When it comes to maintaining outdoor machinery, a solid grasp of its operational mechanisms is essential. This section aims to provide insights into the critical elements that facilitate smooth maneuvering and responsiveness of various models.

Detailed illustrations play a crucial role in demystifying these systems, allowing users to identify and comprehend the intricate connections and functions involved. An effective overview can enhance both troubleshooting and repair processes.

By exploring the various mechanisms and their interactions, enthusiasts and professionals alike can gain a comprehensive understanding of how to optimize performance and ensure longevity of their equipment. Let’s delve into the specifics for a clearer perspective.

Understanding the LX176 Steering System

This section explores the fundamental components and mechanisms that enable precise navigation in specific outdoor machinery. A well-functioning control system is crucial for ensuring optimal maneuverability and safety during operation.

Key Components

Several essential elements contribute to the functionality of this control system. These include the wheel assembly, linkage systems, and control mechanisms, all working in harmony to provide smooth operation.

| Component | Description |

|---|---|

| Wheel Assembly | The primary interface for directional control. |

| Linkage System | Connects the wheel to the control mechanism, facilitating movement. |

| Control Mechanism | Allows the operator to direct the machine effectively. |

Maintenance Tips

Regular upkeep of these components is vital for prolonged functionality. Ensure to check for wear and tear, lubricate moving parts, and adjust settings as needed to maintain peak performance.

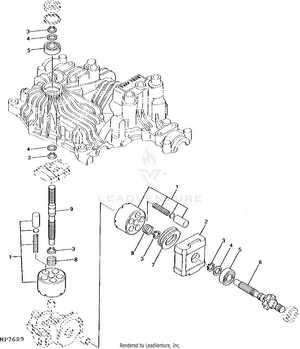

Key Components of John Deere Steering

This section explores the essential elements that contribute to the maneuverability and control of outdoor equipment. Understanding these components can enhance maintenance and performance, ensuring a smoother operation.

| Component | Description |

|---|---|

| Wheel Assembly | Enables directional movement and provides stability during operation. |

| Control Mechanism | Transmits operator input to adjust the path of the machine. |

| Linkage System | Connects the control mechanism to the wheel assembly for effective response. |

| Hydraulic System | Assists in providing smooth and responsive handling under various loads. |

| Pivot Points | Facilitates rotation and maneuvering, critical for tight turns and navigation. |

Importance of Proper Maintenance

Ensuring that machinery operates efficiently requires regular upkeep and attention. This practice not only enhances performance but also extends the lifespan of essential components. Neglecting maintenance can lead to decreased functionality and potentially costly repairs.

Routine checks and servicing help identify wear and tear before it escalates into significant issues. Regular maintenance schedules should include lubrication, inspection of moving parts, and prompt replacement of worn elements. By addressing these factors proactively, operators can avoid unexpected breakdowns and ensure optimal operation.

Moreover, well-maintained equipment contributes to safety, as it minimizes the risk of malfunctions that could result in accidents. Ultimately, investing time and resources into proper care leads to increased reliability and productivity, ensuring that machinery serves its purpose effectively over time.

Common Steering Issues and Solutions

Maintaining control over your vehicle is crucial for safety and performance. Various challenges can arise that impact maneuverability and handling. Identifying these issues early can prevent more significant problems and ensure a smooth operation. This section outlines some frequent complications encountered and provides practical solutions to address them.

Worn Components

One of the most prevalent problems is the deterioration of essential components. Over time, bushings and linkages can wear out, leading to loose handling and decreased responsiveness. Regular inspections can help detect these signs early. Replacing worn elements with high-quality replacements can restore proper functionality and improve overall driving experience.

Misalignment

Another common issue is misalignment, which can result from impacts or normal wear. Misaligned parts can cause uneven tire wear and instability while driving. Adjusting the alignment according to manufacturer specifications is crucial. Utilizing professional services for this adjustment ensures optimal handling and prolongs the lifespan of the tires.

How to Identify Steering Problems

Recognizing issues with the directional control system of your equipment is crucial for maintaining its performance and safety. Being aware of the common signs can help you address potential malfunctions before they escalate, ensuring a smoother operation.

Common Symptoms of Issues

- Unusual noises when turning, such as grinding or clunking sounds.

- Excessive play in the control mechanism, making it feel loose or unresponsive.

- Difficulty in maintaining a straight line, requiring constant adjustments.

- Uneven wear on tires, which may indicate alignment problems.

- Visible damage or wear on connecting components, such as rods or joints.

Steps for Assessment

- Conduct a visual inspection of the assembly for any noticeable wear or damage.

- Test the control mechanism while stationary to identify any excess play.

- Take the equipment for a short drive, observing any unusual resistance or noise.

- Check tire alignment and pressure for inconsistencies.

- Consult a manual for specific adjustment procedures if necessary.

By following these steps and being vigilant about the signs, you can effectively manage and mitigate problems, ensuring your machinery remains in optimal condition.

Step-by-Step Repair Process

Embarking on a repair journey can seem daunting, but breaking it down into manageable steps can simplify the task. This guide provides a structured approach to effectively tackle any challenges that may arise during the maintenance of your machinery.

Preparation and Tools

Before initiating repairs, gather all necessary tools and materials. Ensure that you have the right equipment, including wrenches, screwdrivers, and lubricants. Having everything ready will streamline the process and minimize interruptions.

Assessment and Execution

Start by carefully inspecting the components involved. Identify any issues or wear that need addressing. Once you’ve evaluated the situation, proceed with the repairs methodically, ensuring each step is completed before moving on. Remember to tighten all connections securely and test functionality after each phase.

Tools Required for Steering Repairs

When addressing issues related to directional control systems, having the right tools is essential for efficient and effective repairs. A well-equipped workspace ensures that the necessary components can be accessed and adjusted with precision, ultimately enhancing the longevity of the vehicle’s handling capabilities.

Essential Tools

To start, a comprehensive socket set is crucial for loosening and tightening various fasteners. Wrenches of different sizes will aid in accessing hard-to-reach areas. Additionally, a torque wrench is important to ensure that all connections are secured to manufacturer specifications, preventing future complications.

Specialized Equipment

Moreover, utilizing a hydraulic jack and jack stands allows for safe elevation of the vehicle, providing better access to the undercarriage. Pliers, screwdrivers, and a mallet can help with adjusting and repositioning components as necessary. A service manual is also invaluable for referencing specific assembly instructions and troubleshooting common issues.

Where to Find Replacement Parts

When maintaining or repairing outdoor machinery, locating suitable components is crucial for ensuring optimal performance. Various sources can be explored to obtain the necessary items, each offering unique advantages. Understanding where to look can save time and resources while ensuring high-quality replacements.

Online Retailers

Numerous websites specialize in supplying components for various machinery. They often provide detailed descriptions, specifications, and customer reviews, aiding in informed decisions.

Local Dealers

Visiting local dealerships can yield immediate access to the required components. Representatives can offer valuable insights into compatibility and installation, enhancing the overall experience.

| Source Type | Advantages |

|---|---|

| Online Retailers | Convenient, extensive selection, user reviews |

| Local Dealers | Expert advice, immediate availability, support |

| Salvage Yards | Cost-effective, unique finds, environmentally friendly |

Benefits of Genuine John Deere Parts

When it comes to maintaining equipment, choosing authentic components offers significant advantages. These items are crafted to meet high standards, ensuring optimal performance and longevity.

Reliability is a key factor; genuine components are designed specifically for compatibility with your machinery, minimizing the risk of malfunctions. This attention to detail results in smoother operation and less downtime.

Quality is another crucial aspect. Authentic components undergo rigorous testing to meet strict performance criteria, providing peace of mind that you’re investing in the best available options.

Warranty coverage is often extended when using genuine components, offering additional protection and support. This can save you money on repairs and replacements in the long run.

Additionally, using these high-quality items can enhance the resale value of your equipment, as potential buyers appreciate the assurance of reliable maintenance. In essence, investing in authentic components is a smart choice for both performance and long-term savings.

Exploring Aftermarket Options

When seeking enhancements for machinery, aftermarket solutions can provide valuable alternatives to original components. These options often come with improved performance, cost-effectiveness, and broader availability, making them an attractive choice for many users.

Benefits of Aftermarket Components

Opting for aftermarket items can lead to various advantages. Enhanced durability, better customization, and competitive pricing are key factors that draw consumers towards these alternatives. Additionally, the availability of diverse manufacturers allows for a more tailored approach to meet specific needs.

Considerations Before Purchase

While exploring these options, it’s crucial to evaluate quality, compatibility, and warranty terms. Ensuring that the selected components meet performance expectations will enhance the overall experience and longevity of the equipment.

| Feature | Aftermarket | Original Equipment |

|---|---|---|

| Cost | Generally lower | Higher |

| Durability | Often improved | Standard |

| Customization | More options | Limited |

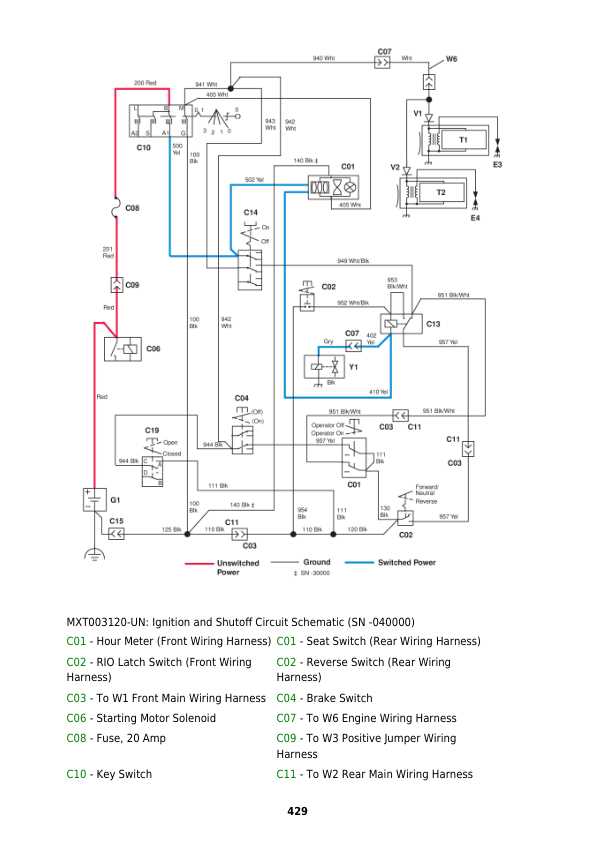

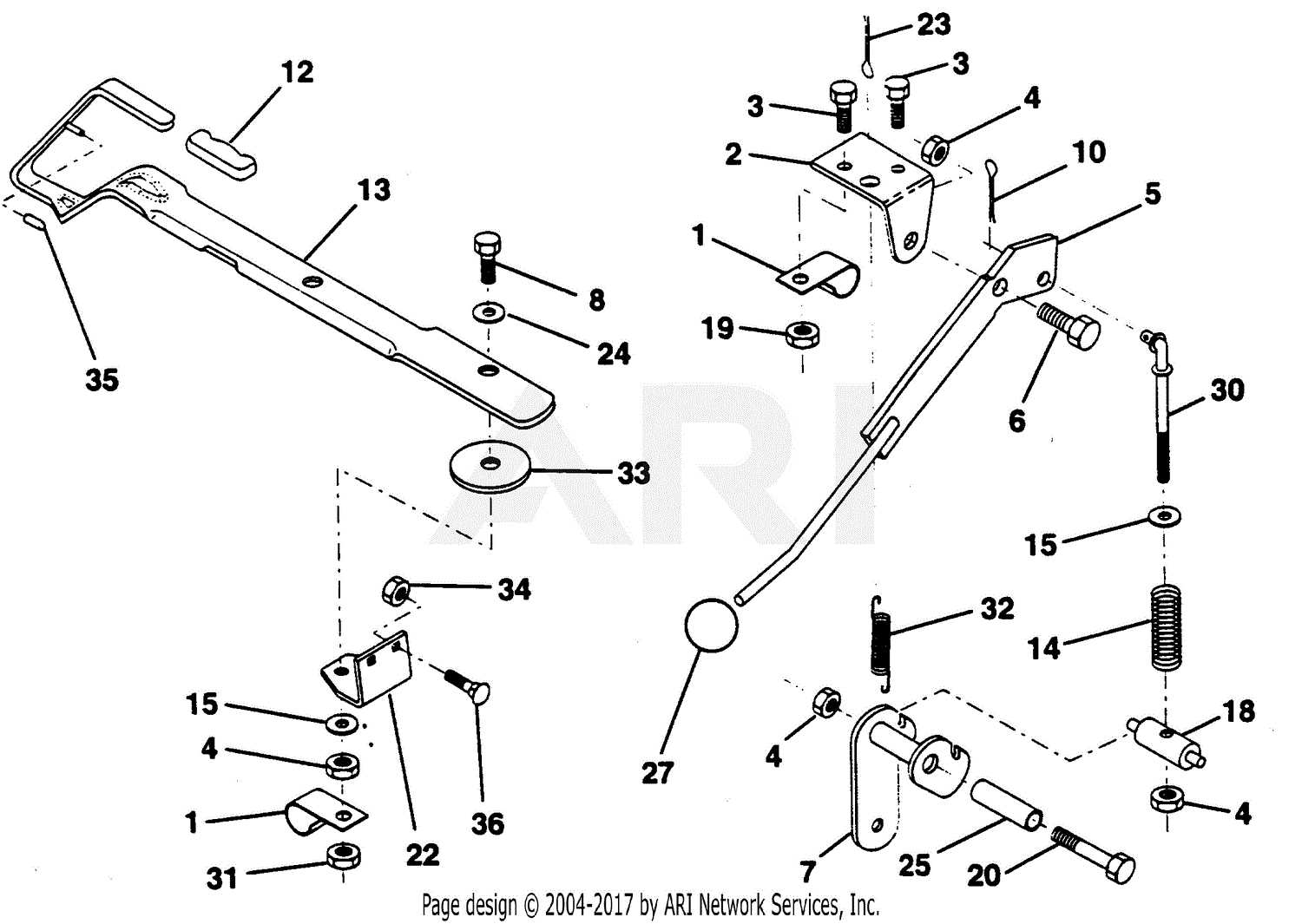

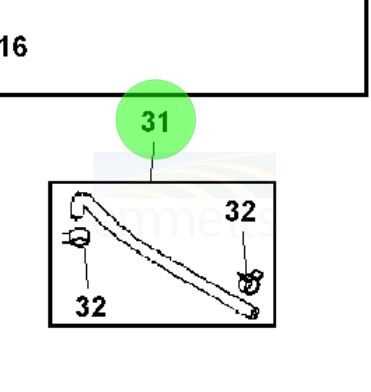

Visual Guide to Steering Parts Diagram

This section provides a comprehensive visual representation of the various components involved in the control mechanism of your equipment. Understanding these elements is essential for maintenance and repairs, ensuring optimal functionality.

Key Components Overview

Identifying crucial elements such as linkages, wheels, and pivot points allows for better insight into the overall system. Each part plays a vital role in achieving precise maneuverability.

Assembly and Maintenance Tips

Regular inspection and upkeep of these components can significantly enhance performance. Familiarity with the layout and assembly will aid in troubleshooting common issues, ultimately leading to improved operational efficiency.

Tips for DIY Steering Maintenance

Maintaining the directional control system of your equipment is essential for optimal performance and safety. Regular upkeep not only prolongs the life of the components but also enhances the overall functionality. Here are some practical suggestions to help you effectively manage maintenance tasks.

Start by inspecting the various elements regularly. Look for signs of wear, such as cracks or unusual looseness, which can indicate the need for replacement or adjustment. Keeping everything clean and free from debris is equally important, as accumulated dirt can hinder movement and cause premature wear.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 10 hours of use | Check for wear and tear |

| Lubrication | Every 20 hours of use | Use recommended lubricants |

| Component Tightening | Monthly | Ensure all bolts and screws are secure |

| Fluid Check | Every 25 hours of use | Inspect fluid levels and quality |

Finally, when making adjustments or replacements, always refer to the manufacturer’s guidelines. Proper procedures are crucial to avoid damage and ensure safety during operation. With these tips, you can confidently maintain the directional control system and keep your equipment running smoothly.