Exploring the intricate world of engine assemblies reveals a wealth of information crucial for enthusiasts and professionals alike. This section aims to illuminate the various elements that come together to form a high-performance machine. By breaking down these components, we can appreciate the engineering marvels that drive innovation in the automotive industry.

Identifying each element not only enhances our comprehension but also equips us with the knowledge necessary for effective maintenance and upgrades. The interaction between these individual pieces plays a vital role in the overall functionality of the system, making it essential to understand their positions and relationships.

In this examination, we will delve into the specifics of each component, uncovering their ultimate roles and significance. This deeper understanding fosters a greater appreciation for the craftsmanship involved in creating reliable and efficient engines.

Understanding Mercury Motor Components

Grasping the intricate elements of an engine is essential for optimal performance and maintenance. Each segment plays a crucial role, contributing to the overall functionality and efficiency of the system. By exploring these individual components, enthusiasts can enhance their knowledge and ensure longevity.

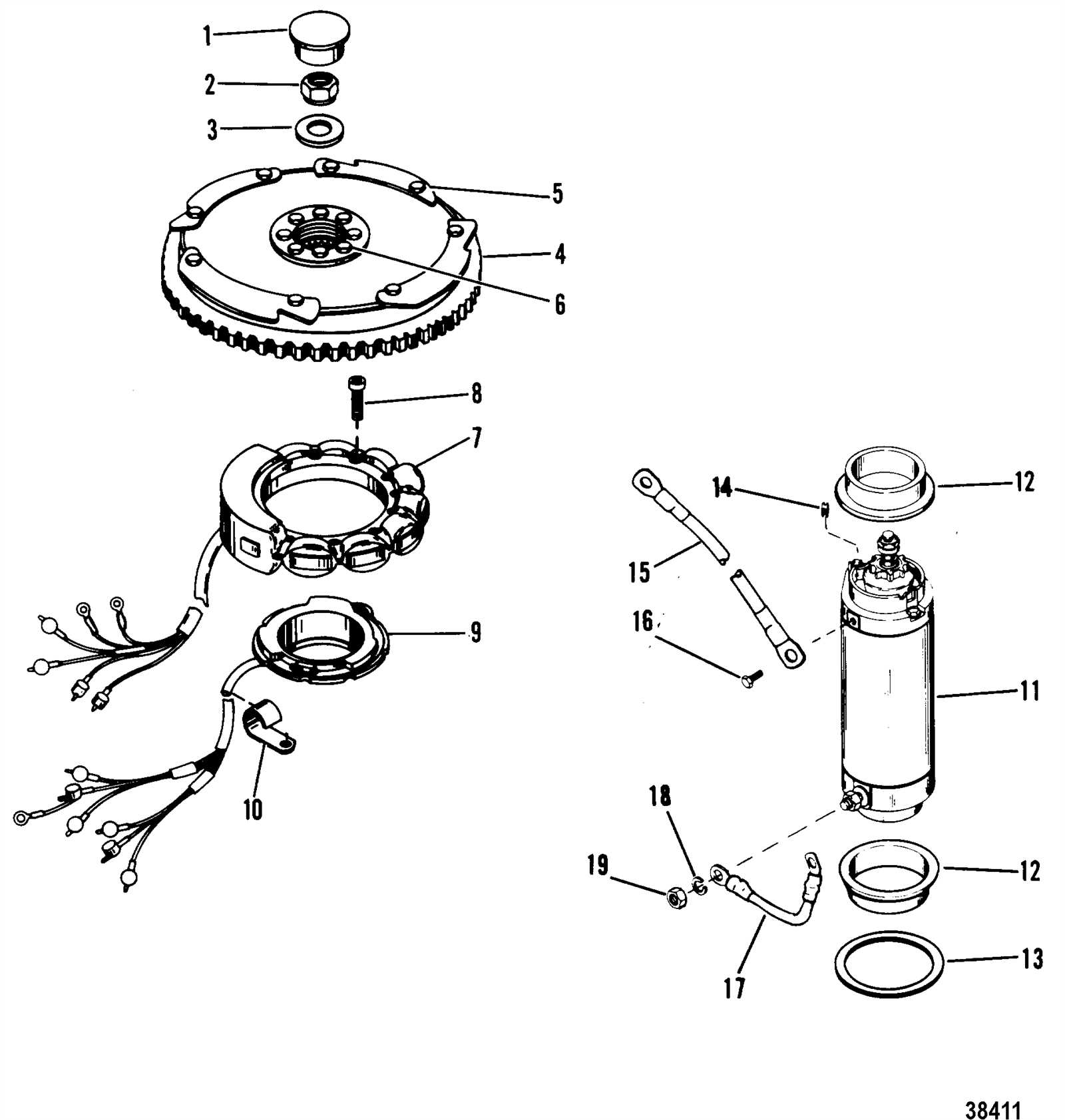

Key Elements: The primary sections include the ignition system, fuel delivery components, and the cooling mechanisms. Each of these areas has specific tasks that, when working harmoniously, lead to smooth operation.

Maintenance Tips: Regular inspections and timely replacements of worn components can prevent major issues. Understanding how these parts interact will help in diagnosing problems swiftly.

Overview of Mercury Engine Parts

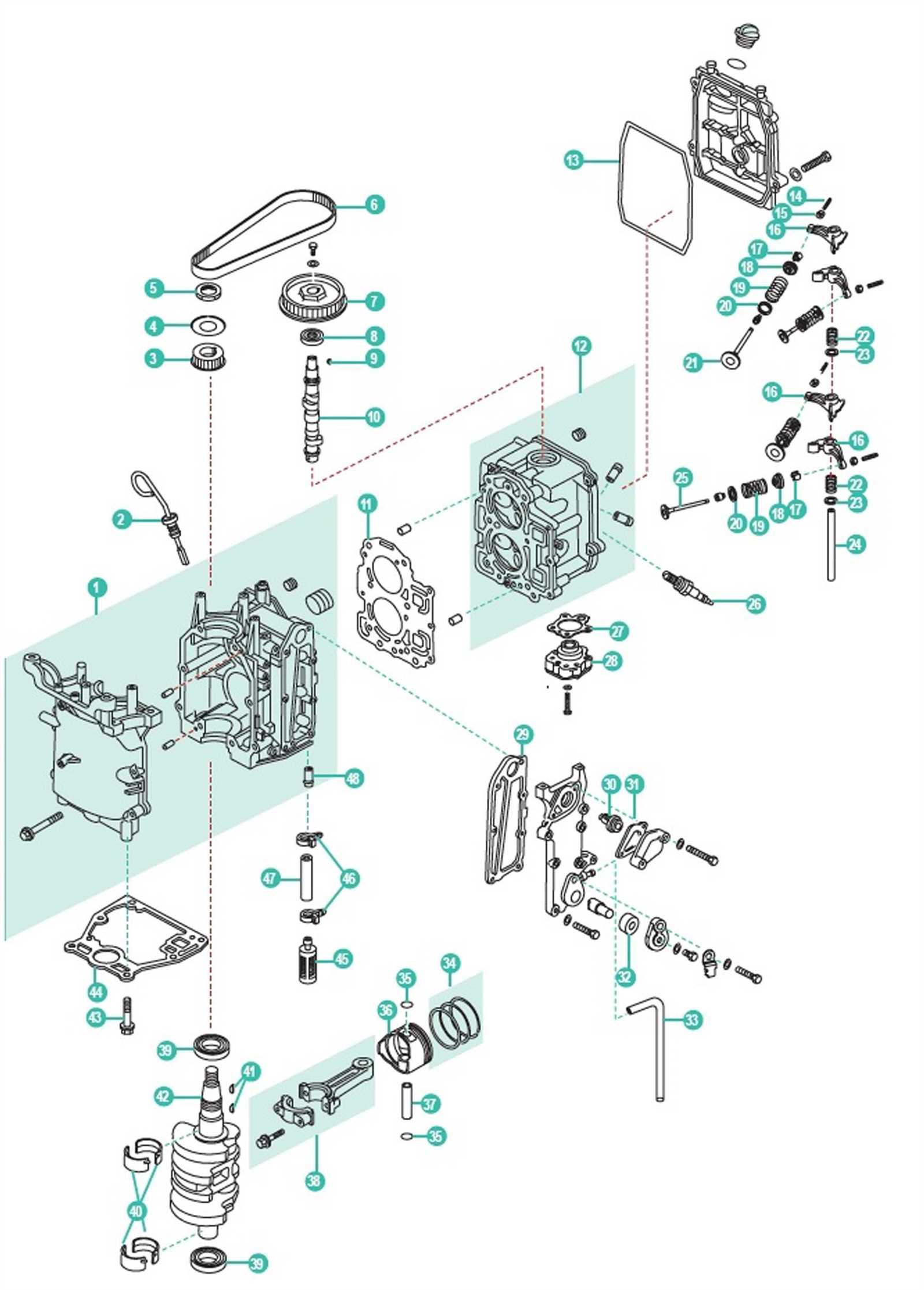

This section provides a comprehensive look at the various components that make up a specific engine model, highlighting their roles and interconnections. Understanding these elements is crucial for anyone looking to maintain or enhance engine performance.

Key Components

At the core of the system are the primary units that facilitate combustion and power generation. These essential pieces include the cylinder block, crankshaft, and camshaft, all of which work together to convert fuel into motion.

Supporting Elements

In addition to the main units, auxiliary components such as the fuel injection system, ignition setup, and exhaust system play vital roles in optimizing functionality. These elements ensure efficient operation and compliance with environmental standards.

Functionality of Each Component

This section explores the roles and responsibilities of various elements within a propulsion system. Each component plays a crucial part in ensuring optimal performance and efficiency, contributing to the overall operation of the engine.

Core Elements

Understanding the core elements allows for better maintenance and troubleshooting. Each component interacts with others, creating a cohesive system that drives functionality.

| Component | Function |

|---|---|

| Fuel Injector | Delivers precise amounts of fuel for combustion. |

| Crankshaft | Transforms linear motion into rotational force. |

| Ignition Coil | Generates high voltage for spark plugs. |

| Cooling System | Maintains optimal operating temperature. |

Supporting Components

In addition to core elements, supporting components enhance efficiency and reliability. Understanding their functions is essential for maximizing performance.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and efficiency of any mechanical system. Neglecting this aspect can lead to unforeseen issues, reduced performance, and ultimately higher costs. By prioritizing routine care, one can maximize reliability and minimize the risk of failures.

Benefits of Regular Upkeep

- Enhanced Performance

- Increased Lifespan

- Cost Efficiency

- Safety Assurance

Key Maintenance Practices

- Regular Inspections

- Fluid Changes

- Component Cleaning

- Timely Repairs

Common Issues with Mercury Motors

Understanding the frequent challenges faced by watercraft engines can significantly enhance their performance and longevity. Owners often encounter issues ranging from mechanical failures to electrical malfunctions, which can lead to decreased efficiency or complete operational failure.

One prevalent problem is overheating, typically caused by inadequate cooling systems or blockages. Regular maintenance can help prevent this by ensuring coolant levels are adequate and the intake is clear.

Fuel system complications, such as clogged filters or stale fuel, can also disrupt functionality. Routine inspections and timely fuel changes are essential for optimal operation.

Electrical failures, including battery issues and faulty wiring, often arise as well. Conducting thorough checks of the electrical components can mitigate these risks.

Lastly, improper lubrication can result in excessive wear and tear on moving parts. Adhering to recommended oil change intervals is crucial for preserving engine integrity.

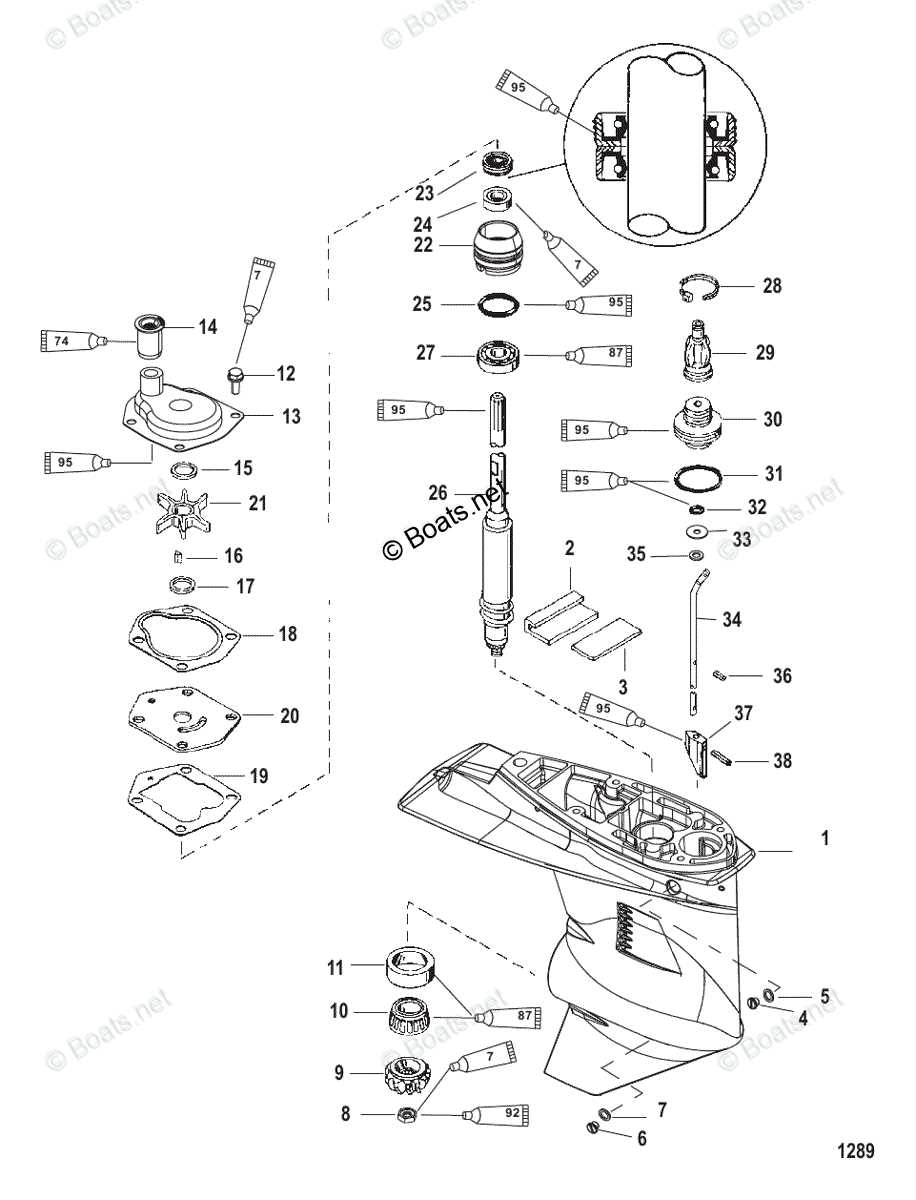

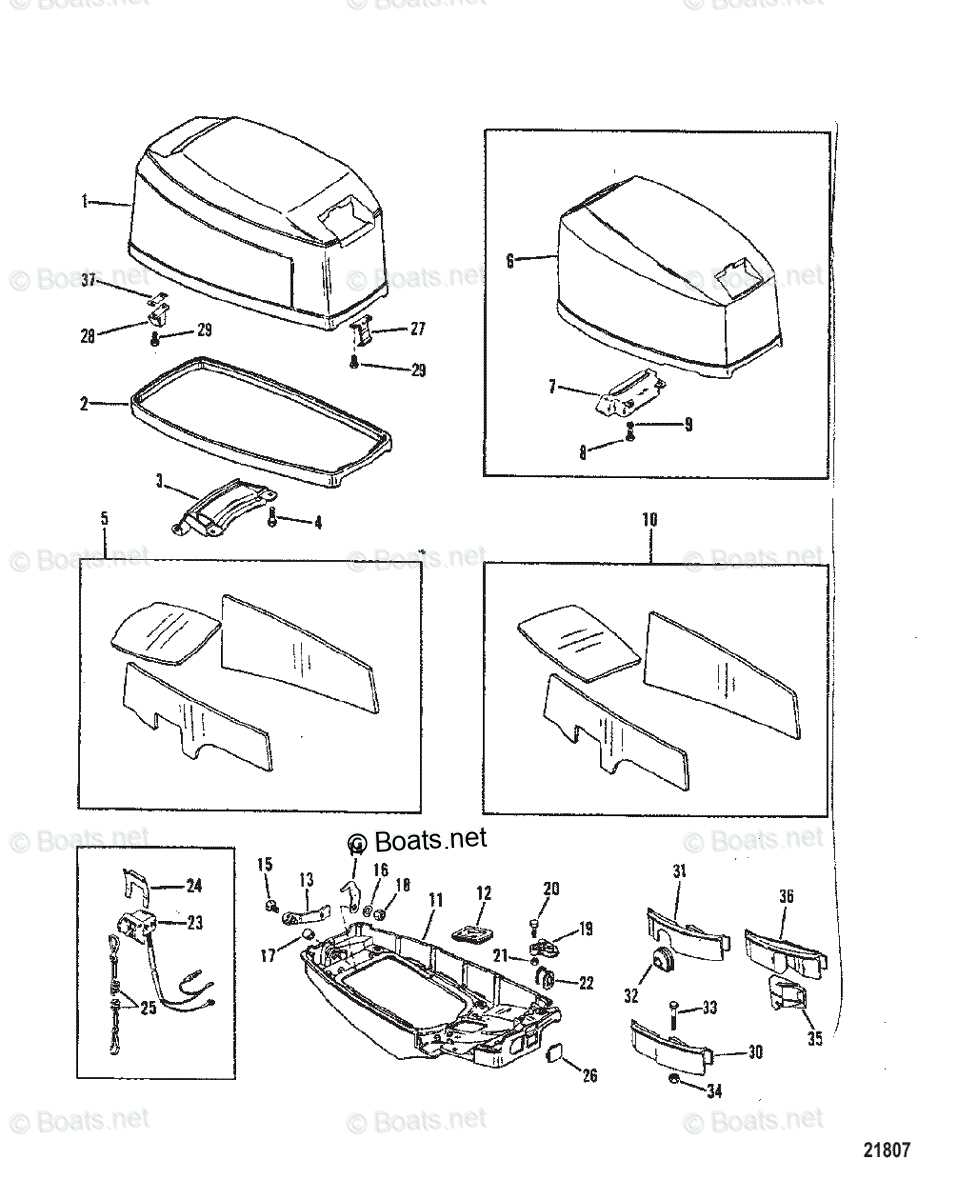

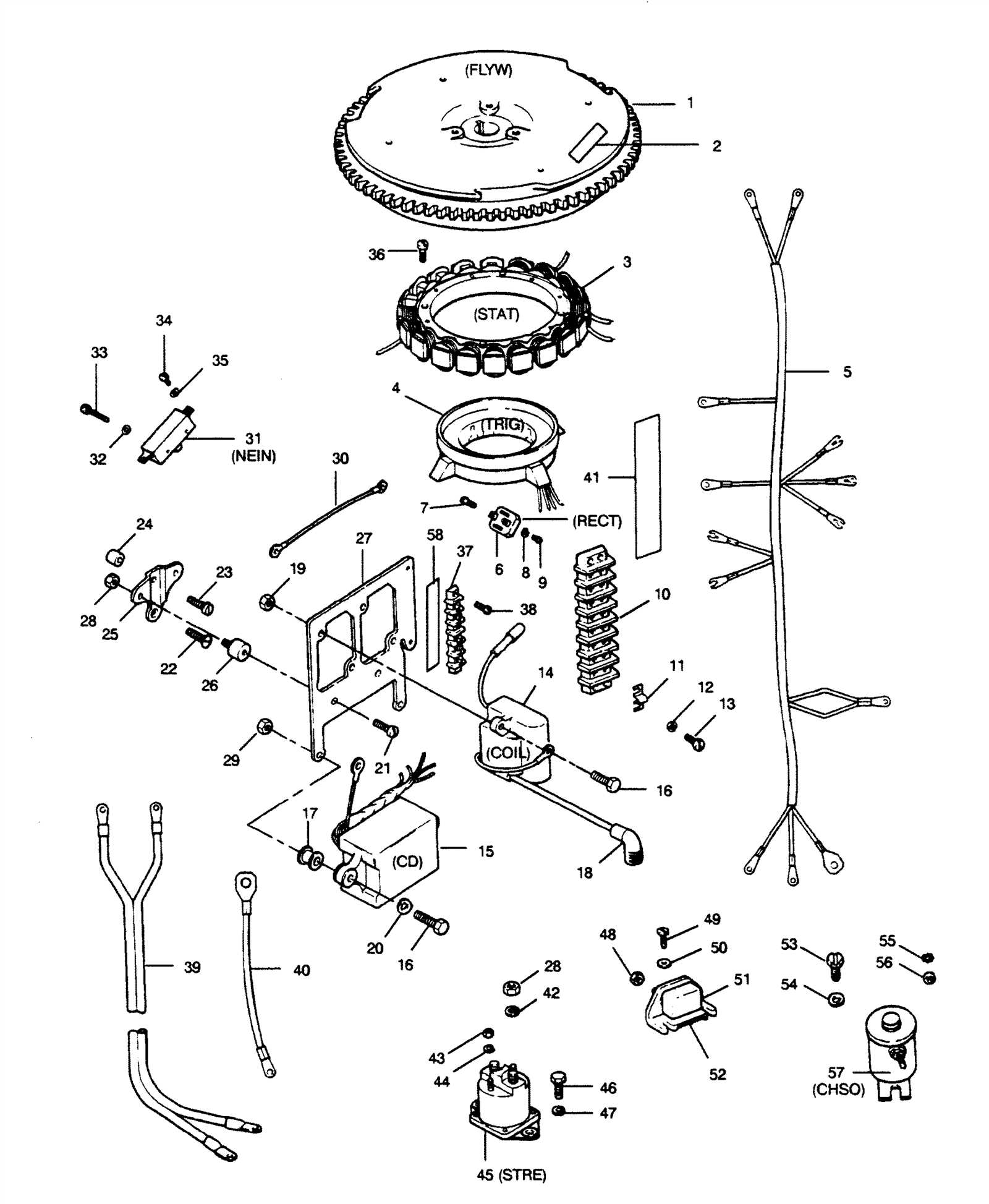

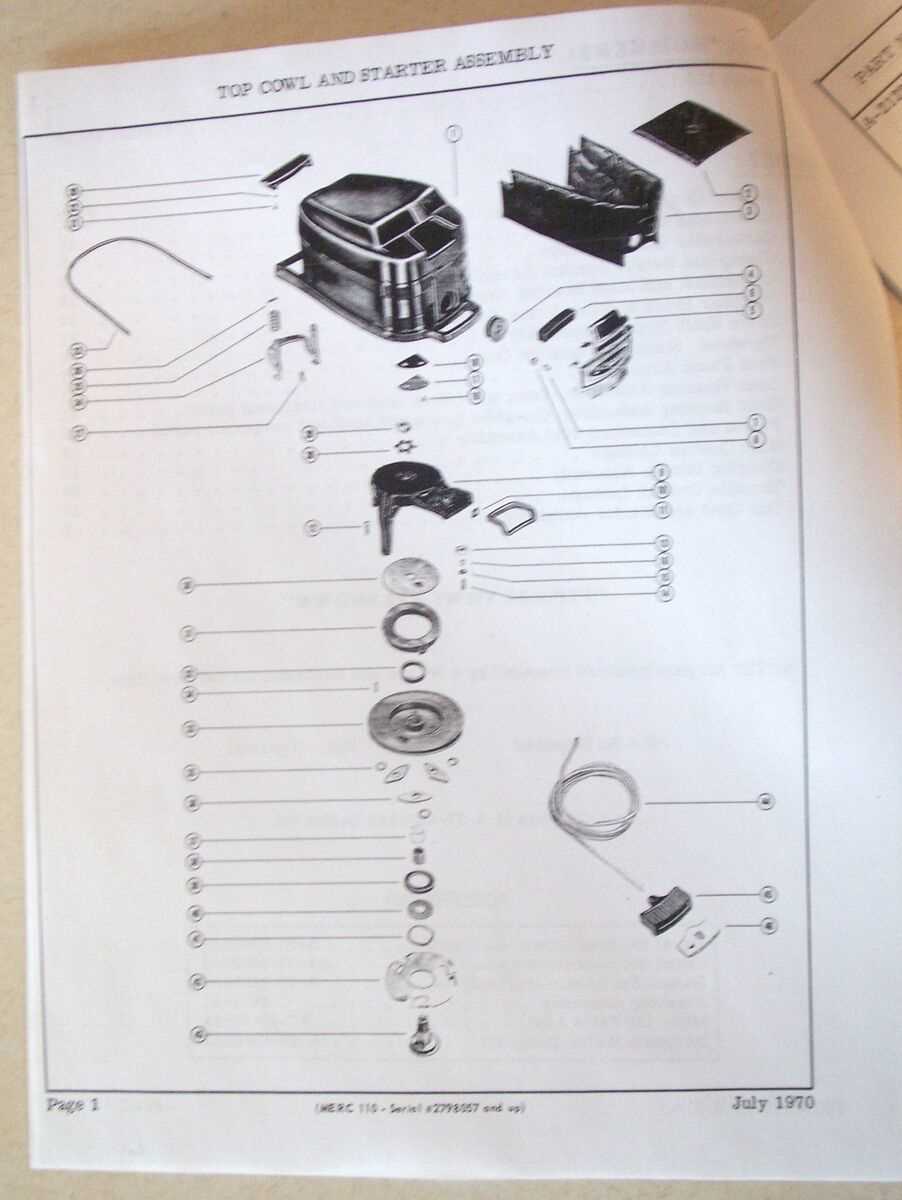

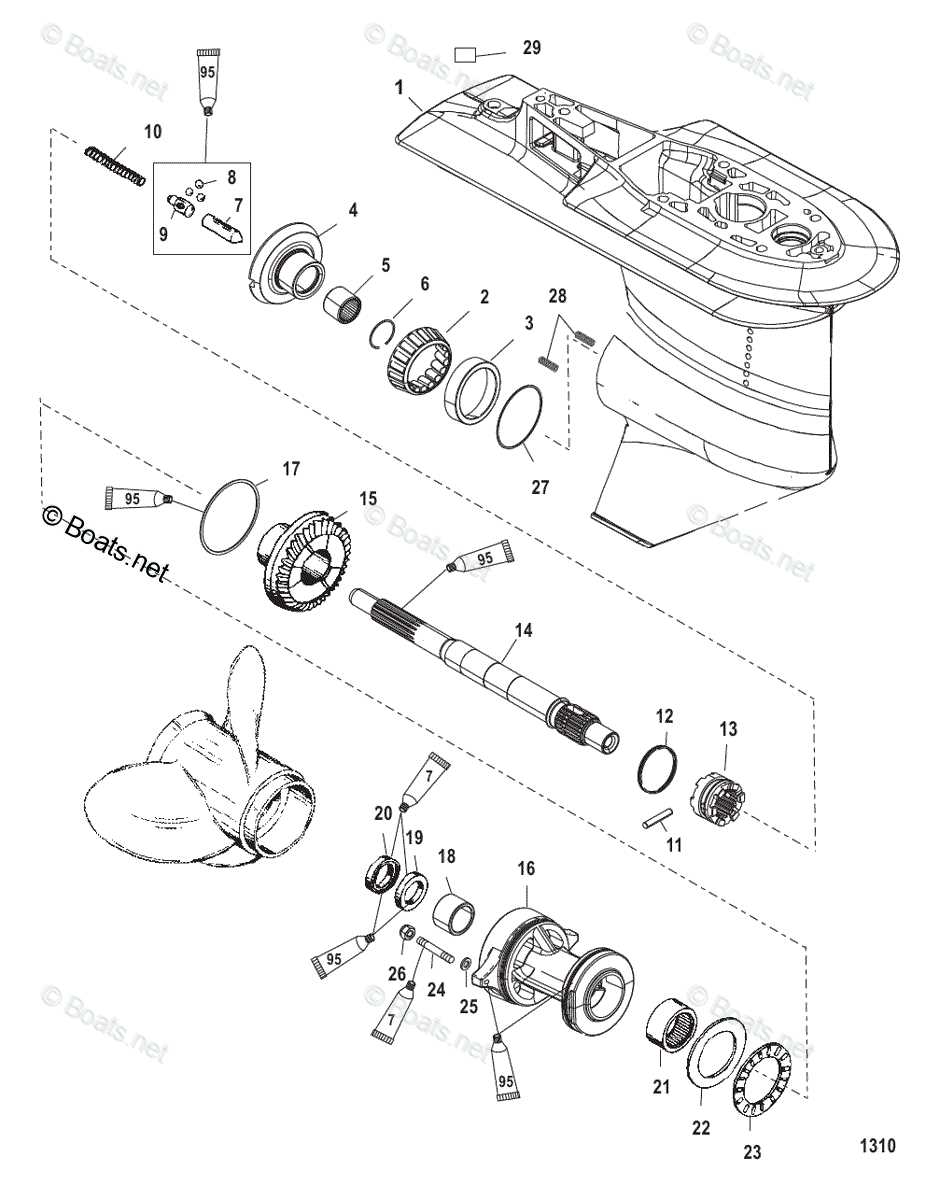

How to Read Motor Diagrams

Understanding technical illustrations is essential for anyone working with mechanical systems. These visual representations convey complex information about components and their interactions, allowing users to troubleshoot and maintain equipment effectively. Familiarity with symbols and layouts is crucial for interpreting these resources accurately.

1. Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent different elements. These may include shapes for components and lines indicating connections. Learning these conventions will enhance your comprehension.

2. Study the Layout: Pay attention to the arrangement of the components. A logical flow often guides you from power sources through various stages of operation. This can help you visualize how the system functions as a whole.

3. Trace the Pathways: Follow the lines connecting the elements to understand how energy or signals move through the system. Identifying these pathways is vital for diagnosing issues or making modifications.

4. Refer to the Legend: Many illustrations include a legend or key that explains the symbols used. Consulting this reference can clarify any uncertainties and ensure accurate interpretation.

5. Practice Regularly: Like any skill, becoming proficient in reading these visual tools takes practice. Regularly reviewing and analyzing different illustrations will build your confidence and expertise.

By mastering these techniques, you’ll be better equipped to engage with technical resources, leading to improved efficiency and effectiveness in your work.

Tools for Mercury Parts Replacement

Replacing components in a vehicle requires specific implements to ensure the job is done efficiently and safely. Having the right tools not only simplifies the process but also minimizes the risk of damage to the system. Understanding the essential instruments can significantly enhance your repair experience.

Basic Hand Tools are crucial for any replacement task. Wrenches, screwdrivers, and pliers form the backbone of any toolkit. Each of these tools serves a specific function, making it easier to access and remove old components.

Specialized Equipment can further aid in the process. For instance, torque wrenches are essential for applying the correct amount of force, preventing overtightening or damage. Additionally, oil filter wrenches help in removing filters without causing unnecessary strain.

Diagnostic Tools are invaluable for identifying issues before beginning any replacement. Scanners can read error codes, providing insights into what needs attention. This can save time and resources by pinpointing the exact problem.

Investing in quality tools can make a significant difference in the outcome of your repairs. Durable and well-designed implements not only enhance efficiency but also ensure a higher standard of workmanship. Prioritize building a comprehensive toolkit to tackle any replacement challenge effectively.

Where to Find Genuine Parts

When seeking authentic components for your engine, it’s crucial to ensure you’re acquiring high-quality items that meet original specifications. Various sources offer reliable options, each with its own advantages.

Authorized Dealers: One of the most dependable places to locate original components is through authorized dealerships. They provide a wide selection of genuine items and often have knowledgeable staff to assist with your inquiries.

Online Retailers: Numerous reputable online platforms specialize in automotive components. Look for websites with good reviews and clear return policies. Verify that the items are authentic by checking product details and seller ratings.

Local Auto Parts Stores: Many local stores carry a range of genuine components. Visiting in person allows you to ask questions and get recommendations from experienced staff, ensuring you find what you need.

Manufacturer’s Website: The official website of the manufacturer often has a dedicated section for genuine items. Here, you can explore the full catalog and possibly find special promotions or deals.

By exploring these options, you can confidently acquire the authentic components necessary for your vehicle’s performance and longevity.

DIY Repair Tips for Enthusiasts

For those passionate about hands-on projects, tackling repairs on your own can be both rewarding and cost-effective. Understanding the intricacies of the machinery allows enthusiasts to gain deeper insights and enhance their skills. Below are some practical tips to guide you through the repair process effectively.

| Tip | Description |

|---|---|

| Research Thoroughly | Before beginning any repair, gather information from manuals, forums, and videos to understand the components involved. |

| Organize Tools | Keep your tools organized and easily accessible. This will save time and frustration during the repair process. |

| Document Your Steps | Take notes or photos as you disassemble components. This will help when reassembling and ensure nothing is overlooked. |

| Safety First | Always prioritize safety by wearing appropriate gear and ensuring the workspace is clear of hazards. |

| Test After Repairs | After completing repairs, conduct thorough tests to confirm that everything is functioning as intended before finalizing the project. |

Safety Precautions During Repairs

Ensuring safety during maintenance and repair tasks is crucial to prevent accidents and injuries. Adopting proper measures not only protects the individual performing the work but also extends the lifespan of the equipment being serviced. It is essential to familiarize oneself with safety protocols and implement them consistently throughout the process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is vital. This includes gloves to shield hands from harmful substances, goggles to protect the eyes from debris, and ear protection if working in a noisy environment. Utilizing this gear minimizes the risk of injury and enhances overall safety.

Work Area Safety

Maintaining a clean and organized workspace is equally important. Ensure that tools are stored properly and that the area is free from clutter. Additionally, be aware of your surroundings and eliminate any hazards, such as spills or obstructions. A well-prepared environment fosters focus and reduces the likelihood of accidents.

Upgrading Your Mercury Motor

Enhancing the performance and efficiency of your engine can lead to a more enjoyable experience on the water. Whether you’re seeking increased speed, better fuel economy, or improved handling, there are numerous modifications available to elevate your vessel’s capabilities. Understanding the options and their implications is essential for making informed decisions.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Propeller Change | Switching to a higher performance propeller can significantly improve thrust and speed. | Enhanced acceleration and maneuverability. |

| EFI System Upgrade | Upgrading to an electronic fuel injection system optimizes fuel delivery. | Better fuel efficiency and reduced emissions. |

| Exhaust System | Installing a performance exhaust can increase horsepower and reduce weight. | Improved engine sound and efficiency. |

| Intake Modifications | Upgrading the air intake system can enhance airflow to the engine. | Boosted power output and responsiveness. |

By carefully selecting upgrades, you can ultimately transform your engine into a more powerful and efficient unit, providing a thrilling experience on the water.

Resources for Further Learning

This section provides a curated list of materials designed to enhance your understanding of mechanical components and their functions. Whether you’re a novice seeking foundational knowledge or an experienced enthusiast looking to deepen your expertise, these resources will guide your exploration.

- Books:

- Understanding Engine Components – A comprehensive guide to the fundamentals of engine design.

- Repairing and Overhauling Engines – A practical manual that covers various techniques and best practices.

- Online Courses:

- Forums and Communities:

- Reddit Mechanics – A community where enthusiasts share advice and experiences.

- The Garage Journal – A forum for DIY enthusiasts to discuss projects and seek guidance.

- Videos and Tutorials:

By utilizing these resources, you can expand your knowledge and gain practical skills that will enhance your understanding of complex machinery and their operation.