Maintaining your machinery requires a comprehensive understanding of its intricate systems and components. When you are equipped with detailed illustrations, navigating the maintenance process becomes significantly more manageable. Such visual aids can enhance your ability to identify and address specific needs effectively.

In this section, we will explore the various elements that contribute to the optimal functioning of your equipment. Each piece plays a crucial role, and grasping their arrangement and functionality can lead to better care and longevity. Understanding these components not only empowers you but also enhances your overall experience with the machinery.

By delving into the specifics of these essential elements, you will be better prepared for any maintenance or repair tasks. Gaining insight into their structure and interrelationships will serve as the ultimate guide for ensuring your equipment operates at its best.

Understanding Stihl HT101 Overview

This section provides a comprehensive insight into a specific model designed for elevated cutting tasks. The equipment is engineered to enhance efficiency while ensuring user safety and comfort. A detailed look at its components and functionalities reveals its strengths and applications in various environments.

| Feature | Description |

|---|---|

| Engine Type | Powerful, efficient motor designed for sustained performance. |

| Weight | Lightweight design for improved maneuverability during operation. |

| Length | Adjustable reach for accessing high branches and foliage. |

| Safety Features | Integrated systems to protect the user during operation. |

| Maintenance | Simple upkeep procedures to ensure longevity and reliability. |

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repairs. Visual representations serve as crucial guides, enabling users to identify each element’s role and facilitate troubleshooting. These illustrations enhance the overall comprehension of the equipment’s structure and function.

Enhanced Clarity

By breaking down complex machinery into understandable sections, visual guides provide clarity. They simplify the identification of individual components, making it easier for users to follow instructions and perform necessary actions.

Efficient Maintenance

Utilizing these visual aids leads to more efficient upkeep. When users can easily locate parts, they can quickly perform repairs, reducing downtime and ensuring optimal performance.

| Benefits | Description |

|---|---|

| Improved Understanding | Helps users grasp how components interact. |

| Time-Saving | Reduces the time needed for repairs and maintenance. |

| Enhanced Safety | Promotes safer handling by clarifying the function of each part. |

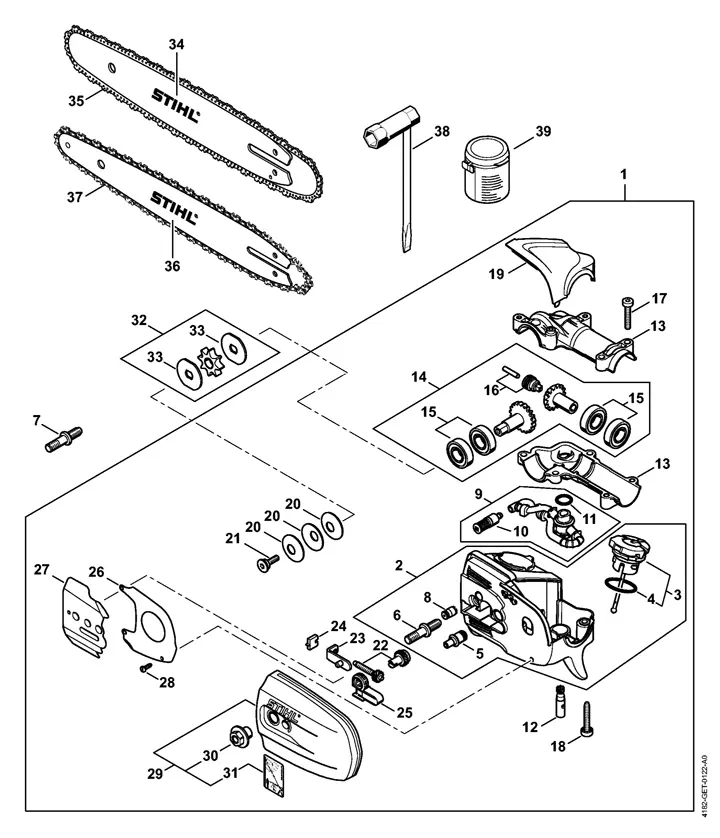

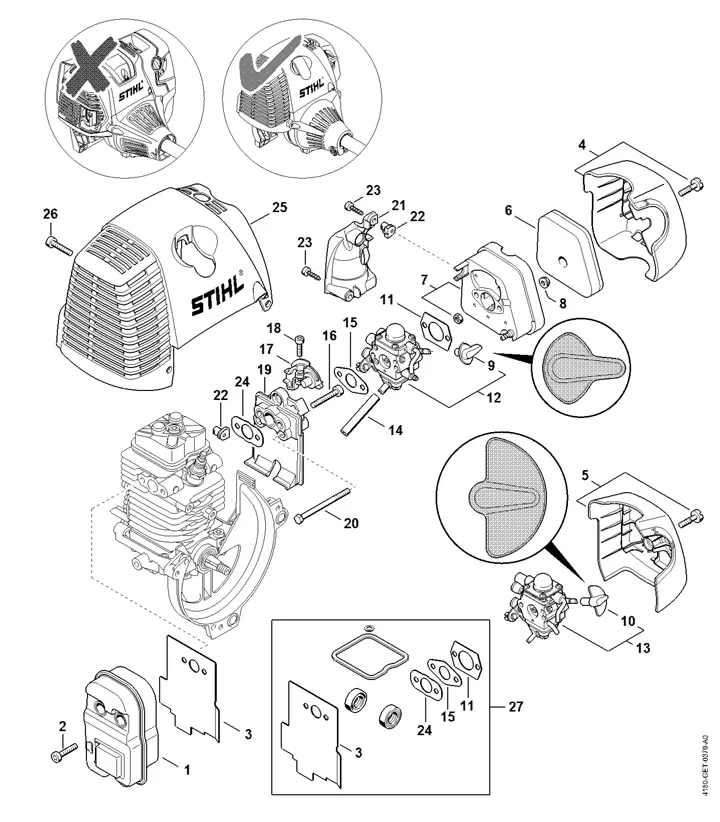

Key Components of the HT101

This section explores the essential elements that contribute to the overall functionality and efficiency of the equipment. Understanding these components can enhance performance and ease of maintenance, allowing users to achieve optimal results during operation.

Power Unit

The power unit serves as the heart of the machine, delivering the necessary energy for operation. It typically includes a robust engine designed to provide reliable performance, ensuring that the equipment runs smoothly during use.

Cutting Head

The cutting head is crucial for executing tasks effectively. It often features interchangeable tools that allow for versatility in applications. A well-designed cutting head not only improves cutting precision but also enhances overall user experience.

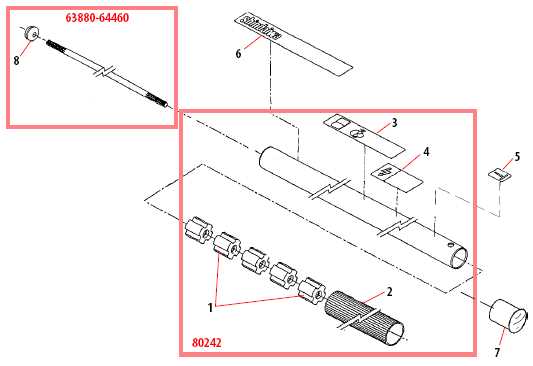

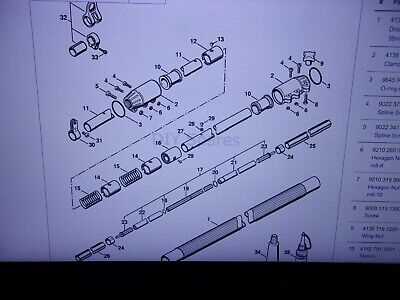

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and locate specific elements in equipment. These illustrations serve as essential guides, providing clarity and detail necessary for maintenance and repair tasks.

Breaking Down the Illustration

Each section of the visual aid typically corresponds to a particular area of the machine. Familiarizing yourself with the layout will enable you to navigate the information more effectively.

Utilizing the Legend

Most visual aids include a legend that explains symbols and terminology. Referencing this will help you decipher the various elements quickly and accurately.

| Symbol | Description |

|---|---|

| Fastener | |

| Tool Required | |

| ⚙️ | Moving Part |

Common Issues and Solutions

Maintaining equipment can often reveal various challenges that users may face. Understanding these common problems and their respective remedies can enhance performance and prolong the lifespan of your tools. Below are frequent issues encountered, along with practical solutions to address them.

Problem: Engine Won’t Start

This issue can arise due to several factors, such as fuel blockage or spark plug failure. Solution: Ensure the fuel is fresh and clean. Check the spark plug for damage and replace it if necessary.

Problem: Poor Cutting Performance

Dull blades or incorrect chain tension often lead to inefficient cutting. Solution: Regularly sharpen the cutting edges and adjust the tension according to the manufacturer’s guidelines.

Problem: Overheating

Excessive heat can indicate improper lubrication or air blockage. Solution: Ensure that lubrication is adequate and check for any obstructions in the air intake.

Problem: Unusual Noises

Strange sounds may suggest loose components or wear. Solution: Inspect all parts for tightness and signs of wear, replacing any damaged elements as needed.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. Implementing simple maintenance practices can significantly extend the life of your tools, ensuring they perform at their best for years to come.

Routine Cleaning

Clean your equipment after each use to prevent debris buildup. Pay special attention to air filters and cooling fins, as these components can affect performance if clogged.

Periodic Inspections

Conduct regular inspections to identify wear and tear. Check for loose bolts, frayed cables, or any signs of damage. Addressing these issues early can prevent more significant problems later on.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various resources are available to help you find the right items needed for maintenance or repairs, ensuring your tools operate effectively.

Online Retailers

Numerous online platforms specialize in selling equipment components. These websites often provide detailed descriptions and specifications, making it easier to find what you need. It’s advisable to compare prices and check customer reviews before making a purchase.

Local Authorized Dealers

Visiting a local authorized dealer can also be beneficial. These retailers typically have knowledgeable staff who can assist you in identifying the correct components. Additionally, purchasing from them may ensure you receive genuine items, which can be critical for the longevity of your tools.

| Resource Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenience, wide selection | Check for compatibility and return policies |

| Local Dealers | Expert assistance, genuine items | Possibly higher prices |

| Manufacturer’s Website | Direct source, updated inventory | May require shipping fees |

| Second-Hand Markets | Cost-effective options | Condition of items varies |

Comparing HT101 with Other Models

When evaluating different equipment options, it is essential to understand how various models stack up against one another. Each variant in this category offers unique features and specifications that cater to different user needs and preferences. A thorough comparison helps potential buyers make informed decisions based on performance, usability, and versatility.

Power and Performance: The examined model excels in delivering robust power for cutting and pruning tasks. While some alternatives may offer similar capabilities, others might lag in performance, making this model a reliable choice for demanding jobs. Users often seek out machinery that balances strength with efficiency.

Design and Ergonomics: User comfort is a significant consideration in tool design. This particular model stands out with its ergonomic design, allowing for extended use without discomfort. In contrast, other options may not prioritize this aspect, leading to fatigue during longer projects. A well-designed tool can enhance productivity and satisfaction.

Maintenance and Durability: Longevity is another crucial factor. This model is known for its durability and ease of maintenance, which reduces downtime and repair costs. Some competitors may require more frequent upkeep or may not withstand rigorous use as well, making reliability a key advantage for this choice.

Price and Value: Budget considerations play a vital role in any purchase. While this model may fall into a mid-range price bracket, its features and performance often justify the investment. Other models might be cheaper but could compromise on quality or longevity, leading to higher costs in the long run.

In conclusion, comparing this model with others in its category reveals distinct advantages that cater to various user requirements. Understanding these differences is vital for making the best choice for both casual and professional tasks.

Customer Reviews and Feedback

Gathering insights from users can significantly enhance the understanding of a product’s performance and reliability. Feedback from customers offers valuable perspectives that can guide potential buyers in making informed decisions. This section delves into the experiences shared by individuals who have utilized this equipment, highlighting their thoughts on usability, durability, and overall satisfaction.

Positive Experiences

Many users have expressed their appreciation for the effectiveness and ease of use of this tool. One reviewer noted that it exceeded their expectations in terms of performance, making yard work much more efficient. Another satisfied customer highlighted the lightweight design, which allowed for extended use without causing fatigue. Such feedback underscores the product’s practicality for both casual users and professionals alike.

Areas for Improvement

While numerous reviews are positive, some customers pointed out aspects that could be enhanced. One frequent comment revolves around the assembly process, with users wishing for clearer instructions. Additionally, a few reviewers mentioned the need for improved customer support when addressing issues, which could elevate the overall experience. Constructive criticism like this is essential for manufacturers aiming to refine their offerings.

Accessories for Enhanced Performance

Enhancing the functionality of your equipment often hinges on the right supplementary tools. These accessories can significantly boost efficiency, ensuring optimal results during operation. By integrating various enhancements, users can unlock the full potential of their machinery.

Tool Attachments

Utilizing specialized attachments can provide versatility and precision. From extended reach tools to specialized cutting heads, these components allow for tailored performance in diverse environments. Investing in quality attachments ensures longevity and effectiveness.

Maintenance Kits

Regular upkeep is crucial for maintaining peak performance. Comprehensive maintenance kits equipped with essential items, such as oils and filters, can streamline care processes. Proper maintenance not only extends the lifespan of your equipment but also enhances its overall functionality.

Expert Recommendations and Advice

When it comes to maintaining and repairing outdoor equipment, having the right guidance can make all the difference. This section offers insights from seasoned professionals who understand the intricacies of machinery and the importance of using high-quality components. Whether you’re looking to enhance performance or extend the lifespan of your tools, expert advice can provide valuable strategies.

Prioritize Quality Components

Choosing superior materials is crucial for optimal functionality. Invest in reputable brands known for their durability and reliability. This not only ensures that your equipment operates efficiently but also reduces the likelihood of frequent replacements and repairs.

Regular Maintenance Practices

Establishing a consistent maintenance routine is essential for prolonging the life of your machinery. Regularly inspect and clean components, checking for wear and tear. Simple tasks like replacing filters and sharpening blades can significantly enhance performance and prevent potential issues down the line.