Understanding the different elements involved in the assembly of a vehicle’s exterior can be crucial for both maintenance and upgrades. Each component plays a vital role in ensuring the safety and functionality of the vehicle. In this section, we will take a closer look at the structure and key pieces that form the protective and aesthetic front area.

Identifying essential sections of the vehicle’s forward exterior can help in making informed decisions about repairs or modifications. From structural reinforcements to smaller accessories, every piece contributes to the overall performance and visual appeal of the vehicle.

By delving into the various parts and their interconnections, we aim to provide a comprehensive understanding of how these elements work together. This knowledge is essential for anyone looking to restore or enhance the visual and functional aspects of a vehicle.

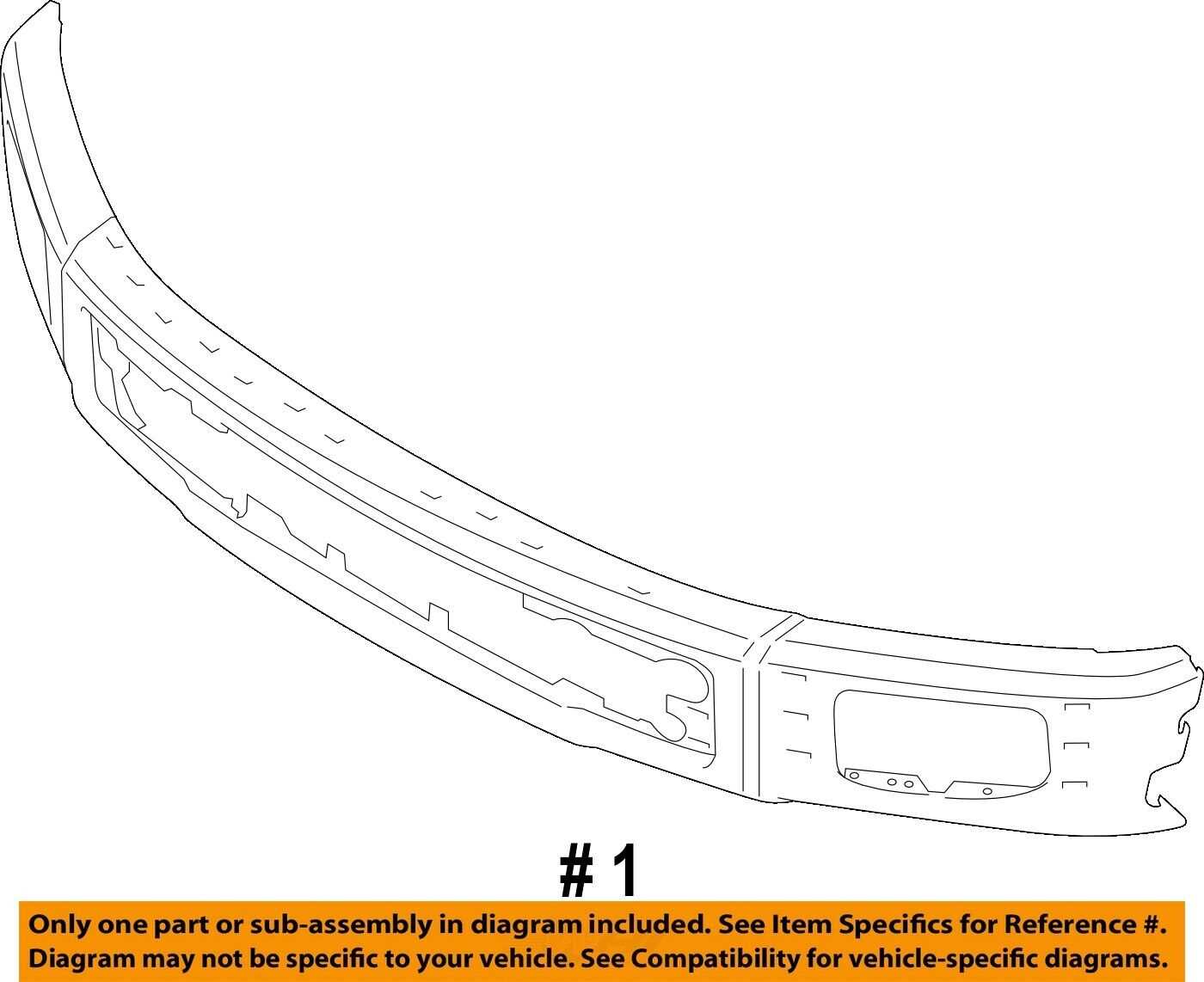

2015 Ford F150 Front Bumper Overview

The leading structure of this popular vehicle plays a crucial role in both aesthetics and protection. Its design balances durability and style, ensuring that it provides both a rugged appearance and the necessary defense against minor impacts. This component is carefully engineered to enhance the overall look while offering support during daily use.

Material composition and structural design are important aspects to consider, as they contribute to the longevity and functionality of this key element. Built to withstand various conditions, it offers resilience without compromising on visual appeal.

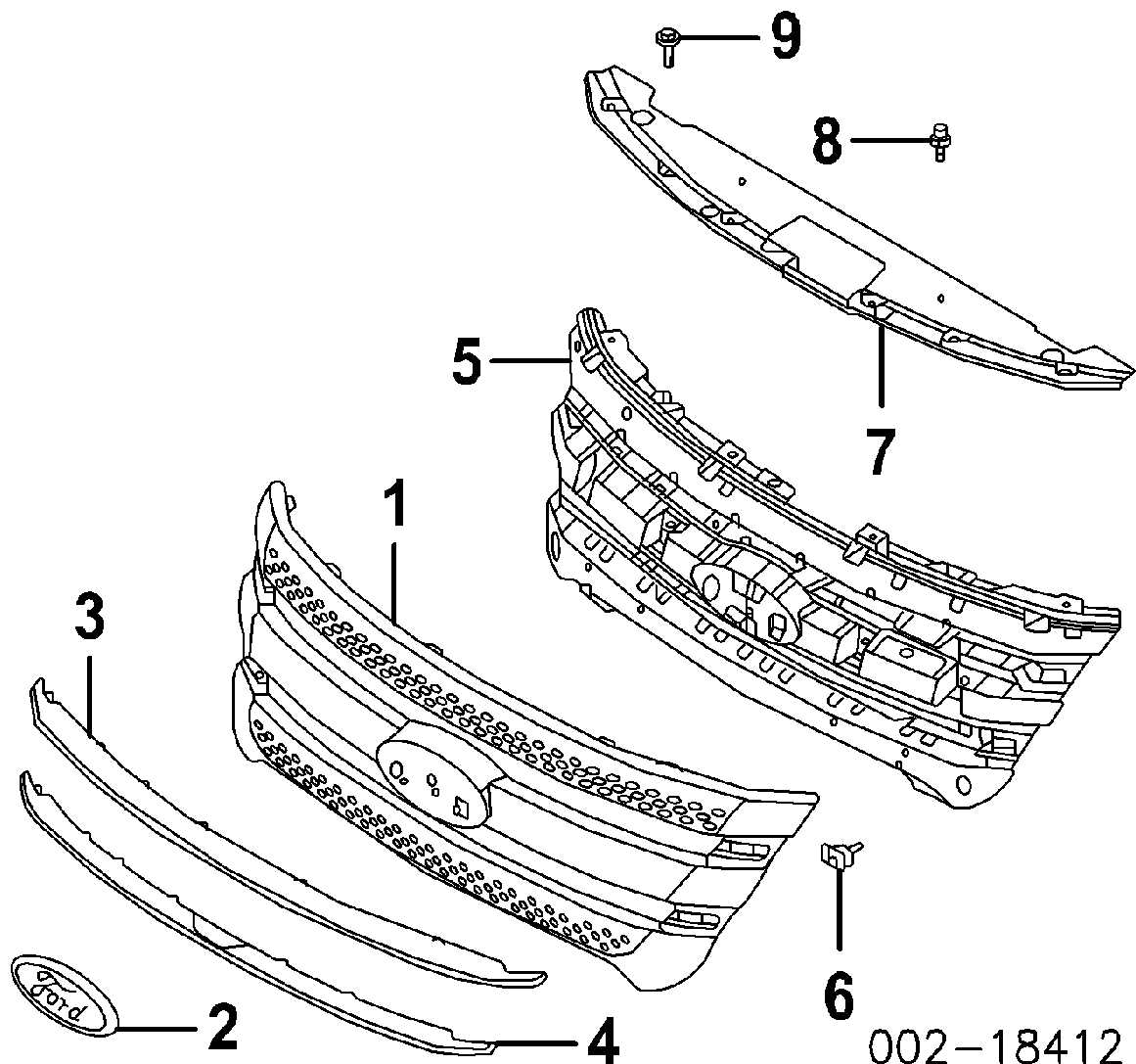

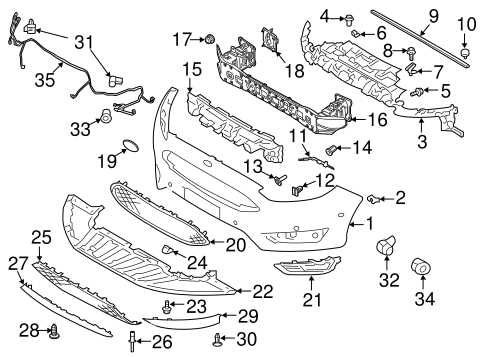

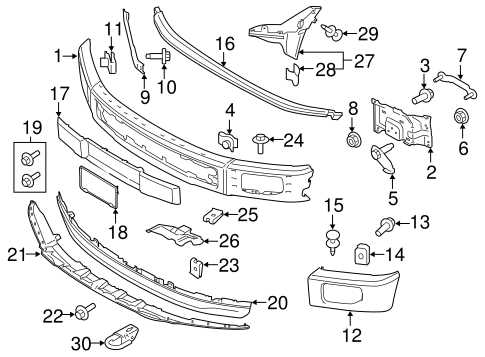

Main Components of the Front Bumper

The protective structure at the front of many vehicles is made up of several essential elements, each designed to enhance safety and durability. These components work together to shield the vehicle from minor impacts while also providing aesthetic appeal and functional support for other systems. Below is an overview of the key components involved in this assembly.

Key Structural Elements

In modern vehicles, the assembly includes reinforcement bars, absorbers, and other structural parts that help absorb energy during a collision. The integration of these parts ensures both safety and functionality.

Accessory Components

Other integral components include brackets, covers, and trim pieces that complete the overall design. These parts not only contribute to the appearance but also provide mounting points for additional equipment like sensors and lights.

| Component | Function |

|---|---|

| Reinforcement Bar | Provides structural support and impact resistance. |

| Absorber | Absorbs and disperses energy during a collision. |

| Bracket | Holds various parts securely in place. |

| Cover | Contributes to the aesthetic finish and provides protection. |

Exploring the Grille and Trim Pieces

The grille and trim components play a crucial role in the overall aesthetic and performance of any vehicle’s front end. These elements not only contribute to the vehicle’s visual identity but also provide functional benefits, such as improved airflow and protection. Understanding the variety of grille designs and trim pieces available can help enhance both the style and efficiency of your vehicle.

Key Grille Features

The grille serves as a central feature in the vehicle’s design, and its structure is engineered to ensure efficient cooling and airflow. Here are some of the key considerations when looking at grille options:

- Material: Common materials include durable plastic, aluminum, and sometimes stainless steel for higher-end models.

- Design: From sleek honeycomb styles to more open mesh patterns, the design impacts both look and function.

- Finish: Grilles often come in finishes like chrome, matte black, or body-colored options, allowing for customization.

Trim Piece Options

Trim pieces around the grille and surrounding areas offer both protection and decorative flair. These components can highlight the vehicle’s unique style or provide a more rugged, robust appearance. Common types of trim pieces include:

- Surrounding frames: Often made from chrome or painted materials, they frame the grille and enhance its appearance.

- Accent strips: Positioned horizontally or vertically, these strip

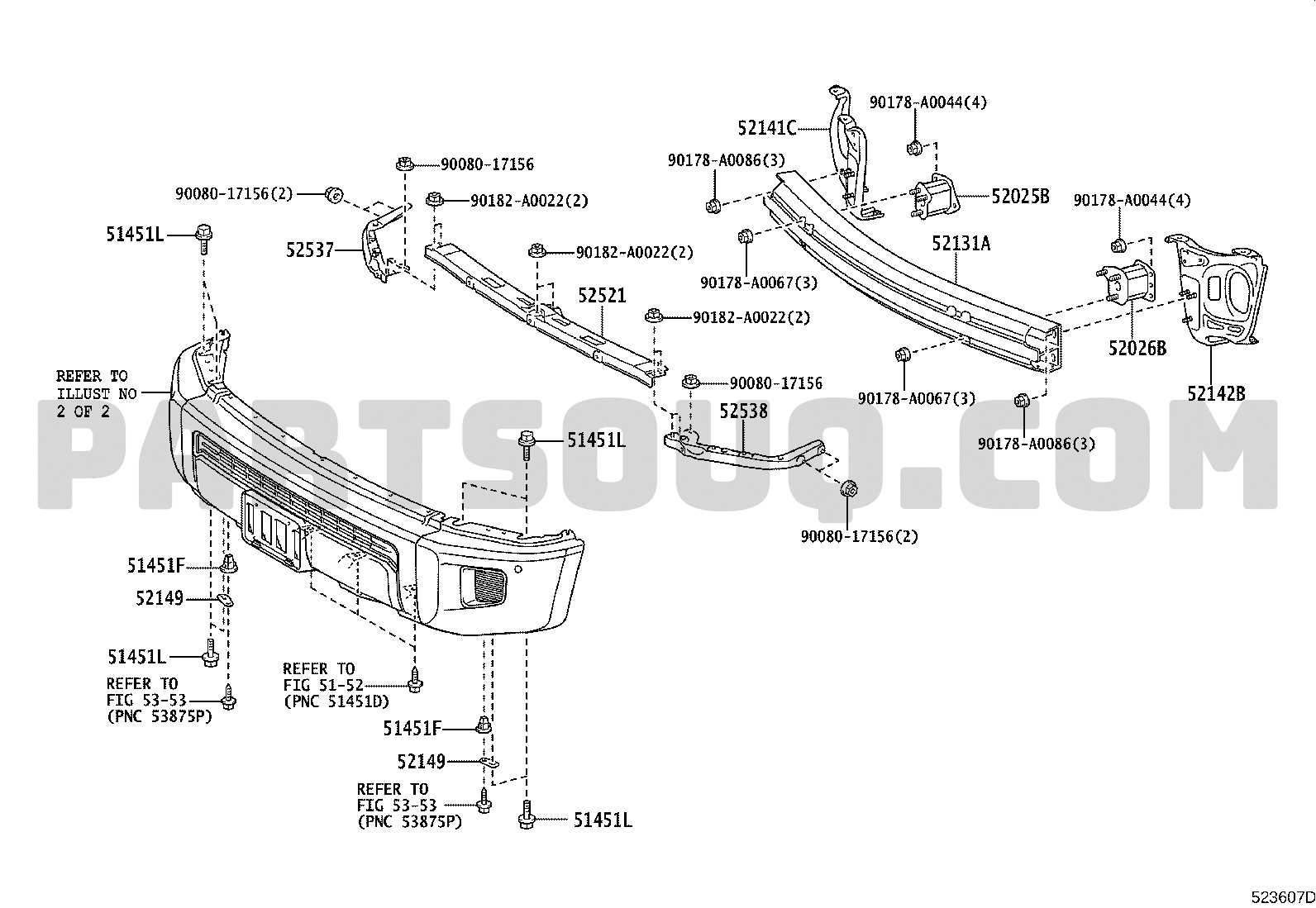

Bumper Reinforcement and Mounting Brackets

Structural reinforcement and the supporting framework are essential for ensuring the durability and safety of vehicle exteriors. These components absorb and distribute impact forces, protecting both the vehicle and its occupants during collisions. Proper installation and alignment of these elements are critical for maintaining overall stability and performance.

Reinforcement Structure

The reinforcement bar plays a crucial role in dissipating energy during impacts. It’s typically made of high-strength steel or aluminum, designed to handle the stress of collisions. Without this component, the vehicle would be more vulnerable to damage in the event of a crash. The reinforcement connects to the main body, providing a rigid base for the other elements.

Mounting Brackets

The brackets serve as connectors between the reinforcement and the vehicle’s frame. These pieces are engineered to align with precision, ensuring that the components stay in place. Each bracket must be securely fastened to maintain the correct positioning of the entire structure.

- High-strength steel or aluminum is used for durability.

- Brackets align reinforcement with the body.

- Secure installation is crucial for safety.

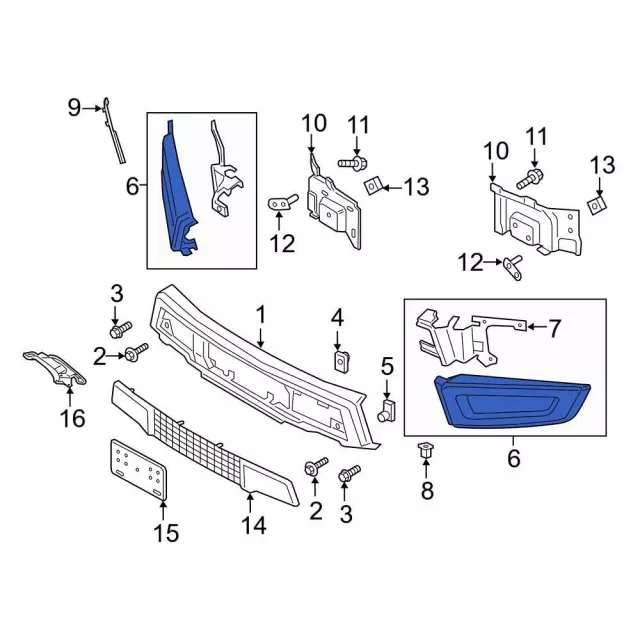

Fog Light Housing and Installation

The installation of fog light housings plays a crucial role in ensuring clear visibility during adverse weather conditions. Properly designed housings protect the light components from moisture and debris, enhancing the performance and durability of the lighting system. This guide covers the general process of mounting and securing the housing, along with tips on ensuring a precise fit.

Choosing the Right Fog Light Housing

Selecting the appropriate fog light housing is essential for optimal function and protection. Various designs are available, offering different levels of weather resistance and light output. Ensure that the housing is compatible with your vehicle’s existing setup for easy installation and enhanced performance.

Installation Process

Installing the fog light housing involves carefully mounting it into the allocated space on your vehicle. Make sure the housing is securely fastened to prevent any movement or damage during use. Tighten all bolts and connections, and ensure the light is properly aligned to avoid misdirection of the beam. Use protective covers or seals to block out moisture and extend the life of the lighting system.

Air Deflector and Skid Plate Options

When considering vehicle protection and aerodynamics, air deflectors and skid plates play a crucial role in enhancing performance. These components help in minimizing drag while providing an additional layer of protection for the undercarriage. Choosing the right options can improve both efficiency and durability, making these features essential for off-road and heavy-duty driving conditions.

Component Function Material Options Benefits Air Deflector Reduces air resistance and improves fuel efficiency Plastic, Aluminum, Carbon Fiber Improved aerodynamics and stability at higher speeds Skid Plate Protects the underside of the vehicle from rough terrain Steel, Aluminum, Composite Increased protection for vulnerable components Impact Sensors and Their Locations

Impact sensors play a crucial role in modern vehicle safety systems. These sensors detect collisions and trigger appropriate responses, such as deploying airbags or activating other safety mechanisms. Understanding their placement on the vehicle is essential for proper maintenance and repair.

Sensor Placement in the Vehicle

These sensors are typically positioned in areas of the vehicle most likely to absorb the impact of a collision. Common locations include the front and rear sections, often near the vehicle’s structural components. They are strategically placed to ensure rapid detection of a crash from multiple directions.

Importance of Accurate Sensor Alignment

Proper alignment of impact sensors is vital for their functionality. Misaligned or damaged sensors may fail to detect impacts correctly, compromising the vehicle’s safety systems. Regular checks and recalibrations are recommended to maintain optimal performance.

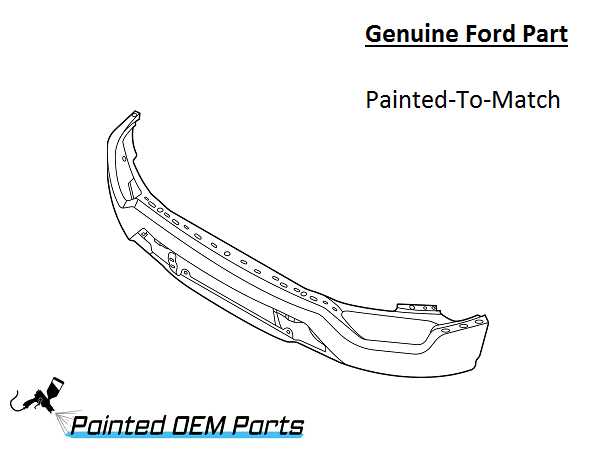

Front Bumper Cover Materials and Variants

Vehicle exterior components are available in a wide range of materials, each offering unique properties that impact durability, weight, and aesthetics. These covers not only provide protection but also contribute to the overall design of the vehicle. Choosing the right material is essential to balance both functional and visual requirements.

Common Materials Used for Covers

The most commonly used materials for vehicle covers include plastic, metal, and composite materials. Each of these options has its own strengths:

- Plastic covers are lightweight and resistant to corrosion, but may be prone to cracks upon impact.

- Metal offers enhanced durability and strength, though it is heavier and can be more expensive to repair.

- Composite materials combine the best of both worlds, offering strength and flexibility with reduced weight.

Variants and Customization Options

Customization options are available for those looking to personalize their vehicle’s appearance. These include textured finishes, chrome accents, or painted surfaces that match the vehicle’s overall design. Each variant not only adds a unique look but can also affect the cover’s performance in terms of resilience and maintenance.

How to Replace the Tow Hooks

Replacing the tow hooks on your vehicle is a relatively straightforward process that can enhance both the functionality and appearance of your vehicle. These hooks are essential for towing and recovery purposes, so ensuring they are in good condition is important for safety and performance.

To replace the tow hooks, you will need a few basic tools, including a wrench set, socket set, and possibly a jack if extra clearance is needed. The process involves removing the old hooks and installing the new ones, following the manufacturer’s guidelines for secure attachment.

Tools Required Details Wrench Set For loosening and tightening bolts Socket Set To access tight bolts Jack (Optional) For additional clearance under the vehicle Front Parking Sensors Integration

Integrating parking sensors into the vehicle’s exterior enhances safety and convenience, ensuring a smoother parking experience. These sensors offer real-time proximity alerts, helping to avoid potential collisions with nearby objects. Properly aligning and installing these sensors is key to their effectiveness and accurate functioning.

Sensor Placement and Installation

To achieve optimal performance, sensors should be positioned at precise locations on the vehicle’s lower fascia. This ensures they detect obstacles from a wide angle and at varying distances. Accurate installation contributes to better sensor calibration and overall system reliability.

Component Purpose Parking Sensors Detect nearby objects and provide distance alerts Wiring Harness Connects the sensors to the control unit for power and signal transmission Control Module Processes sensor data and activates alerts Wiring and Calibration

Once sensors are installed, they must be wired correctly to the vehicle’s electronic system. This step ensures that the sensor outputs are processed in real-time, triggering audible or visual signals to the driver. Calibration must be conducted to fine-tune the system’s response to obstacles of varying size and distance.

License Plate Bracket Positioning

Proper placement of the license plate holder is crucial for both aesthetics and functionality. Correct positioning ensures visibility, compliance with regulations, and protects the vehicle’s front area from damage. It is important to consider the structure and layout of the vehicle when installing this component, ensuring it doesn’t interfere with any other parts or obstruct air flow.

Guidelines for Placement

- The license plate holder should be installed in a location that is clearly visible from the front of the vehicle.

- Avoid placing it where it might block airflow to essential cooling systems.

- Ensure that the bracket is securely fastened to prevent rattling or movement during driving.

Considerations for Different Vehicles

- Some vehicles may have pre-drilled holes designed for the plate holder, simplifying the installation process.

- In cases where no mounting points exist, a universal mounting bracket can be used to secure the plate in an optimal position.

- Always check local regulations regarding height and visibility requirements for license plates.

Common Issues with Front Bumper Components

Several common problems can arise with the essential components located at the vehicle’s nose. These issues may affect the performance, aesthetics, and safety of the vehicle, often caused by wear, accidental damage, or poor maintenance. Identifying these concerns early can help prevent more severe damage and costly repairs down the line.

Cracks and Dents

One of the most frequent issues encountered involves the presence of cracks or dents. These can occur due to minor collisions, debris on the road, or even everyday wear. Over time, such damage can worsen, leading to structural weaknesses that compromise the vehicle’s integrity and appearance.

Loose or Misaligned Components

Another issue that often arises is the loosening or misalignment of parts. Whether due to wear or incorrect installation, these components can shift, making the vehicle look uneven and potentially affecting aerodynamic performance. Proper inspection and adjustment are essential to maintain proper alignment and prevent further issues.