In the realm of machinery, comprehending the intricate design and functionality of various elements is essential for efficient operation. Each component plays a vital role in ensuring optimal performance, and a clear understanding of their arrangement can significantly enhance maintenance and repair efforts.

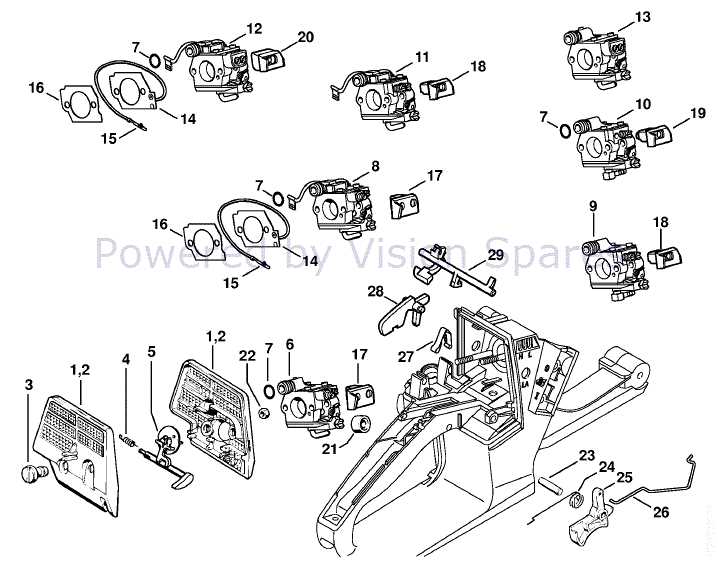

Accessing visual representations of these elements can greatly assist users in identifying parts and understanding their interconnections. Such schematics provide valuable insights into the assembly and disassembly processes, enabling users to troubleshoot issues more effectively.

For those engaged in equipment management or repair, having detailed illustrations readily available can streamline the workflow. This knowledge not only fosters confidence but also promotes a more hands-on approach to equipment care, leading to increased longevity and reliability of the machine.

Understanding the layout of components within machinery is crucial for effective maintenance and repair. A visual representation of the elements involved serves as a valuable resource for both technicians and hobbyists. This tool simplifies the identification and organization of various parts, enhancing overall efficiency in repair tasks.

Utilizing such illustrations can yield several benefits:

- Streamlined Repairs: Clear visuals allow for quick recognition of parts, reducing the time spent searching for specific components.

- Improved Accuracy: A detailed visual guide minimizes the risk of errors during assembly or disassembly, ensuring that every piece is correctly placed.

- Enhanced Learning: For those new to machinery, visual aids provide an excellent learning tool, helping to familiarize them with the layout and function of different elements.

- Effective Communication: When discussing repairs or maintenance with others, having a visual reference can facilitate clearer communication, leading to more productive discussions.

In summary, a comprehensive visual representation of components significantly contributes to the efficiency, accuracy, and understanding of maintenance and repair tasks. This resource proves invaluable, making the process smoother and more accessible for all users.

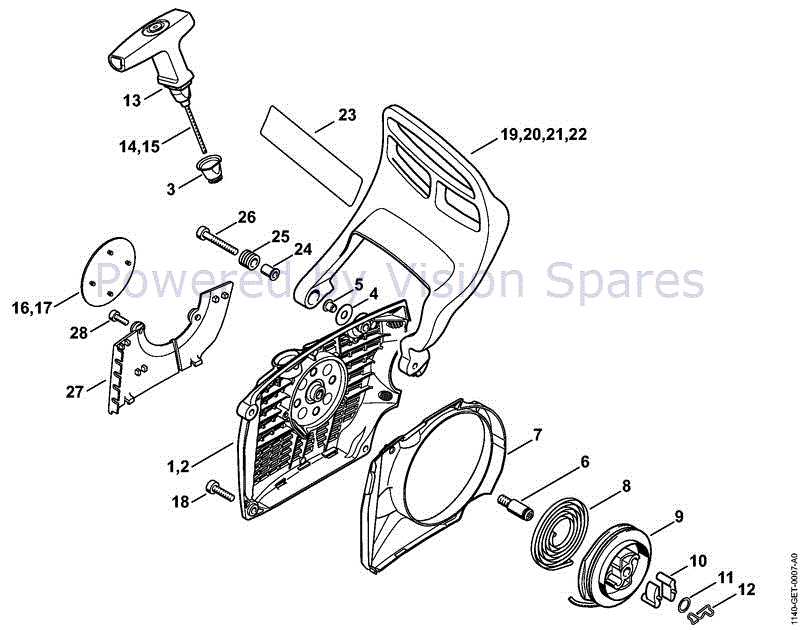

How to Access the Parts Diagram

Obtaining a visual representation of components for maintenance or repair is crucial for effective troubleshooting. This guide will walk you through the methods to find these illustrations, ensuring you can identify and understand the various elements of your equipment with ease.

Online Resources

Many manufacturers offer digital resources on their websites. Navigate to the official site and look for sections dedicated to support or resources. Here, you can often find downloadable materials that include detailed visual references. Make sure to select the appropriate model to access the correct information.

User Manuals and Guides

In addition to online resources, printed user manuals may provide valuable insights. These manuals typically include illustrations and descriptions of components. If you possess a physical copy, consult it to locate the relevant visuals. For those who do not have the manual, it may be available for purchase or as a digital download from various retailers.

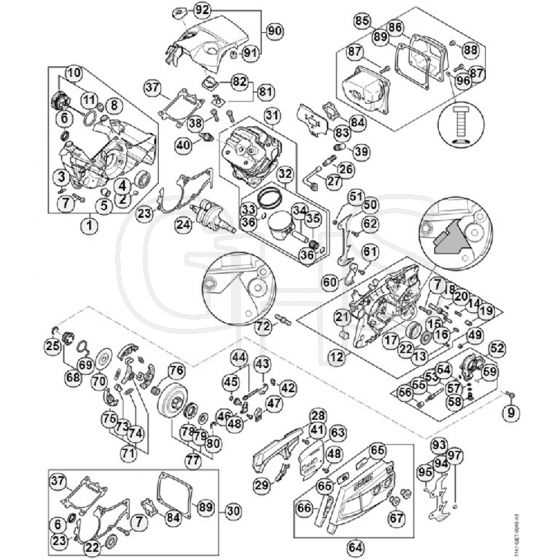

Key Parts of the MS500i Chainsaw

Understanding the essential components of a high-performance cutting tool is crucial for effective operation and maintenance. Each segment plays a specific role in ensuring smooth functionality and durability. Familiarizing oneself with these elements enhances the user experience and prolongs the lifespan of the equipment.

Engine and Fuel System

The engine serves as the powerhouse, converting fuel into mechanical energy. An efficient fuel system ensures the proper mixture of air and gasoline, which is vital for optimal performance. Regular checks on these components can prevent operational issues and enhance efficiency.

Bar and Chain Assembly

This assembly is critical for cutting operations, as it provides the necessary length and sharpness for various tasks. The chain travels around the bar, and its maintenance involves regular sharpening and lubrication to ensure effective cutting and to reduce wear and tear.

Overall, understanding the key elements of this cutting tool not only improves performance but also aids in troubleshooting common problems, allowing users to maintain their equipment effectively.

Common Repairs for Stihl MS500i

Maintaining a chainsaw is essential for ensuring optimal performance and longevity. Over time, various components may wear out or become damaged, necessitating specific repairs. Understanding common issues can help users quickly diagnose problems and determine the best course of action for maintenance.

Some typical repairs include addressing fuel system issues, replacing the spark plug, and inspecting the bar and chain for wear. Each of these tasks can significantly impact the efficiency and safety of the tool.

| Repair Type | Description | Frequency |

|---|---|---|

| Fuel System Cleaning | Cleaning or replacing the fuel filter and lines to ensure proper fuel flow. | Every 25 hours of use |

| Spark Plug Replacement | Replacing the spark plug to improve ignition and overall engine performance. | Every 50 hours of use |

| Chain and Bar Inspection | Checking for wear and ensuring proper tension and lubrication. | After each use |

| Air Filter Maintenance | Cleaning or replacing the air filter to prevent engine damage from dirt. | Every 25 hours of use |

By regularly conducting these repairs, users can ensure their chainsaw operates smoothly and efficiently, ultimately extending its lifespan.

Identifying Wear and Tear on Parts

Regular maintenance of equipment is crucial for ensuring its longevity and efficiency. Recognizing signs of degradation on various components can prevent costly repairs and extend the lifespan of the machinery. This section will guide you through the key indicators of wear and how to assess them effectively.

Common indicators of wear include:

- Visual Damage: Look for cracks, chips, or deformations that may compromise functionality.

- Surface Abrasion: Check for any roughness or smooth spots that indicate excessive friction.

- Discoloration: Changes in color may signify overheating or chemical exposure.

- Loose Connections: Ensure that all fittings and fasteners are secure to avoid malfunctions.

To effectively evaluate the condition of the components:

- Perform regular inspections to catch wear early.

- Use appropriate tools to measure dimensions and tolerances.

- Consult manufacturer guidelines for specific wear limits.

- Replace worn components promptly to maintain optimal performance.

By staying vigilant and conducting thorough inspections, you can keep your equipment in peak condition and minimize the risk of unexpected failures.

Maintaining Your Chainsaw Effectively

Proper upkeep of your cutting tool is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also promotes safety during operation. By following a systematic approach, you can prevent common issues and keep your equipment in top condition.

Start by regularly inspecting the various components of your tool, such as the chain, bar, and engine. Clean any debris that may accumulate and check for signs of wear. It’s also important to keep the air filter clean and replace it as needed to ensure proper airflow.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Chain Tension Adjustment | Before each use | Ensure the chain is properly tensioned to avoid slippage and ensure smooth operation. |

| Oil Level Check | Before each use | Verify that the oil reservoir is full to lubricate the chain effectively during cutting. |

| Cleaning Air Filter | Every 5 uses | Remove and clean the air filter to maintain optimal airflow and engine performance. |

| Chain Sharpening | As needed | Regularly sharpen the chain to ensure clean cuts and reduce strain on the motor. |

By adhering to these maintenance practices, you can ensure that your cutting tool remains reliable and efficient. Regular care not only extends the lifespan of your equipment but also enhances your overall experience during use.

Safety Tips When Handling Parts

When working with equipment components, it’s essential to prioritize safety to prevent accidents and ensure efficient operations. Understanding the risks involved and adopting proper handling practices can significantly reduce the likelihood of injuries. Here are some essential guidelines to follow when managing these items.

Preparation and Awareness

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses, to shield against potential hazards.

- Inspect the work area to ensure it’s clean and free of obstacles that could lead to slips or falls.

- Be aware of your surroundings and avoid distractions while working to maintain focus on the task at hand.

Proper Handling Techniques

- Use tools specifically designed for the task to prevent strain and ensure accuracy.

- Lift components using proper body mechanics, keeping your back straight and lifting with your legs to avoid injury.

- Store parts securely when not in use, ensuring they are placed in designated areas to prevent accidents.

Ordering Replacement Parts Easily

When it comes to maintaining outdoor power equipment, ensuring you have the right components on hand is crucial. Acquiring suitable replacements can significantly enhance the longevity and performance of your machinery. This section outlines effective methods for obtaining the necessary items without hassle.

Utilizing Online Resources

In the digital age, numerous platforms specialize in providing high-quality alternatives for various machinery components. Websites dedicated to equipment maintenance offer comprehensive catalogs, allowing users to search by model or category. This not only saves time but also ensures that you find the exact item needed for your device.

Contacting Local Dealers

Establishing a relationship with nearby retailers can be advantageous. Local dealers often have access to a wide range of products and can assist in identifying the right components. Additionally, they may provide insights into compatible alternatives that can be beneficial for your specific equipment needs.

Comparing Stihl MS500i with Other Models

When evaluating the latest innovations in power equipment, it’s essential to analyze how a specific model stands against its competitors. This section delves into the features, performance, and usability of one advanced machine in relation to other similar devices in the market. By examining various aspects, users can make informed decisions on which option best suits their needs.

In terms of performance, factors such as engine capacity, weight, and cutting efficiency play crucial roles. Below is a comparison table highlighting key specifications of several models, showcasing their strengths and weaknesses:

| Model | Engine Capacity (cc) | Weight (lbs) | Power Output (hp) | Chain Speed (m/s) |

|---|---|---|---|---|

| Model A | 72 | 11.2 | 5.2 | 25.5 |

| Model B | 75 | 10.5 | 5.6 | 24.0 |

| Model C | 80 | 12.0 | 6.0 | 26.0 |

| Model D | 73 | 10.8 | 5.4 | 25.0 |

Ultimately, selecting the right equipment depends on individual requirements and preferences, making direct comparisons vital for achieving the best results in various tasks.

FAQs About Stihl MS500i Maintenance

Proper upkeep of outdoor power equipment is essential for longevity and performance. Many users have common inquiries regarding care and maintenance practices to ensure their tools function optimally. This section addresses frequently asked questions to provide clarity and guidance for effective equipment management.

What are the best practices for maintaining my chainsaw?

Regular cleaning and inspection are vital. Ensure that the air filter is free from debris and replace it if necessary. Lubricate the chain frequently to prevent wear and tear, and always check the tension before use. Additionally, make sure to keep the fuel system clean and use the recommended fuel mixture for optimal performance.

How often should I perform maintenance tasks?

Maintenance frequency depends on usage. For occasional users, conducting a thorough inspection and servicing every few months is adequate. However, for frequent users, a monthly check is advisable. Always refer to the manufacturer’s guidelines for specific maintenance schedules to keep your equipment in top condition.

Community Resources and Support

Accessing reliable resources and support can significantly enhance the ownership experience of outdoor power equipment. Engaging with community networks provides valuable insights and assistance for users, helping them navigate common challenges and optimize their tools for various tasks.

Online Forums and Discussion Groups

Many online platforms cater to enthusiasts and professionals alike, allowing users to share knowledge and experiences. These spaces often feature:

- Technical advice and troubleshooting tips

- Product reviews and recommendations

- Event announcements and community meetups

Local Workshops and Training Sessions

Participating in local workshops can offer hands-on experience and guidance from experts. These sessions often cover:

- Maintenance techniques and best practices

- Safety protocols and operational training

- Networking opportunities with fellow users