In the realm of outdoor machinery, having a clear visual representation of the various elements is crucial for effective maintenance and repair. This knowledge empowers users to identify individual components, ensuring that each part functions harmoniously within the entire system. A well-structured overview can significantly enhance the efficiency of both troubleshooting and routine upkeep.

Every piece of equipment comprises a unique assembly of mechanisms that work together to achieve optimal performance. Grasping the arrangement of these elements is essential for anyone involved in the operation or maintenance of such machinery. A comprehensive layout not only simplifies repairs but also helps in understanding how each section contributes to the overall functionality.

Whether you are a seasoned technician or a novice user, familiarizing yourself with the intricate configurations of your equipment can lead to better handling and longevity. Detailed illustrations serve as valuable references, guiding you through the complexities of assembly and disassembly. With this foundational knowledge, tackling issues becomes a less daunting task.

Understanding the John Deere S1400

This section aims to explore a specific model from a well-known agricultural machinery brand, focusing on its components and functionality. By examining various elements of this machine, users can gain insights into its operational capabilities and maintenance needs.

Key Features and Functionality

This model is designed to enhance efficiency in farming tasks. With robust construction and user-friendly controls, it caters to the demands of both professionals and hobbyists, ensuring reliable performance across various applications.

Maintenance and Care

Key Components of the S1400 Model

This section explores the essential elements that contribute to the functionality and performance of the machine. Understanding these core components is vital for maintenance and operational efficiency.

Engine and Transmission

The heart of the machine lies in its robust engine and transmission system, which work in unison to deliver power and control. These elements are designed for optimal torque and responsiveness, ensuring seamless operation in various conditions.

Chassis and Frame

The chassis and frame provide structural integrity and support for all other components. Their design influences stability, weight distribution, and overall durability, making them crucial for heavy-duty applications.

| Component | Function |

|---|---|

| Engine | Provides power and performance |

| Transmission | Facilitates speed and torque management |

| Chassis | Ensures stability and support |

| Hydraulics | Enables efficient operation of attachments |

| Controls | Allows operator input and machine maneuverability |

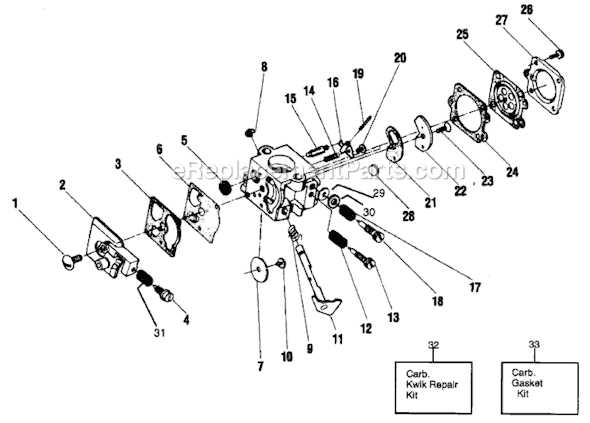

Importance of Parts Diagrams

Understanding the intricacies of machinery requires clear visual representations. These schematics serve as essential tools for identifying components and their interrelationships. They play a critical role in maintenance, repair, and assembly processes, enabling technicians to locate and replace items efficiently.

Moreover, these illustrations enhance communication among team members, ensuring everyone is on the same page regarding tasks and procedures. This leads to reduced errors and improved workflow in any mechanical setting.

| Benefits | Description |

|---|---|

| Clarity | Provides a visual guide to understand the structure and layout of machinery. |

| Efficiency | Speeds up the identification and replacement of components. |

| Collaboration | Facilitates better teamwork by standardizing information across the group. |

| Accuracy | Reduces the likelihood of mistakes during repairs and assembly. |

Where to Find S1400 Diagrams

Locating accurate illustrations and schematics for specific machinery can significantly aid in maintenance and repair tasks. Understanding the various sources available for these resources is crucial for ensuring the efficiency and longevity of your equipment.

Online Resources

- Manufacturer’s Website: The official website often provides a wealth of information, including downloadable manuals and schematics.

- Online Retailers: E-commerce platforms frequently feature user manuals and support documents as part of their product listings.

- Forums and Communities: Dedicated online forums are invaluable for sharing resources and advice among fellow enthusiasts and professionals.

Printed Materials

- Service Manuals: Purchasing a service manual specific to your model can offer comprehensive details and illustrations.

- Local Dealers: Authorized dealers often carry printed manuals and can assist in obtaining the necessary documents.

- Libraries: Some public or university libraries maintain collections of machinery manuals that can be accessed by the public.

Common Issues with S1400 Parts

When dealing with machinery components, various challenges can arise that may affect performance and longevity. Understanding these common problems can help in identifying potential failures and ensuring efficient operation. From wear and tear to compatibility issues, several factors contribute to the overall functionality of equipment.

Wear and Tear

One of the most prevalent issues encountered involves the natural degradation of components over time. Regular use can lead to diminished efficiency, impacting the effectiveness of the entire system. Components may require replacement sooner than anticipated, particularly if maintenance schedules are not adhered to.

Compatibility Problems

Another significant concern is the compatibility of different elements within the system. Mismatched components can lead to improper functioning, causing strain on both the machinery and its operator. Ensuring that all parts are compatible is crucial for optimal performance and to prevent additional complications.

How to Read Parts Diagrams

Understanding schematic representations is essential for efficient maintenance and repair tasks. These illustrations provide a visual guide, showcasing how various components fit together and function within a larger system.

Key Elements to Identify

- Labels: Clear markings that indicate the name and function of each component.

- Numbers: Reference codes that correlate with a list for easy identification.

- Connections: Lines or arrows that show how parts are linked or interact with one another.

Tips for Effective Interpretation

- Familiarize yourself with common symbols used in technical illustrations.

- Cross-reference with the accompanying documentation for detailed descriptions.

- Practice by analyzing simpler schematics before tackling more complex layouts.

Maintenance Tips for S1400 Owners

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular attention to various components can prevent issues and enhance efficiency, allowing you to maximize productivity.

Regular Inspections: Conduct frequent checks on belts, blades, and filters. Identifying wear early can save time and resources.

Lubrication: Keep all moving parts well-lubricated. This reduces friction and prolongs the lifespan of mechanical components.

Cleanliness: Maintain a clean work environment by removing debris and clippings. This not only prevents rust but also enhances performance.

Fuel Quality: Use high-quality fuel to ensure efficient operation. Contaminated fuel can lead to significant engine issues.

Storage: When not in use, store your equipment in a dry, sheltered area. This protects it from weather elements and prolongs its lifespan.

Comparing S1400 with Other Models

In this section, we will explore how this specific model measures up against its competitors in the market. By examining various features, performance metrics, and overall user satisfaction, we can gain a better understanding of its position among similar products.

| Feature | This Model | Competitor A | Competitor B |

|---|---|---|---|

| Engine Power | 25 HP | 23 HP | 27 HP |

| Cutting Width | 42 inches | 38 inches | 48 inches |

| Fuel Capacity | 2.5 gallons | 2.0 gallons | 3.0 gallons |

| Weight | 450 lbs | 430 lbs | 480 lbs |

| User Rating | 4.5/5 | 4.0/5 | 4.7/5 |

This comparison highlights key differences and similarities that potential buyers should consider. Understanding these aspects can significantly influence purchasing decisions, ensuring that users select a model best suited to their needs.

Aftermarket vs. OEM Parts

When considering replacements for machinery components, users often face a choice between two main types of offerings. Each category presents unique advantages and potential drawbacks that can impact performance and maintenance costs. Understanding these differences is essential for making informed purchasing decisions.

| Aspect | Aftermarket | OEM |

|---|---|---|

| Cost | Typically more affordable | Generally higher priced |

| Quality | Varies widely | Consistently meets original specifications |

| Availability | Often widely available | May require special ordering |

| Warranty | Limited or no warranty | Comes with a manufacturer warranty |

Expert Recommendations for S1400 Parts

When maintaining machinery, ensuring you have the right components is crucial for optimal performance. This section provides guidance on selecting quality replacements and upgrades to enhance functionality and longevity.

Quality Components

Investing in high-grade replacements can make a significant difference. Here are some key suggestions:

- Always opt for OEM (Original Equipment Manufacturer) options when available.

- Research aftermarket alternatives to find reputable brands with positive reviews.

- Check for warranties or guarantees that come with the components.

Maintenance Tips

Proper upkeep can extend the lifespan of your equipment. Consider these maintenance practices:

- Regularly inspect components for signs of wear and tear.

- Keep a schedule for replacing essential parts based on usage frequency.

- Consult the manufacturer’s manual for specific maintenance recommendations.