In the realm of marine propulsion systems, a clear comprehension of the essential elements that contribute to functionality is paramount. This section explores the intricate components that play a critical role in ensuring optimal performance and reliability. By examining these elements, one can gain insights into the mechanisms that allow for efficient operation and maintenance of these sophisticated systems.

Every element within a propulsion assembly is meticulously designed to fulfill specific functions, which ultimately enhances the overall performance of marine vessels. Understanding how these components interact and their individual roles is crucial for anyone involved in maintenance or repair tasks. This exploration not only aids in identifying potential issues but also facilitates informed decision-making during servicing.

Delving into the assembly of these components provides a foundational understanding that benefits both professionals and enthusiasts alike. Whether one is seeking to troubleshoot or simply expand their knowledge, grasping the arrangement and functionality of these parts is essential for effective marine operations.

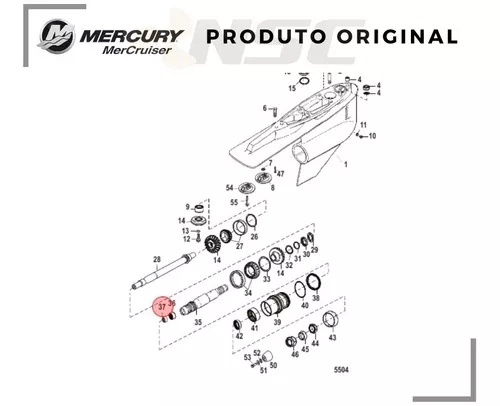

The assembly beneath the watercraft’s exterior plays a crucial role in its performance and functionality. Understanding the various elements involved can enhance maintenance practices and operational efficiency.

Key components that constitute this assembly include:

- Gear Set: Responsible for transmitting power from the engine to the propeller, influencing speed and torque.

- Shaft: Acts as a conduit for power transfer, connecting the gear set to the propeller.

- Housing: Provides structural integrity, protecting internal mechanisms from water and debris.

- Seal: Prevents water ingress, ensuring the longevity of the internal components.

- Propeller: The key component that generates thrust, propelling the vessel forward through the water.

Each of these elements plays a vital role in the overall operation, and awareness of their functions can facilitate better care and repair strategies.

Functions of Key Parts

The various components of a propulsion system play crucial roles in ensuring optimal performance and efficiency. Understanding their specific functions can enhance the maintenance and operation of the entire mechanism.

- Housing: This element provides structural integrity and protection to the internal mechanisms, safeguarding them from external elements.

- Drive Shaft: This component transmits power from the engine to the propeller, enabling the vessel to move effectively through water.

- Propeller: The blade-like structure converts rotational energy into thrust, propelling the watercraft forward.

- Gear Assembly: This system manages torque and speed, allowing for smooth transitions during operation.

- Oil Pump: Essential for lubrication, this part ensures that all moving components operate efficiently and reduces wear and tear.

Each of these elements contributes to the overall functionality of the propulsion system, playing a vital role in ensuring seamless operation and longevity.

Maintenance Tips for Longevity

Ensuring the durability of your marine propulsion system requires consistent care and attention. Regular maintenance not only extends the lifespan of components but also enhances overall performance. By implementing a proactive approach, you can prevent potential issues and keep your equipment operating efficiently.

Routine Inspections

Conducting regular assessments of the mechanical assemblies is essential. Check for signs of wear, corrosion, or damage, and address any findings promptly. Pay close attention to seals and gaskets, as these components are vital for preventing leaks and maintaining optimal function.

Proper Lubrication

Utilizing the correct lubricants at specified intervals is crucial for reducing friction and minimizing wear on moving parts. Adhere to manufacturer recommendations regarding the types and frequencies of lubrication to ensure optimal protection and performance.

Common Issues and Solutions

When dealing with marine propulsion systems, various challenges can arise that affect performance and reliability. Identifying these typical problems is essential for maintaining optimal functionality and ensuring a smooth operation on the water.

Wear and Tear: Over time, components may experience deterioration due to exposure to harsh marine environments. Regular inspections can help detect signs of damage early. Replacing worn parts promptly can prevent further complications and maintain efficiency.

Overheating: Insufficient cooling can lead to overheating, which may cause significant damage to the engine. Ensuring proper water intake and checking the cooling system for blockages are crucial steps to avoid this issue.

Noisy Operation: Unusual sounds during operation can indicate misalignment or insufficient lubrication. Regular maintenance and ensuring all moving parts are adequately lubricated can minimize noise and prolong the lifespan of the system.

Fuel Efficiency: Decreased fuel efficiency may arise from various factors, including improper tuning or obstructions in fuel lines. Conducting periodic assessments of the fuel system can help pinpoint and rectify these issues, enhancing performance and cost-effectiveness.

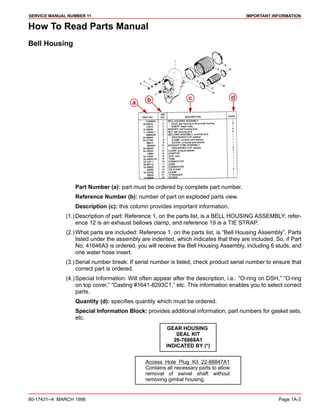

How to Identify Parts Quickly

Recognizing components efficiently is essential for effective maintenance and repair. Familiarity with the structure and features of each element can streamline the identification process, saving time and enhancing accuracy. Here are some practical strategies to enhance your ability to identify various components with ease.

Utilizing Visual References

Visual aids can significantly improve your understanding of the components you are working with. Here are some tips for leveraging these tools:

- Consult user manuals that include illustrations or photographs to familiarize yourself with different elements.

- Use online resources or catalogs featuring labeled images for quick reference.

- Take note of distinctive features such as shapes, sizes, and colors to aid in differentiation.

Organizing Your Workspace

A well-structured environment can enhance your ability to recognize components promptly. Consider the following organization strategies:

- Group similar components together to make identification easier.

- Label storage containers or bins to ensure quick access to frequently used elements.

- Maintain a clean and orderly workspace to minimize distractions and streamline the identification process.

Repair Techniques for Lower Units

Effective restoration methods are crucial for maintaining the performance and longevity of marine propulsion components. Proper techniques can ensure that the assembly functions smoothly and efficiently, preventing potential failures during operation. Understanding the various strategies available for repair can significantly enhance the reliability of these essential systems.

Identifying Common Issues

Recognizing typical problems such as wear, corrosion, or misalignment is the first step in the repair process. Regular inspections help in diagnosing these issues early, allowing for timely interventions. Using specialized tools to assess the condition of the assembly can provide valuable insights into the necessary repairs.

Restoration Methods

Various methods can be employed to restore functionality, including part replacement, realignment, and sealing. Employing high-quality materials during these repairs is essential to ensure durability and performance. Additionally, following manufacturer guidelines during the restoration process can help achieve optimal results.

Upgrading Components for Performance

Enhancing the efficiency and responsiveness of a marine propulsion system can significantly improve overall functionality. By focusing on key elements of the assembly, individuals can achieve better speed, increased torque, and enhanced fuel economy. Modifications to specific components allow for a more tailored performance that meets the demands of various operating conditions.

Evaluating Current Parts is the first step toward any improvement. Assessing the condition and capabilities of existing elements provides a baseline for necessary upgrades. This includes checking for wear and tear, as well as understanding how each part contributes to the system’s operation.

Investing in Quality Materials can lead to significant gains. Upgrading to high-performance materials or technologically advanced alternatives can yield better durability and efficiency. Components such as gears, seals, and bearings should be chosen for their reliability and compatibility with the specific design.

Regular Maintenance plays a crucial role in sustaining performance. Routine inspections and timely replacements can prevent issues that might hinder efficiency. Implementing a consistent maintenance schedule ensures that all upgrades continue to function at their optimal level.

Overall, a strategic approach to enhancing the assembly can result in noticeable improvements, allowing for a more enjoyable and effective boating experience.

Tools Required for Disassembly

To successfully dismantle the assembly, a specific set of instruments is essential. Each tool plays a critical role in ensuring that the process is efficient and minimizes the risk of damage to components.

Begin with basic hand tools, including wrenches and screwdrivers, which are crucial for loosening fasteners. Additionally, pliers can aid in gripping and manipulating various elements during the procedure. A torque wrench is recommended to apply precise force, preventing over-tightening when reassembling.

For more intricate tasks, consider using specialized devices such as a puller for removing bearings or gears without causing harm. A soft mallet may also be beneficial for gently persuading components apart without risking deformation. Keeping a clean workspace and organized tools will further enhance the efficiency of the disassembly process.

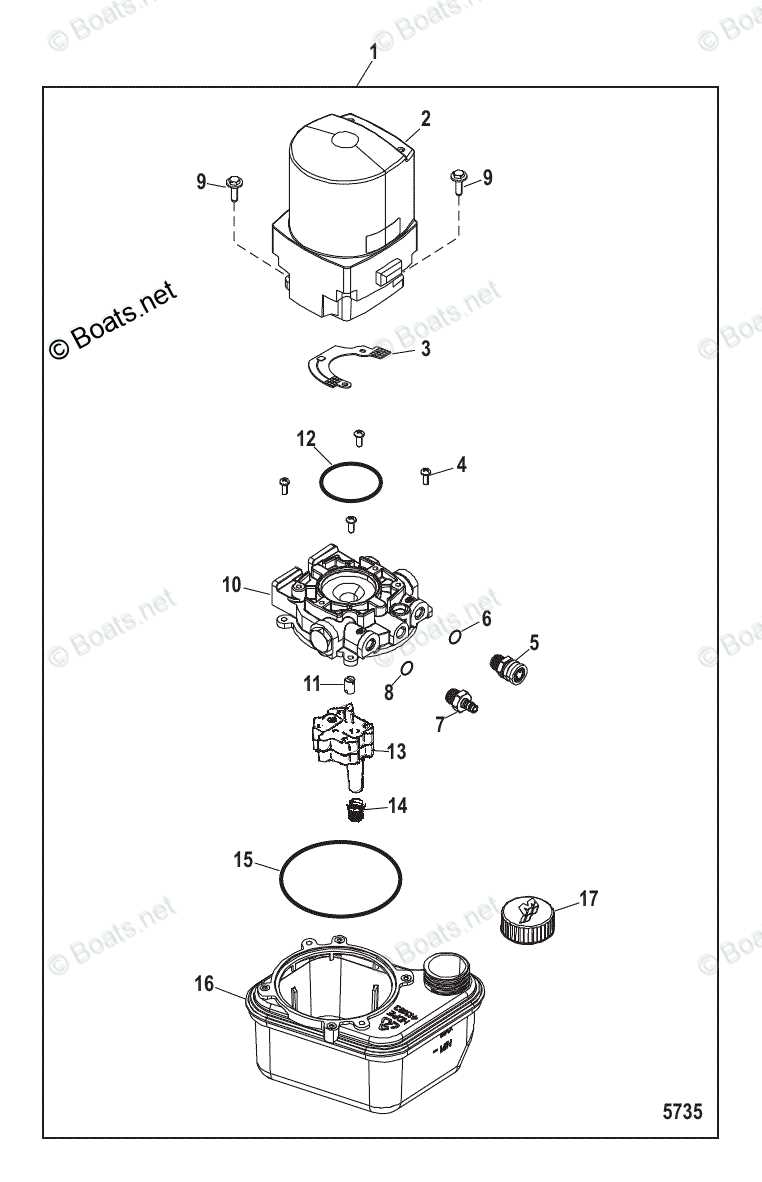

Understanding Hydraulic Systems

Hydraulic systems are integral to various mechanical applications, leveraging fluid power to facilitate motion and control. These systems operate by transmitting force through incompressible liquids, allowing for the efficient transfer of energy. The interplay of components within these systems plays a critical role in their functionality.

Key Elements of hydraulic systems include pumps, valves, and cylinders. The pump is responsible for moving the hydraulic fluid, creating pressure that drives the system. Valves manage the flow and direction of the fluid, ensuring that power is directed where it is needed. Cylinders convert hydraulic energy into linear motion, enabling tasks such as lifting or steering.

Applications of hydraulic systems span across industries, from automotive to manufacturing, showcasing their versatility and efficiency. Understanding these systems enhances one’s ability to troubleshoot and maintain equipment effectively, ensuring optimal performance and longevity.

Best Practices for Storage

Ensuring the longevity and efficiency of components requires careful consideration during the storage process. Proper handling and environment play crucial roles in maintaining optimal performance and preventing damage. By adhering to established guidelines, you can safeguard equipment and enhance its lifespan.

Optimal Environmental Conditions

Creating the right conditions is essential for preserving the integrity of stored items. Consider the following factors:

- Temperature: Maintain a consistent, moderate temperature to avoid thermal stress.

- Humidity: Control moisture levels to prevent corrosion and degradation.

- Lighting: Minimize exposure to direct sunlight to protect sensitive materials from fading and warping.

Organizational Strategies

Efficient organization can streamline access and improve maintenance practices. Implement these strategies:

- Label all containers clearly to facilitate quick identification.

- Utilize shelves and racks to maximize space and prevent overcrowding.

- Regularly inspect stored items to identify any signs of wear or deterioration.

Resources for Further Learning

Expanding your knowledge on marine propulsion systems can significantly enhance your understanding and skills. A wealth of materials is available for those looking to deepen their expertise, whether through online platforms, books, or hands-on experiences. Engaging with diverse resources can provide insights into the mechanics, maintenance, and innovations within this field.

Online Platforms

Numerous websites and forums cater to enthusiasts and professionals alike, offering tutorials, forums for discussion, and instructional videos. These platforms often provide a community where individuals can share experiences and tips.

Books and Manuals

Comprehensive literature is essential for anyone serious about mastering this domain. Manuals and guides often contain detailed information on troubleshooting and maintenance, making them invaluable for both novices and experts.

| Resource Type | Examples |

|---|---|

| Online Courses | Udemy, Coursera |

| Books | Marine Propulsion Systems by John Doe |

| Forums | Boat Forums, The Hull Truth |

| Videos | YouTube channels focused on marine engineering |