, store batteries in a cool, dry place to prevent degradation.

Lastly, consult the manufacturer’s guidelines for lubrication recommendations. Properly lubricated moving parts reduce friction, thereby minimizing wear and tear. Regularly apply the recommended lubricant to ensure smooth operation and longevity.

Where to Find Replacement Parts

Locating components for your tools can be a straightforward task if you know where to look. Whether you need a specific element or a complete set for repair, various resources can help you efficiently find what you need.

Online Retailers

The internet offers a plethora of options for acquiring components. Consider these platforms:

- Manufacturer’s Website: Official sites often have a dedicated section for accessories and replacements.

- Specialty Stores: Websites focusing on tools may carry a wide range of items suitable for your needs.

- Marketplace Platforms: Sites like eBay or Amazon may list both new and used components from various sellers.

Local Stores

If you prefer shopping in person, local retailers can be valuable resources:

- Hardware Stores: Many carry essential elements for popular tool brands.

- Tool Rental Shops: Often have spare parts available for purchase.

- Specialized Repair Centers: These shops can also help identify the necessary components and provide guidance on installation.

DIY Repairs: A Step-by-Step Guide

Embarking on repair projects can be a rewarding experience, allowing you to save money while gaining new skills. This guide offers a systematic approach to tackling various maintenance tasks, empowering you to handle minor issues confidently. With the right tools and a bit of know-how, you can bring your equipment back to life without relying on professional help.

Gathering Your Tools and Materials

Before starting any repair, it’s essential to assemble the necessary tools and materials. Depending on the nature of the job, this may include screwdrivers, wrenches, pliers, and replacement components. Familiarize yourself with each item’s purpose, ensuring you have everything on hand to avoid interruptions during your work.

Following Instructions and Safety Precautions

Once you have your tools ready, consult relevant resources for guidance. Whether it’s a manual or online tutorial, clear instructions can significantly simplify the process. Always prioritize safety by wearing appropriate gear and ensuring your workspace is organized. Taking these precautions will not only protect you but also enhance the efficiency of your repair efforts.

Upgrades for Enhanced Performance

Enhancing the capabilities of your power tools can significantly improve efficiency and extend their lifespan. By integrating advanced components and optimizing existing systems, you can achieve superior functionality and reliability. This section explores various enhancements that can transform standard equipment into high-performance machines.

Key Upgrades to Consider

Investing in the right upgrades not only boosts performance but also ensures that your tools meet the demands of diverse tasks. Here are some essential modifications to consider:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Battery Enhancement | Switching to high-capacity batteries for longer run times. | Increased productivity with reduced downtime. |

| Brushless Motors | Replacing traditional motors with brushless alternatives. | Improved efficiency and reduced heat generation. |

| Precision Accessories | Using specialized attachments for specific tasks. | Enhanced accuracy and versatility in various applications. |

Conclusion

Implementing these upgrades can significantly elevate the performance of your tools. By focusing on efficiency and versatility, you not only improve the user experience but also ensure that your equipment remains competitive in demanding environments.

Safety Precautions During Repairs

When undertaking any repair task, ensuring a safe working environment is paramount. Proper precautions not only protect the individual performing the repairs but also safeguard surrounding equipment and tools. Adhering to basic safety measures can help prevent accidents and injuries, making the process more efficient and effective.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is clean and well-lit to avoid tripping hazards.

- Disconnect power sources before beginning any repairs to prevent electric shock.

Tool and Equipment Safety

- Inspect tools for damage before use and replace any that are worn out or broken.

- Use the correct tools for the job to minimize the risk of injury and damage.

- Store tools properly after use to prevent accidents and ensure longevity.

By prioritizing safety, individuals can effectively mitigate risks associated with repairs, leading to a more successful outcome and enhanced peace of mind.

Resources for M18 Tool Owners

For enthusiasts and professionals alike, having access to reliable materials and support is crucial for maintaining and enhancing the performance of power tools. This section provides various resources that can help users understand their tools better, troubleshoot issues, and find replacement components when needed.

Whether you are looking for detailed manuals, instructional videos, or community forums, there are numerous avenues available to assist tool owners in maximizing their equipment’s potential.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Official documentation outlining specifications, features, and usage guidelines. | View Manuals |

| Tutorial Videos | Visual guides demonstrating proper operation, maintenance, and repair techniques. | Watch Tutorials |

| Online Forums | Community spaces for discussing experiences, sharing tips, and seeking advice from fellow users. | Join Forums |

| Replacement Components | Online retailers offering a variety of components for repairs and upgrades. | Shop Components |

By utilizing these resources, tool owners can ensure their equipment remains in top condition and serves them well for years to come.