In the world of power equipment, having a clear understanding of the individual elements that make up your machinery is essential for efficient operation and maintenance. Each component plays a vital role in the overall functionality, contributing to performance, durability, and ease of use. By familiarizing yourself with these pieces, you can enhance your knowledge and ensure optimal care for your equipment.

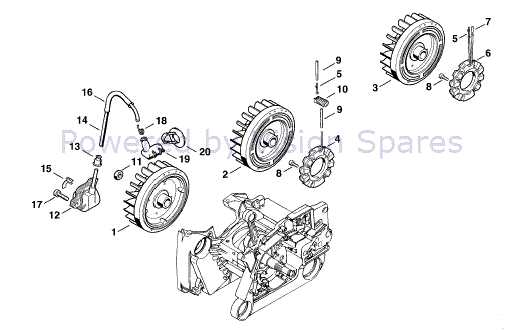

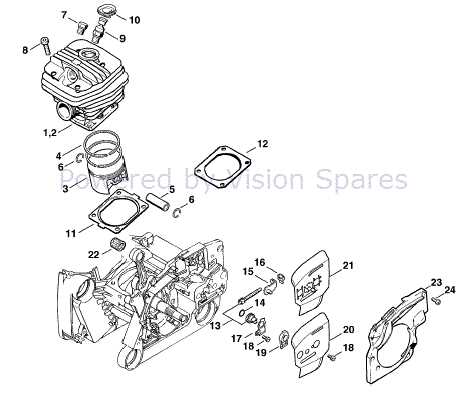

Detailed visual representations of these crucial elements can greatly assist users in identifying parts and understanding their functions. Such illustrations often highlight the relationships between different sections, providing insights into how they work together to achieve the desired results. This knowledge not only aids in troubleshooting issues but also empowers users to perform repairs and replacements with confidence.

Moreover, having access to comprehensive breakdowns can facilitate smoother maintenance routines. By knowing exactly what to look for, you can prevent potential problems before they escalate, ultimately extending the lifespan of your equipment. Emphasizing the importance of recognizing each segment’s role will lead to more informed decisions and improved operational efficiency.

Understanding the MS660 Chainsaw Parts

In the realm of powerful cutting tools, a comprehensive grasp of the individual components is essential for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency and safety during operation. By familiarizing oneself with these essential components, users can better troubleshoot issues, perform repairs, and prolong the lifespan of their equipment.

The anatomy of this particular cutting machine comprises various crucial sections, each contributing to its overall functionality. Below is a brief overview of the key components commonly found in these machines:

| Component | Function |

|---|---|

| Engine | Provides power to drive the chain. |

| Bar | Supports and guides the cutting chain. |

| Chain | Engages with the wood to make cuts. |

| Air Filter | Prevents debris from entering the engine. |

| Fuel Tank | Holds the mixture of fuel and oil for the engine. |

| Throttle Trigger | Controls the speed of the engine. |

| Chain Brake | Stops the chain in emergencies to enhance safety. |

| Clutch | Engages and disengages the chain from the engine. |

Understanding these components enables operators to enhance their cutting experience and maintain the machinery effectively. Regular inspections and proper care of each section will contribute to improved reliability and performance over time.

Overview of the MS660 Components

This section provides a comprehensive look at the essential elements that comprise a specific model of power equipment, highlighting their functions and interrelationships. Understanding these components is crucial for effective maintenance and operation, ensuring optimal performance and longevity of the machine.

Key Elements

The primary components play distinct roles, contributing to the overall functionality and efficiency. Below is a brief description of some of the main elements:

| Component | Function |

|---|---|

| Engine | Powers the equipment, converting fuel into mechanical energy. |

| Bar | Guides the cutting chain and provides stability during operation. |

| Chain | Interacts with the bar to cut through materials effectively. |

| Air Filter | Prevents debris from entering the engine, ensuring clean airflow. |

| Fuel Tank | Holds the fuel required for engine operation. |

Interconnection of Components

The efficiency of the machine relies heavily on the harmonious interaction of its parts. Regular inspection and understanding of how each element influences the others can significantly enhance performance and reduce wear and tear.

Importance of Genuine Parts

Utilizing authentic components in machinery and equipment is crucial for ensuring optimal performance and longevity. These original elements are specifically designed to work harmoniously with the system, minimizing the risk of malfunctions and enhancing overall efficiency.

Here are several reasons why choosing genuine components is essential:

- Quality Assurance: Original items undergo rigorous testing to meet high standards, ensuring reliability and durability.

- Perfect Fit: Genuine components are crafted to exact specifications, guaranteeing compatibility and preventing issues related to incorrect installations.

- Enhanced Performance: Using authentic elements helps maintain the intended functionality of the equipment, leading to better results in operation.

- Long-Term Savings: Although authentic items may come at a higher initial cost, their reliability can lead to lower maintenance expenses and extended equipment lifespan.

- Warranty Protection: Many manufacturers provide warranties that cover only the use of original components, safeguarding your investment.

In conclusion, opting for genuine components not only safeguards the functionality of your equipment but also promotes a longer operational life, making it a wise investment in the long run.

Common Issues with MS660 Parts

When working with specific components of high-performance equipment, various challenges may arise that can hinder functionality and efficiency. Understanding these common problems is essential for maintenance and effective troubleshooting, ensuring that the machinery operates smoothly and reliably.

One frequent issue involves wear and tear of crucial elements, which can lead to decreased performance and increased friction. Regular inspection is vital to identify signs of deterioration early, allowing for timely replacements. Another common concern is the buildup of debris and contaminants that can obstruct proper operation. Keeping components clean is essential to maintain optimal performance.

In addition, misalignment or improper installation can result in malfunctioning parts, causing the system to work inefficiently or even fail. Ensuring that all components are correctly positioned and securely fastened can mitigate this risk. Furthermore, inadequate lubrication is a prevalent issue that can cause overheating and rapid wear. Maintaining proper lubrication levels is crucial for the longevity of the equipment.

Lastly, electrical issues can arise in systems that rely on electronic components, leading to intermittent failures or complete breakdowns. Regular diagnostics can help in identifying these electrical faults before they escalate into more severe problems.

How to Identify Faulty Components

Identifying malfunctioning elements in machinery is crucial for effective maintenance and optimal performance. Understanding common signs of failure can help users take timely action to prevent further damage. This section will explore various techniques to recognize issues in mechanical components, ensuring a smoother repair process.

Common Symptoms of Defective Parts

Recognizing specific indicators can significantly ease the troubleshooting process. Users should be vigilant for the following symptoms:

| Symptom | Possible Cause |

|---|---|

| Unusual Noises | Worn bearings or misalignment |

| Decreased Performance | Clogged filters or degraded components |

| Overheating | Insufficient lubrication or electrical faults |

| Visible Damage | Impact or wear and tear |

Testing Methods for Component Evaluation

To confirm suspicions about malfunctioning parts, several testing methods can be employed. Utilizing diagnostic tools can provide valuable insights into the condition of mechanical elements:

- Visual Inspection: Regular checks for signs of wear, rust, or cracks.

- Multimeter Testing: Measuring electrical resistance can reveal issues in wiring.

- Vibration Analysis: Monitoring vibrations can identify imbalances or misalignments.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By following essential maintenance practices, you can enhance performance and prevent premature wear. Here are some vital tips to keep in mind:

- Regular Cleaning: Remove debris and buildup after each use to maintain optimal performance.

- Check Lubrication: Ensure all moving components are adequately lubricated to reduce friction and wear.

- Inspect for Wear: Periodically examine components for signs of wear or damage to address issues early.

- Replace Worn Parts: Timely replacement of damaged or worn-out elements can prevent more significant failures.

- Keep It Dry: Store equipment in a dry environment to prevent rust and corrosion.

Incorporating these practices into your routine will help sustain the functionality and reliability of your equipment over time.

Where to Buy Replacement Parts

Finding suitable components for your equipment can be a challenge, especially when you want to ensure quality and reliability. Numerous options are available, from specialized retailers to online marketplaces, each offering a range of alternatives to meet your needs.

Local Retailers often provide a direct solution. Visiting a nearby store allows you to examine items firsthand and seek advice from knowledgeable staff. Many of these shops focus on outdoor equipment and maintenance, making them a valuable resource.

Online Marketplaces offer convenience and a wider selection. Websites like Amazon, eBay, and dedicated equipment suppliers allow you to compare prices and read reviews from other users. Ensure you verify the seller’s reputation to avoid subpar quality.

Manufacturer’s Websites are another reliable option. Purchasing directly from the original producer guarantees that you receive authentic items designed specifically for your machinery. This option often comes with customer support for any inquiries you might have.

Finally, consider aftermarket suppliers that provide alternatives at competitive prices. While these can be cost-effective, it’s crucial to research their quality and compatibility to ensure they meet your expectations.

Using the Parts Diagram Effectively

Understanding a visual representation of components is essential for anyone looking to maintain or repair equipment. This tool serves as a guide to identify each element and its function, enabling users to locate issues more efficiently. Mastering this resource can significantly enhance the repair process, making it smoother and more intuitive.

Familiarize Yourself with the Layout

Begin by exploring the structure of the visual guide. Each section typically corresponds to a specific area of the device, allowing for targeted troubleshooting. Recognizing where each part fits within the overall assembly can save time and reduce frustration during repairs.

Utilize Reference Numbers

Reference numbers play a crucial role in streamlining your approach. By associating each component with its designated number, you can easily cross-reference with manuals or online resources. This practice not only ensures accuracy but also aids in ordering replacements when necessary.

Incorporating these strategies will ultimately lead to a more efficient and confident repair experience.

Assembly Instructions for MS660

Assembling your equipment is a crucial step to ensure optimal performance and longevity. This guide provides a systematic approach to put together the various components effectively, ensuring each part functions harmoniously.

Step 1: Begin by organizing all elements in a designated workspace. Check that you have all necessary components and tools at hand.

Step 2: Follow the provided sequence for connecting each piece. Start with the base, ensuring it is stable before adding additional sections.

Step 3: Secure each connection tightly but avoid over-tightening, which may damage the components.

Step 4: After assembly, conduct a thorough inspection to confirm that everything is aligned correctly and securely fastened.

Step 5: Finally, perform a test run to ensure the entire setup operates smoothly and efficiently.

Upgrading Your Chainsaw Parts

Enhancing the components of your cutting tool can significantly improve its performance and longevity. By carefully selecting upgrades, you can optimize efficiency, increase power, and achieve better cutting results. Whether you’re a professional or a hobbyist, investing in quality enhancements is essential for maintaining a reliable machine.

Choosing the Right Upgrades

When considering modifications, focus on areas such as the engine, bar, and chain. Upgrading to a higher-quality engine can deliver greater torque and speed, while a longer bar allows for deeper cuts. Additionally, selecting a chain designed for specific tasks can enhance precision and reduce wear.

Installation and Maintenance

Proper installation is crucial for the benefits of enhancements to be realized. Always refer to manufacturer guidelines or seek professional assistance if needed. Regular maintenance of upgraded components ensures optimal performance and extends the lifespan of your tool.

Frequently Asked Questions about MS660

This section addresses common inquiries regarding the specifications, maintenance, and troubleshooting of a popular chainsaw model. Understanding these aspects can enhance performance and prolong its lifespan.

What are the key features of this chainsaw?

The device is known for its powerful engine, durability, and ergonomic design, making it suitable for various cutting tasks. It offers advanced safety features and is often preferred by professionals for its efficiency.

How can I maintain my chainsaw effectively?

Regular maintenance includes cleaning the air filter, sharpening the chain, and checking fuel and oil levels. Following the manufacturer’s guidelines ensures optimal performance and reduces the risk of breakdowns.