Maintaining outdoor machinery requires a comprehensive grasp of its various elements. A well-functioning device hinges on the seamless operation of each individual component. For users aiming to ensure optimal performance, familiarizing themselves with the layout and interactions of these parts is crucial.

In this guide, we will delve into the intricate assembly of a specific model, providing a clear representation of its essential elements. By exploring the arrangement and functions of these components, users can enhance their maintenance skills and troubleshoot issues more effectively.

Moreover, recognizing the significance of each part not only aids in repairs but also contributes to informed decision-making when acquiring replacements. Understanding how everything fits together can ultimately lead to prolonged equipment lifespan and superior efficiency.

Overview of the Lawn Tractor

This section provides a comprehensive look at a popular model in the realm of gardening machinery. Renowned for its efficiency and robust design, this equipment is tailored for both residential and professional landscaping tasks. With a blend of power and maneuverability, it stands out as a reliable choice for maintaining green spaces.

Key Features

- Powerful engine for optimal performance

- Ergonomic controls for user-friendly operation

- Durable construction ensuring longevity

- Versatile attachment options for various tasks

Benefits of Using This Model

- Enhances efficiency in lawn care.

- Reduces time spent on maintenance activities.

- Increases comfort with adjustable seating and controls.

- Offers excellent maneuverability in tight spaces.

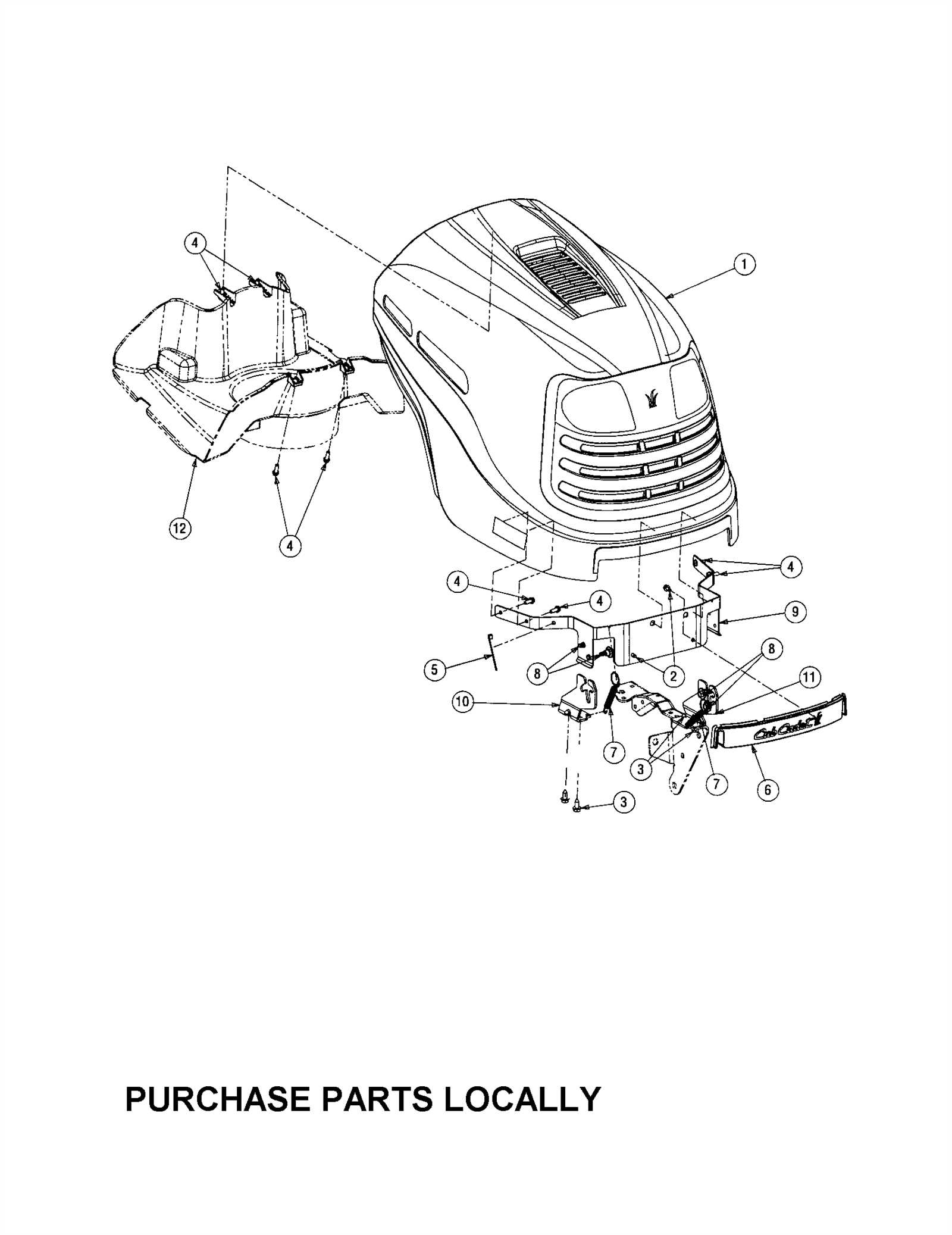

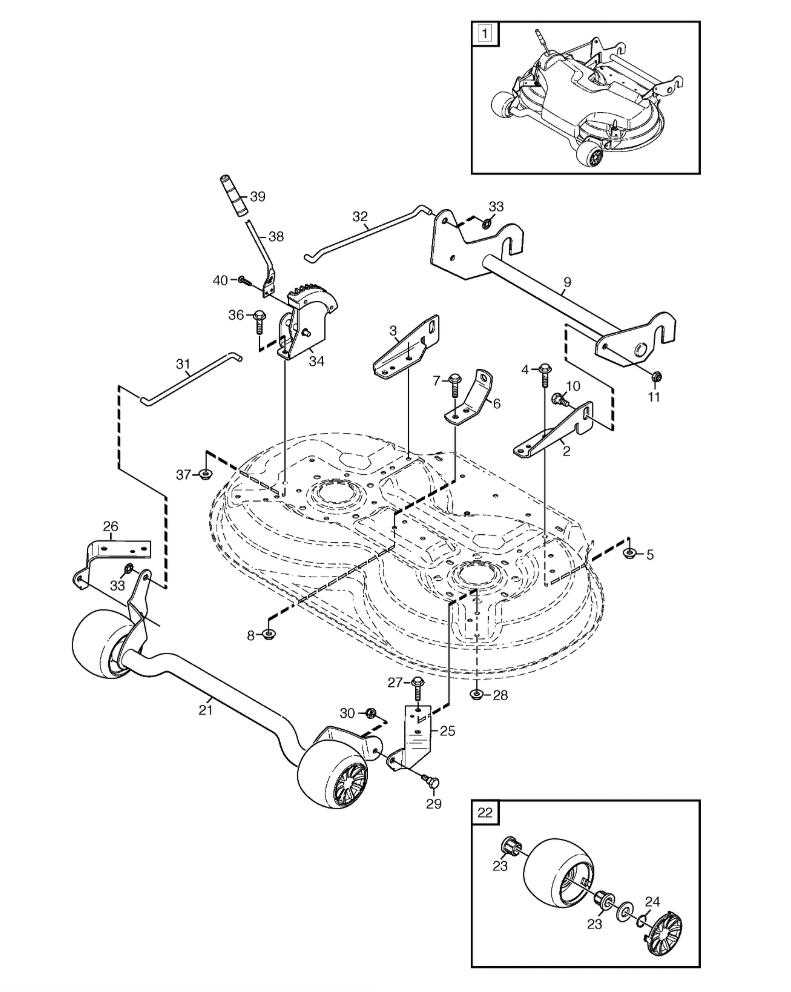

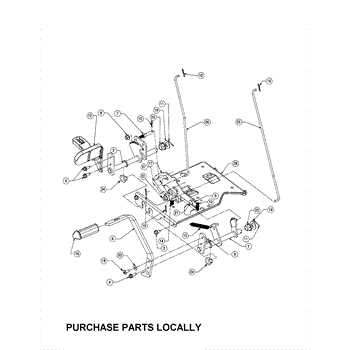

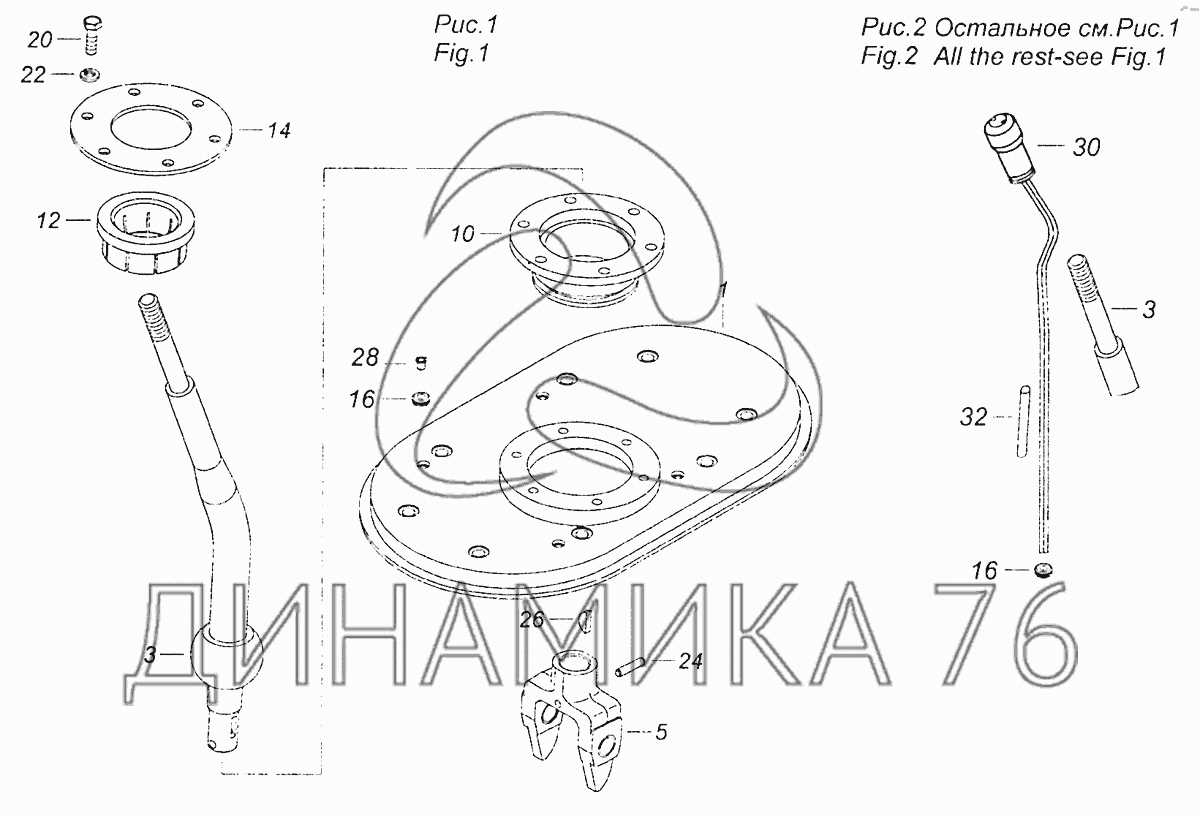

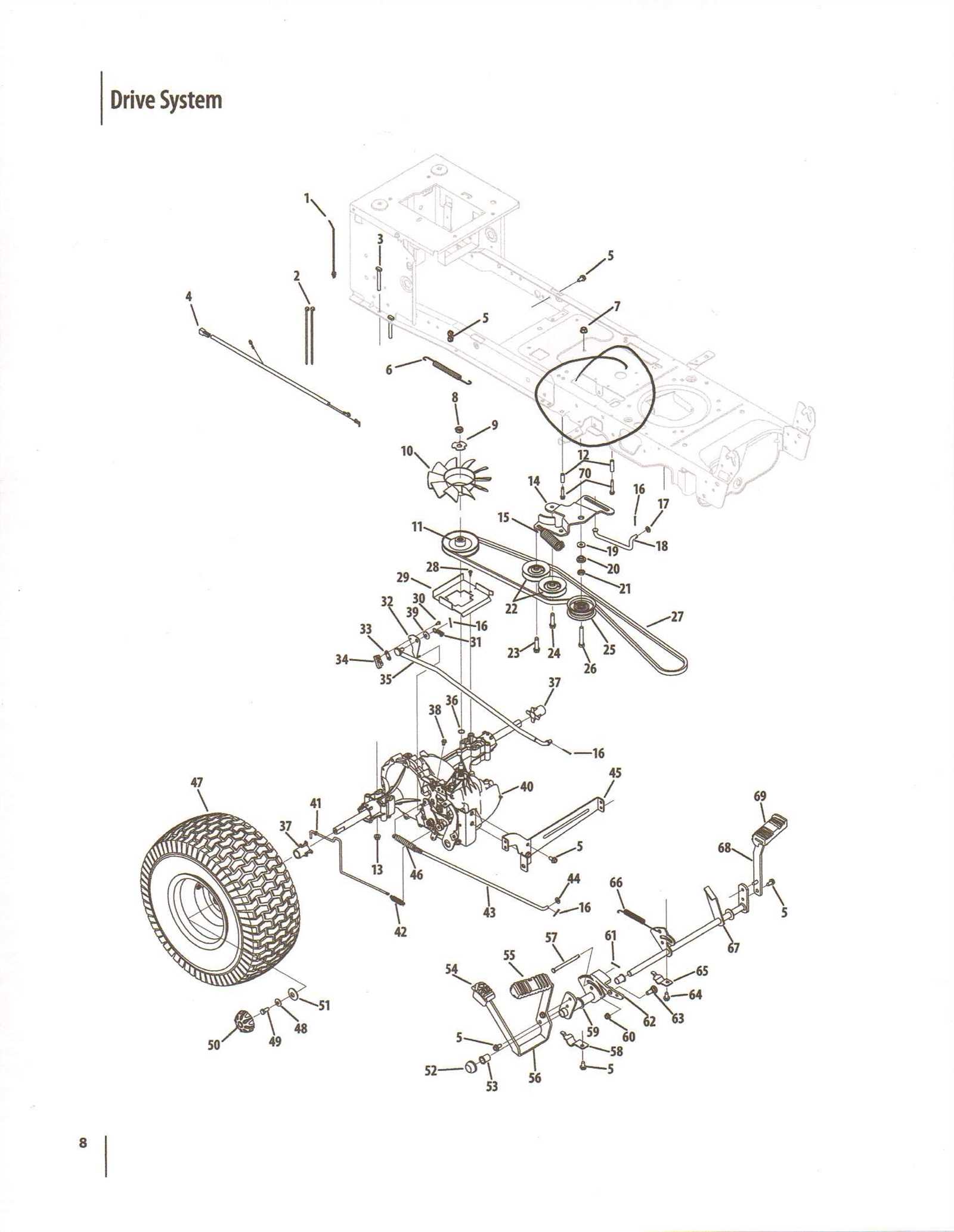

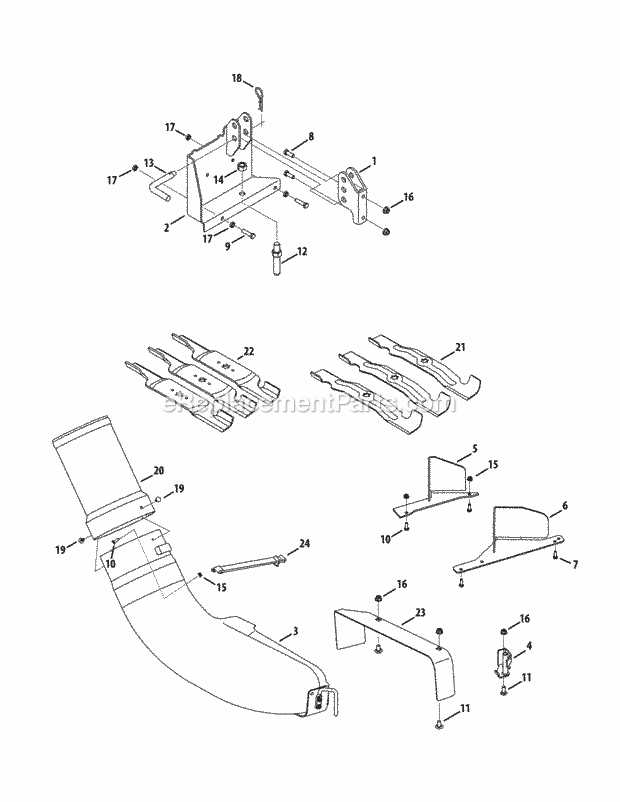

Understanding Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations serve as valuable tools for identifying individual elements and understanding their relationships within a larger system. By interpreting these visuals, users can efficiently locate necessary components and streamline their restoration efforts.

Benefits of Component Illustrations

- Clarity: Visual aids enhance comprehension by providing a clear view of where each piece fits.

- Efficiency: Quick identification of parts reduces downtime during repairs.

- Organization: Structured layouts help in systematic disassembly and reassembly.

How to Read Component Visuals

- Start by familiarizing yourself with the overall layout of the illustration.

- Identify the key sections and note any labels or part numbers provided.

- Use a magnifying tool if necessary to view smaller components clearly.

- Cross-reference the visual with a list of components to ensure accuracy.

By mastering the art of interpreting these illustrations, individuals can enhance their repair skills and ensure that machinery remains in optimal working condition.

Key Components of the Cub Cadet 1045

The efficiency of any machinery relies on its fundamental elements, each playing a crucial role in overall performance. Understanding these vital components can enhance maintenance practices and operational knowledge.

Engine: This is the powerhouse, responsible for converting fuel into mechanical energy. Its reliability ensures consistent operation.

Transmission: The system that transfers power from the engine to the wheels, affecting speed and control. Proper functioning is essential for smooth maneuverability.

Deck: This component houses the cutting blades and is pivotal for achieving a precise and even cut. Its design influences cutting efficiency and durability.

Wheels: These elements provide mobility and stability, ensuring optimal traction on various terrains. Choosing the right type enhances performance significantly.

Controls: The interface that allows the operator to manage the machine. Ergonomic design contributes to ease of use and overall user experience.

Frame: The structural foundation that supports all other components. A robust frame ensures longevity and resilience under heavy use.

Delving into these fundamental parts not only fosters better understanding but also guides owners in effective upkeep and troubleshooting.

Importance of Maintenance Manuals

Maintenance manuals serve as essential resources for ensuring the longevity and efficiency of equipment. They provide detailed instructions, troubleshooting tips, and maintenance schedules, enabling users to perform necessary tasks effectively. By following these guidelines, operators can prevent breakdowns and enhance performance over time.

Having access to comprehensive documentation empowers users to understand the inner workings of their machinery. This knowledge allows for informed decisions regarding repairs and replacements, ultimately leading to reduced downtime and increased productivity. Proper adherence to maintenance protocols not only preserves the functionality but also ensures safety during operation.

Moreover, utilizing these manuals fosters a proactive approach to upkeep. Regular reference to the provided guidelines can help identify potential issues before they escalate, saving time and resources. In essence, maintenance manuals are invaluable tools that contribute to the ultimate success of any equipment operation.

Identifying Common Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and repair. By recognizing these key elements, you can ensure optimal performance and longevity of your machinery.

- Blades: Vital for cutting performance, they require regular inspection for wear and damage.

- Belts: Essential for power transmission, these components need to be checked for fraying and tension.

- Filters: Air and oil filters prevent contaminants from affecting engine performance, necessitating periodic replacement.

- Batteries: Power supply units should be tested regularly to avoid starting issues.

- Tires: Proper tread depth and air pressure are important for traction and stability.

By knowing these components, you can make informed decisions about when to replace or maintain them, ultimately enhancing the efficiency of your machine.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding you through various elements and their relationships within a mechanical system.

Identify Key Elements

Start by familiarizing yourself with the primary sections of the illustration. Look for labels, symbols, and color codes that indicate specific parts and their functions. Recognizing these details can streamline your workflow and enhance comprehension.

Utilize Reference Tables

A reference table can clarify part numbers and descriptions. This allows for efficient cross-referencing when ordering or replacing items. Below is a simple example of what such a table might include:

| Part Number | Description | Quantity |

|---|---|---|

| 12345 | Drive Belt | 1 |

| 67890 | Air Filter | 1 |

| 54321 | Spark Plug | 2 |

Finding OEM vs. Aftermarket Parts

When maintaining or repairing machinery, choosing the right components is crucial. Two primary options exist: original equipment manufacturer items and alternative solutions. Each type has its own set of benefits and drawbacks, which can influence decision-making based on individual needs and circumstances.

Benefits of OEM Components

Original items are designed specifically for a particular model. They often provide the following advantages:

- Guaranteed compatibility with the equipment.

- High quality, often backed by warranties.

- Reliability in performance, as they meet the manufacturer’s standards.

Advantages of Aftermarket Solutions

On the other hand, alternative components can also be appealing for various reasons:

- Potential cost savings, often making them more accessible.

- Wider availability, as many suppliers offer diverse options.

- Innovation, with some aftermarket manufacturers providing improved designs.

Ultimately, the choice between these options depends on budget, availability, and the specific requirements of the task at hand.

Tools Needed for Repairs

Effective maintenance and restoration of machinery require a specific set of tools that ensure precision and efficiency. Having the right equipment at your disposal can significantly streamline the repair process and enhance the quality of the work performed.

Firstly, a comprehensive toolkit should include wrenches, screwdrivers, and pliers, as these are fundamental for loosening and tightening various components. A socket set is also essential for reaching bolts that are otherwise difficult to access.

In addition to hand tools, investing in a reliable jack and stands will provide necessary support for lifting the equipment safely during repairs. Furthermore, having a multimeter on hand is crucial for diagnosing electrical issues, allowing for accurate troubleshooting and repairs.

For cleaning and maintenance tasks, brushes, solvents, and lubricants should be readily available to ensure optimal functioning and longevity of the machinery. Lastly, a detailed manual or schematic will serve as an invaluable reference, guiding you through specific repair procedures and configurations.

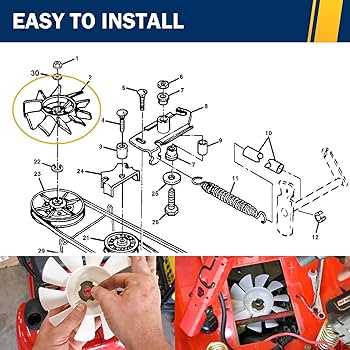

Step-by-Step Repair Process

The repair process for machinery involves several crucial stages to ensure optimal functionality and longevity. This guide outlines the essential steps to systematically address issues and restore your equipment to peak performance.

1. Diagnosis: Begin by identifying the problem. Carefully inspect all components and listen for unusual sounds during operation. This step is vital to determine the specific area requiring attention.

2. Preparation: Gather necessary tools and replacement components before commencing repairs. A well-organized workspace enhances efficiency and minimizes interruptions during the task.

3. Disassembly: Carefully disassemble the affected sections, taking care to document the arrangement of parts. This practice aids in reassembly and ensures nothing is overlooked.

4. Inspection: Examine the removed components for signs of wear or damage. Replace any defective items to prevent future malfunctions.

5. Reassembly: Follow your documentation to reassemble the machinery accurately. Ensure that all fasteners are tightened securely, and parts are aligned correctly.

6. Testing: Once reassembled, conduct a thorough test run to verify that the equipment operates smoothly. Pay attention to any abnormal sounds or performance issues.

7. Maintenance: Finally, perform routine maintenance checks to prolong the lifespan of the machinery. Regular inspections and upkeep are essential for consistent performance.

Safety Tips for Maintenance

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions and awareness of potential hazards can significantly enhance the overall experience and effectiveness of your upkeep activities.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear is essential for shielding yourself from debris, chemicals, and moving parts. Before starting any work, take a moment to familiarize yourself with the equipment’s manual to understand safety features and recommended procedures.

When operating machinery, make sure it is on a stable surface and securely parked. Disconnect power sources, if applicable, before performing any repairs or inspections to eliminate the risk of accidental start-up. Additionally, keep your workspace organized to prevent slips and trips caused by clutter.

Regularly inspect tools and equipment for wear or damage. Using faulty tools can lead to unexpected failures or injuries. It’s also wise to work in pairs or let someone know your plans, especially when dealing with heavy or complex machinery.

Finally, remain alert and focused during maintenance tasks. Avoid distractions and take breaks as needed to maintain concentration. Prioritizing safety will not only protect you but also extend the lifespan of your equipment.

Frequently Asked Questions

This section aims to address common inquiries related to equipment maintenance and component identification, providing clarity and support for users navigating the intricacies of their machines.

| Question | Answer |

|---|---|

| What should I do if I can’t find a specific component? | Check your manual for detailed information or consult with a local dealer for assistance. |

| Are there alternatives for original parts? | Yes, many aftermarket options are available; however, ensure they meet quality standards. |

| How often should I perform maintenance? | Regular checks every season are recommended to keep your equipment in optimal condition. |

| Can I replace parts myself? | Many users can, but for complex repairs, seeking professional help is advised. |

| Where can I find detailed illustrations for my equipment? | Visit official websites or consult the user manual for comprehensive diagrams. |

Resources for Further Assistance

When navigating the complexities of machinery maintenance and repair, having access to reliable resources can significantly enhance your understanding and troubleshooting capabilities. Various platforms offer invaluable information, including manuals, community forums, and instructional videos. These tools can help you identify issues and provide step-by-step guidance for effective resolution.

Online forums and discussion groups are excellent for connecting with fellow enthusiasts and experts who share their experiences and advice. Additionally, official websites often feature comprehensive documentation, including user manuals and technical specifications. For visual learners, video tutorials can serve as a practical guide, demonstrating processes in real-time.

Don’t overlook local retailers or service centers, as they may have knowledgeable staff available for consultation. Combining these resources will empower you to approach any challenges confidently and effectively.