The intricate design and functionality of modern tools make them indispensable for both professionals and hobbyists. Understanding the internal and external features of these devices allows users to maintain, repair, and optimize their performance. By exploring the various elements, one gains a deeper appreciation for the engineering that goes into creating these essential instruments.

Each element in a versatile tool contributes to its overall functionality. These components work together, ensuring precision and efficiency during operation. Recognizing the importance of each part helps in troubleshooting and maintaining optimal performance over time.

This guide provides a comprehensive overview of the key components that make up a high-performance device, offering clarity on their functions and how they interconnect. With this knowledge, users can confidently address any maintenance or replacement needs.

Bosch 1617EVSPK Router Overview

The versatile woodworking tool in question stands out due to its performance and durability, making it a popular choice among both professionals and hobbyists. It combines precision and power, offering users the ability to work with a variety of materials and complete detailed tasks with ease. Its design ensures comfort during prolonged use, while the robust construction guarantees long-term reliability. This device is especially useful for those requiring an adaptable and efficient tool for their woodworking projects.

Features of this router include variable speed control, which allows users to adjust the pace to match specific project requirements. Additionally, its ergonomic handles provide superior control, reducing fatigue even during extended use. The device also boasts a powerful motor that handles tougher materials with minimal effort, ensuring smooth operation throughout.

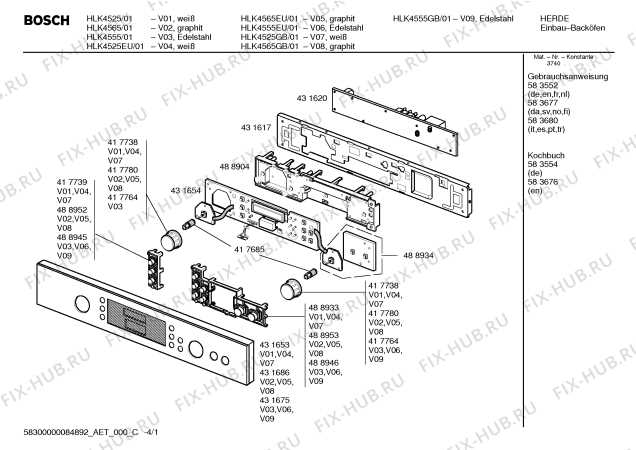

Main Components of the Bosch 1617EVSPK

The power tool in question features a range of essential elements that ensure its efficient performance. Each piece plays a vital role in its functionality, offering durability and precision for various applications. Understanding the key elements allows users to maintain and optimize their equipment effectively.

Motor Assembly

The central component driving the device’s operations is the motor. This part is designed to provide adjustable speeds, ensuring that the tool can handle different materials and tasks with ease. Its robust construction ensures long-term use even under heavy loads.

Base Options

Another significant feature includes the interchangeable bases, which offer versatility in different tasks. Whether it’s for fine detail work or heavy-duty routing, these bases ensure stability and control.

- Fixed base – provides steady handling for precision work.

- Router Bits: Different profiles and materials can create specific cuts and shapes, enhancing the versatility of your equipment.

- Guide Rails: These ensure straight and accurate cuts, making it easier to achieve professional-quality results.

- Dust Collection Systems: Keeping your workspace clean not only improves safety but also maintains visibility and tool efficiency.

- Carrying Cases: Protecting your tools during transport helps prolong their lifespan and maintain functionality.

- Extension Cords: These provide flexibility in movement, allowing for greater reach and convenience during projects.

Motor Assembly and Specifications

The motor is a critical component of any power tool, designed to provide the necessary force for various applications. It ensures smooth operation and efficient power transfer, making it essential for optimal performance. Understanding the motor’s structure and technical details can help in maintaining and enhancing its longevity.

Key Motor Components

The motor comprises several important elements that work together to deliver power. These include the rotor, stator, and brushes, each playing a specific role in the overall functionality. Proper coordination of these parts ensures minimal friction and maximum energy efficiency during operation.

Specifications and Performance

Various technical specifications, such as voltage, horsepower, and RPM (revolutions per minute), determine the motor’s performance. These factors are crucial in selecting the right tool for the job, as they directly impact the tool’s speed, power, and durability. Ensuring that the motor meets the required specifications is key to achieving consistent results in demanding tasks.

Base Options and Attachments

When working with woodworking tools, it’s essential to choose the right base for your project. Different bases and attachments can significantly enhance precision, control, and versatility. Understanding the variety of available options allows users to tackle different tasks more efficiently.

Fixed Base

The fixed base is ideal for tasks requiring consistency and accuracy. It offers stability, ensuring that the tool remains at a set depth throughout the work. This base is perfect for edge routing or projects where uniformity is key.

Plunge Base

For more dynamic tasks, the plunge base allows for deeper cuts and adjustments during the operation. It provides greater flexibility, making it suitable for intricate work like inlaying or creating grooves, where you need to start cutting in the middle of a piece.

Collet and Wrench Details

The collet and wrench are essential components in maintaining the stability and functionality of the router. These elements ensure that the bits are securely held and easily changed, providing precision and control during operation. Understanding the proper use and handling of these tools is key to maximizing performance and safety.

Collet Sizes and Functionality

The collet is

Plunge Base Features and Functions

The plunge base is a crucial component of a versatile power tool, designed to enhance user experience and precision during various woodworking tasks. It allows for controlled depth adjustments, enabling users to achieve intricate cuts with ease. Understanding the features and functionalities of this base can significantly improve the effectiveness of any routing project.

Adjustable Depth Settings

One of the standout features of the plunge base is its adjustable depth mechanism. This functionality permits users to set the cutting depth accurately, ensuring consistent results across multiple applications. Whether creating grooves or shaping edges, the ability to modify depth simplifies complex tasks, making it a valuable asset for both novice and experienced woodworkers.

Enhanced Stability and Control

The design of the plunge base prioritizes stability during operation. Its robust construction provides a steady platform, reducing vibrations and enhancing control. This feature is particularly beneficial when executing detailed work, as it minimizes the risk of errors and allows for smoother movements. Consequently, users can focus on their craftsmanship without worrying about tool performance.

Fixed Base Design and Adjustments

The fixed base configuration is a crucial aspect of routing tools, providing stability and precision during operation. This design allows for secure placement on a work surface, ensuring that the tool remains steady while making cuts. Additionally, proper adjustments can enhance the effectiveness of the fixed base, enabling users to achieve the desired depth and angle with ease.

Adjusting the fixed base is essential for achieving accurate results. By understanding the components involved and how they interact, users can make the necessary modifications to optimize their tool’s performance. The following table outlines key elements and their functions in the fixed base design:

| Component | Function |

|---|---|

| Base Plate | Provides a stable platform for the tool, ensuring even contact with the work surface. |

| Depth Adjustment Knob | Allows users to set the desired cutting depth for precise routing tasks. |

| Height Adjustment Mechanism | Enables users to modify the height of the tool for different routing applications. |

| Locking Lever | Secures the position of the base, preventing accidental adjustments during use. |

Guide Bushing and Compatibility

The selection of guide bushings plays a crucial role in ensuring the optimal functioning of routing equipment. These components are designed to enhance precision and control during various woodworking tasks. Understanding their compatibility with different models is essential for achieving the best performance and results.

Types of Guide Bushings

Various types of guide bushings are available, each tailored for specific applications. Some are designed for larger bits, while others cater to finer tasks. When choosing a guide bushing, it is important to consider the bit size and the intended use to ensure that the components work harmoniously together.

Compatibility Considerations

Compatibility between the guide bushing and the router is vital. Manufacturers typically provide guidelines on which bushings are suitable for their tools. Adhering to these recommendations helps avoid potential issues and ensures effective operation. Furthermore, checking the specifications can save time and effort in the long run, allowing for a seamless woodworking experience.

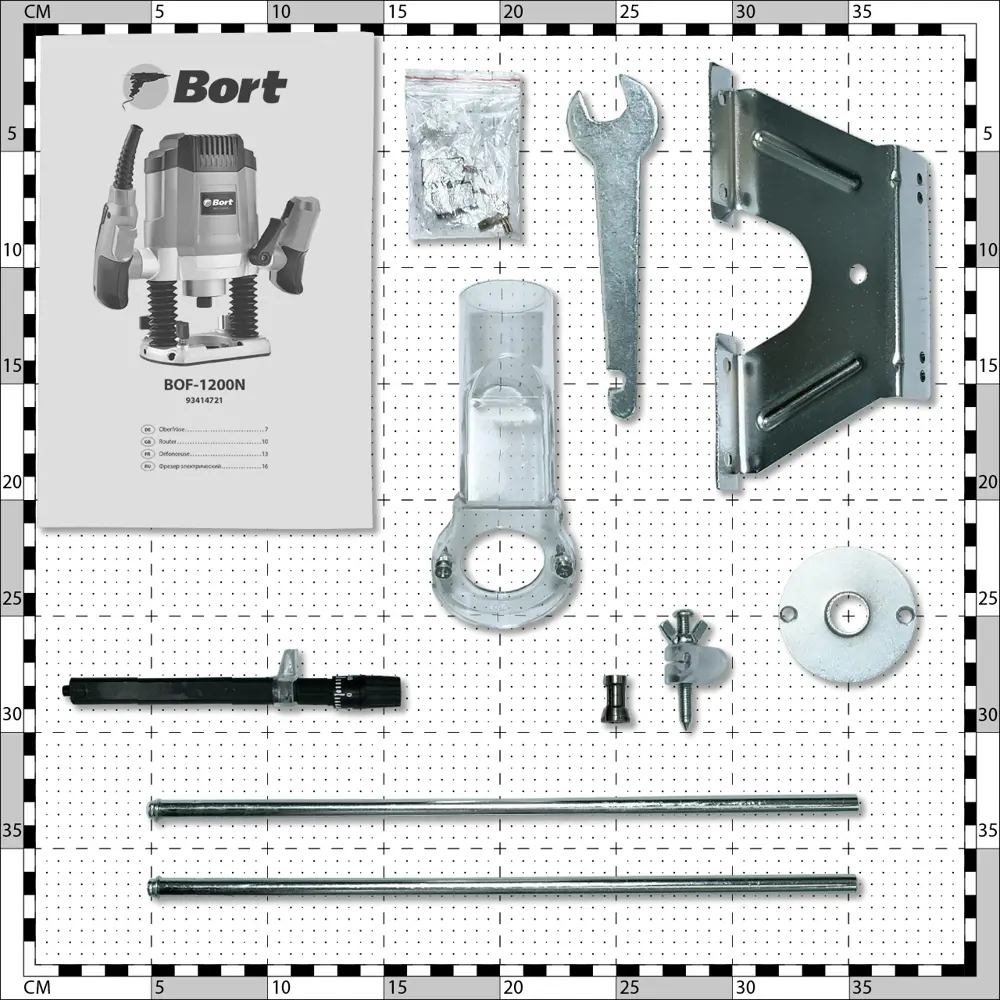

Replacement Parts for Bosch 1617EVSPK

When it comes to maintaining power tools, having access to suitable components is essential for ensuring optimal performance and longevity. Various elements can wear out over time, and identifying the right substitutes is crucial for efficient repairs. Understanding the available alternatives can make the replacement process smoother and enhance the functionality of your equipment.

Common Components for Repair

Several essential items are often sought after for replacement in power tools. These may include motors, bearings, and switches. Ensuring that you select high-quality substitutes will not only restore your tool’s performance but also extend its lifespan. Additionally, using compatible accessories can improve efficiency and adaptability for various tasks.

Where to Find Quality Substitutes

Reliable sources for acquiring quality replacements include authorized retailers, online marketplaces, and specialty stores. It’s important to check for compatibility and customer reviews to ensure that the components meet the required specifications. Doing thorough research can help you find the best options for your specific needs.

Maintenance Tips for Router Longevity

Ensuring the durability and efficiency of a routing tool requires regular care and attention. Implementing simple maintenance practices can significantly enhance performance and prolong its lifespan. By following these guidelines, users can avoid common pitfalls and keep their equipment in optimal condition.

Regular Cleaning

One of the most crucial aspects of maintaining routing equipment is keeping it clean. Dust and debris can accumulate in the machine, potentially leading to overheating and decreased efficiency. Regularly wipe down the exterior and ensure that all vents and openings are free from obstructions.

Lubrication and Inspection

Proper lubrication of moving parts is essential for smooth operation. Inspect components frequently for signs of wear and tear. Replace any damaged or worn parts promptly to prevent further issues. A well-lubricated tool runs more efficiently and is less prone to breakdowns.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | After each use |

| Lubrication | Monthly |

| Inspection | Every 3 months |

Accessories to Enhance Performance

In the realm of woodworking and crafting, utilizing the right tools and attachments can significantly improve efficiency and precision. Enhancements in functionality can often be achieved through various supplementary items designed to work seamlessly with core devices.

Below are some key accessories that can elevate overall performance:

By integrating these enhancements, users can optimize their equipment, ensuring that each project is executed with the utmost precision and ease.

Troubleshooting Common Router Issues

Router malfunctions can disrupt your workflow and cause frustration. Identifying and addressing these issues efficiently can enhance the performance and longevity of your equipment. This section provides insights into typical problems users may encounter and practical solutions to resolve them.

One frequent issue is the router failing to power on. Check the power source and ensure the device is plugged in properly. If it still does not respond, inspect the power cable for any signs of damage.

Connectivity problems are another common concern. If your device is not connecting to the internet, start by verifying your network settings. Restarting both the router and the connected devices can often resolve temporary glitches.

Performance issues, such as slow internet speeds, can arise due to various factors. Check for any interference from other electronic devices and ensure that your router’s firmware is updated. Additionally, consider the placement of your router to optimize signal strength.

Lastly, users may experience unexpected disconnections. This can be caused by network congestion or outdated hardware. Reducing the number of connected devices and upgrading to a newer model can help maintain a stable connection.