The world of off-road vehicles is fascinating, characterized by a complex interplay of various elements that work together to create an exhilarating riding experience. Each segment plays a vital role in ensuring optimal performance, and a clear understanding of these components is essential for enthusiasts and mechanics alike. By exploring the intricacies of these systems, one can appreciate the engineering behind high-performance machines designed for rugged terrains.

When delving into the specifics, one encounters a variety of crucial mechanisms that contribute to the functionality and efficiency of these vehicles. From propulsion to handling, each element is meticulously designed to withstand the challenges of off-road adventures. Identifying and understanding these components not only enhances one’s technical knowledge but also empowers riders to make informed decisions regarding maintenance and upgrades.

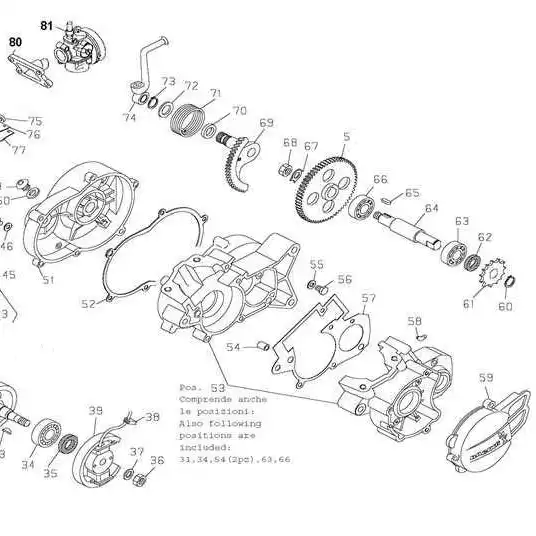

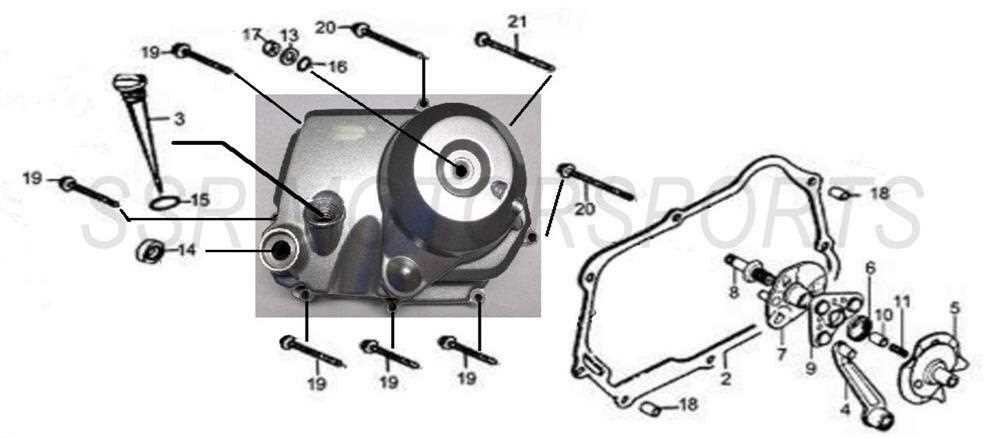

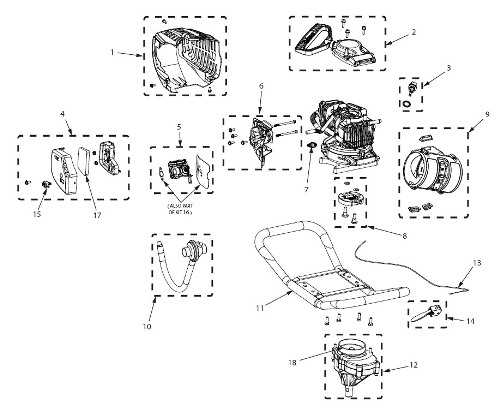

Moreover, visual representations of these mechanisms serve as invaluable tools for both learning and troubleshooting. By examining illustrations and schematics, individuals can gain deeper insights into how each component interacts within the larger system. This understanding can lead to more effective repairs and enhancements, ensuring that the thrill of the ride remains uncompromised.

Dirt Bike Engine Basics

This section explores the fundamental components and principles that power off-road two-wheeled vehicles. Understanding these essentials is crucial for enthusiasts and those looking to maintain or modify their machines. Each element plays a significant role in performance and overall functionality.

Core Components

The heart of any motorized cycle includes various key elements, such as the combustion chamber, fuel delivery system, and cooling mechanisms. Each of these components interacts harmoniously to ensure efficient operation and optimal output. Recognizing how they work together can enhance one’s ability to troubleshoot and enhance the vehicle’s performance.

Operational Principles

The functionality relies on a series of processes that convert fuel into motion. This transformation involves the ignition process, which ignites the fuel-air mixture, creating an explosive force that drives the pistons. Understanding these operational principles can empower riders to make informed decisions regarding modifications and maintenance, ultimately leading to a better riding experience.

Key Components of Dirt Bike Engines

Understanding the fundamental elements that drive two-wheeled off-road vehicles is essential for enthusiasts and mechanics alike. Each component plays a vital role in ensuring optimal performance, reliability, and efficiency. Here, we explore the critical constituents that make up these powerful machines.

Core Elements

- Cylinder: The chamber where fuel and air mix, igniting to create power.

- Piston: A moving part within the cylinder that translates combustion energy into mechanical work.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the wheels.

- Carburetor: Responsible for mixing air and fuel in the correct proportions for combustion.

Supporting Mechanisms

- Valves: Control the intake of air-fuel mixture and the expulsion of exhaust gases.

- Camshaft: Operates the valves at precise intervals to optimize engine timing.

- Ignition System: Initiates combustion through electrical sparks.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

Understanding Engine Functionality

Comprehending how power sources operate is essential for enthusiasts and professionals alike. Each component plays a crucial role in transforming fuel into mechanical energy, resulting in movement. This process involves various elements that work in harmony, showcasing the intricate design and engineering behind these machines.

Core Components and Their Roles

The primary elements involved in this conversion process include the fuel delivery system, ignition setup, and the mechanical assembly. The fuel delivery mechanism ensures that the right amount of fuel reaches the combustion chamber, while the ignition system is responsible for creating the spark that ignites the mixture. Meanwhile, the mechanical assembly translates the explosive force generated by combustion into rotational motion.

The Importance of Maintenance

Regular upkeep of these crucial components is vital for optimal performance. Neglecting any part can lead to inefficiencies or failures, significantly affecting the overall functionality. Understanding the interdependence of these systems allows operators to identify potential issues early, ensuring longevity and reliability in performance.

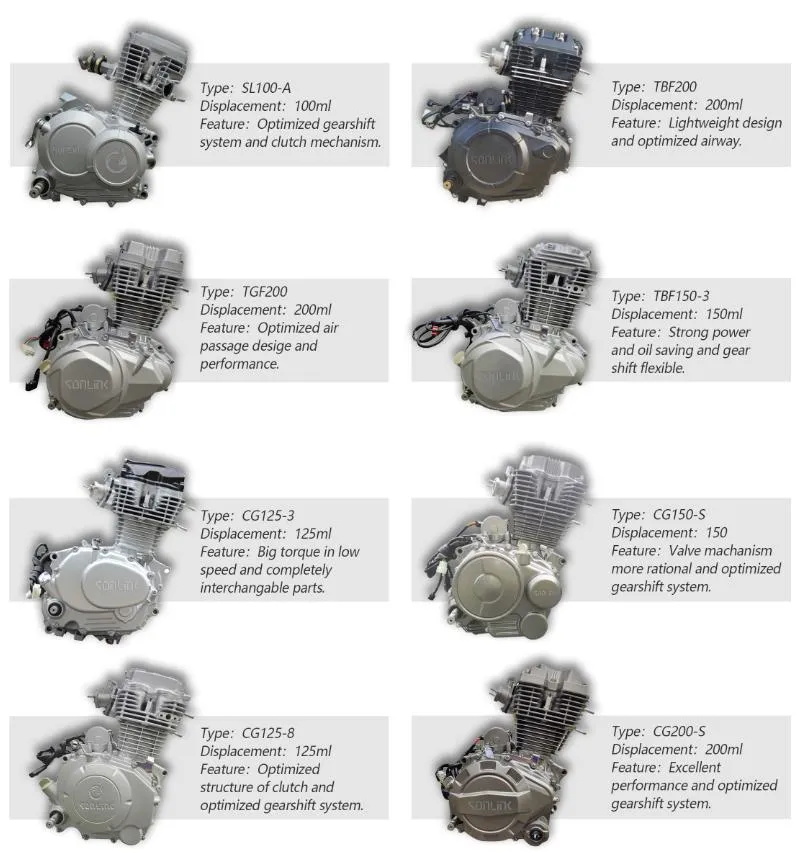

Common Engine Types for Dirt Bikes

In the realm of off-road motorcycles, the variety of powertrains plays a crucial role in performance and handling. Each type offers distinct characteristics that cater to different riding styles and conditions. Understanding these variations can greatly enhance the experience of enthusiasts and competitors alike.

Two-Stroke Powerplants

Two-stroke configurations are known for their lightweight design and impressive power-to-weight ratio. These units deliver a burst of acceleration, making them popular among riders who seek agility and responsiveness. Their simpler construction often results in easier maintenance, though they typically consume more fuel and emit higher levels of emissions.

Four-Stroke Powerplants

Four-stroke configurations provide a smoother and more consistent power delivery. They are often favored for their durability and efficiency, making them suitable for longer rides and varied terrains. With a more complex design, these engines tend to require more maintenance, yet they offer a satisfying balance between power and control, appealing to both recreational and competitive riders.

How to Read Engine Diagrams

Understanding technical illustrations related to mechanical systems can greatly enhance your comprehension of their functions and interconnections. These visual representations often include various components and their relationships, enabling users to identify how each piece contributes to the overall operation.

Familiarize Yourself with Symbols

Each visual guide typically employs specific symbols to denote various elements. Familiarizing yourself with these icons is crucial, as it allows for quicker identification and comprehension. Look for legends or keys that explain what each symbol represents to ensure clarity.

Follow the Flow of Information

Most illustrations will have a logical progression, showing how energy or motion travels through the system. By tracing this flow, you can better understand the sequence of operations. Pay attention to arrows or lines that indicate direction, as they are essential for grasping the complete picture.

Essential Parts for Performance Upgrades

Enhancing the capabilities of your two-wheeled machine involves a careful selection of components that work synergistically to boost speed, agility, and overall functionality. Upgrading various elements not only improves performance but can also lead to a more exhilarating riding experience.

| Component | Description | Benefits |

|---|---|---|

| Carburetor | A device that mixes air with fuel for combustion. | Improved throttle response and increased power output. |

| Exhaust System | The assembly that channels exhaust gases away from the engine. | Enhanced airflow and reduced back pressure for better performance. |

| Ignition Coil | A component that transforms low battery voltage to high voltage for ignition. | Quicker starts and more efficient fuel combustion. |

| Suspension | The system that absorbs shocks and maintains contact with the terrain. | Improved handling and comfort on varied surfaces. |

| Clutch Kit | A set of components that engage and disengage the power from the engine. | Smoother gear transitions and increased control. |

By focusing on these critical upgrades, riders can achieve a notable enhancement in their machine’s performance, leading to an unmatched riding experience. Each component plays a pivotal role in maximizing efficiency and responsiveness.

Maintenance Tips for Engine Longevity

Ensuring the durability of your machinery requires a commitment to regular care and attention. By following essential guidelines, you can significantly enhance performance and extend the lifespan of your equipment.

Regular Inspections

Frequent evaluations are vital. Look for signs of wear and tear, and address any issues promptly. Ignoring small problems can lead to more significant complications later on. Establish a routine that includes checking fluid levels and inspecting components.

Quality Lubrication

Using the right lubricant is crucial. High-quality oils reduce friction and prevent overheating. Make it a habit to change lubricants as recommended, ensuring all moving parts are well-protected and functioning smoothly.

Troubleshooting Engine Problems

Identifying issues with mechanical systems requires a systematic approach. By understanding the common symptoms and their potential causes, users can effectively diagnose and resolve malfunctions. This section will guide you through essential steps for troubleshooting, helping to restore optimal performance.

Common Symptoms and Their Causes

- Loss of Power:

- Clogged fuel filter

- Faulty spark plug

- Insufficient air intake

- Unusual Noises:

- Worn bearings

- Loose components

- Excessive vibration

- Overheating:

- Low coolant levels

- Malfunctioning thermostat

- Blocked radiator

Steps for Effective Diagnosis

- Perform a visual inspection of the system.

- Check fluid levels and condition.

- Examine electrical connections and components.

- Conduct a test run to observe any abnormal behavior.

- Consult the manufacturer’s manual for specific troubleshooting advice.

By systematically following these guidelines, users can effectively pinpoint and address issues, ensuring smooth operation and longevity of their mechanical systems.

Comparing Two-Stroke and Four-Stroke Engines

The choice between different types of power systems significantly impacts performance, efficiency, and maintenance. Understanding the fundamental differences can guide enthusiasts in selecting the right model for their needs.

Two-stroke systems are known for their simplicity and lightweight design, offering a power stroke with every revolution. This results in increased power output for a smaller size, making them ideal for agility and quick responses. However, they tend to be less fuel-efficient and produce higher emissions due to incomplete combustion.

On the other hand, four-stroke systems provide greater fuel efficiency and reduced emissions, as they complete a full cycle in four distinct strokes. This leads to smoother operation and longer lifespan, though they are generally heavier and more complex, requiring more maintenance. Ultimately, the choice depends on the user’s specific requirements and intended use.

Tools Needed for Engine Repairs

When undertaking mechanical work, having the right instruments is essential for achieving optimal results. Proper tools not only facilitate the repair process but also enhance safety and efficiency.

- Wrenches: Essential for loosening and tightening various components.

- Screwdrivers: Useful for adjusting screws of different sizes and types.

- Pliers: Handy for gripping and manipulating small parts.

- Torque wrench: Ensures that fasteners are tightened to the correct specifications.

- Socket set: Provides versatility for various bolt sizes.

Additionally, consider the following:

- Safety goggles: Protect your eyes from debris.

- Gloves: Offer hand protection while working with sharp or hot elements.

- Cleaning supplies: Keep the workspace organized and components clear of dirt.

Equipping yourself with these tools will ultimately make the repair process smoother and more effective.

Safety Precautions During Engine Work

When engaging in mechanical maintenance or repairs, ensuring personal safety and preventing accidents is paramount. Proper precautions not only protect the individual but also enhance the efficiency of the task at hand. Adopting safety measures creates a secure working environment that minimizes risks associated with handling machinery.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-lit and free from clutter to avoid tripping hazards.

- Use tools correctly and maintain them in good condition to prevent injuries.

- Keep a fire extinguisher nearby in case of emergencies.

- Always work in a well-ventilated area to prevent inhaling harmful fumes.

Handling and Storage Tips

- Disconnect the power source before starting any repair work.

- Secure loose clothing and long hair to prevent entanglement in moving parts.

- Store fuel and other flammable materials in approved containers away from the work area.

- Read and understand the equipment manual to follow specific safety instructions.

- Have a first-aid kit accessible for any minor injuries that may occur.