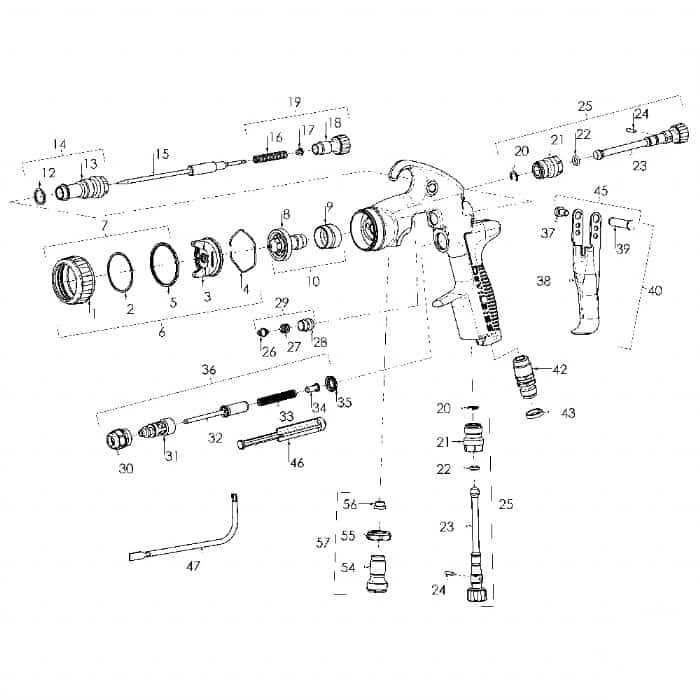

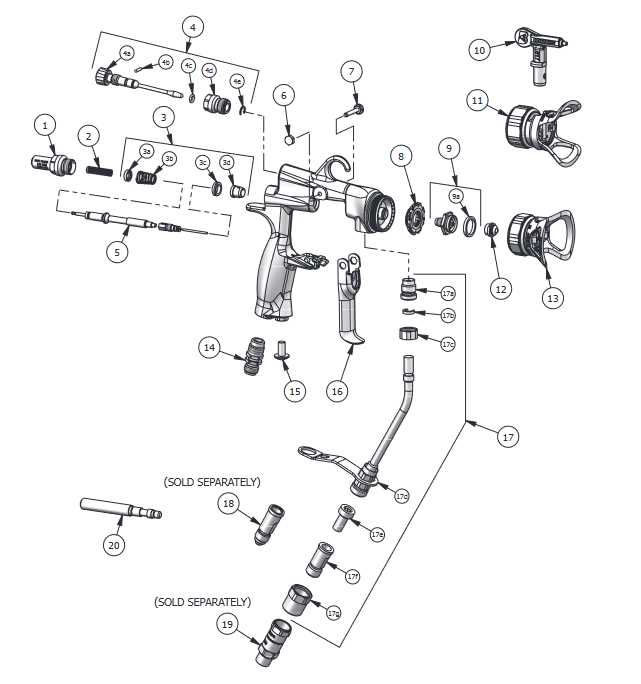

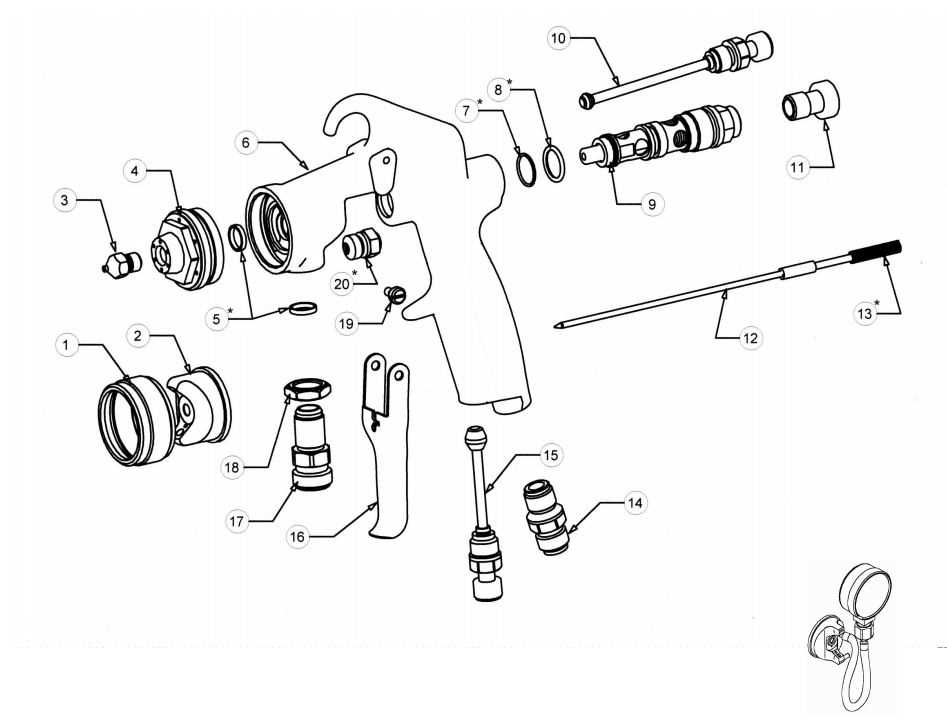

In the realm of pneumatic tools, understanding the inner workings and structural elements of a particular equipment configuration serves as a vital foundation for operational proficiency. This section delves into the intricacies of visual representation, detailing the essential constituents that compose the mechanism.

Essential Components: Delving into the intricacies of visual representation entails a thorough examination of the fundamental constituents constituting the mechanism, including critical parts that contribute to its operational efficiency.

Key Elements of Precision Tools

In examining the core components of precision tools, we delve into the fundamental building blocks that define their functionality and efficiency. These elements encompass the intricate mechanisms that drive performance and reliability, ensuring optimal operation across various applications.

Essential Mechanisms

Essential mechanisms encapsulate the intricate workings that drive efficiency and performance. These elements are vital for overall system functionality, ensuring optimal operation in a range of applications.

Advanced Components

Advanced components comprise the sophisticated parts that elevate tool performance to meet stringent demands. These components integrate seamlessly, enhancing precision and durability for superior results.

Functionality of Each Part

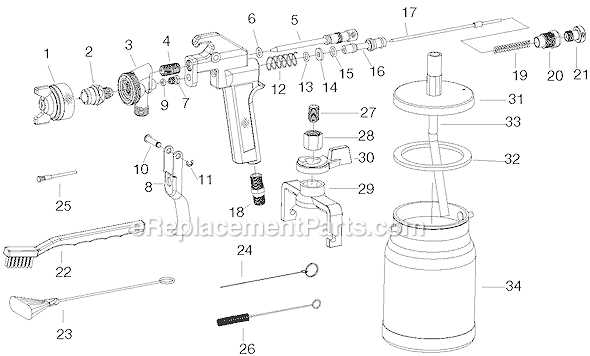

The efficient operation of a spraying device relies on the harmonious interaction of its various components. Understanding the role of each element is crucial for achieving optimal performance and maintenance. This section delves into the specific functions of each constituent, highlighting their significance in the overall mechanism.

| Component | Function |

|---|---|

| Nozzle | Regulates the flow and atomization of the material, ensuring an even application. |

| Trigger | Controls the release of the substance, allowing for precise handling during operation. |

| Fluid Cup | Holds the liquid material, providing a reservoir from which it is drawn for application. |

| Air Cap | Facilitates the mixing of air and fluid, creating the necessary pressure for effective atomization. |

| Handle | Offers grip and maneuverability, enabling the user to control the direction and pressure of the application. |

Importance of Proper Maintenance

Maintaining equipment is crucial for ensuring optimal performance and longevity. Regular upkeep not only enhances functionality but also prevents unexpected failures that can disrupt operations. Understanding the significance of systematic care helps in maximizing the efficiency of tools used in various applications.

Routine checks are essential for identifying wear and tear early. By addressing minor issues before they escalate, users can save time and resources, avoiding costly repairs or replacements. Furthermore, consistent maintenance contributes to a safer working environment, reducing the risk of accidents caused by malfunctioning equipment.

Proper cleaning is another vital aspect, as it prevents buildup that can affect performance. Using the correct cleaning techniques ensures that all components operate smoothly, resulting in better output quality. Additionally, maintaining a clean tool not only prolongs its life but also enhances the user experience.

Lastly, keeping an eye on the manufacturer’s guidelines for care and upkeep is fundamental. Adhering to these recommendations ensures that all tools operate within their designed parameters, leading to superior results and greater satisfaction in their use.

Identifying Common Issues

Recognizing frequent problems in equipment can significantly enhance performance and extend lifespan. Many users encounter similar challenges, which can often be traced back to specific components or misuse. Understanding these issues is crucial for effective troubleshooting and maintenance.

1. Uneven Application

One of the most common challenges is the uneven distribution of material. This can result from clogged nozzles or improper pressure settings. Regular cleaning and checking of the mechanism can help maintain consistent output. Ensure that the viscosity of the fluid is appropriate, as overly thick substances can also lead to application difficulties.

2. Excessive Overspray

Overspray not only wastes materials but can also lead to a messy work environment. This issue often arises from incorrect fan adjustments or the distance between the applicator and the surface. Adjusting the spray pattern and maintaining the correct distance can minimize excess dispersion, resulting in a cleaner finish.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for a successful outcome. Each repair task requires specific implements that ensure precision and efficiency, ultimately leading to optimal performance.

Wrenches are crucial for loosening or tightening various components. A good set that includes both adjustable and socket styles will provide versatility for different sizes and shapes of fittings.

Screwdrivers in various sizes and types, including flathead and Phillips, are necessary for removing and securing screws that hold parts in place. Having a magnetic tip can make the job easier, especially in tight spaces.

Pliers can be invaluable for gripping, twisting, or cutting wires and small pieces. Needle-nose pliers, in particular, allow for greater reach and maneuverability in confined areas.

Cleaning supplies, such as brushes and solvents, are also important. Keeping your equipment clean will enhance performance and prolong its lifespan. Regular maintenance prevents buildup that could impede functionality.

Finally, a multimeter is an excellent tool for diagnosing electrical issues, ensuring that connections are secure and voltages are within acceptable ranges. Having the right tools at your disposal can make all the difference in effectively restoring your equipment.

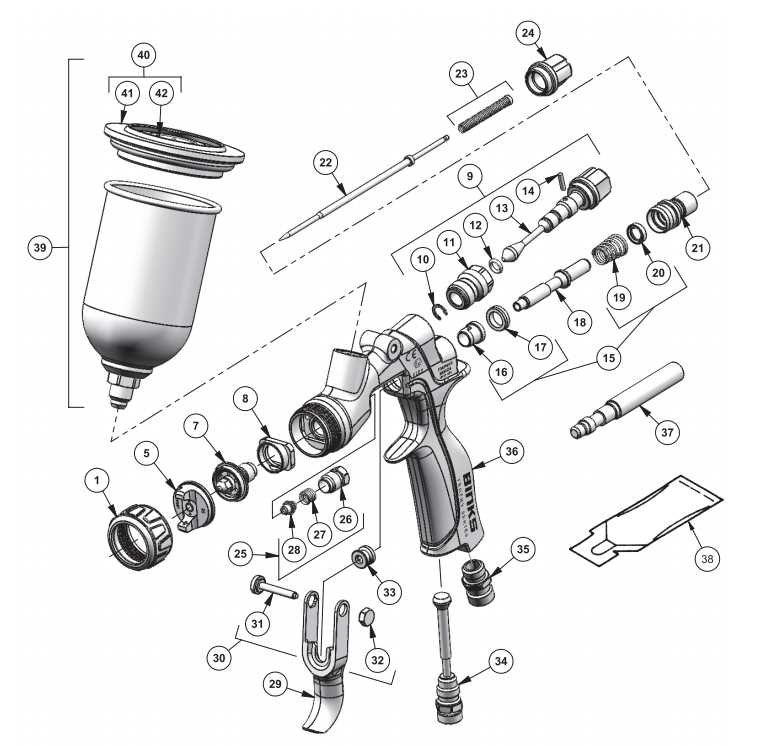

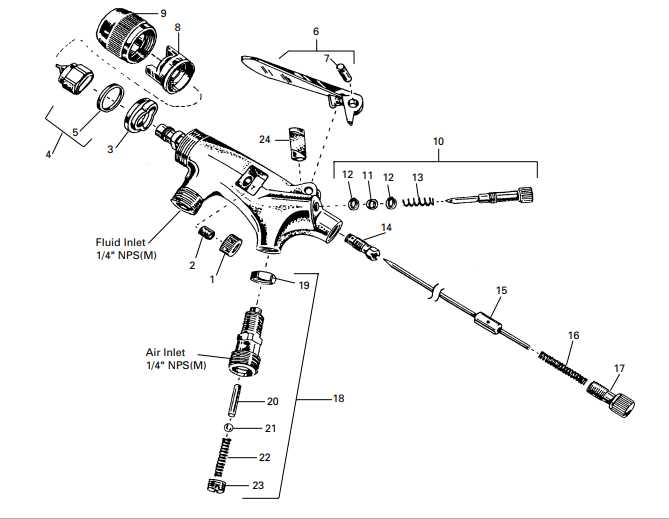

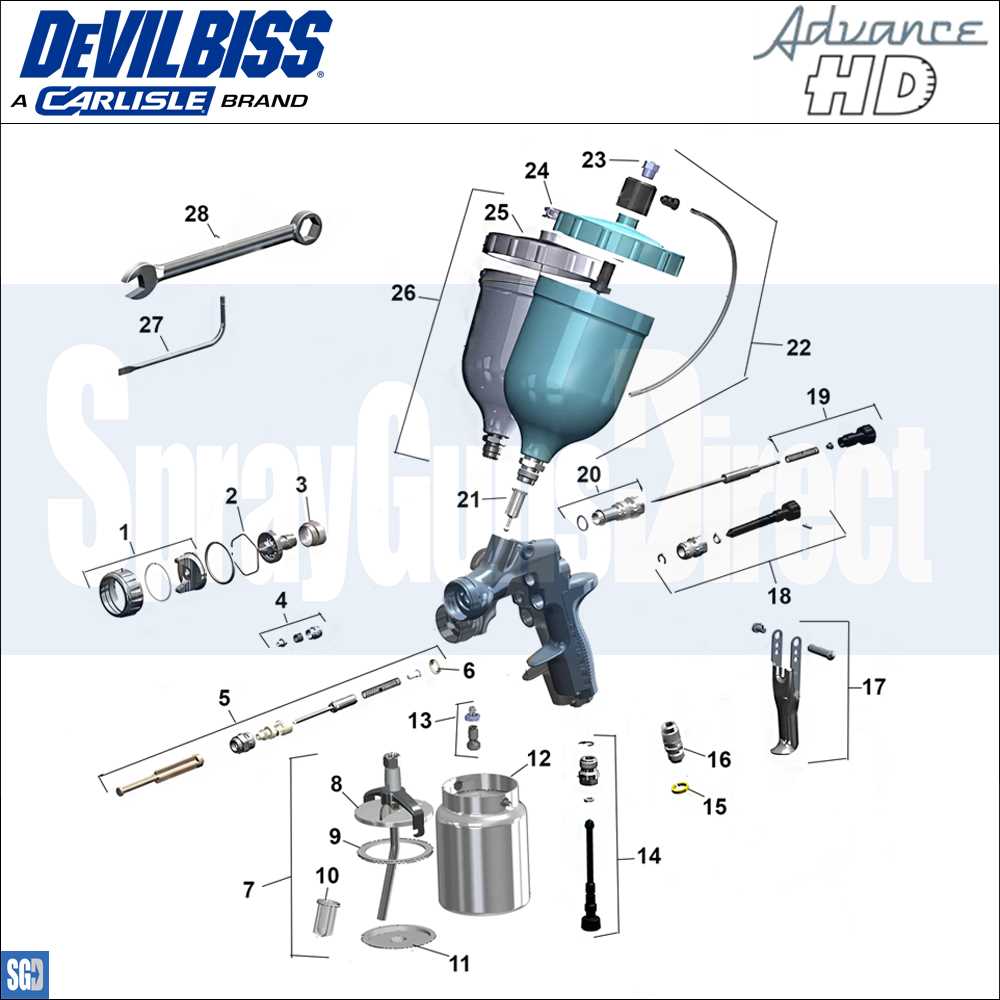

Step-by-Step Assembly Guide

This guide provides a clear and concise approach to assembling your equipment, ensuring optimal performance and efficiency. By following each step meticulously, you will be able to put together the components seamlessly, enhancing your overall experience and satisfaction with the tool.

Preparation and Organization

Before you begin the assembly process, gather all necessary components and tools in one place. Review the manual to familiarize yourself with each element and its function. Creating a clean and organized workspace will streamline the assembly and help prevent any loss of pieces.

Assembly Steps

Start by attaching the primary sections together, ensuring a secure fit. Follow with the installation of any connectors, making sure they are tight to avoid leaks. Next, add the adjustment features, checking that they move freely and are easily accessible. Finally, conduct a thorough inspection of the assembled unit to confirm that everything is properly aligned and functioning as intended. This attention to detail will result in a reliable and effective tool ready for use.

Differences Between Models

Understanding the variations among different designs is crucial for selecting the most suitable option for your needs. Each version may feature unique characteristics that influence performance, usability, and efficiency. By examining these distinctions, users can make informed decisions that align with their specific requirements.

Key Variations in Features

One of the primary differences lies in the functionality offered by each model. Some variants are engineered for fine detail work, while others are designed for broader coverage. Additionally, the type of nozzle and air cap can significantly impact the application process. For instance, a model equipped with a fine nozzle is ideal for intricate tasks, whereas a larger nozzle is more effective for extensive surfaces.

Ergonomics and Design

Another aspect to consider is the ergonomic design. Certain models prioritize user comfort, featuring lightweight materials and strategically placed grips that reduce fatigue during prolonged use. This can enhance overall productivity and improve the quality of the outcome. Furthermore, variations in the assembly and disassembly process can affect maintenance and cleaning, making some designs more user-friendly than others.

Upgrades and Enhancements Available

In the world of painting and coating tools, there are numerous opportunities for improvement and customization that can significantly enhance performance and efficiency. These modifications can lead to better application results, increased durability, and a more comfortable user experience.

Performance Boosters: Upgrading to high-efficiency nozzles and tips can provide a finer finish and reduce overspray, allowing for greater control during the application process. Advanced needle designs also facilitate smoother flow and precise material atomization.

Ergonomic Features: Comfort is key in extended usage. Ergonomic handles and grips can reduce fatigue, making the tool easier to handle. Some models offer adjustable features that allow users to tailor the tool to their specific needs.

Maintenance Enhancements: Investing in high-quality seals and filters can extend the lifespan of your equipment. Easy-to-clean components ensure that maintenance is quick and hassle-free, minimizing downtime between projects.

Compatibility and Adaptability: Many enhancements are designed to be compatible with a variety of models, offering versatility for different applications. Upgradable accessories, such as pressure regulators and hoses, can further optimize performance.

Exploring these options allows users to not only improve their tools but also elevate their overall painting experience, achieving superior results with each project.

Compatibility with Other Brands

Understanding the interchangeability of components across various manufacturers can greatly enhance versatility and efficiency. Users often seek solutions that enable the seamless integration of elements from different brands, thus expanding their options and optimizing performance.

| Brand | Compatible Models | Notes |

|---|---|---|

| Brand A | Model X, Model Y | Similar threading and design. |

| Brand B | Model Z | Adapters may be required. |

| Brand C | Model W, Model V | Direct fit for certain components. |

Exploring these relationships not only aids in effective repairs but also allows for cost-effective upgrades and replacements. By recognizing compatible alternatives, users can maximize their investments and ensure high-quality results.

Choosing the Right Accessories

Selecting the appropriate attachments and enhancements for your equipment is crucial for achieving optimal performance and results. The right accessories can significantly influence the efficiency and quality of your projects, making the task at hand easier and more enjoyable.

When considering which enhancements to incorporate, it’s important to evaluate several key factors:

- Compatibility: Ensure that the accessories are suitable for your specific model to avoid any operational issues.

- Purpose: Identify what tasks you intend to accomplish. Different attachments cater to varying applications, from detailed work to broader coverage.

- Quality: Invest in high-quality products that promise durability and reliability, as this will save you time and money in the long run.

- User Feedback: Look for reviews or testimonials from other users to gauge the performance of the accessories you are considering.

To assist in your selection process, consider the following popular types of enhancements:

- Fluid Nozzles: Varying sizes and types can alter the flow rate and spray pattern, which is essential for different applications.

- Filters: These help prevent debris from clogging your equipment, ensuring a smooth operation.

- Hoses: Choosing the right length and material is vital for maneuverability and flexibility during use.

- Pressure Regulators: Maintaining the right pressure can enhance control and precision in your work.

Ultimately, taking the time to choose the right accessories can elevate your projects to a new level of quality and efficiency. Investing in the right tools is an investment in your craft.

Best Practices for Usage

When utilizing a high-efficiency application tool, it is essential to follow certain guidelines to achieve optimal results. Adopting best practices not only enhances the quality of your work but also prolongs the lifespan of the equipment. This section outlines key strategies to ensure effective and efficient use of your device.

Preparation and Setup

Before commencing any project, thorough preparation is vital. Ensure that the workspace is clean and well-ventilated. Gather all necessary materials and perform a detailed inspection of the device to confirm it is in good working condition. Properly adjust the settings based on the type of medium being used, as this can significantly affect the finish quality.

Technique and Maintenance

Employing the correct technique is crucial for achieving a smooth and even application. Maintain a consistent distance and angle while operating the tool, and practice fluid motions to avoid streaks or uneven coverage. After each use, perform routine cleaning and maintenance to remove any residue, preventing clogs and ensuring long-term performance.

Safety Tips While Operating

Ensuring a secure working environment is crucial when handling equipment. Awareness and precautionary measures can prevent accidents and enhance overall efficiency. Following basic guidelines contributes to a safer experience, allowing users to focus on the task at hand.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and masks to shield against harmful substances. |

| Maintain Proper Ventilation | Ensure the workspace is well-ventilated to avoid inhaling fumes. |

| Check Equipment Regularly | Inspect tools and devices for any signs of wear or damage before use. |

| Keep Area Clean | Remove clutter and spills to minimize hazards in the work area. |

| Read Instructions | Familiarize yourself with the operating manual and guidelines provided by the manufacturer. |