Material and Design Considerations

When selecting components for external structures, the choice of materials and the overall design play a crucial role in ensuring durability, functionality, and aesthetics. The right combination of these factors can significantly influence the performance and lifespan of the assembly, especially in environments exposed to weather and physical stress.

Durability and Strength

One of the key factors to consider is the strength of the materials used. Metals such as steel and aluminum are commonly chosen for their resistance to impact and corrosion. Additionally, incorporating reinforcements or treatments like galvanization can further enhance the resilience of the material, making it more suitable for long-term use.

Aesthetic and Functional Design

Alongside durability, the visual and functional aspects of the design should be considered. Sleek contours, combined with precise alignment, can create a harmonious look while maintaining essential features such as aerodynamic efficiency. Additionally, strategic placement of fasteners and supports ensures ease of assembly and replacement without compromising the overall structure.

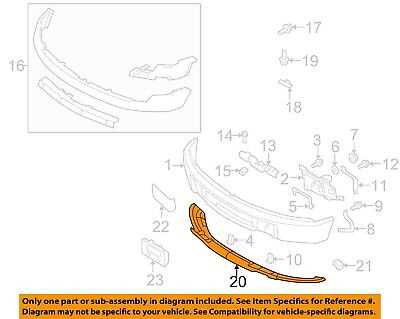

Protective Skid Plate Features

A protective undercarriage shield is an essential component for vehicles designed to navigate rugged terrains. This feature plays a critical role in safeguarding vital components from potential damage caused by rocks, debris, and other obstacles encountered on off-road adventures.

- Durability: Constructed from high-strength materials, these shields are engineered to withstand impacts and resist wear over time.

- Weight Considerations: Lightweight designs help maintain overall vehicle efficiency while still providing robust protection.

- Compatibility: These shields are often designed to fit various vehicle models, ensuring a snug installation without compromising performance.

- Ease of Installation: Many options come with straightforward mounting systems, allowing for quick and hassle-free attachment.

- Enhanced Ground Clearance: Some designs may elevate the vehicle slightly, improving approach and departure angles for off-road situations.

In summary, a well-designed undercarriage shield not only provides essential protection but also contributes to the overall capability of the vehicle, making it a valuable addition for enthusiasts who venture beyond paved roads.

Fog Light Mounting Brackets Overview

When it comes to enhancing visibility during low-light conditions, the installation of illumination fixtures is crucial. The components designed to secure these fixtures play a significant role in ensuring their stability and proper alignment. This section will delve into the essential elements of these securing components, outlining their function, features, and compatibility.

Key features of these securing components include:

- Sturdy Construction: Typically made from durable materials, these components are designed to withstand the rigors of various driving conditions.

- Easy Installation: Most options are user-friendly, allowing for straightforward mounting without the need for extensive modifications.

- Adjustable Design: Many securing components offer adjustable settings, ensuring optimal positioning for maximum illumination.

Compatibility with various illumination fixtures is another important aspect:

- Ensure that the brackets match the specifications of the light fixtures.

- Check for compatibility with the vehicle’s mounting points to facilitate proper installation.

- Consider the weight and dimensions of the light fixtures to ensure adequate support.

Understanding these securing components can significantly enhance the functionality and effectiveness of illumination fixtures, leading to improved safety and visibility on the road.

Grille and Bumper Integration Points

The harmonious relationship between the front decorative shield and the protective structure is essential for both aesthetics and functionality. Understanding how these components interact can enhance the overall design and performance of the vehicle.

Typically, the integration points between these two elements serve multiple purposes. They not only provide structural support but also play a crucial role in airflow management and cooling. Proper alignment and secure attachment ensure that the decorative shield fits seamlessly with the protective structure, preventing vibrations and potential damage.

Attachment methods vary, including clips, bolts, and brackets, which help maintain stability during various driving conditions. Additionally, the integration of these components can influence the ease of maintenance and accessibility for repairs, making it essential to consider their configuration during any modifications.

Ultimately, a well-designed connection between the decorative shield and the protective structure not only enhances the vehicle’s appearance but also contributes to its overall durability and performance.

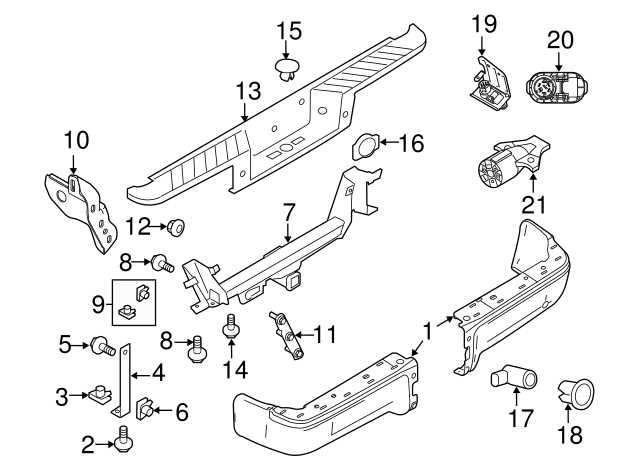

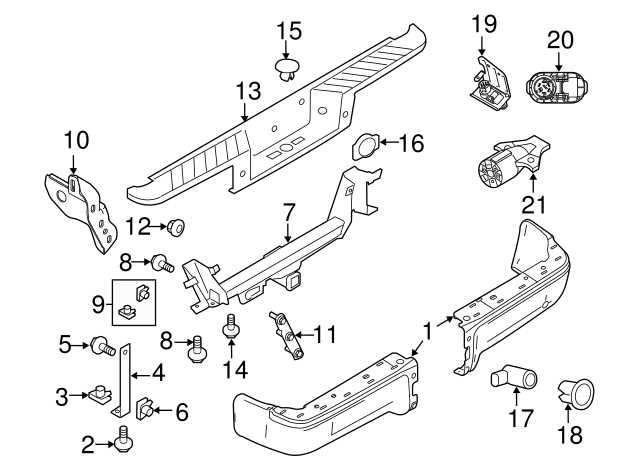

Impact Absorbers and Reinforcement Bars

The effectiveness of vehicular safety systems largely relies on specific components designed to mitigate collision forces. Among these, specialized elements play a crucial role in energy absorption and structural integrity during an impact. Their design and material selection are critical in enhancing vehicle resilience against various collision scenarios.

Impact absorbers are engineered to compress and deform upon collision, absorbing kinetic energy to reduce the force transferred to the vehicle occupants. Typically crafted from advanced polymers or metal alloys, these components undergo rigorous testing to ensure optimal performance in real-world conditions. Their placement is strategically chosen to maximize protective capabilities while minimizing weight.

Reinforcement bars, on the other hand, provide additional strength to the vehicle’s structure, helping to maintain its shape during an impact. These bars are often constructed from high-strength steel or aluminum, designed to withstand significant forces. Their integration into the vehicle framework is essential for distributing impact loads and safeguarding critical areas, ultimately enhancing overall safety.

Mounting Hardware and Fasteners Guide

This section provides an overview of the essential components needed for secure installation. Proper fasteners and hardware play a crucial role in ensuring that assemblies remain intact and functional under various conditions. Understanding the types of mounting solutions available can significantly enhance the stability and safety of the structure.

Types of Fasteners

Fasteners are available in various forms, including bolts, screws, and nuts, each serving distinct purposes. Selecting the right fastener type is vital for compatibility with the materials being used. For instance, bolts are often preferred for heavy-duty applications, while screws may suffice for lighter setups.

Materials

Fasteners can be made from different materials, such as stainless steel, aluminum, or plastic. Each material offers unique benefits in terms of strength, corrosion resistance, and weight. Choosing the appropriate material is essential to match the environmental conditions and load requirements.

Installation Techniques

Correct installation techniques ensure that fasteners are secure and prevent loosening over time. Utilizing tools such as torque wrenches and impact drivers can help achieve optimal tightening. Additionally, following manufacturer guidelines is critical for successful assembly.

Maintenance Considerations

Regular inspections of mounting hardware are recommended to identify signs of wear or damage. Ensuring that fasteners are intact and functional helps maintain overall integrity. Implementing a routine check can prevent potential failures and prolong the lifespan of the assembly.

Replacing Damaged Bumper Sections

When it comes to restoring the exterior of your vehicle, addressing damaged sections of the front shield is essential. This process not only enhances aesthetics but also ensures safety and functionality. Identifying the right components and understanding the replacement procedure can make this task more manageable.

Here are some key steps to follow when replacing damaged sections:

- Assessment: Begin by evaluating the extent of the damage. Determine which areas require replacement and note any additional components that might be affected.

- Gather Necessary Tools: Collect all the tools required for the task. Common items include a socket set, screwdrivers, and safety gear.

- Purchase Replacement Sections: Acquire the new components from a reliable supplier. Ensure that they match the specifications of your vehicle.

- Removal: Carefully detach the damaged sections. Follow any specific instructions for your vehicle model to avoid causing further harm.

- Installation: Secure the new sections in place, making sure all fasteners are tightened to the manufacturer’s specifications.

- Final Check: Inspect the installation for proper alignment and ensure that all components function correctly.

By following these guidelines, you can effectively restore the integrity of your vehicle’s exterior, ensuring it looks great and performs safely on the road.

Aerodynamic Features of the Front End

The design of the vehicle’s leading section plays a crucial role in enhancing overall efficiency and performance. By streamlining contours and incorporating specific elements, manufacturers aim to reduce drag and improve stability at various speeds. Understanding these characteristics can provide insight into how a vehicle navigates through air, impacting fuel consumption and handling.

Key components that contribute to the aerodynamic performance include the shape of the grille, the angle of the hood, and the integration of air intakes. These features work collectively to channel airflow smoothly around the exterior, minimizing turbulence and optimizing downforce.

| Feature |

Description |

| Grille Design |

The configuration and openings in the grille allow for controlled airflow, aiding in engine cooling while maintaining aerodynamic efficiency. |

| Hood Angle |

An inclined hood can significantly reduce air resistance by directing airflow more efficiently over the vehicle’s surface. |

| Air Intakes |

Strategically placed intakes not only provide necessary air to the engine but also assist in managing airflow around the vehicle. |

| Lower Valence |

A well-designed lower valence helps to minimize drag by smoothing the airflow beneath the vehicle. |

Choosing Aftermarket or OEM Parts

When it comes to vehicle maintenance and repairs, selecting the right components is crucial for ensuring optimal performance and longevity. Enthusiasts often face the decision between opting for original equipment manufacturer items or aftermarket alternatives, each of which offers its own set of advantages and considerations.

OEM components are produced by the vehicle’s manufacturer and are designed to meet the original specifications. They tend to be more reliable in terms of compatibility and quality. However, they may come at a higher price point.

On the other hand, aftermarket options can provide cost savings and a wider variety of choices. These alternatives are manufactured by third-party companies, allowing for potential upgrades and customization. Yet, not all aftermarket products are created equal, and some may lack the same level of quality assurance as their OEM counterparts.

- Benefits of OEM Parts:

- Exact fit and compatibility with your vehicle.

- Typically backed by warranties from the manufacturer.

- Assured quality and durability based on original specifications.

- Benefits of Aftermarket Parts:

- Potential for lower costs, making repairs more affordable.

- A broader range of options for customization and performance enhancements.

- Availability from various manufacturers, providing more choices.

Ultimately, the choice between OEM and aftermarket components depends on individual preferences, budget, and specific needs for the vehicle. It is essential to conduct thorough research and consider factors such as warranty, performance, and intended use when making a decision.

|