When maintaining your outdoor equipment, it’s crucial to have a clear understanding of how its various elements work together. Each component plays a role in ensuring smooth operation, whether you’re addressing performance issues or simply looking to prolong the life of your tool. Identifying these components and their functions can simplify repairs and improve efficiency.

From the engine system to smaller internal pieces, each part has a specific function. Familiarizing yourself with the setup can help you pinpoint areas that might require attention. A solid grasp of this knowledge will ultimately aid in troubleshooting, allowing you to address concerns swiftly and with confidence.

Understanding Echo Backpack Blower Components

The various elements of this machine work together seamlessly to ensure optimal performance. Recognizing the function of each part helps in maintaining its efficiency and extending its lifespan. By familiarizing yourself with these key components, you can easily address common issues and improve overall functionality.

Main Engine Section

The core section houses the powerful motor that drives the entire system. This motor converts fuel into energy, producing the necessary force for efficient operation. Proper upkeep of this area ensures longevity and reduces the chances of wear.

Control and Airflow Systems

The control mechanisms allow the user to adjust power and speed, while the airflow system ensures smooth air distribution. This system in

Key Parts of the Echo Blower

The functionality and performance of this powerful outdoor tool rely on several essential components. Each piece plays a role in ensuring smooth operation, from controlling airflow to maintaining user comfort. Understanding these elements is crucial for proper maintenance and optimal performance.

- Engine: The heart of the machine, responsible for powering the entire system, ensuring consistent performance.

- Air Tube: This directs the force of the airflow, allowing precise control when clearing debris.

- Throttle Control:

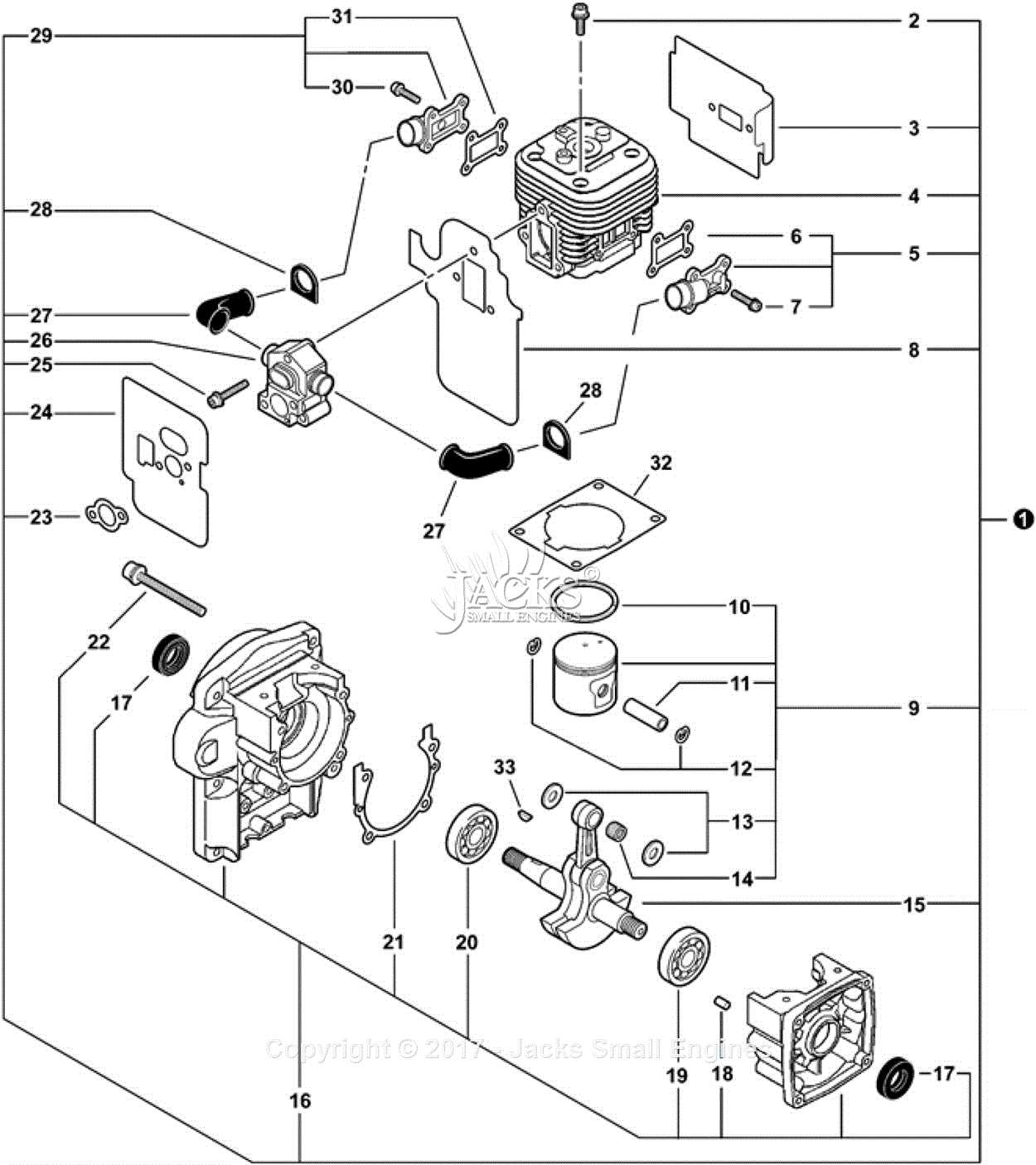

How the Engine Powers the Blower

The core component of any air-moving tool is its engine, which serves as the driving force behind the entire mechanism. Through a precise balance of fuel combustion and mechanical movement, this power source generates the necessary force to propel air efficiently. This process is essential for creating the high-velocity output required for the machine’s effective operation.

Once the engine is running, it converts energy from fuel into kinetic motion. A system of interconnected parts, including pistons and a crankshaft, translates this motion into a rotating force. This rotation is then transferred to a fan or

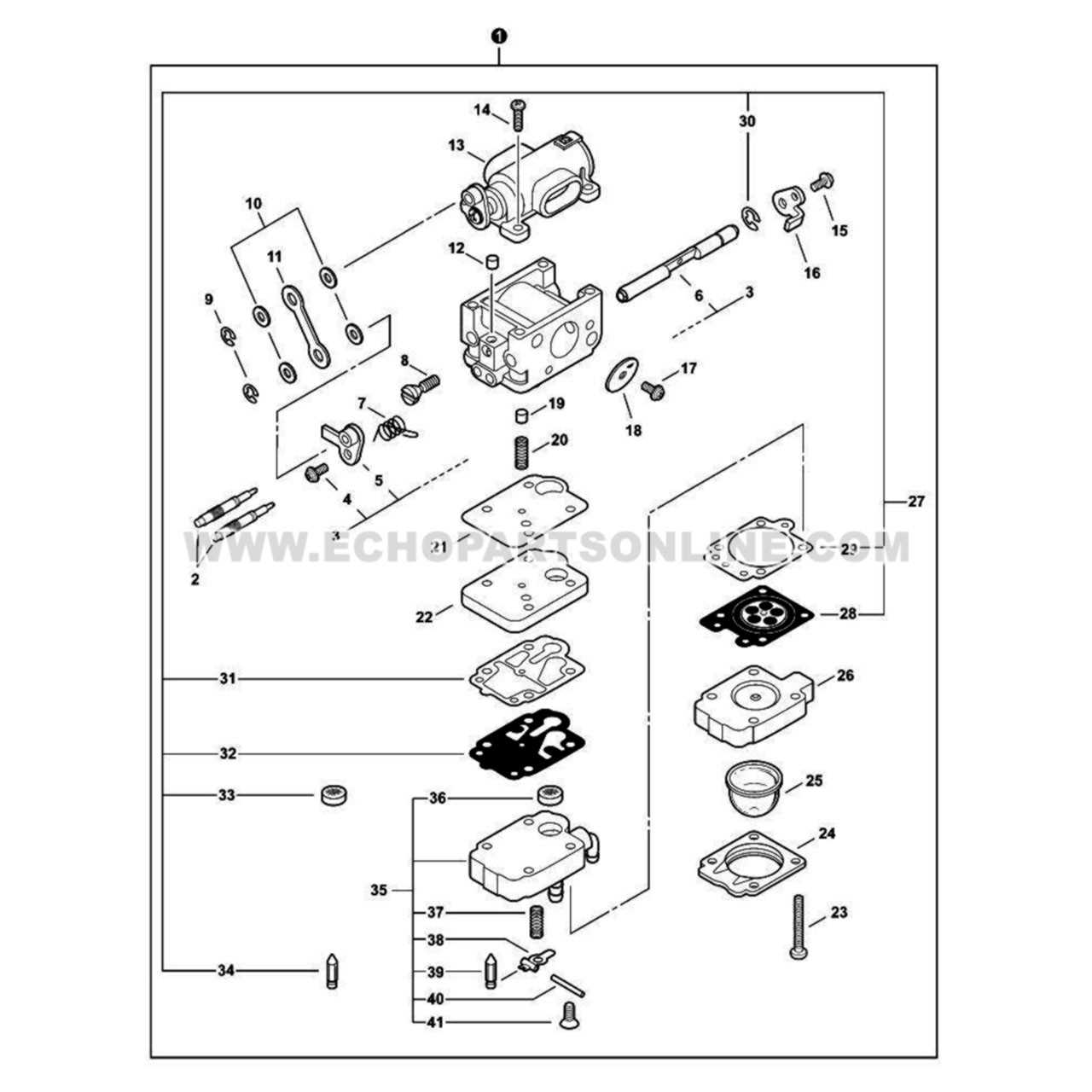

Role of the Carburetor in Performance

The carburetor plays a key role in ensuring optimal engine function. It is responsible for mixing fuel and air in the right proportions to ensure efficient combustion. A finely tuned balance between these two elements is essential for smooth operation and long-term reliability. When the fuel delivery is precise, it impacts overall efficiency, minimizing any potential issues during use.

Fuel-Air Mixture Control

The main task of the carburetor is to control the fuel-air ratio. If too much fuel is supplied, it leads to excessive consumption and possibly fouled components. Conversely, an overly lean mixture can cause overheating

Air Filter: Keeping the Blower Efficient

Maintaining optimal airflow is crucial for the performance of any outdoor equipment. One of the most important components in ensuring this is the air filter, a key element that prevents debris from entering the engine. Proper care of this component helps extend the life of the machine and ensures consistent power output.

To keep the engine functioning smoothly, it is essential to regularly check and clean the filter. Neglecting this can lead to decreased efficiency and potential damage.

- Inspect regularly: Periodically remove the filter and inspect for dirt buildup or damage.

- Clean as needed: If it’s reusable, gently clean the filter with soap and water or a suitable cleaner, allowing it to dry completely before reinstallation.

- Fuel Line Maintenance and Replacement

Proper upkeep of fuel conduits is essential for ensuring optimal performance and longevity of your equipment. Regular checks and timely replacements can prevent leaks and ensure a steady flow of fuel, which is vital for effective operation. Understanding the signs of wear or damage is crucial in maintaining the integrity of these components, as any malfunction can lead to decreased efficiency or operational failure.

Identifying Issues

Common indicators of fuel line problems include visible cracks, leaks, or brittleness in the material. Additionally, if you notice an unusual drop in power or difficulty starting the engine, it may signal that the fuel lines require immediate attention. Regular inspection helps in catching these issues early, preventing more extensive damage to the overall system.

Replacement Process

When it comes to replacing damaged fuel lines, ensure you have the correct tools and materials ready. Begin by safely disconnecting the fuel supply before removing the old lines. Carefully measure and cut the new conduit to match the original dimensions, then securely attach it, ensuring there are no leaks. After installation, test the equipment to confirm proper function and inspect for any signs of leakage.

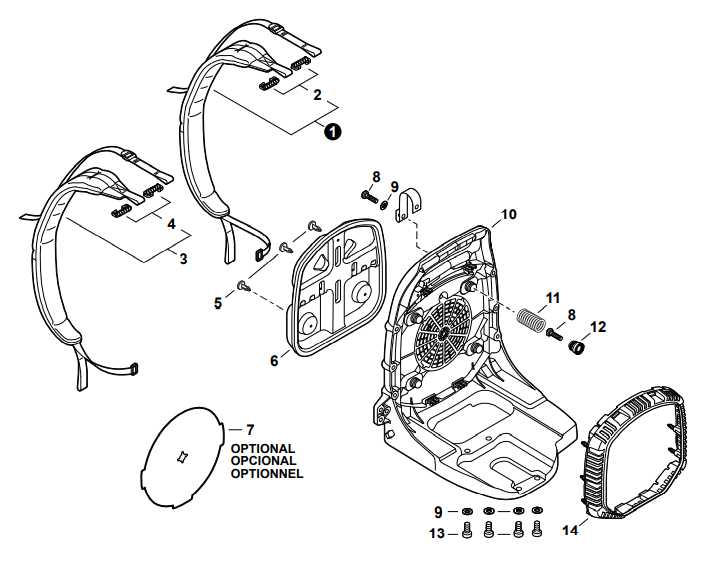

Understanding the Function of the Recoil Starter

The recoil starter plays a crucial role in initiating the operation of small engines. It is designed to provide the necessary force to turn the engine’s flywheel, allowing for a smooth and effective start. This mechanism is particularly significant in various handheld tools and equipment, enabling users to engage the engine with minimal effort.

How the Recoil Starter Works

The operation of the recoil starter involves several key components working in harmony:

- Pull Cord: The user pulls the cord, which is attached to a spool inside the starter housing.

- Spring Mechanism: As the cord is pulled, the spring mechanism unwinds, storing energy for the next cycle.

- Engagement: Once the engine begins to turn, the pawls engage with the flywheel, transferring the rotational force.

- Resetting: After starting, the cord retracts back into place, ready for the next use.

Benefits of a Recoil Starter

Using a recoil starter offers several advantages:

- Ease of use: It allows for quick and straightforward engine engagement.

- Portability: The compact design makes it suitable for a variety of tools and environments.

- Reliability: Mechanical operation reduces the risk of electrical failures common in other starting systems.

In summary, the recoil starter is an essential component that facilitates the starting process of small engines, enhancing user experience and efficiency in various applications.

How the Muffler Impacts Noise Reduction

The design of a sound-dampening component is crucial for minimizing noise emissions in various mechanical devices. This component serves as a barrier that helps attenuate disruptive sounds produced during operation, contributing to a more pleasant user experience and a quieter environment.

Functionality of the Sound-Dampening Device

This device primarily operates by channeling exhaust gases through a series of chambers and baffles. As the gases flow, they encounter obstacles that disrupt sound waves, leading to a significant reduction in noise levels. The effectiveness of this device relies on its structure, materials, and overall design.

Importance of Noise Control

Reducing noise pollution is not only essential for user comfort but also plays a vital role in adhering to local regulations. A well-engineered sound-dampening component can enhance the functionality of equipment while ensuring that it operates within acceptable noise limits. By investing in quality designs, manufacturers can produce machinery that is both efficient and considerate of surrounding environments.

Vibration Dampeners: Ensuring User Comfort

In the realm of outdoor power equipment, user comfort is paramount, especially during prolonged use. One critical component that contributes to this comfort is the system designed to reduce vibrations. By minimizing the impact of mechanical oscillations, these devices help in alleviating fatigue and enhancing the overall experience for the operator.

The effectiveness of vibration dampeners lies in their ability to absorb shocks and vibrations generated by the machinery. These elements are strategically placed to isolate the operator from the machine’s movements, promoting a more pleasant working environment. As a result, users can maintain focus and productivity without the distraction of discomfort caused by excessive vibrations.

Furthermore, investing in equipment with high-quality vibration-dampening features can lead to increased efficiency and longer operational hours. This not only benefits the user’s well-being but also enhances the longevity of the equipment itself. By choosing tools that prioritize vibration reduction, users can ensure a smoother, more enjoyable experience while working in the field.

Handle and Throttle Control Mechanism

The handle and throttle control mechanism play a crucial role in the operation of outdoor equipment, providing users with the ability to manage speed and power efficiently. This system allows for intuitive manipulation, ensuring that the user can easily adjust the performance according to the task at hand. Understanding its components and functionality is essential for effective use and maintenance of the equipment.

Components of the Control System

The control mechanism consists of several integral parts, including the grip, throttle trigger, and associated cables. The grip is designed for comfort and ease of use, enabling operators to maintain a secure hold while maneuvering the device. The throttle trigger, typically located on the handle, allows for precise speed adjustments. Cables connect these elements, transmitting the user’s input to the engine, resulting in responsive operation.

Functionality and Maintenance

Proper functionality of the control mechanism is vital for safe and efficient operation. Regular inspection of the components for wear and tear is recommended. Ensuring that the throttle trigger moves freely and the cables are properly adjusted can prevent potential issues, enhancing performance and longevity. By keeping these elements in good condition, users can achieve optimal results during their outdoor tasks.

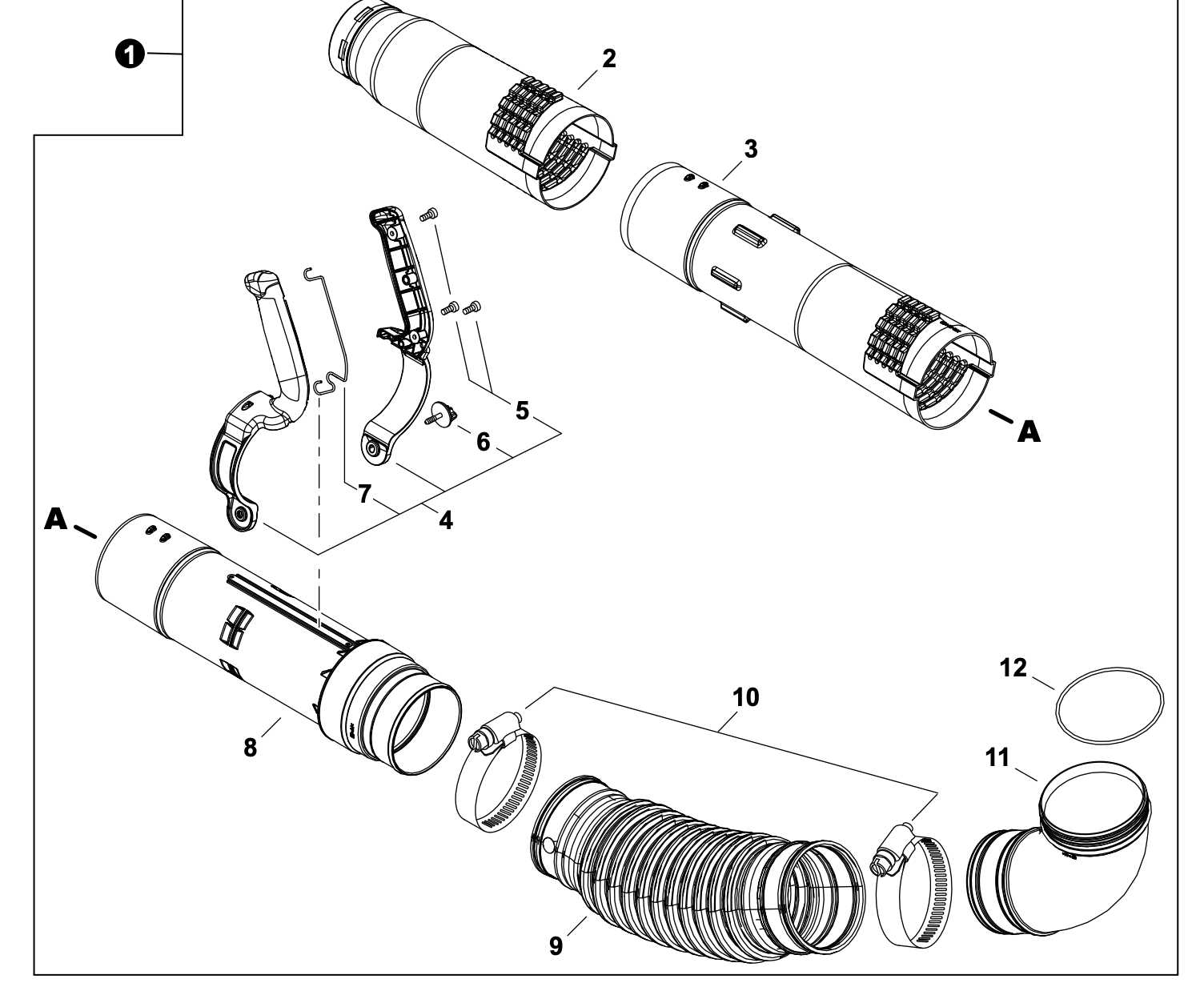

The Importance of the Blower Tube

The component designed to direct airflow is essential for achieving optimal performance in outdoor maintenance equipment. Its functionality significantly influences the efficiency and effectiveness of debris removal tasks, ensuring that users can complete their work quickly and thoroughly.

Optimal Airflow and Control

A well-designed air channel allows for the precise direction of the air stream, which is crucial for managing various materials, from leaves to grass clippings. Users can easily maneuver the device, directing airflow to specific areas without causing unnecessary disturbance, thereby enhancing the overall cleaning experience.

Durability and Maintenance

The longevity of this crucial component is also vital. Constructed from resilient materials, it can withstand frequent use and exposure to outdoor elements. Regular inspections and maintenance help prevent wear and tear, ensuring the device remains functional for an extended period. Proper care extends the lifespan and improves the reliability of the equipment, ultimately leading to cost savings.

Replacing the Spark Plug for Optimal Performance

Ensuring the efficiency of your outdoor equipment often hinges on maintaining key components, and the spark plug plays a vital role in engine performance. A worn or faulty spark plug can lead to poor combustion, reduced power, and increased emissions. Regularly replacing this essential part can significantly enhance the functionality and longevity of your machine.

Why Spark Plug Maintenance Matters

Neglecting the spark plug can result in various operational issues. Here are some reasons why timely replacement is crucial:

- Improves fuel efficiency by ensuring optimal combustion.

- Enhances engine reliability and reduces the likelihood of unexpected failures.

- Promotes smoother operation, leading to a more enjoyable user experience.

Steps for Replacing the Spark Plug

Follow these steps to effectively replace the spark plug:

- Gather necessary tools: a new spark plug, socket wrench, and a gap tool.

- Ensure the engine is cool and disconnect the power source to avoid accidents.

- Locate the spark plug and remove the old one using the socket wrench.

- Check the gap of the new spark plug with the gap tool and adjust if necessary.

- Install the new spark plug, tightening it securely but avoid over-tightening.

- Reconnect the power source and start the engine to ensure proper function.

By adhering to these guidelines, you can maintain peak performance and extend the lifespan of your equipment, ensuring it operates effectively for years to come.

Inspecting and Replacing the Blower Fan

Maintaining the efficiency of your outdoor equipment often requires attention to its internal components. One crucial element is the fan, responsible for generating airflow. Regularly assessing its condition can prevent performance issues and prolong the life of your device.

Begin by disconnecting the power source to ensure safety during inspection. Remove any housing or coverings that protect the fan area, giving you clear access. Examine the fan blades for signs of damage or wear, such as cracks or chips, which can significantly affect operation. Additionally, check for any debris or obstructions that may hinder movement.

If you identify any issues, replacing the fan is straightforward. Secure a compatible replacement and follow the reverse steps of disassembly for installation. Ensure all components are properly aligned and tightened to avoid operational failures. Regular maintenance will help keep your equipment running smoothly and efficiently.