The intricate world of watercraft propulsion involves a complex interplay of various elements working in harmony. Each component plays a crucial role in ensuring optimal performance and efficiency, making it essential for enthusiasts and professionals alike to grasp their functions.

In this section, we will explore the essential machinery that drives these vessels, highlighting the importance of each segment. By gaining insight into their arrangement and operation, one can appreciate the craftsmanship involved in maritime engineering.

Moreover, a clear understanding of these mechanical sections can aid in troubleshooting and maintenance, ultimately enhancing the longevity and reliability of the entire system. Whether for recreational use or professional ventures, mastering the details of these crucial elements is the ultimate goal for any maritime aficionado.

Understanding Boat Engine Components

Grasping the various elements of a marine propulsion system is essential for anyone involved in maritime activities. Each component plays a crucial role in ensuring efficient operation, reliability, and performance. By familiarizing oneself with these elements, one can appreciate how they work together to facilitate movement through water.

Key Elements and Their Functions

Every assembly consists of multiple key elements that contribute to its overall functionality. The primary unit converts fuel into energy, driving the entire system. Supporting mechanisms ensure smooth operation and maintenance, while auxiliary systems regulate temperature and manage exhaust. Understanding the specific roles of these components can enhance troubleshooting and maintenance capabilities.

Importance of Regular Maintenance

Regular upkeep of these essential components cannot be overstated. Routine checks and timely replacements of worn elements help prevent unexpected failures and prolong the lifespan of the entire system. Awareness of each unit’s condition allows for proactive measures, ensuring optimal performance during excursions.

Key Parts of Marine Engines

Understanding the essential components that drive aquatic vessels is crucial for effective maintenance and performance. These elements work in harmony to ensure smooth navigation and reliability on the water.

- Cooling System: Vital for regulating temperature, preventing overheating.

- Fuel System: Responsible for delivering the necessary fuel for combustion.

- Lubrication System: Ensures all moving components operate smoothly by reducing friction.

- Ignition System: Initiates the combustion process, crucial for power generation.

- Exhaust System: Safely expels gases produced during combustion, enhancing efficiency.

By examining these key elements, one can delve deeper into the functionality and upkeep of maritime propulsion systems, leading to improved performance and longevity.

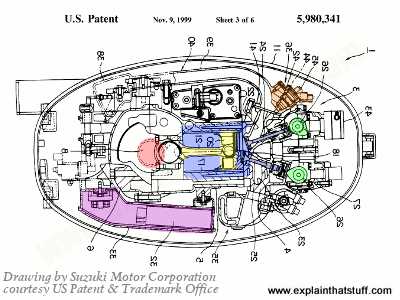

Importance of Engine Diagrams

Visual representations play a crucial role in understanding complex machinery. They simplify intricate systems, making it easier for individuals to grasp how components interact and function together.

Utilizing these illustrations offers several benefits:

- Enhanced comprehension of mechanical relationships.

- Facilitation of troubleshooting and repairs.

- Streamlined communication among technicians and engineers.

- Efficient training tools for newcomers in the field.

Ultimately, these visuals serve as essential resources, helping users navigate technical challenges and ensuring optimal performance of machinery.

Types of Boat Engines Explained

Understanding the various propulsion systems available is essential for any enthusiast looking to navigate the waters effectively. Each type offers distinct advantages and caters to specific needs, influencing everything from speed to fuel efficiency.

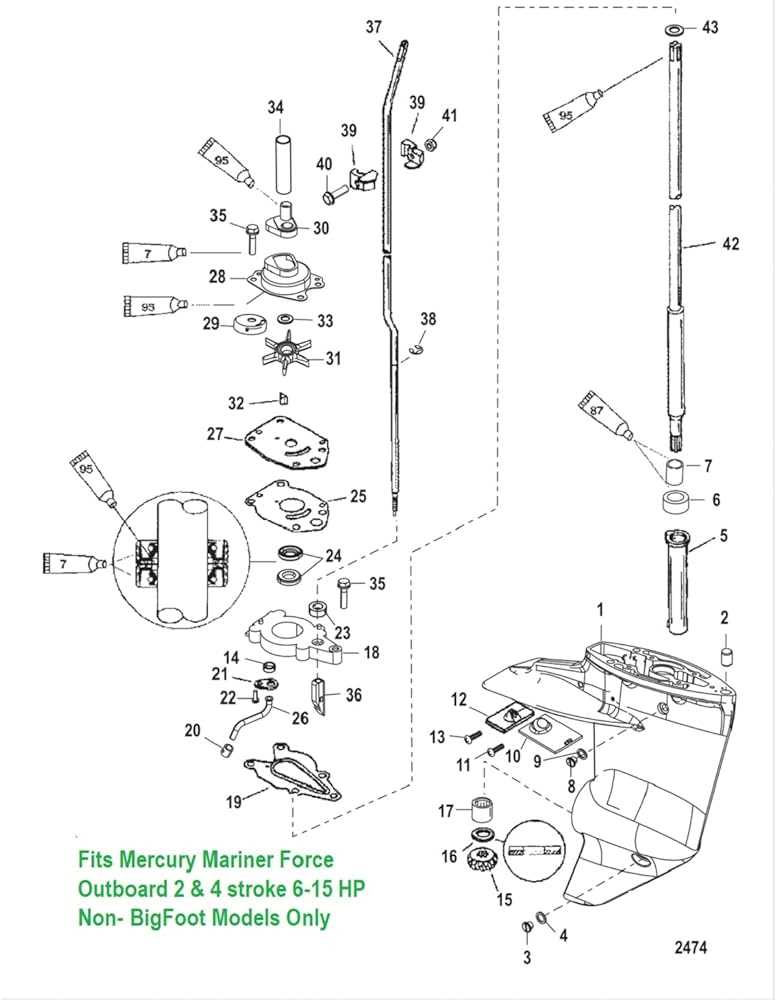

Outboard Motors are commonly found on smaller vessels, providing flexibility and ease of maintenance. These units are mounted externally, making them simple to remove and service.

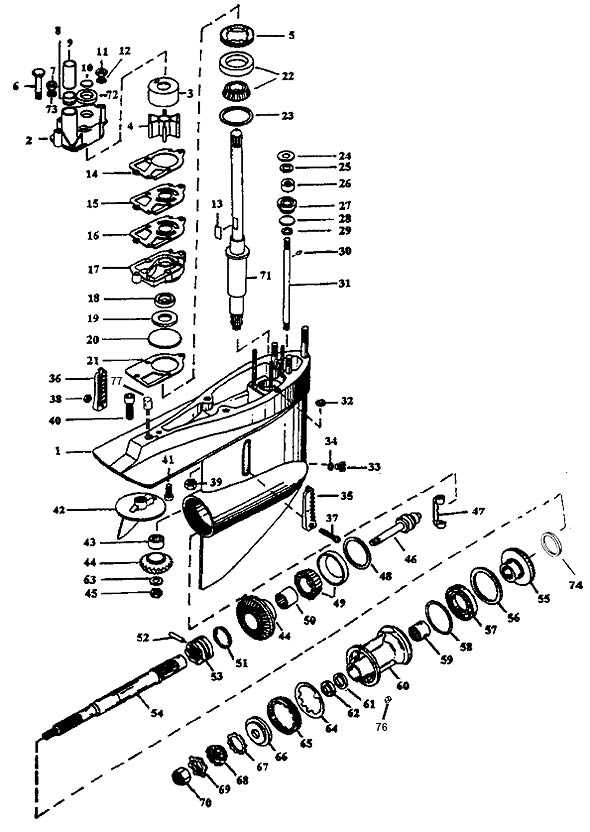

Inboard Systems are integrated into the hull, offering a sleek design and typically better weight distribution. They are favored for larger crafts where space allows for more complex configurations.

Stern Drives combine elements of both outboard and inboard setups. They provide the power of an inboard while maintaining the maneuverability of an outboard, making them versatile for various applications.

Electric Propulsion is gaining traction as an eco-friendly alternative, utilizing batteries for power. This type appeals to those who prioritize sustainability and quiet operation on the water.

Choosing the right system ultimately depends on individual preferences, intended use, and environmental considerations, allowing for an optimal experience on the water.

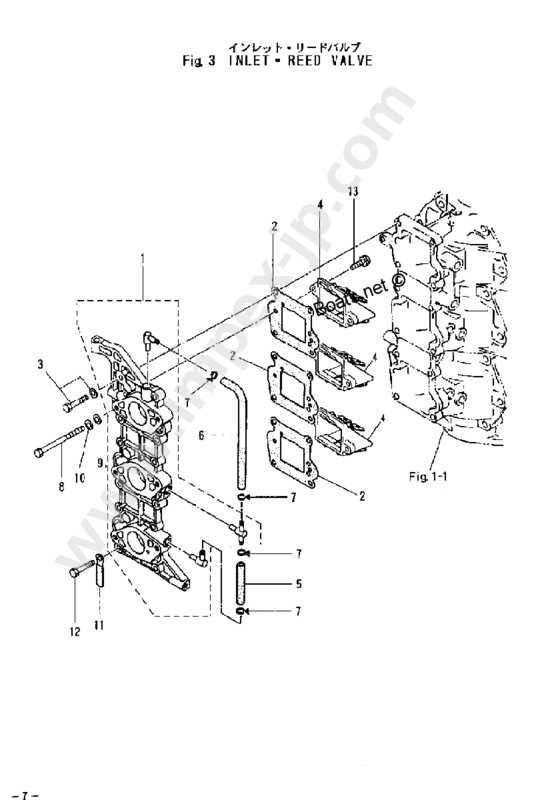

How to Read Engine Schematics

Understanding technical illustrations is essential for anyone involved in machinery maintenance or repair. These visual representations provide crucial insights into the various components and their interconnections, enabling effective troubleshooting and assembly. Mastering the ability to interpret these schematics can significantly enhance your efficiency and accuracy in working with complex systems.

Familiarize yourself with symbols: Each illustration uses specific symbols to represent different components. Take the time to learn these icons, as they form the foundation for comprehending the layout and function of the machinery.

Follow the flow: Most visuals depict a logical flow of operations. Identifying the sequence of actions can help you understand how each element interacts with others, providing clarity on overall functionality.

Pay attention to annotations: Descriptive notes often accompany illustrations. These annotations contain valuable information, such as measurements and specifications, which are vital for proper understanding and implementation.

Practice with examples: Start with simpler schematics before moving on to more intricate designs. Regular practice will build your confidence and improve your ability to decipher complex layouts.

By mastering these techniques, you will empower yourself to navigate technical illustrations with ease, ultimately leading to more effective maintenance and repair practices.

Common Issues with Engine Parts

Understanding the frequent challenges encountered in mechanical systems is crucial for optimal performance and longevity. Various components can face specific malfunctions that may affect overall functionality.

Frequent Problems

- Overheating due to insufficient cooling.

- Fuel leaks caused by worn seals or fittings.

- Corrosion from exposure to moisture and salt.

- Misalignment leading to increased wear and tear.

Preventive Measures

- Regular inspections to identify wear early.

- Proper maintenance of cooling systems.

- Using quality materials to prevent corrosion.

- Ensuring correct alignment during assembly.

Maintenance Tips for Boat Engines

Regular upkeep is crucial for ensuring optimal performance and longevity of your watercraft’s machinery. By adhering to specific guidelines, you can prevent issues and enhance efficiency, allowing for smoother voyages and reduced repair costs.

First, always check and replace fluids as recommended. Clean lubricants help in reducing friction and wear. Additionally, inspect belts and hoses for signs of wear and replace them as needed to avoid unexpected breakdowns.

Furthermore, ensure that the cooling system is functioning properly. Regularly clean any debris from the intake and flush the system to prevent overheating. Also, pay attention to electrical connections, ensuring they are clean and free of corrosion.

Lastly, conduct a thorough inspection before the season starts. This includes checking filters, examining the condition of the hull, and ensuring safety equipment is onboard and operational. Proactive measures will ultimately lead to a more enjoyable experience on the water.

Choosing the Right Engine for Your Vessel

Selecting the ideal power source for your craft is crucial for optimal performance and efficiency. It involves understanding various factors that influence the suitability of a motor for your specific needs.

- Type of Activity: Consider how you plan to use your vessel–whether for leisure, fishing, or long voyages.

- Size and Weight: Assess the dimensions and load capacity to ensure compatibility with your chosen motor.

- Fuel Efficiency: Evaluate the fuel consumption rates and costs associated with different models.

- Maintenance: Research the upkeep requirements and availability of service for each option.

Ultimately, making an informed choice will enhance your experience on the water.

Comparing Outboard and Inboard Engines

This section explores the distinct characteristics and applications of two popular propulsion systems, highlighting their advantages and limitations. Understanding these differences can help users make informed choices based on their specific needs and preferences.

Performance and Efficiency

Outboard units are typically lighter and more maneuverable, offering quicker acceleration and better fuel efficiency in certain conditions. In contrast, inboard systems generally provide more stability and power for larger vessels, making them suitable for prolonged journeys.

Maintenance and Accessibility

One key difference lies in maintenance; outboard configurations are easier to access and service, often requiring less time and effort. However, inboard systems can be more complex, potentially leading to higher upkeep costs due to their integrated design.

Upgrading Your Boat’s Engine System

Enhancing the power system of your vessel can significantly improve its performance and efficiency. This process often involves integrating advanced components and technologies that allow for better fuel consumption, increased speed, and improved reliability on the water.

Assessing Current Components is essential before embarking on any upgrades. Understanding the existing setup enables you to identify which areas need improvement. Consider factors like age, wear, and overall performance to make informed decisions.

Investing in high-quality aftermarket enhancements can lead to remarkable improvements. Options such as turbochargers, upgraded ignition systems, and advanced fuel management solutions can significantly boost your craft’s capabilities.

Moreover, regular maintenance plays a crucial role in maximizing the benefits of any upgrades. Ensure all systems are functioning optimally to fully enjoy the ultimate performance enhancements you’ve implemented.

Resources for Marine Engine Repairs

When it comes to maintaining your aquatic vehicle, having access to the right tools and information is essential. Various sources can assist enthusiasts and professionals alike in enhancing their repair skills and understanding complex systems.

Online Forums and Communities: Engaging with fellow hobbyists can provide invaluable insights. Platforms dedicated to marine mechanics often feature troubleshooting tips and shared experiences that can guide you through challenges.

Manufacturer Manuals: These documents offer detailed instructions tailored to specific models. They serve as the ultimate reference point for repair procedures and specifications.

Video Tutorials: Visual aids can simplify complicated tasks. Numerous channels provide step-by-step guides, allowing you to delve into repairs with confidence.

Local Workshops and Classes: Participating in hands-on training can deepen your understanding and build practical skills. Many organizations offer courses designed to teach various repair techniques.

Retail Stores and Online Suppliers: Accessing quality tools and materials is crucial. Both physical shops and online platforms offer a wide range of resources necessary for effective maintenance.