The efficient operation of outdoor maintenance tools relies on a comprehensive understanding of their individual components. Each element plays a vital role in ensuring the overall functionality and performance of the machinery. Familiarity with these elements not only enhances the user experience but also aids in effective troubleshooting and maintenance.

In this section, we will explore the various essential components that contribute to the efficient operation of these tools. A detailed examination of each segment will help users identify and understand their specific functions, thereby facilitating informed decisions during repairs or replacements. Knowledge of these components is invaluable for both novice users and seasoned professionals alike.

By gaining insights into the construction and arrangement of these elements, users can maximize the efficiency of their equipment. This understanding empowers them to carry out routine checks and address any issues that may arise, ensuring that their tools remain in optimal working condition throughout their lifespan.

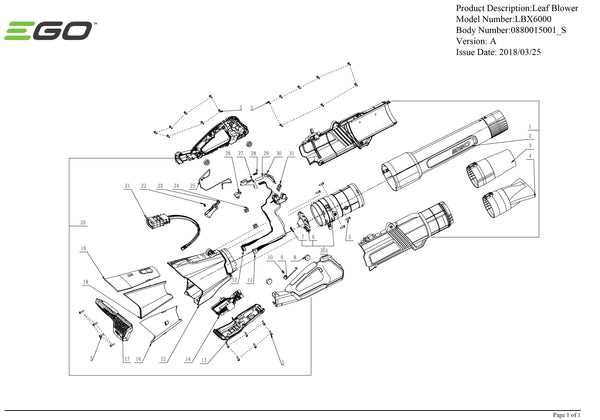

Understanding Leaf Blower Components

Every gardening device consists of various essential elements that work together to enhance its functionality. Understanding these components can help users maintain, troubleshoot, and operate their equipment more efficiently. Each part plays a crucial role in delivering optimal performance, ensuring that tasks are completed effectively.

The motor is the heart of the machine, providing the necessary power to drive the other components. It converts electrical energy into mechanical energy, enabling movement. Connected to the motor, the fan or impeller is responsible for generating airflow, pushing debris away from surfaces. A well-designed fan optimizes air movement, significantly impacting overall efficiency.

Another important element is the nozzle, which directs the airflow towards the intended target. The design and shape of the nozzle can affect the velocity and volume of air produced, making it crucial for achieving desired results. Additionally, the housing protects the internal components while allowing for easy access during maintenance.

Control features such as triggers or switches enable users to manage power levels and airflow intensity, providing versatility for different tasks. The fuel tank, if applicable, holds the energy source required for operation, while the exhaust system ensures that emissions are released safely and efficiently.

Understanding each of these components not only aids in effective operation but also enhances the longevity of the equipment. Regular maintenance and proper usage can prevent common issues, ensuring that the device remains a reliable tool for outdoor tasks.

Common Types of Leaf Blowers

There are various types of tools designed for managing outdoor spaces, each offering unique features and benefits tailored to specific tasks. Understanding these variations can help users select the most suitable equipment for their landscaping needs. Below are the primary classifications of these devices based on their power source and functionality.

Classification by Power Source

Tools can be categorized based on the energy that drives them. The choice between electric, gas-powered, and battery-operated units significantly influences their performance, weight, and maintenance requirements.

| Type | Power Source | Advantages | Disadvantages |

|---|---|---|---|

| Electric | Electricity | Lightweight, quiet operation, low maintenance | Limited mobility, dependent on power source |

| Gas-powered | Gasoline | High power, excellent for large areas | Heavier, louder, more maintenance required |

| Battery-operated | Rechargeable battery | Portable, no cords, relatively quiet | Limited runtime, lower power compared to gas |

Functional Variations

Beyond the power source, the functionality of these tools can vary. Some models are designed for specific tasks, enhancing their efficiency and effectiveness.

| Function | Description |

|---|---|

| Vacuum | Designed to suck up debris and mulch it for easy disposal. |

| Shredder | Shreds leaves and other debris into smaller pieces for composting or easier handling. |

| Multi-functional | Combines blowing, vacuuming, and shredding capabilities in one device. |

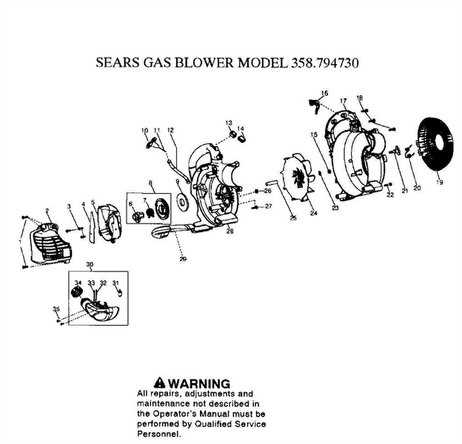

Key Parts of a Leaf Blower

Understanding the essential components of a garden cleaning device is crucial for both effective operation and maintenance. Each element plays a significant role in the overall functionality, ensuring optimal performance and longevity.

Essential Components

- Motor: The powerhouse that drives the device, providing the necessary energy to operate.

- Air Intake: This section allows ambient air to enter, which is essential for the motor’s performance.

- Impeller: A vital part that rotates rapidly to create airflow, pushing debris away with force.

- Nozzle: This directs the airflow to ensure precise control when clearing leaves and other materials.

- Fuel Tank: Holds the necessary fuel to power the motor, critical for combustion engines.

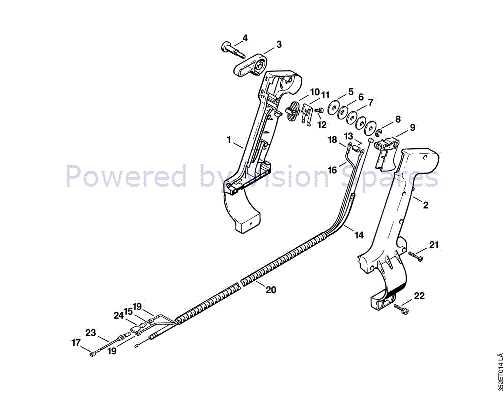

- Throttle Control: Allows the user to adjust the speed of the airflow, providing versatility in operation.

Maintenance Considerations

- Regularly check and clean the air intake to prevent clogging.

- Inspect the motor for signs of wear or damage to ensure efficient operation.

- Keep the nozzle clear to maintain optimal airflow direction and strength.

- Ensure that the fuel tank is filled with the appropriate fuel type to avoid engine issues.

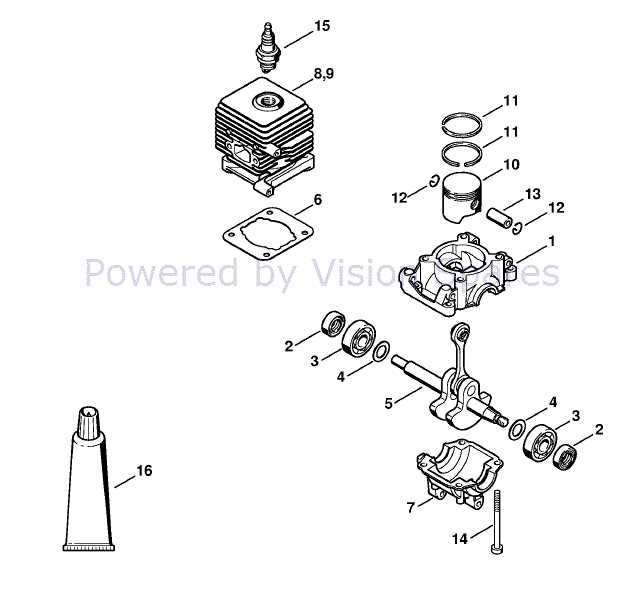

Function of the Engine Assembly

The engine assembly plays a crucial role in the operation of outdoor equipment designed for air movement. Its primary purpose is to convert fuel into mechanical energy, enabling the device to perform various tasks effectively. This assembly is integral to generating the necessary power and efficiency for optimal performance.

Key components of the engine assembly include the crankshaft, pistons, and fuel system. The crankshaft converts the linear motion of the pistons into rotational motion, driving the fan or impeller that produces airflow. The pistons are responsible for compressing the air-fuel mixture, facilitating combustion within the cylinder, which is essential for generating power.

Additionally, the fuel system ensures a consistent supply of fuel to the combustion chamber, allowing for smooth operation and preventing performance issues. A well-maintained engine assembly contributes significantly to the overall efficiency and reliability of the equipment, making it an essential aspect of its design and functionality.

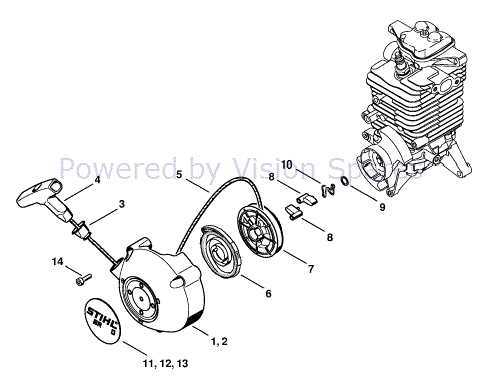

Blower Housing and Its Purpose

The outer casing of a device designed for air movement serves several critical functions that enhance its overall performance and longevity. This structure not only protects the internal components but also plays a vital role in directing airflow efficiently, ensuring optimal operation during use.

One of the primary purposes of the outer shell is to create a controlled environment for the internal mechanisms. By encasing the essential components, it minimizes the risk of damage from external debris or impacts, contributing to the durability of the equipment.

Additionally, this enclosure aids in sound reduction, allowing for quieter operation. It absorbs vibrations and noise generated by the engine, resulting in a more pleasant experience for the user and those nearby.

Moreover, the design of the casing influences the airflow pattern. An effective housing allows for better airflow management, maximizing performance and ensuring that air is directed where it’s needed most.

Key features of the outer structure include:

- Material: Typically made from durable plastics or metals, chosen for their strength and resistance to wear.

- Ventilation: Strategically placed openings that facilitate air intake and exhaust.

- Mounting Points: Locations for attaching the device to various accessories or supports.

- Weight Distribution: A well-engineered design that balances the overall weight for ease of handling.

In summary, the outer casing is an integral component that not only protects but also enhances functionality, making it essential for effective air movement tools.

Importance of the Fan Blade

The fan blade plays a critical role in the functionality of many outdoor tools designed for efficient air movement. This component is essential for generating the necessary airflow to accomplish tasks such as clearing debris or moving dust. Its design and efficiency significantly impact the overall performance of the equipment, making it a key element to consider when discussing operational effectiveness.

Airflow Generation

Effective airflow generation is one of the primary functions of the fan blade. The design, including its shape and material, determines how well it can push air forward. A well-engineered blade enhances air velocity and volume, allowing for quicker and more efficient completion of tasks. Poorly designed blades may struggle to produce the required force, leading to decreased performance and extended working times.

Durability and Maintenance

The longevity of the fan blade is another important aspect. Regular wear and tear can affect its ability to function properly, so maintenance is crucial. Choosing high-quality materials and understanding how to care for the blade can significantly extend its lifespan. Proper upkeep not only ensures optimal performance but also minimizes the risk of unexpected failures during use.

Role of the Air Filter

The air filtration system plays a crucial role in maintaining the efficiency and longevity of outdoor power equipment. By ensuring a clean airflow, it helps prevent dirt and debris from entering the engine, which can cause significant damage over time.

Functionality is paramount; the filter traps particles, ensuring only clean air reaches the combustion chamber. This process optimizes performance and enhances fuel efficiency, allowing the machine to operate smoothly.

Regular maintenance of the air filtration unit is essential for optimal functioning. A clogged or dirty filter can restrict airflow, leading to reduced power output and increased fuel consumption. Therefore, routine inspections and timely replacements are necessary to keep the equipment running efficiently.

In summary, the air filtration component is vital for protecting the internal mechanisms of outdoor machinery, contributing to overall effectiveness and operational lifespan.

Understanding the Fuel System

The fuel system is a crucial component in any engine, playing a vital role in its operation and efficiency. It is responsible for delivering the necessary fuel to the engine, ensuring optimal performance and functionality. A thorough comprehension of how this system works can significantly enhance maintenance practices and troubleshooting efforts.

Key Components of the Fuel System

The primary elements of the fuel system include the fuel tank, fuel lines, pump, filter, and carburetor or fuel injection system. Each component serves a specific function, contributing to the overall efficiency of the engine. For instance, the fuel tank stores the fuel, while the fuel pump moves it to the engine. The fuel filter plays a vital role in removing impurities, ensuring that only clean fuel reaches the combustion chamber.

Maintenance Tips

Regular maintenance of the fuel system is essential for optimal performance. This includes checking the fuel lines for leaks, replacing the fuel filter periodically, and ensuring the fuel tank is free of contaminants. Proper care will not only prolong the lifespan of the engine but also enhance its efficiency, leading to better fuel consumption and reduced emissions.

Electrical Components Explained

Understanding the various electrical elements within outdoor equipment is essential for effective maintenance and operation. These components play crucial roles in ensuring the machinery functions efficiently, providing power to the necessary systems and facilitating smooth operation. A clear grasp of these elements allows users to troubleshoot issues effectively and ensure the longevity of their equipment.

Key Electrical Elements

Among the most important electrical components are the motor and the switch. The motor is responsible for converting electrical energy into mechanical energy, enabling the equipment to perform its intended tasks. The switch controls the flow of electricity, allowing the user to turn the device on or off with ease. These components work in tandem to ensure reliable operation and optimal performance.

Understanding Wiring and Connections

The wiring system connects various electrical parts, facilitating communication between them. Proper wiring is crucial for safety and efficiency, as it ensures that the right voltage reaches each component. Additionally, connections must be secure to prevent power loss or malfunction. Familiarity with these aspects can greatly enhance the user’s ability to maintain and troubleshoot their equipment effectively.

Maintenance of Leaf Blower Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Implementing a consistent maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns. This section outlines effective strategies to keep your equipment in top condition.

Here are some key maintenance tasks to consider:

- Clean the Air Filter: Regularly inspect and clean the air filter to prevent debris buildup that can hinder airflow.

- Inspect the Spark Plug: Check the spark plug for wear and replace it if necessary to ensure reliable starting and operation.

- Check Fuel System: Ensure the fuel lines are free from leaks and that the fuel is fresh to maintain optimal engine performance.

- Examine the Fan and Housing: Remove any accumulated debris from the fan and housing to promote efficient airflow.

- Lubricate Moving Parts: Apply appropriate lubricants to the moving components to reduce friction and wear.

By following these guidelines, you can significantly extend the life of your outdoor equipment and maintain its functionality throughout the seasons.

Troubleshooting Common Issues

When using outdoor equipment, encountering difficulties can be frustrating. Identifying and addressing these problems promptly can enhance performance and prolong the lifespan of your device. This section will explore typical challenges faced by users and provide practical solutions to rectify them.

Here are some common issues and their respective troubleshooting steps:

-

Difficulty Starting:

- Check the fuel level and ensure it is fresh and clean.

- Inspect the ignition system for faults or worn components.

- Examine the air filter for clogs or dirt buildup.

-

Poor Performance:

- Ensure the fuel mix is correct if using a two-stroke engine.

- Inspect the nozzle for blockages that may impede airflow.

- Check the spark plug for wear and replace if necessary.

-

Excessive Vibration:

- Ensure all screws and bolts are tightened securely.

- Inspect the housing for cracks or damage that may affect stability.

- Check the fan for debris that could cause imbalance.

-

Strange Noises:

- Listen for unusual sounds indicating potential mechanical issues.

- Check for loose components or damaged parts that may be causing rattling.

- Inspect the motor for any signs of malfunction or wear.

By systematically addressing these common challenges, users can enhance the efficiency and reliability of their equipment. Regular maintenance and timely intervention can prevent minor issues from escalating into significant problems.

Replacing Worn-Out Components

Maintaining optimal performance in your equipment often requires addressing components that have experienced wear and tear. Regular inspection and timely replacement of these elements can enhance efficiency and extend the life of your device. This section outlines essential steps to identify and replace damaged or degraded components effectively.

Identifying Worn Components

Before proceeding with replacements, it’s crucial to accurately identify which components need attention. Here are some common indicators of wear:

- Decreased efficiency or power output

- Unusual noises or vibrations during operation

- Visible damage, such as cracks or breaks

- Increased operational difficulty or resistance

Steps for Replacement

Once you’ve pinpointed the worn components, follow these steps for replacement:

- Gather the necessary tools and replacement components.

- Ensure the device is powered off and disconnected from any power source.

- Refer to the manufacturer’s guidelines for proper disassembly.

- Carefully remove the damaged components, noting their positioning for correct installation of the new parts.

- Install the new components, ensuring a secure and proper fit.

- Reassemble the device according to the manufacturer’s instructions.

- Test the equipment to confirm that it operates as intended.

By promptly replacing worn elements, you can maintain the performance and reliability of your equipment, ensuring it remains functional for your needs.

Benefits of Using Original Parts

Utilizing authentic components in machinery is crucial for ensuring optimal performance and longevity. Genuine replacements are specifically engineered to meet the manufacturer’s standards, providing a seamless fit and functionality. This adherence to quality not only enhances the efficiency of the equipment but also contributes to overall user satisfaction.

Improved Performance

Original components are designed to work harmoniously with the system, resulting in enhanced operational effectiveness. These genuine pieces are subjected to rigorous testing, ensuring they can withstand demanding conditions. When you choose authentic options, you can be confident that your equipment will perform at its best.

Long-Term Cost Savings

While it may be tempting to opt for cheaper alternatives, investing in genuine components can lead to significant long-term savings. Imitation parts often lack durability, leading to more frequent replacements and repairs. By choosing authentic replacements, users can reduce the risk of breakdowns and associated costs, ultimately proving more economical over time.