Understanding the various elements of a well-known outdoor tool is essential for efficient operation and maintenance. This section delves into the intricate arrangement of components, providing a comprehensive view that assists users in identifying each part’s function and relevance. With a clear layout, users can navigate through the essential features effortlessly.

By familiarizing oneself with the configuration of these essential elements, users can enhance their ability to troubleshoot issues and perform necessary repairs. This knowledge not only contributes to better functionality but also prolongs the lifespan of the equipment. In this exploration, special emphasis is placed on clarity and accessibility, ensuring that both novices and seasoned users can benefit.

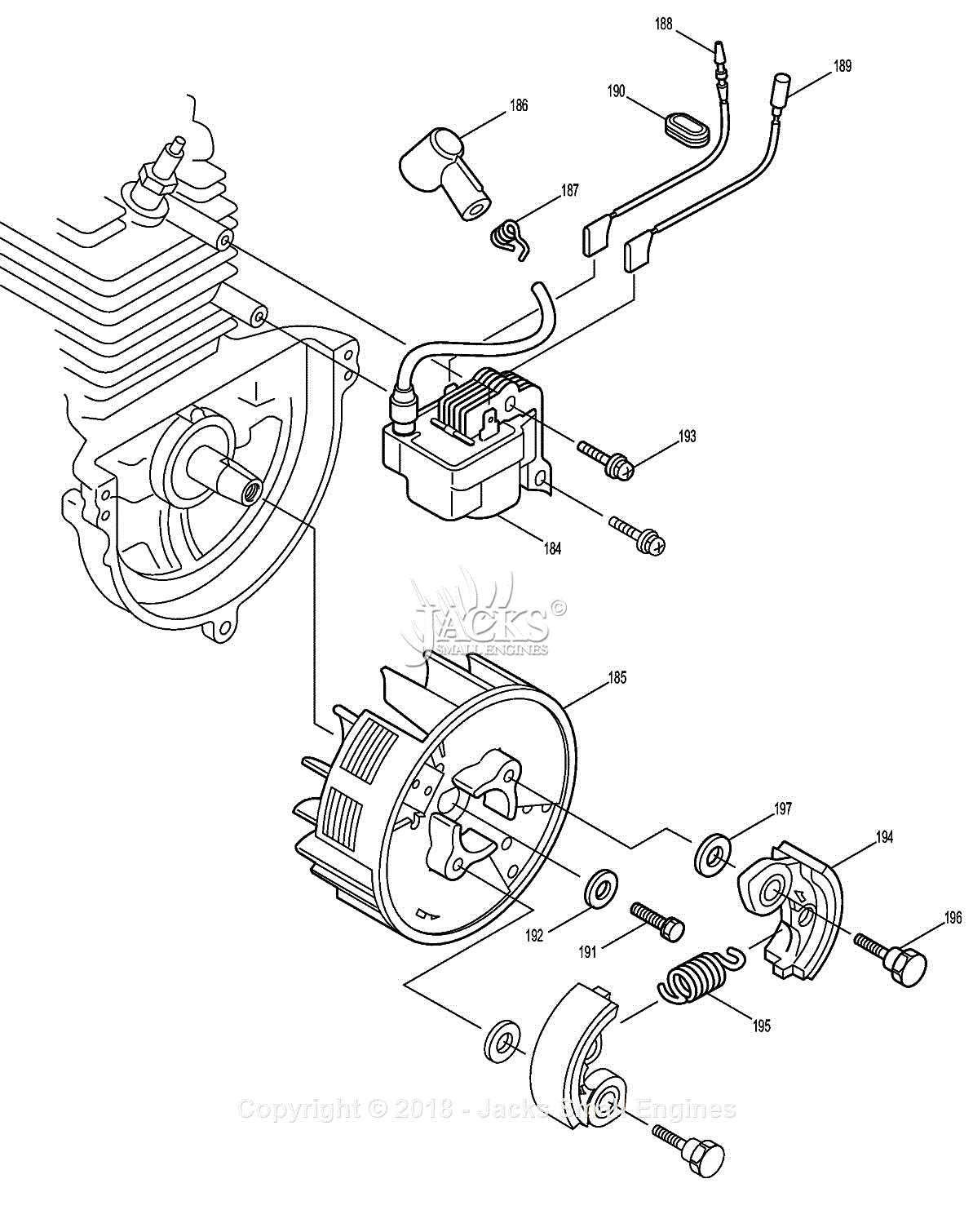

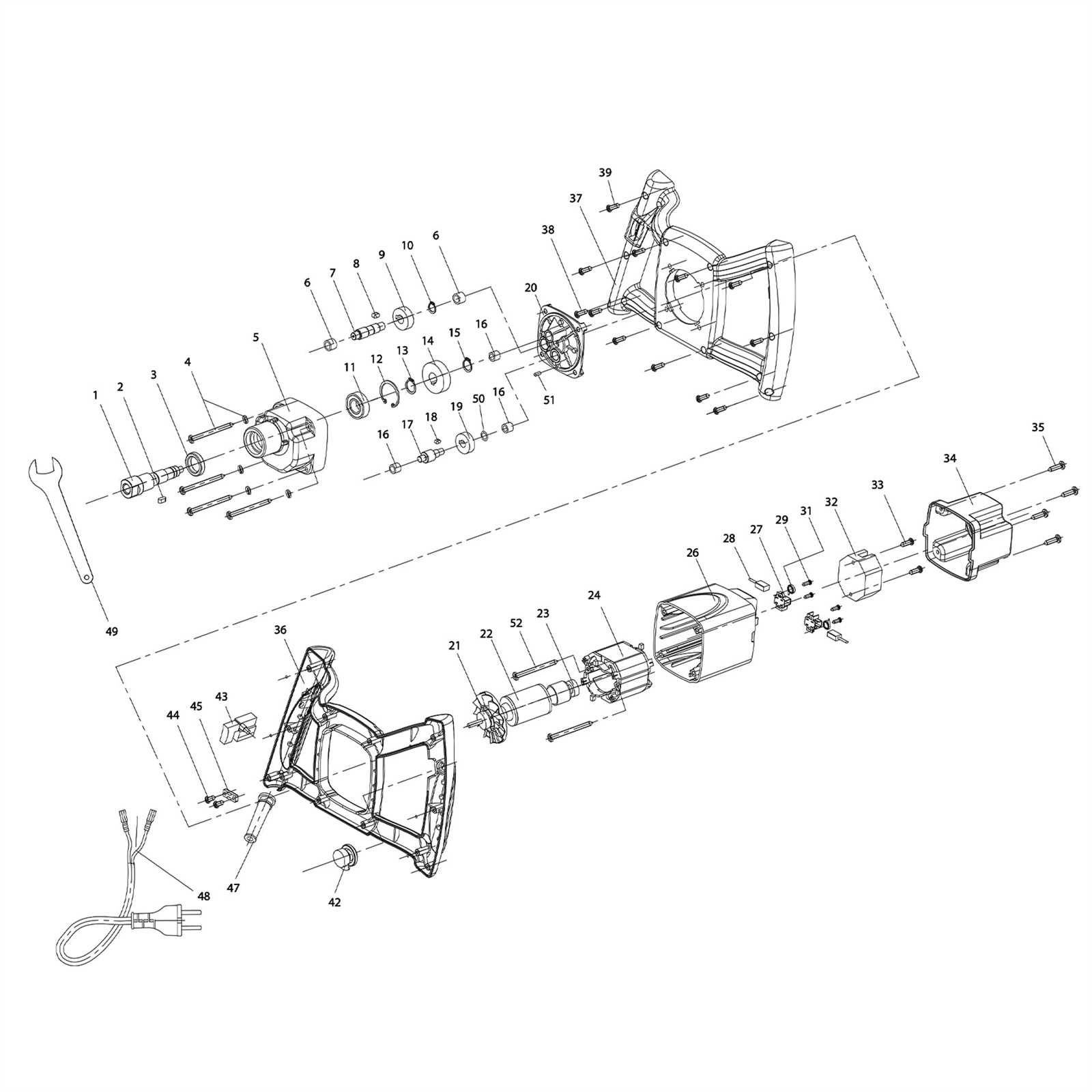

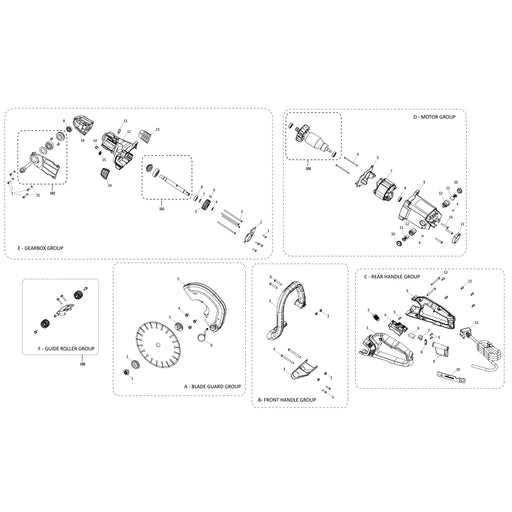

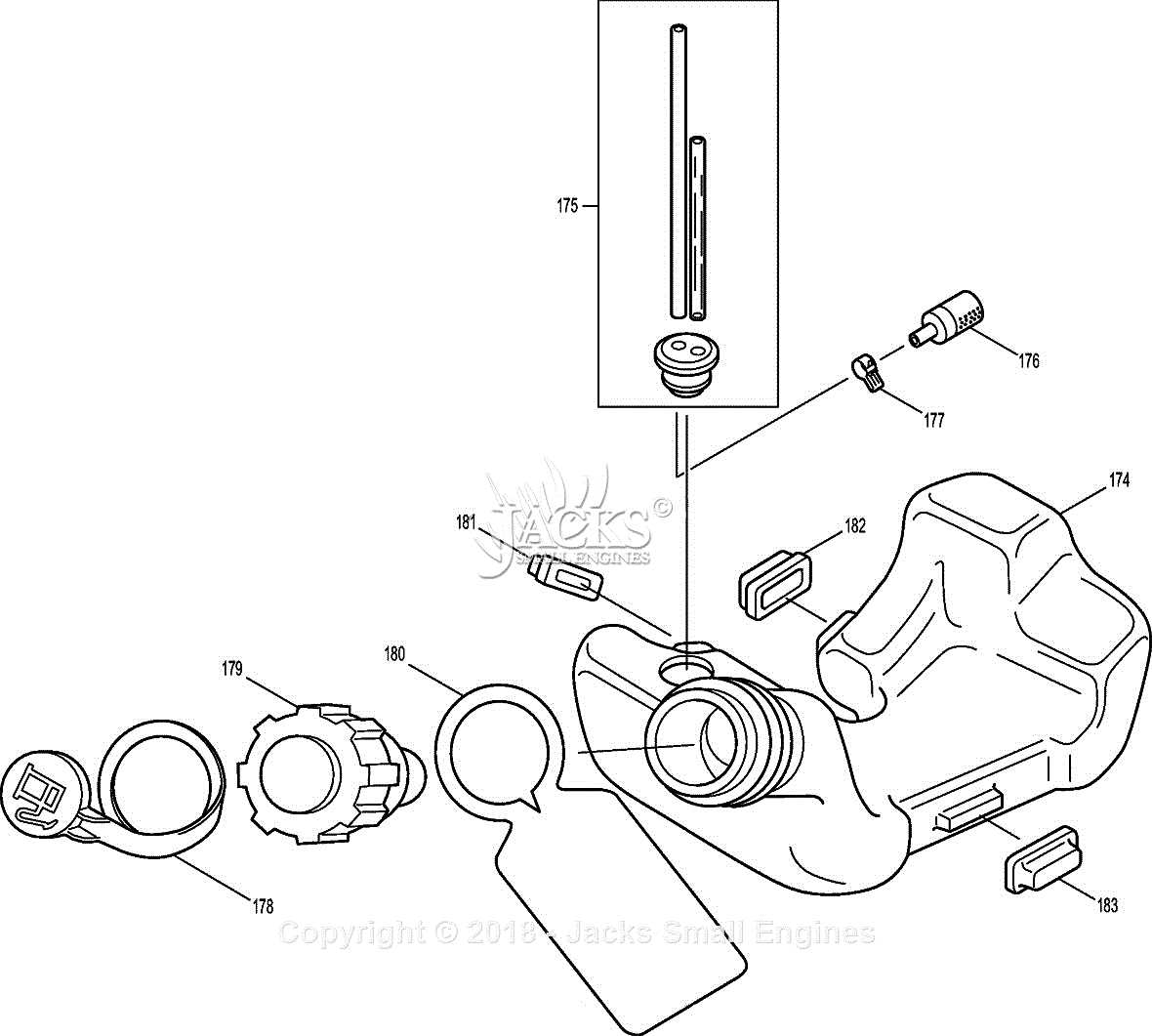

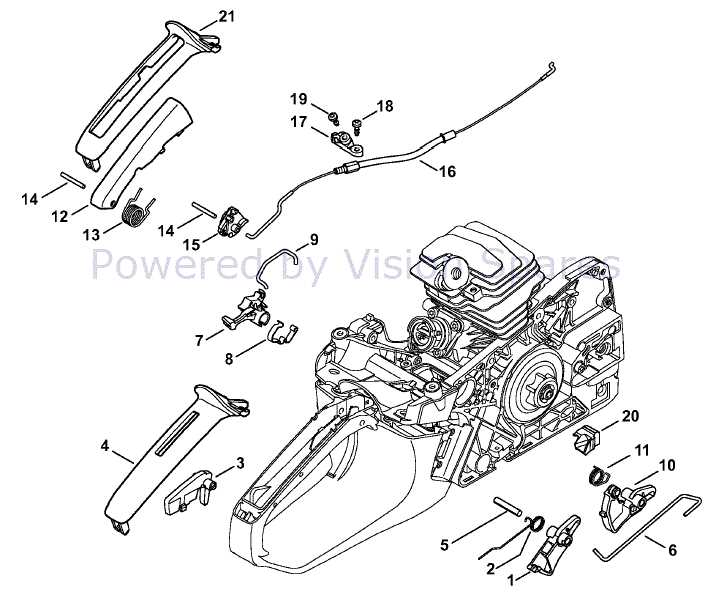

Stihl 251 Parts Overview

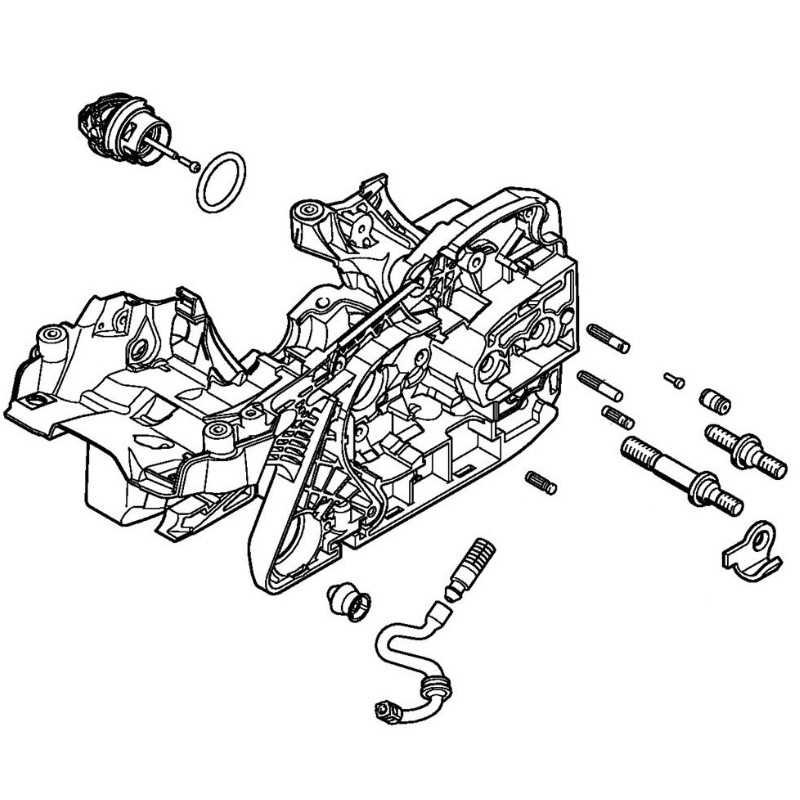

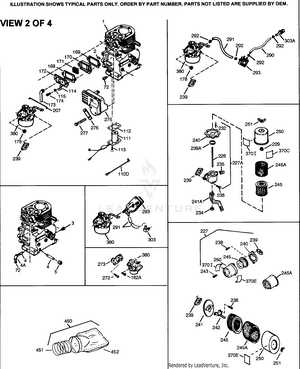

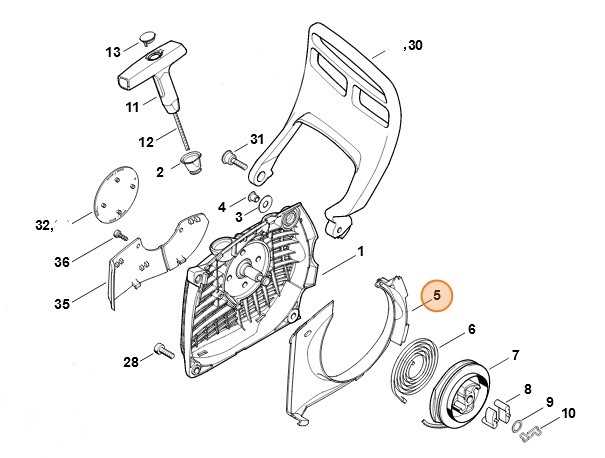

This section provides a comprehensive look at the various components essential for the efficient operation of the machine. Understanding these elements is crucial for maintenance and optimal performance. Each part plays a vital role in ensuring that the equipment functions smoothly and reliably.

Key Components and Their Functions

The primary components include the engine assembly, fuel system, and cutting mechanism. The engine assembly is responsible for power generation, while the fuel system ensures the proper delivery of fuel for combustion. The cutting mechanism, comprising blades and attachments, is essential for executing tasks effectively.

Maintenance and Replacement Considerations

Regular maintenance is crucial to extend the lifespan of these components. Identifying wear and tear early on allows for timely replacements, preventing further damage. It is recommended to consult the user manual for specific maintenance schedules and replacement guidelines to ensure continued efficiency.

Understanding the Chainsaw Components

Chainsaws consist of various essential elements that work together to deliver optimal performance. Each component plays a unique role in the functionality and efficiency of the tool, making it crucial to comprehend their significance. This understanding can enhance maintenance practices and ensure longevity.

Among the primary components are the power unit, guide bar, and cutting chain, each contributing to the saw’s overall operation. Familiarity with these elements can assist users in troubleshooting issues and performing effective repairs.

| Component | Description |

|---|---|

| Power Unit | The engine that drives the chainsaw, providing the necessary energy for operation. |

| Guide Bar | A metal bar that supports the cutting chain, enabling it to rotate and cut through materials. |

| Cutting Chain | The sharp, toothed loop that engages with the material to facilitate cutting. |

| Chain Brake | A safety feature designed to stop the chain quickly in case of kickback or operator error. |

| Fuel System | Components that supply the necessary fuel to the engine for operation. |

Identifying Replacement Parts

When maintaining outdoor equipment, recognizing the necessary components for replacement is crucial for optimal performance. Understanding the various elements that comprise the machinery helps ensure that repairs are carried out efficiently and effectively. Accurate identification of these components not only prolongs the life of the equipment but also enhances safety during operation.

Begin by consulting the user manual or online resources to familiarize yourself with the terminology and function of each component. Pay close attention to the model specifications and reference numbers, as these details are essential when sourcing new items. Utilizing resources such as online marketplaces or specialized retailers can assist in locating the correct replacements.

Moreover, consider examining existing components for any markings or identifiers that can guide you in your search. Photographs or diagrams from reliable sources can further clarify the configuration and arrangement of parts. Taking the time to accurately identify the necessary elements will ultimately lead to a more successful maintenance process.

Exploring Engine Specifications

This section delves into the crucial features and attributes of the power unit that drive performance and efficiency. Understanding these elements is essential for optimizing functionality and ensuring longevity in various applications.

Key Features

- Displacement: The volume of the engine, typically measured in cubic centimeters (cc), indicating the power potential.

- Power Output: The maximum power generated, expressed in horsepower (hp) or kilowatts (kW), which directly influences performance.

- Fuel Type: The kind of fuel utilized, affecting combustion efficiency and overall operation.

- Ignition System: The mechanism responsible for starting the combustion process, impacting reliability and ease of use.

- Cooling Method: The approach used to regulate engine temperature, which is vital for maintaining optimal performance.

Performance Metrics

- Torque: The rotational force produced by the engine, significant for cutting and handling tasks.

- Idle Speed: The speed at which the engine runs when not under load, influencing responsiveness and stability.

- Fuel Efficiency: The consumption rate of fuel relative to power output, crucial for operational cost management.

- Emission Levels: The amount of pollutants released during operation, important for compliance with environmental standards.

Maintenance and Service Requirements

Regular upkeep and servicing are essential for ensuring optimal performance and longevity of equipment. Adhering to a maintenance schedule helps to prevent unexpected breakdowns and extends the lifespan of the machine. Proper care not only enhances efficiency but also ensures safety during operation.

Routine Maintenance Tasks

- Inspect and clean air filters regularly to ensure proper airflow.

- Sharpen or replace cutting tools as needed to maintain cutting efficiency.

- Check and tighten all screws and bolts to prevent vibrations from loosening components.

- Inspect fuel lines for leaks and replace them if necessary.

- Keep the exterior clean to prevent debris buildup, which can affect performance.

Service Intervals

It is advisable to follow specific intervals for comprehensive service checks:

- Weekly: Conduct basic inspections and cleanings.

- Monthly: Perform detailed checks, including oil changes and component assessments.

- Annually: Schedule a professional service for thorough evaluation and maintenance.

Adhering to these requirements will ensure your equipment remains in peak condition, ready to tackle tasks effectively.

Common Issues and Solutions

This section addresses frequent challenges encountered with various machinery and offers practical remedies to enhance performance and reliability. Understanding these common complications can help users maintain optimal functionality and avoid unnecessary downtime.

One prevalent issue is difficulty starting the equipment. This can often be attributed to a depleted power source or a clogged air filter. Regularly checking and replacing the spark plug or cleaning the filter can mitigate this problem effectively.

Another common complication is the engine stalling during operation. This may result from fuel delivery issues, such as impurities in the fuel system. Ensuring the use of clean fuel and performing routine maintenance on the fuel lines can help resolve this matter.

Users may also experience excessive vibrations while operating the tool. This is typically due to loose components or worn-out parts. Conducting regular inspections and tightening loose screws or replacing damaged elements can significantly reduce vibrations.

Finally, improper cutting performance can occur, often stemming from a dull blade or incorrect tension settings. Sharpening the blade and adjusting the tension according to the manufacturer’s recommendations can enhance cutting efficiency and prevent further damage.

How to Access the Diagram

Gaining access to the schematic representation of your device is essential for understanding its components and ensuring proper maintenance. This section will guide you through the necessary steps to obtain the visual breakdown efficiently.

Online Resources

Numerous online platforms offer comprehensive illustrations of various models. To find the right visual representation, consider the following methods:

- Visit the official website of the manufacturer.

- Search for specialized online forums or communities dedicated to similar equipment.

- Utilize search engines to locate digital manuals or resources.

Local Support Centers

If online searches do not yield satisfactory results, consider reaching out to local support services. They can provide physical copies or direct assistance in locating the necessary illustrations:

- Contact authorized service centers for expert guidance.

- Inquire at local retailers that specialize in outdoor equipment.

- Attend workshops or training sessions that may offer resources.

Parts Diagram Benefits for Users

Understanding the assembly of a tool can significantly enhance user experience and maintenance efficiency. Accessing visual representations of components allows individuals to quickly identify necessary elements and their interrelations. This clarity promotes effective troubleshooting and repair processes.

Utilizing these visual guides can lead to informed decision-making when it comes to replacements or upgrades. Users can easily ascertain compatibility and functionality, ultimately resulting in a more streamlined approach to maintenance. This resource also aids in extending the lifespan of the equipment by encouraging proper care and timely replacements.

Moreover, having a clear overview fosters confidence in users as they engage with their equipment. Enhanced understanding of how various elements work together empowers individuals to tackle minor repairs independently, reducing reliance on professional services and saving time and costs. Overall, these visual aids contribute to a more satisfying and efficient user experience.

Comparing Stihl Models

When evaluating various models from a renowned brand, it’s essential to understand the differences in their design, functionality, and intended use. Each unit offers unique features that cater to specific tasks, whether for professional landscaping, agriculture, or casual gardening. By analyzing these distinctions, users can make informed decisions tailored to their needs.

Key Features and Specifications

Different models often come equipped with distinct specifications, such as engine power, weight, and ergonomic design. Understanding these characteristics allows users to select a machine that provides optimal performance and comfort during operation. For instance, a lightweight version may be ideal for homeowners who require ease of handling, while a more powerful option might suit commercial users with demanding workloads.

Price Points and Value

Cost is another critical factor in the decision-making process. While some variants may come with a higher price tag, they often justify this through advanced technology and enhanced durability. Consumers should weigh the initial investment against the long-term benefits and potential savings in maintenance and repairs.

Where to Buy Genuine Parts

When seeking components for your outdoor equipment, ensuring authenticity is crucial for maintaining performance and longevity. Genuine replacements guarantee compatibility and reliability, which is essential for optimal functionality.

Authorized retailers and specialty stores are excellent sources for obtaining authentic replacements. These locations typically have a dedicated inventory of certified items that meet manufacturer specifications. Additionally, checking the official website of the equipment brand can provide information on verified dealers and online purchasing options.

Another reliable avenue is to connect with local service centers that focus on maintenance and repairs for outdoor machinery. These establishments often stock genuine items or can assist in ordering them directly from the manufacturer.

Online platforms also offer a wide selection of authentic components. Look for reputable websites that specialize in outdoor tools, ensuring they feature customer reviews and detailed product descriptions to confirm authenticity.

In summary, sourcing certified replacements involves a mix of physical and online options, ensuring you maintain the highest standards for your outdoor machinery.

Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be a rewarding experience, allowing individuals to save money and gain valuable skills. Understanding the essential components of the equipment and familiarizing oneself with the repair process is crucial for success.

Start with the Basics: Before diving into any repairs, gather the necessary tools and a user manual or schematic that outlines the assembly of the device. This will help you identify parts and understand their functions.

Safety First: Always prioritize safety by wearing appropriate protective gear. Ensure the equipment is turned off and disconnected from any power source before beginning any work.

Take Notes: Document the disassembly process by taking notes or photos. This will aid in reassembly and help you remember where each component belongs.

Patience is Key: Approach each repair task methodically. Rushing can lead to mistakes, which might cause further damage. Take your time to ensure every step is executed properly.

Seek Help if Needed: If you encounter challenges, don’t hesitate to consult online forums or seek advice from experienced individuals. Sharing knowledge can provide insights that enhance your understanding of the repair process.

Test Thoroughly: Once the repair is completed, conduct thorough tests to ensure everything is functioning correctly. This step is essential to confirm that the issue has been resolved and the device operates smoothly.