The design and engineering of modern outdoor equipment require careful attention to detail and robust construction. Each component plays a vital role in ensuring the machinery operates efficiently under challenging conditions. Understanding how these elements fit together can significantly improve the maintenance and longevity of the equipment.

In this section, we explore the essential elements that contribute to the overall performance of the machine. From drive mechanisms to control systems, every aspect must be considered to ensure reliability and ease of use. Identifying and familiarizing yourself with the various components will help optimize the device’s functionality.

Ensuring timely upkeep and knowing the structure of the machine will not only enhance its effectiveness but also minimize the chances of downtime. Regular inspections of these critical parts are key to maintaining a high level of performance and avoiding costly repairs.

Key Components of Husqvarna ST224

The machinery in question is equipped with several essential elements designed to ensure optimal performance during challenging winter conditions. These elements work in unison to deliver reliable functionality, even in the most demanding environments. The design focuses on efficiency and durability, providing users with a seamless operational experience.

Engine System: A powerful engine drives the entire operation, delivering the necessary force to handle tough tasks with ease. This core component ensures smooth and consistent performance throughout.

Auger and Impeller: The mechanism includes a rotating auger that feeds material into an impeller. This synchronized motion allows for effective collection and discharge of debris, maximizing output efficiency.

Transmission: The unit’s transmission provides multiple speed options, offering control and adaptability depending on the specific task. This

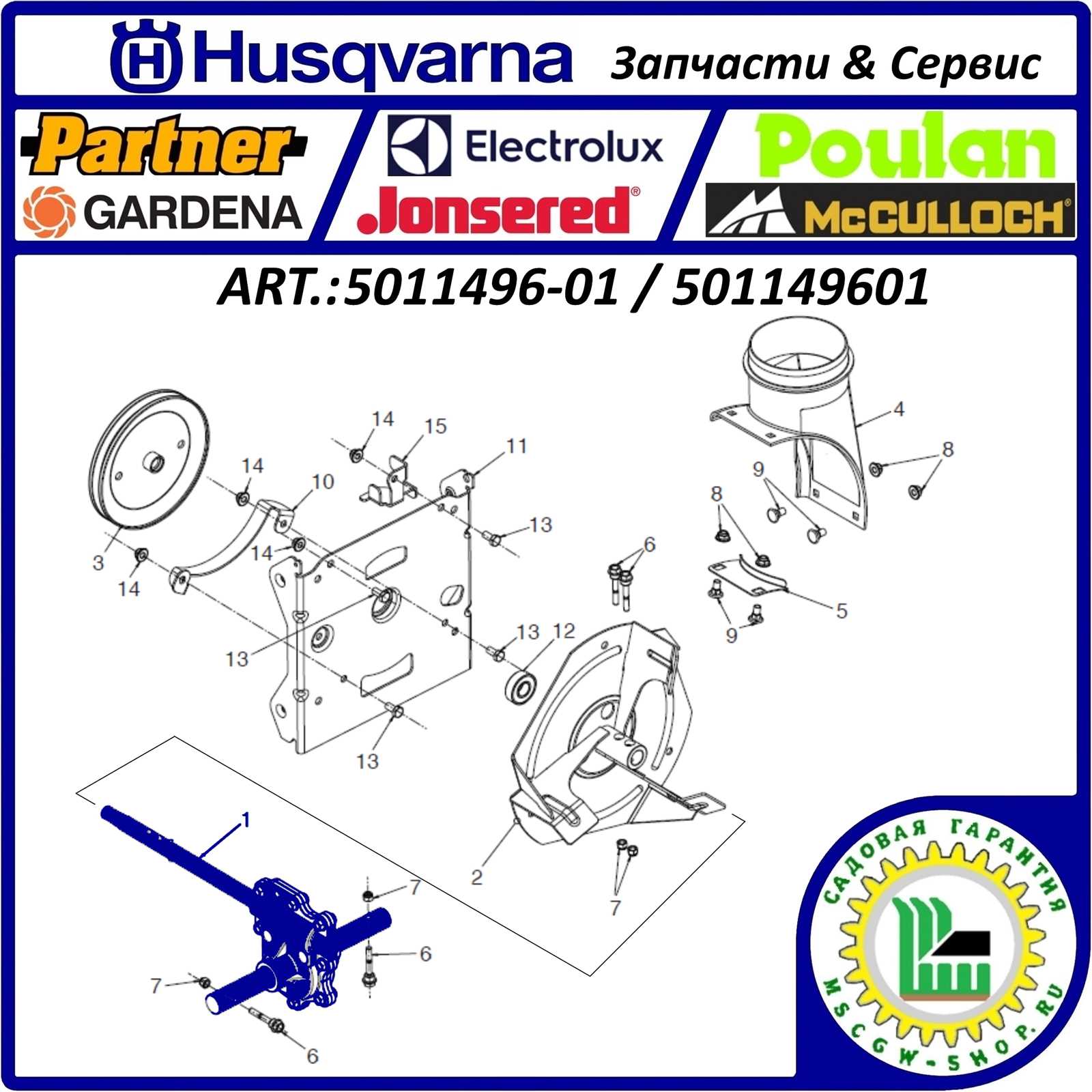

Snow Blower Belt and Pulley System

The belt and pulley mechanism plays a crucial role in the efficient operation of outdoor machines designed for handling large amounts of material. This system is responsible for transferring power from the engine to various components, ensuring smooth and reliable performance during challenging tasks.

Main Components

The belt and pulley assembly consists of several key parts that work together to deliver power. These elements are designed to function in unison, providing consistent force transmission.

- Belt: The main component that transmits power from the engine to other parts of the equipment.

- Drive Pulley: Attached to the engine shaft, this pulley helps transfer rotational energy to the belt.

- Driven Pulley: Receives power from the belt and distributes it to the necessary mechanical parts.

Common Maintenance Tasks

Engine and Ignition System Overview

The engine and ignition system play a crucial role in ensuring the smooth and efficient operation of any outdoor power equipment. Understanding the core components and their functions helps to maintain reliability and prolong the machine’s lifespan.

- Engine Structure: The heart of the machine, the engine, is responsible for generating the necessary power. It consists of various moving parts, including pistons, valves, and the crankshaft, working in unison to convert fuel into mechanical energy.

- Ignition Mechanism: The ignition system is designed to ignite the air-fuel mixture inside the engine’s combustion chamber. This process is initiated by a spark plug, which receives an electrical signal from the ignition coil, ensuring timely combustion.

- Fuel Supply: Fuel is supplied through a carburetor or fuel injection system, which regulates the air-f

Auger and Impeller Mechanism

The auger and impeller system is crucial for efficiently handling large volumes of material, ensuring smooth and consistent operation. This mechanism plays a key role in collecting and moving material through the machine, providing an effective and reliable solution in challenging conditions.

Function of the Auger

The auger consists of rotating blades designed to break down and gather material from the surface. Its robust construction allows it to work through a variety of different types of debris, guiding it towards the center of the unit for further processing.

- Breaks down and gathers material

- Works with heavy and compacted surfaces

- Guides material towards the central discharge area

Role of the Impeller

Once the material is collected by the auger, the impeller takes over. Its high-speed rotational movement forces the material out of the machine, ensuring that it is directed to the desired location with efficiency.

- Receives material from the auger

- Drive System and Transmission Parts

The operational efficiency of any machine relies heavily on the proper functioning of its drive system and transmission. These components ensure smooth power delivery and consistent motion, allowing the device to operate under varying conditions. Understanding the key elements involved in this system is crucial for maintaining reliable performance over time.

Key Components of the Drive System

The drive system typically includes gears, belts, and pulleys, all working together to transfer energy from the engine to the wheels. Proper alignment and tension of these components are vital for ensuring smooth operation and preventing wear. Regular inspection can help identify issues before they lead to major malfunctions.

Transmission Maintenance and Care

The transmission plays a central role in controlling speed and torque. It is essential to keep the transmission well-lubricated and free from debris to avoid overheating and excessive wear. Periodic maintenance, including lubrication and adjustment, can significantly extend the lifespan of the transmission and improve overall functionality

Control Panel and Operating Levers

The control interface of a winter clearing machine plays a crucial role in ensuring smooth operation and user comfort. Understanding the layout and functions of various levers and buttons is essential for effective usage. This section delves into the components of the control panel and their respective roles in managing the equipment’s performance.

Key Components of the Control Interface

Within the control panel, several essential components allow the operator to manage the equipment efficiently. Each lever and button has a specific function, contributing to the overall effectiveness of the machine. Familiarity with these components enhances operational efficiency and safety during use.

Component Function Throttle Control Regulates engine speed for optimal performance. Auger Control Activates the auger to collect and throw material. Chute Control Adjusts the direction of discharged material. Starter Button Initiates the engine start sequence. Headlight Switch Turns on the headlights for improved visibility. Importance of Proper Usage

Correctly utilizing the controls not only enhances the effectiveness of the machine but also ensures safety during operation. Understanding how to manage each component allows for precise control over the clearing process, adapting to various conditions and challenges encountered in winter weather.

Chute Assembly and Rotation Mechanism

The chute assembly is a crucial component in any clearing machine, responsible for directing the discharged material effectively. This mechanism not only influences the performance of the equipment but also plays a vital role in user convenience and control. Understanding its structure and functionality is essential for optimal operation and maintenance.

Components of the Chute Assembly

The assembly consists of several key elements, including the chute itself, which guides the expelled material, and the rotation mechanism that allows for adjustable discharge direction. The quality of materials used in construction significantly affects durability and performance. Regular inspection of these components ensures efficient operation and prolongs the lifespan of the machine.

Rotation Mechanism Functionality

The rotation mechanism typically features a user-friendly control system, allowing the operator to adjust the chute’s angle with ease. This functionality is essential for adapting to various clearing conditions, ensuring that the material is effectively directed away from the user and obstacles. Proper lubrication and adjustment of this mechanism are necessary to maintain its responsiveness and accuracy.

Tire and Wheel Replacement Guide

Replacing the tires and wheels on your outdoor equipment is essential for maintaining optimal performance and safety. This guide provides step-by-step instructions for effectively changing these components, ensuring your machinery operates smoothly and efficiently.

Before starting the replacement process, gather the necessary tools and materials, including a jack, wrenches, and the new tires and wheels. Always consult the manufacturer’s specifications to ensure compatibility with your equipment.

Step Action 1 Park the equipment on a flat, stable surface and engage the parking brake. 2 Loosen the lug nuts on the wheels using a wrench. 3 Lift the equipment with a jack to access the wheels. 4 Remove the loosened lug nuts and take off the old wheels. 5 Install the new wheels, aligning them properly. 6 Secure the new wheels by tightening the lug nuts in a star pattern. 7 Lower the equipment and check for any loose parts before use. Following these steps will help you successfully replace the tires and wheels, contributing to the longevity and performance of your machinery.

Shear Pin and Bolt Maintenance

Regular upkeep of shear pins and bolts is essential for the efficient operation of your equipment. These components play a crucial role in ensuring safety and preventing damage during operation. Proper maintenance not only extends the lifespan of these parts but also enhances overall performance.

To maintain the integrity of shear pins and bolts, follow these essential practices:

- Inspection: Regularly examine shear pins and bolts for signs of wear, rust, or damage. Replace any compromised components immediately.

- Cleaning: Keep these parts free from debris and dirt. Use a soft brush or cloth to clean them, ensuring no residue interferes with their function.

- Tightening: Periodically check the tightness of bolts. Loose bolts can lead to misalignment and potential failure.

- Lubrication: Apply appropriate lubricants to prevent rust and facilitate smooth movement. Ensure that you use lubricants that are suitable for the operating environment.

By following these maintenance steps, you will ensure that your equipment operates smoothly and reliably, reducing the likelihood of costly repairs and downtime.

Fuel Tank and Carburetor Parts

The components responsible for fuel storage and delivery play a crucial role in the efficient operation of outdoor power equipment. Understanding these elements helps ensure optimal performance and longevity of the machinery. The fuel tank is designed to securely hold the necessary fuel, while the carburetor is essential for mixing air and fuel in the correct proportions for combustion.

Fuel Tank: This container is specifically engineered to maintain a stable supply of fuel, preventing leaks and ensuring easy access for refueling. Key features often include durable construction and secure fittings to minimize any potential spills.

Carburetor: The device plays a vital role in regulating the air-fuel mixture entering the engine. It consists of various components such as jets, float chambers, and gaskets, each contributing to the efficient mixing process. Regular maintenance and occasional cleaning are recommended to prevent clogs and ensure smooth operation.

Maintaining the integrity of these components not only enhances performance but also extends the life of the equipment. Regular inspections can identify wear and tear, allowing for timely replacements and adjustments.

Skid Shoes and Scraper Bar Installation

Proper installation of the glide pads and scraping edge is essential for optimal performance and longevity of your equipment. These components play a crucial role in ensuring smooth operation and effective clearing of surfaces, preventing damage to both the machine and the area being worked on.

Follow these steps for a successful installation:

- Gather necessary tools, including a wrench and a screwdriver.

- Ensure the equipment is turned off and disconnected from any power source.

- Locate the existing glide pads and scraping edge, examining their condition.

- Remove the old components by unscrewing them carefully.

- Align the new glide pads with the designated holes on the machine.

- Secure the glide pads using the appropriate screws and tighten them adequately.

- Attach the scraping edge in a similar manner, ensuring it sits flush against the surface for maximum effectiveness.

Once installation is complete, check for stability and proper alignment. This will ensure that the equipment operates smoothly, providing the best results during use.

Electric Starter and Power Cord Setup

The electric starting mechanism significantly enhances the convenience of operating your equipment during harsh winter conditions. Proper setup and maintenance of the electrical components are essential for ensuring reliable performance and longevity. This section outlines the necessary steps for connecting and managing the power supply efficiently.

To begin, ensure that the electric starter is correctly installed according to the manufacturer’s specifications. Following the installation, connect the power cord securely to both the starter and an appropriate electrical outlet. It’s important to verify that the cord is rated for the necessary voltage and amperage to prevent any electrical issues during operation.

Component Description Electric Starter Device that initiates the engine’s operation using electrical power. Power Cord Cable used to supply electricity to the electric starter from an outlet. Outlet Wall socket where the power cord is plugged in to access electricity. Voltage Rating Specification indicating the electrical potential the device requires. Amperage Rating Specification indicating the maximum electrical current the cord can safely carry. Regular inspections of the power cord and starter are recommended to identify any wear or damage. Ensure that connections are clean and free from corrosion, as this can hinder performance. By adhering to these guidelines, users can maximize the efficiency and reliability of their electric starting system.

Replacement Parts for Safety Features

Ensuring the reliability of safety components is crucial for the effective operation of any outdoor equipment. These elements play a vital role in preventing accidents and protecting users from potential hazards. Regular inspection and timely replacement of these features can significantly enhance operational safety.

When considering replacements, it is essential to focus on high-quality alternatives that meet or exceed original specifications. Components such as safety switches, protective shields, and emergency stop mechanisms are fundamental for maintaining a secure environment during use. Utilizing authentic replacements ensures that safety standards are upheld, thereby reducing the risk of malfunction or injury.

In addition to the core safety elements, supplementary items like operator manuals and safety labels can further aid in promoting safe usage practices. By investing in these crucial replacements, users can ensure their equipment operates smoothly while adhering to safety protocols.