In the realm of automotive engineering, the efficiency of halting mechanisms is paramount for safety and performance. A thorough exploration of these systems reveals a complex interplay of elements, each playing a crucial role in achieving optimal functionality.

To fully appreciate how these mechanisms operate, it is essential to dissect their individual components. From the initial engagement to the final stopping action, understanding these elements enhances both maintenance practices and performance evaluation.

By delving into the intricate relationships among various constituents, one can gain valuable insights into the ultimate efficacy of these vital systems. This knowledge not only aids in troubleshooting but also fosters a deeper appreciation for the engineering behind safe vehicular operation.

Understanding Disk Brake Components

The effective operation of a vehicle’s stopping mechanism relies on a complex assembly of elements working in harmony. Each component plays a crucial role in ensuring safety and performance during deceleration. By exploring these essential elements, one can gain insight into how they contribute to the overall functionality.

Key Elements of the System

At the heart of this assembly are the friction materials, which create the necessary resistance against the rotating wheel assembly. Coupled with these are the calipers, which house the friction elements and apply force to them, facilitating the slowing process. Additionally, hydraulic fluid transfers pressure from the pedal to the calipers, enhancing responsiveness.

Maintenance and Performance

Understanding the longevity and efficiency of each element is vital for optimal performance. Regular inspection can prevent premature wear and ensure that all components function effectively. Moreover, keeping an eye on the condition of the friction materials and hydraulic system can significantly enhance safety during operation.

Key Parts of a Disk Brake System

This section explores the essential components that contribute to the efficient functioning of a friction-based slowing mechanism in vehicles. Each element plays a crucial role in ensuring safety and performance while allowing for responsive stopping power.

Rotors

Rotors are the metallic discs that rotate with the wheel. They provide a surface for the friction material to grip, generating the necessary force to slow down the vehicle. Their design and material significantly influence heat dissipation and overall performance.

Pads

Pads are the friction materials that press against the rotors when the slowing mechanism is activated. They are designed to create a high coefficient of friction, which is essential for effective deceleration. The quality and composition of these components are vital for optimal performance and longevity.

Functionality of Brake Calipers

The mechanism responsible for slowing down a vehicle plays a crucial role in ensuring safety and control during movement. It converts hydraulic pressure into mechanical force, allowing for effective stopping. Understanding how this system operates is essential for maintenance and performance enhancement.

Components Involved

- Housing: Provides structural integrity.

- Piston: Activates the friction material.

- Seals: Prevent fluid leaks and contamination.

- Mounting Bracket: Attaches the assembly to the frame.

Operational Process

- Fluid enters the housing through the master cylinder.

- The piston moves forward, pressing against the friction material.

- Friction is generated, slowing the wheel rotation.

- Release occurs when pressure is released, allowing the system to reset.

Role of Brake Rotors Explained

Understanding the significance of the circular components that engage with pads during deceleration is crucial for grasping vehicle performance. These elements play a vital role in converting kinetic energy into heat, ensuring safe stopping power while maintaining control.

Heat Dissipation and Performance

One of the primary functions of these circular elements is to dissipate heat generated during friction. As energy transforms, effective cooling mechanisms are essential to prevent overheating, which can lead to diminished efficiency and potential failure.

Material and Design Influence

The materials and design of these components significantly affect overall performance. High-quality substances offer enhanced durability and resistance to wear, while innovative designs can improve airflow and cooling, ultimately contributing to optimal functionality.

Brake Pads: Types and Materials

In the world of vehicle safety, certain components play a crucial role in ensuring effective stopping power. Among these, one element stands out due to its direct interaction with the rotating surfaces. Understanding the various types and materials of this essential component is vital for both performance and longevity.

Types of Brake Pads

There are several categories of these components, each designed to cater to different driving styles and conditions. Organic pads, made from a mixture of fibers and fillers, offer quiet operation and are often preferred for everyday driving. Metallic pads, on the other hand, are known for their durability and high-temperature performance, making them suitable for more aggressive driving. Ceramic pads provide a balance between performance and noise reduction, appealing to those who seek both efficiency and comfort.

Materials Used in Brake Pads

The choice of materials significantly impacts performance. Organic materials typically consist of rubber, glass, and other organic substances, which provide good stopping power but may wear out faster. Metallic materials contain varying percentages of metal shavings, delivering superior heat dissipation but often at the cost of increased noise. Ceramic compositions incorporate ceramic fibers and are favored for their low dust production and consistent performance across a range of temperatures.

Importance of Brake Lines and Hoses

The efficiency of a vehicle’s stopping mechanism relies heavily on the integrity and functionality of its fluid transfer components. These essential conduits ensure that hydraulic pressure is transmitted effectively, allowing for reliable deceleration when needed. Without properly functioning lines and hoses, the overall performance and safety of the vehicle can be compromised.

Durability and resilience are critical attributes of these components. They must withstand high pressures and varying temperatures, as well as exposure to road conditions and environmental factors. Over time, wear and tear can lead to leaks or failures, making regular inspection and maintenance crucial for ensuring optimal operation.

Safety is paramount; compromised lines can lead to a complete loss of hydraulic pressure, resulting in a dangerous situation. Proper installation and periodic replacement of these conduits are essential practices for any vehicle owner who prioritizes both performance and protection on the road.

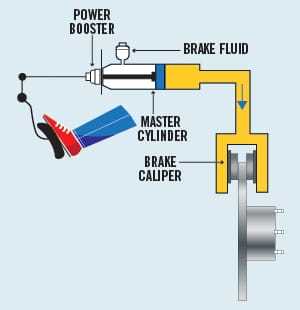

Master Cylinder and Its Significance

The master cylinder serves as a crucial component within the hydraulic system of a vehicle, facilitating the transfer of force from the driver’s foot to the necessary mechanisms that create stopping power. This essential element converts the mechanical force exerted on the pedal into hydraulic pressure, enabling effective control over the system. Its reliability and efficiency directly impact the overall performance and safety of the vehicle.

Understanding the significance of the master cylinder involves recognizing its role in ensuring responsive and smooth operation. A well-functioning master cylinder maintains optimal fluid levels and pressure, which is vital for the proper functioning of the entire system. Any failure or inefficiency in this component can lead to decreased performance, making it imperative for regular inspection and maintenance.

| Function | Impact on Performance | Maintenance Tips |

|---|---|---|

| Converts force to hydraulic pressure | Ensures responsive stopping | Regular fluid checks |

| Maintains fluid levels | Prevents system failure | Inspect for leaks |

| Controls pressure distribution | Enhances overall safety | Replace worn seals |

In summary, the master cylinder is an integral element that significantly influences the functionality and safety of the entire hydraulic system. Its proper maintenance is essential for ensuring optimal performance and preventing potential hazards on the road.

How Brake Fluid Works in the System

This section explores the essential role of hydraulic fluid within the stopping mechanism of vehicles. Its primary function is to transmit force from the pedal to the components that ultimately halt motion, ensuring a smooth and reliable operation.

The Role of Hydraulic Fluid

Hydraulic fluid operates under pressure, facilitating the transfer of energy through the system. When the pedal is engaged, the fluid moves through various channels, activating the components that apply friction. This process is critical for effective deceleration and overall safety.

Maintaining Optimal Performance

To ensure the fluid functions properly, regular maintenance is crucial. Contaminants can compromise its effectiveness, leading to reduced responsiveness. Therefore, timely replacement and monitoring of fluid levels contribute significantly to the ultimate performance of the entire system.

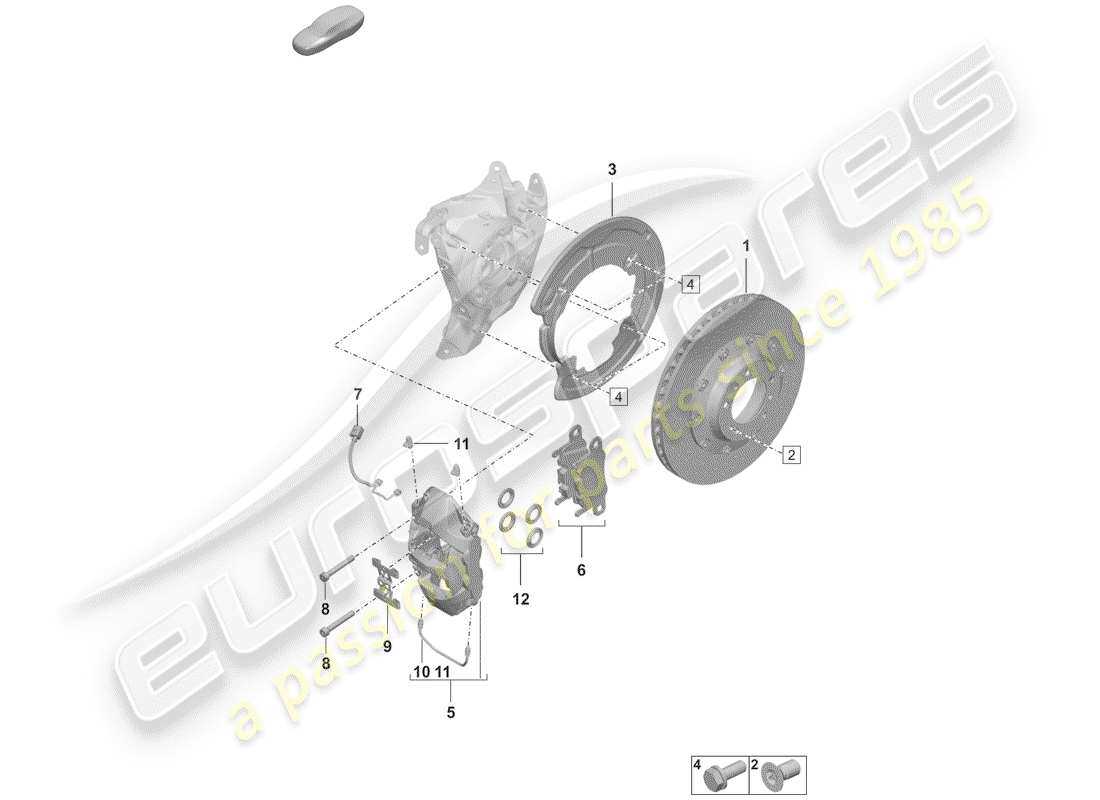

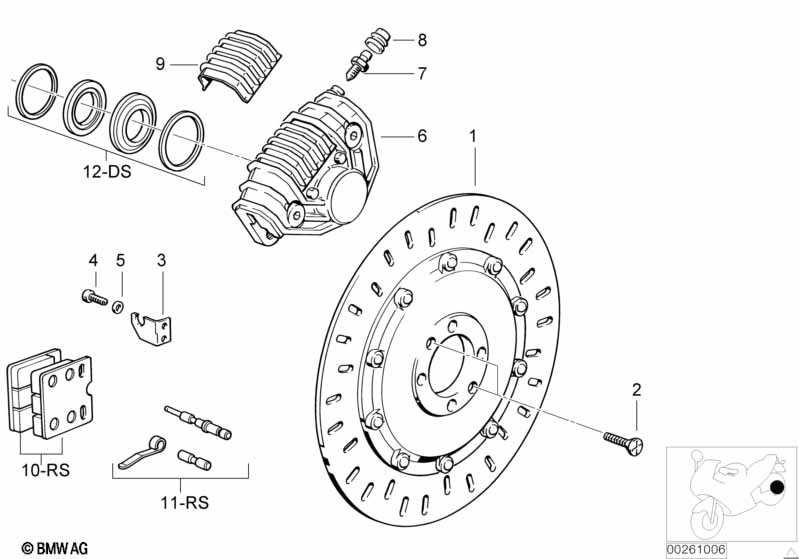

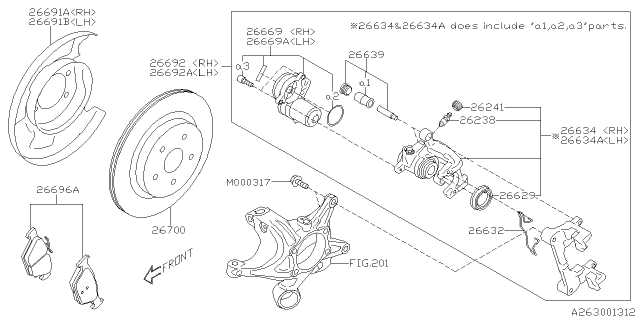

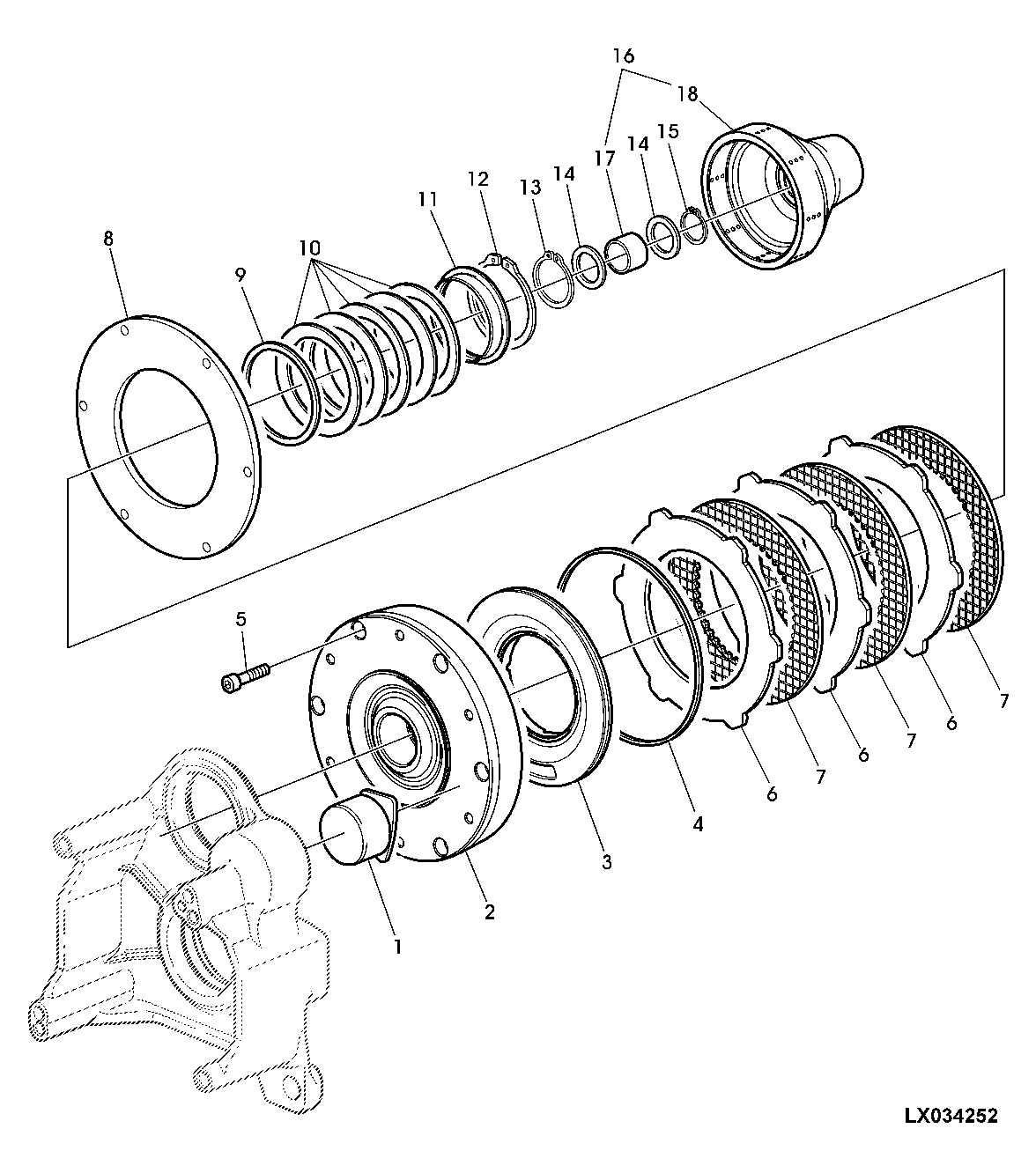

Diagram: Visualizing Brake Assembly

Understanding the intricate components involved in the stopping mechanism is essential for both maintenance and performance. A comprehensive representation can enhance clarity and foster a deeper appreciation of how these elements interact during operation.

Key Elements: Central to the assembly are the friction components, which generate the necessary force to halt motion. Surrounding these are structural elements that provide stability and support. Additionally, hydraulic systems play a vital role in amplifying the force applied.

Functionality Overview: Each component serves a unique purpose, contributing to the overall efficiency of the system. From the initial application of force to the resultant halt, every interaction is meticulously designed to ensure safety and reliability.

By visualizing these components together, one can better grasp their interdependencies and the ultimate importance of each in achieving effective stopping power.

Common Issues in Disk Brake Parts

Understanding the frequent challenges faced in the components of a stopping system is essential for ensuring safety and performance. Various factors can lead to decreased efficiency, unusual noises, or even failure of the mechanism, impacting overall vehicle reliability.

One common problem is uneven wear, often resulting from poor alignment or faulty installation. This can lead to vibrations and a decrease in responsiveness. Additionally, moisture exposure can cause corrosion, affecting the integrity of the system and potentially leading to costly repairs.

Another issue arises from the accumulation of debris, which can hinder movement and create friction. Regular maintenance and inspections are crucial to identify these concerns early, allowing for timely interventions that can prolong the lifespan of the components.

Furthermore, inadequate lubrication can result in sticking or seizing, affecting overall performance. Drivers should remain vigilant for any signs of irregularities, as addressing them promptly can prevent more severe problems down the line.

Maintenance Tips for Brake Systems

Regular upkeep of your stopping mechanism is crucial for ensuring optimal performance and safety. Proper maintenance not only extends the life of the components but also enhances the overall driving experience. Here are some essential tips to keep your system in top shape.

Routine Inspection

Conducting frequent inspections helps identify potential issues before they escalate. Look for wear signs, such as unusual noises or vibrations, and check fluid levels regularly.

Proper Cleaning

Keeping the system clean is vital to prevent dirt and debris from affecting functionality. Use appropriate cleaners and avoid abrasive materials that could damage sensitive components.

| Task | Frequency |

|---|---|

| Visual Inspection | Every Month |

| Fluid Level Check | Every 3 Months |

| Component Cleaning | Every 6 Months |

| Full System Check | Yearly |

Upgrading Your Brake Components

Enhancing the efficiency of your vehicle’s stopping system is a crucial aspect of maintaining overall performance and safety. By focusing on the individual elements involved in deceleration, you can achieve significant improvements in responsiveness and reliability. This section explores various methods for upgrading these essential components, ensuring a smoother and more effective operation.

Choosing High-Performance Materials

One of the most impactful ways to elevate your system’s functionality is by selecting superior materials. Opting for ceramic or carbon-based materials can offer enhanced heat resistance and reduced wear, contributing to longer lifespan and improved stopping power. Additionally, these materials often produce less dust, leading to cleaner wheels and a more aesthetically pleasing vehicle.

Upgrading Calipers and Rotors

Another effective strategy involves replacing calipers and rotors with high-performance alternatives. Upgraded calipers can provide better clamping force, resulting in more consistent performance under various driving conditions. Furthermore, larger and slotted or drilled rotors can improve heat dissipation and prevent fading, ensuring your system remains effective even during prolonged use. Consider these enhancements as integral to achieving optimal safety and performance on the road.