In the realm of vehicle safety, the significance of an efficient slowing system cannot be overstated. This essential assembly is pivotal in ensuring that vehicles come to a halt smoothly and reliably. A comprehensive exploration of its individual elements provides insight into how they collectively contribute to overall functionality.

To fully appreciate the intricacies of this system, one must delve into its various components. Each element plays a unique role, working harmoniously to enhance performance and safety. Understanding these roles is crucial for anyone interested in vehicle maintenance or engineering.

In this section, we will examine a detailed representation of these crucial components, highlighting their relationships and ultimate contributions to the stopping mechanism. This knowledge not only aids in effective repairs but also fosters a deeper understanding of automotive design.

Understanding Brake Drum Components

In the world of vehicle safety, certain elements play a critical role in ensuring efficient stopping power. These components work together in a system designed to manage friction and heat, allowing for smooth deceleration. Gaining insight into these mechanisms is essential for maintaining optimal performance and longevity of your vehicle.

Key Elements of the Stopping Mechanism

The assembly consists of various essential components, each serving a distinct purpose. The outer shell is typically made from durable materials, designed to withstand intense heat generated during operation. Inside, you will find a lining that interacts with the main body, facilitating the necessary grip. Additionally, there are springs that maintain tension, ensuring proper engagement and disengagement during use.

Importance of Regular Maintenance

Regular inspection and upkeep of these elements are vital for safe driving. Worn components can lead to decreased performance, increasing stopping distances and compromising safety. Periodic checks allow for early detection of wear and tear, helping to prevent costly repairs and ensuring that all components function harmoniously.

In summary, understanding the intricacies of this stopping mechanism enhances your ability to care for your vehicle effectively. A well-maintained system not only promotes safety but also contributes to a more pleasant driving experience.

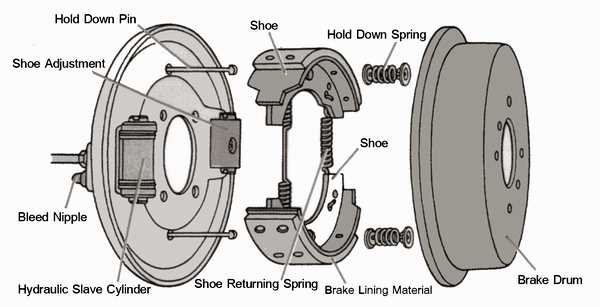

What is a Brake Drum?

This component plays a crucial role in a vehicle’s stopping mechanism, providing the necessary friction to bring the wheels to a halt. It is typically made from durable materials designed to withstand significant heat and wear over time.

Functionality

The primary function of this assembly involves transforming kinetic energy into thermal energy through friction. Here’s how it works:

- The actuator applies pressure.

- The friction material contacts the circular surface.

- Heat is generated, slowing down the wheel’s rotation.

Importance

Understanding this element is essential for vehicle safety and performance. Regular maintenance can enhance its longevity and efficiency:

- Ensures optimal stopping power.

- Reduces wear on other components.

- Improves overall vehicle handling.

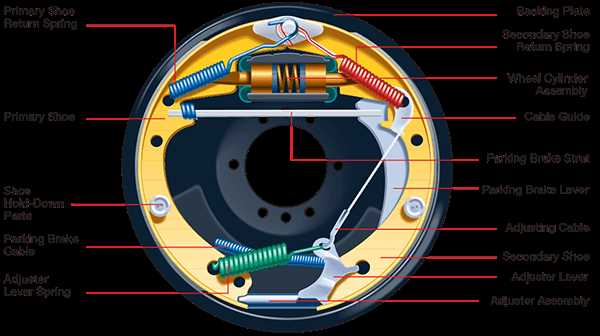

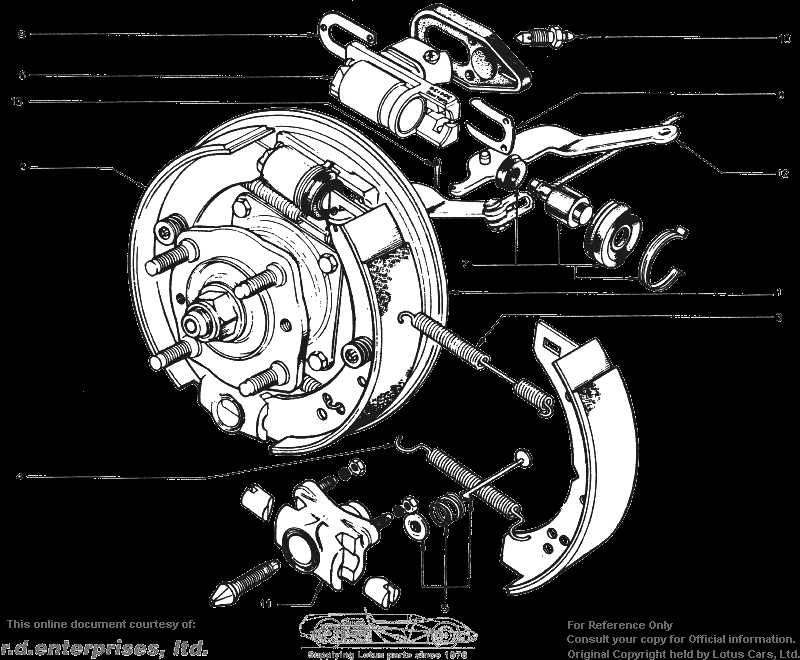

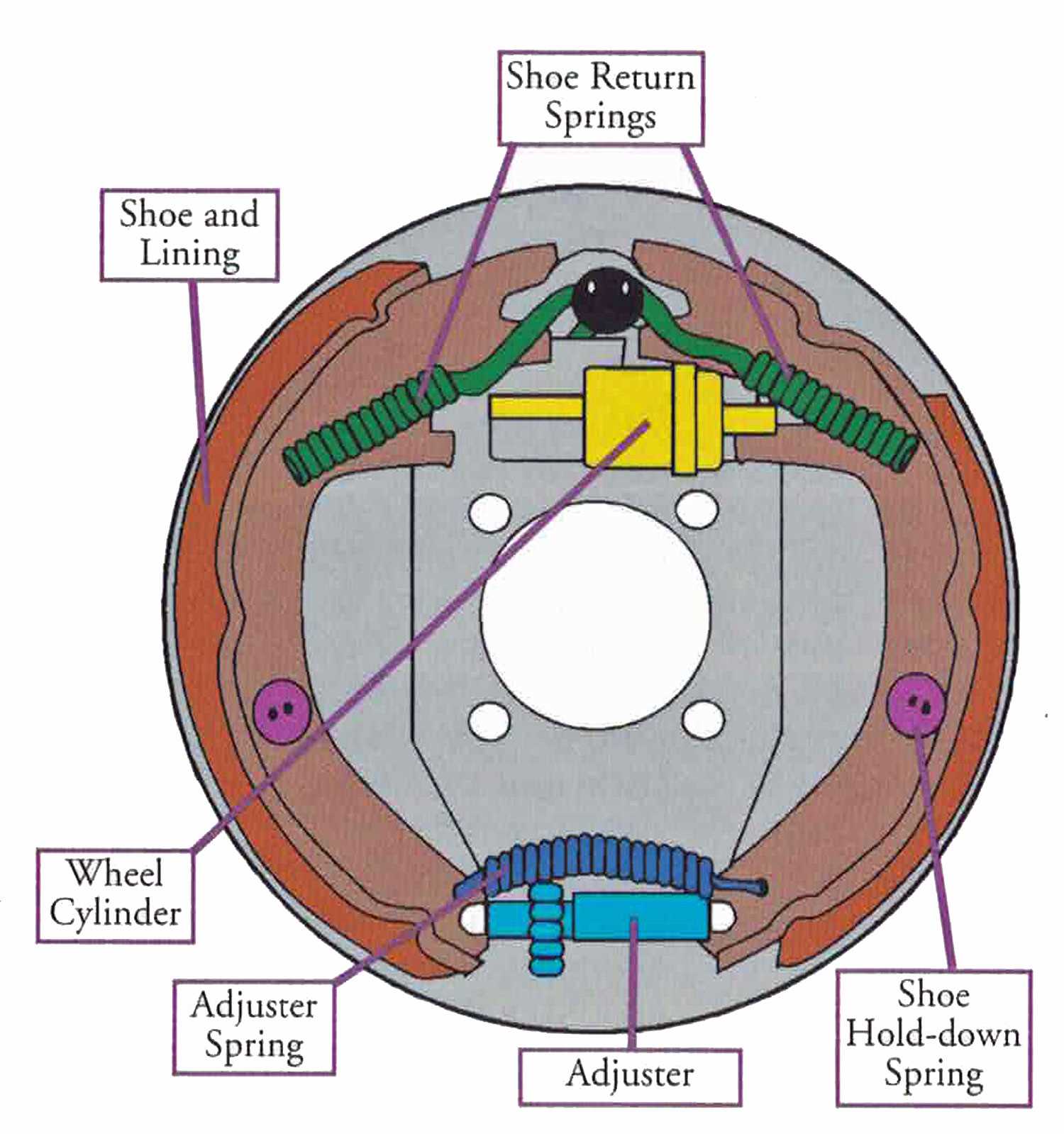

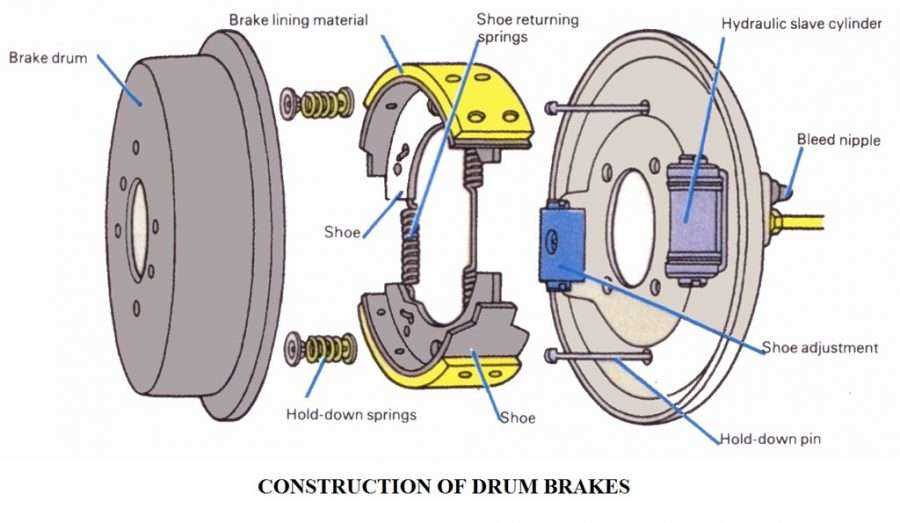

Essential Parts of Brake Drums

The effective functioning of the stopping mechanism relies on various critical components that work together to ensure safety and performance. Understanding these elements can enhance awareness of their roles and the importance of regular maintenance.

| Component | Description |

|---|---|

| Shell | The outer casing that houses the inner mechanism and provides structural integrity. |

| Friction Surface | The area where contact occurs with the lining, generating the necessary friction for deceleration. |

| Backing Plate | A sturdy plate that supports the friction lining, ensuring it remains in place during operation. |

| Wheel Cylinder | This component pushes the linings outward against the friction surface when engaged. |

| Adjustment Mechanism | A system that maintains optimal spacing between the linings and the friction surface for consistent performance. |

| Spring Assembly | A collection of springs that help return the linings to their original position after engagement. |

By familiarizing oneself with these essential elements, individuals can better appreciate their significance in maintaining vehicle safety and reliability.

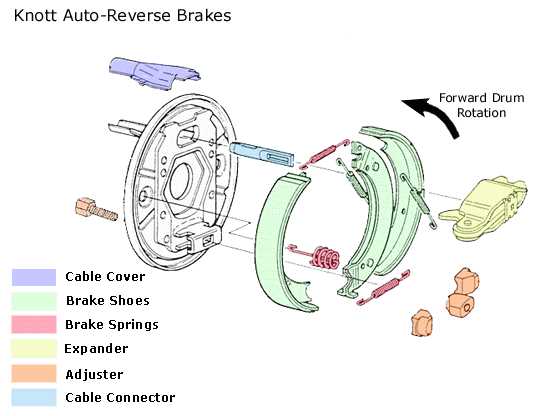

How Brake Drums Function

The system designed for slowing down vehicles relies on friction and mechanical action to bring motion to a halt. Understanding the mechanics involved is essential for appreciating how various components interact to ensure safety and efficiency while driving. This section will delve into the operational principles and characteristics that make this slowing mechanism effective.

| Component | Function |

|---|---|

| Housing | Encases the friction elements and provides a stable structure for operation. |

| Friction Shoes | Engage with the inner surface to create the necessary resistance for slowing. |

| Actuator | Transmits force from the pedal, activating the friction shoes against the housing. |

| Springs | Assist in retracting the friction shoes when pressure is released. |

When the driver applies pressure, the actuator engages, causing the friction elements to expand outward. This contact generates heat and resistance, effectively diminishing the vehicle’s speed. The precise balance and interaction among all elements ensure optimal performance and reliability.

Brake Drum vs. Disc Brake

When it comes to vehicle stopping mechanisms, two primary systems dominate the landscape, each with its own unique characteristics and advantages. Understanding the distinctions between these systems is essential for making informed choices regarding performance, maintenance, and overall safety.

One of the main differences lies in their construction and operation. The first system typically features a cylindrical design that houses the friction material, while the alternative employs a flat, disc-like configuration. This fundamental difference influences factors such as heat dissipation, weight, and responsiveness during deceleration.

Heat management is crucial in ensuring effective stopping power. The disc system tends to perform better in high-temperature situations, as its design allows for more efficient cooling. Conversely, the cylindrical option may experience brake fade under extreme conditions, reducing its effectiveness.

Maintenance requirements also vary significantly. The disc mechanism generally demands less frequent servicing, making it a more convenient choice for many drivers. On the other hand, the cylindrical design may require more regular checks and adjustments to maintain optimal performance.

Ultimately, the choice between these two systems will depend on various factors, including driving style, vehicle type, and specific performance needs. Each has its own set of benefits that can cater to different preferences and requirements.

Materials Used in Brake Drums

Understanding the composition of essential components in a vehicle’s stopping system is crucial for ensuring optimal performance and safety. Various materials are utilized to achieve durability, heat resistance, and effective friction characteristics, which are vital for reliable operation.

Cast Iron is the most common material, known for its excellent heat dissipation and structural integrity. This metal can withstand high temperatures generated during operation, making it a preferred choice for heavy-duty applications.

Aluminum has gained popularity due to its lightweight nature, which contributes to overall vehicle efficiency. It offers good resistance to corrosion and helps reduce unsprung weight, enhancing handling and ride quality.

Composite Materials are also increasingly used, as they combine the benefits of multiple substances. These advanced options can provide a balance of weight, strength, and thermal stability, catering to modern performance demands.

In addition, Carbon-Carbon Composites are utilized in high-performance environments, such as motorsports. Their ability to endure extreme temperatures while maintaining integrity sets them apart, although they come at a higher cost.

Each material has unique properties that cater to different applications, emphasizing the importance of selecting the right composition for specific vehicle needs. Understanding these elements helps manufacturers innovate and improve the efficiency and safety of their designs.

Common Issues with Brake Drums

Several challenges can arise with the components responsible for slowing down vehicles. Understanding these issues is crucial for maintaining safety and performance on the road. Many drivers may overlook signs of wear or malfunction until it becomes critical.

One prevalent problem is uneven wear, which can lead to vibrations and decreased efficiency. This often occurs due to misalignment or improper installation. Regular inspections can help identify these issues before they escalate.

Overheating is another concern, typically resulting from excessive friction or prolonged use. This can cause warping and damage, ultimately affecting the overall functionality. Keeping an eye on temperature levels during operation is essential for prevention.

Noise is a common indicator of underlying problems, often manifesting as grinding or squeaking sounds. These noises can signal that components are not functioning smoothly or are in need of replacement. Prompt attention to such sounds can prevent further damage.

Corrosion can also be a significant issue, especially in areas with harsh weather conditions. Moisture and road salt can lead to rust, weakening the structure and compromising safety. Regular cleaning and inspections can help mitigate this risk.

Ultimately, proactive maintenance and awareness of these common issues can enhance vehicle performance and extend the lifespan of crucial components involved in slowing down or stopping. Regular check-ups by professionals are advisable to ensure everything is functioning as it should.

Maintenance Tips for Brake Drums

Ensuring the longevity and effectiveness of your vehicle’s stopping system requires regular upkeep and attention to specific components. Proper maintenance can enhance safety and performance while extending the lifespan of critical elements.

- Regular Inspection: Periodically check for signs of wear or damage. Look for cracks, warping, or uneven surfaces.

- Cleaning: Keep the surfaces free from dust, debris, and grease. Use a suitable cleaner to ensure optimal contact and performance.

- Adjustment: Ensure that the alignment and spacing are correct. Misalignment can lead to uneven wear and decreased efficiency.

- Lubrication: Apply the appropriate lubricant to moving components to reduce friction and prevent corrosion.

- Monitor Performance: Pay attention to any changes in how your vehicle responds when stopping. Unusual noises or vibrations may indicate a need for maintenance.

By following these guidelines, you can maintain the reliability of your vehicle’s stopping mechanisms, contributing to safer driving experiences.

Signs of Worn Brake Drums

Understanding the indicators of deterioration in your vehicle’s stopping components is crucial for ensuring safety and performance. Recognizing these signs early can prevent more severe issues and costly repairs. Pay attention to the following symptoms that may suggest the need for maintenance or replacement.

Unusual Noises

One of the most noticeable signs of wear is the emergence of strange sounds during operation. If you hear grinding, squealing, or any unusual noise when engaging the stopping system, it may indicate that the friction material is wearing thin or that other components are damaged.

Vibration and Pulsation

Another indicator is the sensation of vibrations or pulsations felt through the pedal when applying pressure. This can result from uneven wear or warping, signaling that the components are no longer functioning effectively and may require attention.

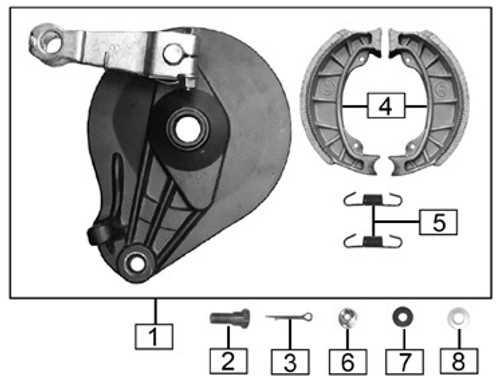

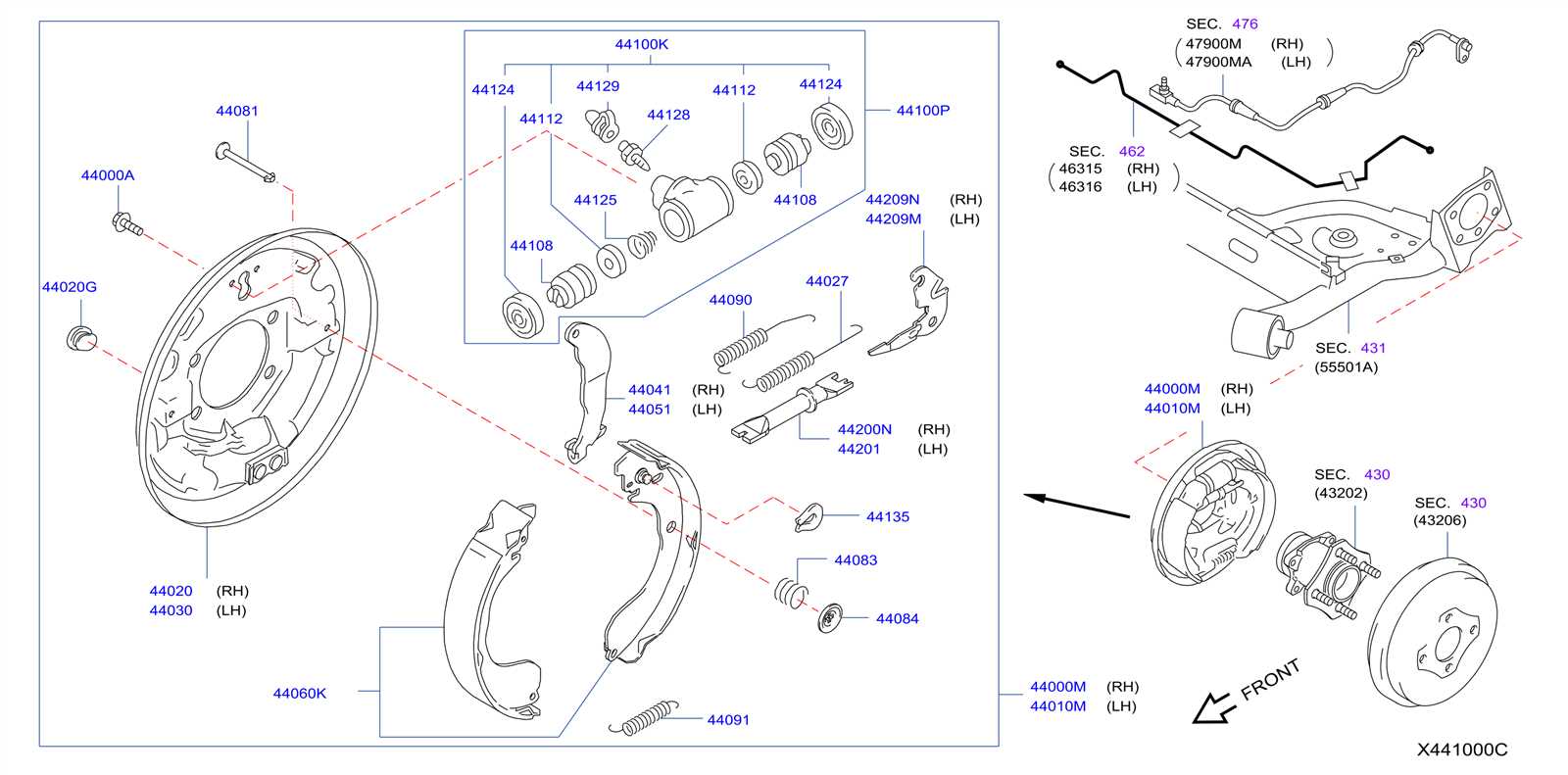

Brake Drum Installation Process

Installing a crucial component in the vehicle’s stopping system is essential for ensuring optimal performance and safety. This process requires attention to detail and adherence to proper procedures to guarantee effective functionality.

- Preparation

- Gather necessary tools and materials.

- Ensure the vehicle is on a flat surface and securely lifted.

- Remove the wheel to access the assembly.

cssCopy code

- Disconnect any connected hardware or fittings.

- Carefully detach the existing unit from its housing.

- Inspect surrounding areas for wear or damage.

- Position the new component in the correct orientation.

- Secure it with the appropriate fasteners.

- Reconnect any previously detached hardware.

- Verify that all connections are tight and secure.

- Reinstall the wheel and lower the vehicle.

- Test the system before regular use to ensure everything functions properly.

By following these steps diligently, you can ensure that the vehicle’s stopping system operates effectively, enhancing overall safety and performance.

Brake Drum Design Variations

The construction of stopping mechanisms can vary significantly, reflecting diverse engineering approaches and performance requirements. Each design serves specific purposes, enhancing functionality and adapting to various vehicle types and conditions.

Material Composition: Variations in material can lead to differences in weight, heat resistance, and durability. Common choices include cast iron, aluminum, and composite materials, each offering unique benefits.

Shape and Size: The dimensions and contours of these components can impact overall performance. Larger surfaces may provide better friction, while unique geometries can optimize airflow and cooling.

Cooling Features: Some designs incorporate ventilation or finning to improve heat dissipation. These features are essential for maintaining performance under heavy use, preventing overheating.

Attachment Methods: The way these components connect to the surrounding assembly can also vary. Options include traditional bolts or innovative quick-release mechanisms, influencing ease of maintenance and repair.

Integration with Other Systems: Advanced designs often integrate with electronic controls or adaptive systems, enhancing overall vehicle performance. This synergy allows for more responsive and efficient operation.

Importance of Brake Drum Safety

Ensuring the functionality of a crucial component in the stopping mechanism is essential for the overall safety of any vehicle. Neglecting maintenance or overlooking potential issues can lead to serious consequences, not only affecting the vehicle’s performance but also jeopardizing the safety of its occupants and others on the road.

Regular inspections and timely replacements are vital to maintain optimal performance. Components that wear out or malfunction can drastically reduce stopping power, increasing the risk of accidents. Understanding the signs of wear and addressing them promptly can enhance reliability and prevent costly repairs in the long run.

Moreover, safety standards and regulations are designed to protect everyone involved. Adhering to these guidelines not only promotes safe driving practices but also fosters a culture of responsibility among vehicle owners. Prioritizing the integrity of these essential elements can significantly contribute to a safer driving experience.