For anyone looking to maintain or repair their lawn mowing machine, having a clear understanding of its components is essential. Identifying the various parts and how they work together can significantly simplify the troubleshooting process and enhance overall functionality. This knowledge not only aids in repairs but also ensures that your equipment operates efficiently for years to come.

In this section, we will explore a detailed overview of the essential elements that comprise this particular model. Each component plays a crucial role in the machine’s performance, and being familiar with them can help you make informed decisions when it comes to upgrades or replacements. Whether you’re a seasoned technician or a beginner, understanding these intricacies can empower you to keep your mower in optimal condition.

Furthermore, recognizing the layout and connections of each element can prevent common issues and save time during maintenance. By familiarizing yourself with these specifications, you can ensure that your equipment runs smoothly, allowing for a more enjoyable and productive experience when tending to your lawn. Embracing this knowledge is the first step towards becoming proficient in the care of your machinery.

This section aims to provide a comprehensive understanding of a specific model of a well-known brand in the lawn care industry. The focus will be on various components that contribute to its overall functionality and performance. By exploring the key elements, users can gain insights into how each part plays a vital role in the efficient operation of the machine.

- Engine: The powerhouse of the equipment, responsible for delivering the necessary energy for movement and operation.

- Transmission: This system enables smooth gear shifts and controls the speed of the mower.

- Chassis: The framework that supports all other components, providing stability and structure.

- Cutting Deck: The critical element for achieving an even cut, featuring blades designed for precision.

- Wheels: Essential for mobility, ensuring smooth navigation across different terrains.

- Electrical System: Includes the battery and wiring that power various electrical components for enhanced functionality.

Understanding these components helps users not only to appreciate the complexity of the machinery but also to troubleshoot and maintain it effectively. Knowledge of each part’s function can lead to better care practices and ultimately prolong the life of the equipment.

Key Features of the Model

This model stands out due to its exceptional engineering and robust design, catering to a variety of tasks efficiently. Users can expect high performance and durability, making it a reliable choice for lawn care and maintenance.

Powerful Engine: The unit is equipped with a high-performance engine that ensures optimal power output, allowing it to tackle even the most challenging terrains with ease.

Superior Maneuverability: Its compact design offers enhanced maneuverability, enabling users to navigate through tight spaces and around obstacles effortlessly.

Advanced Cutting System: The innovative cutting mechanism guarantees precise and even grass trimming, resulting in a pristine lawn finish.

Durable Construction: Built with high-quality materials, the machine is designed to withstand the rigors of outdoor use, ensuring long-lasting performance.

User-Friendly Controls: The intuitive control layout simplifies operation, making it accessible for users of all experience levels.

Comfort Features: Equipped with ergonomic seating and easy-to-reach controls, the model enhances user comfort during extended use, reducing fatigue.

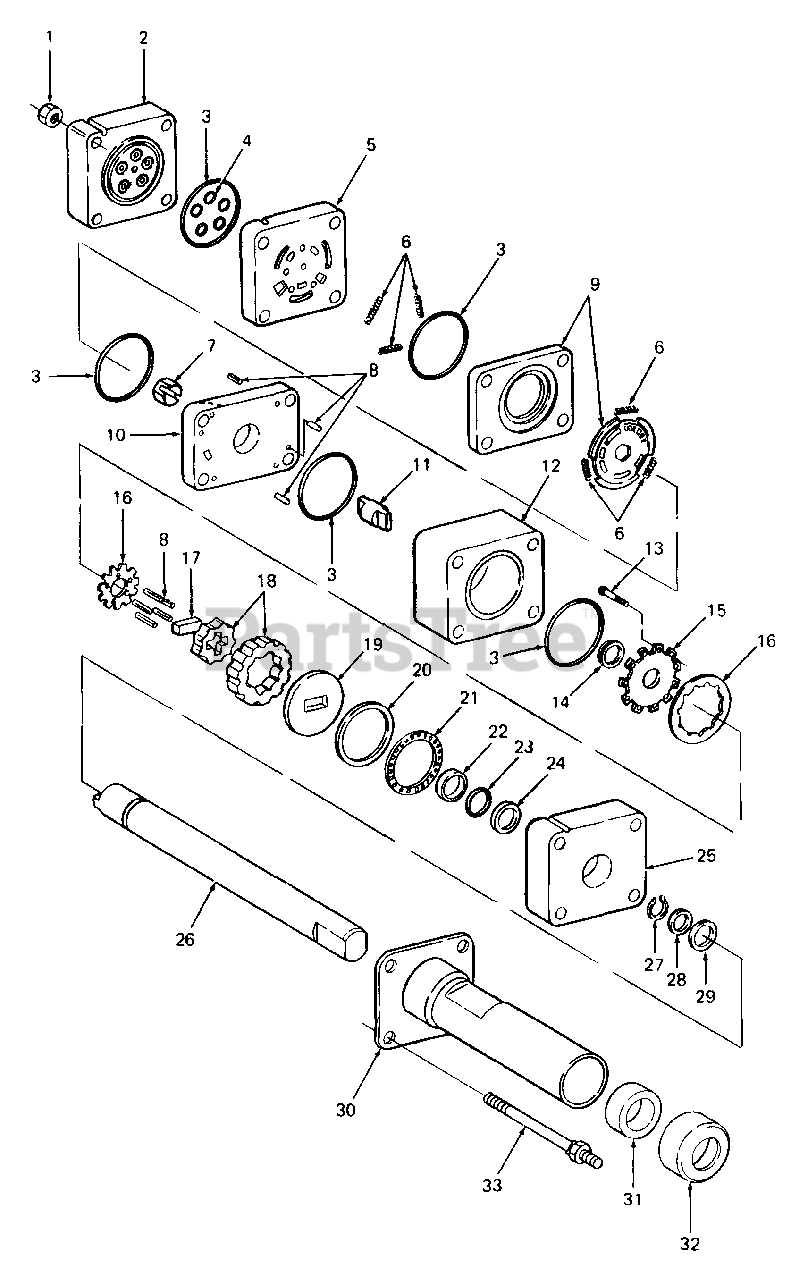

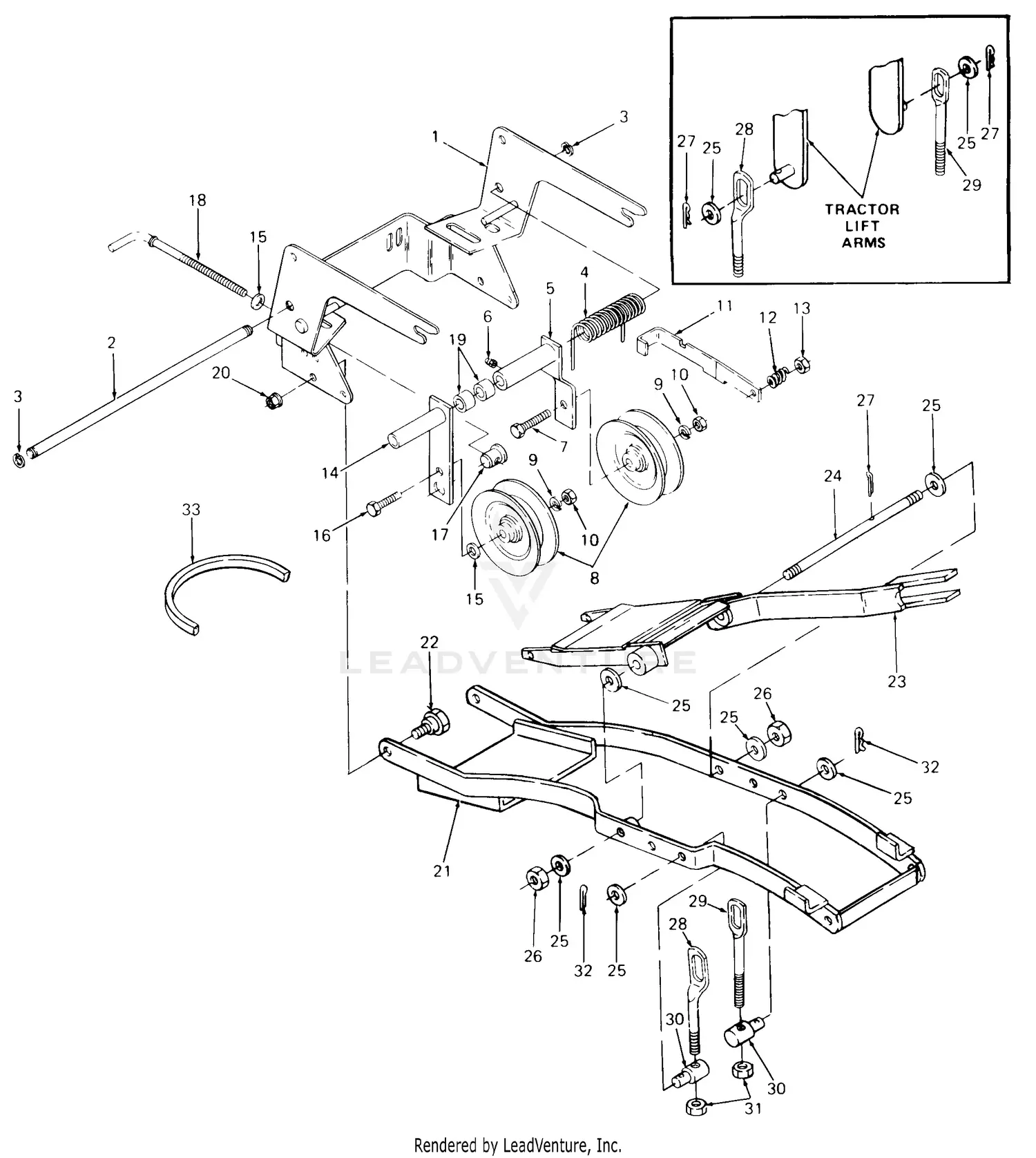

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations that illustrate components and their arrangements serve as invaluable resources for technicians and enthusiasts alike. These resources not only aid in identifying individual elements but also enhance comprehension of how these pieces interact within the system.

One of the primary benefits of such visual aids is the clarity they provide. Complex machines can often intimidate users, but with clear visuals, users can break down the assembly into manageable sections. This simplification reduces errors during repairs and helps prevent unnecessary damage.

Moreover, these resources facilitate communication among users, repair professionals, and parts suppliers. When discussing specific components, referring to visuals ensures everyone is on the same page, minimizing confusion and streamlining the procurement process. In turn, this leads to quicker repairs and less downtime for equipment.

Additionally, the availability of these illustrations can foster a greater understanding of a machine’s design and functionality. Users who familiarize themselves with the layout are more equipped to troubleshoot issues independently, saving both time and money. Overall, having access to accurate visuals is crucial for anyone looking to maintain or repair their equipment efficiently.

Main Components and Their Functions

This section delves into the essential elements that contribute to the overall performance of the machinery, highlighting their respective roles and significance. Understanding these components helps users to better maintain and optimize their equipment for efficient operation.

- Engine: The powerhouse of the unit, responsible for providing the necessary energy to perform various tasks. It converts fuel into mechanical energy.

- Transmission: This component transmits power from the engine to the wheels, allowing for smooth movement and control. It enables the operator to adjust speed and direction.

- Chassis: The framework that supports all other components, ensuring structural integrity and stability during operation. It also houses important systems like steering and braking.

- Steering Mechanism: This system allows the operator to navigate the machine with precision. It connects the steering wheel to the wheels for responsive maneuvering.

- Cutting Deck: Designed for tasks related to lawn care, this element features blades that trim grass and other vegetation to the desired length.

- Fuel System: This assembly stores and delivers fuel to the engine, ensuring it runs smoothly and efficiently.

- Electrical System: Comprising batteries and wiring, this system powers lights, start mechanisms, and other electrical components, enhancing functionality.

By familiarizing oneself with these critical components and their functions, operators can enhance their understanding of the equipment, ultimately leading to better maintenance practices and improved performance in the field.

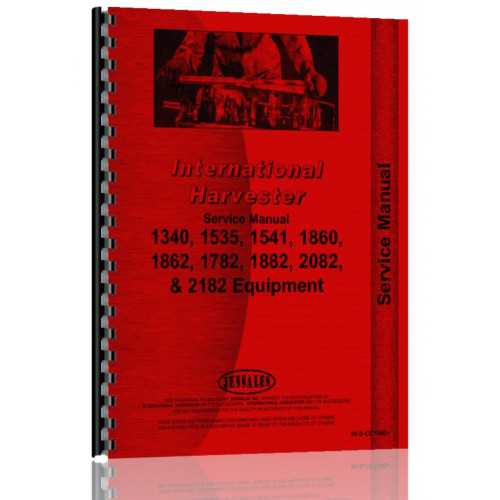

Locating Replacement Parts

Finding suitable components for your equipment is essential for maintaining its functionality and longevity. Whether you’re looking for a specific item or need to replace a worn-out piece, there are various avenues to explore that can help you source the necessary replacements.

Online Retailers: Many online platforms specialize in providing a wide range of items for machinery. These websites often feature user-friendly search functions that allow you to filter results based on the equipment type or specific needs. Be sure to check customer reviews to gauge the reliability of the supplier.

Manufacturer’s Website: Visiting the official site of the manufacturer can provide direct access to their catalog. Many manufacturers offer detailed information on available components, including part numbers and compatibility, ensuring you select the correct items for your needs.

Local Dealers: Contacting authorized local dealers can be beneficial. They often carry a selection of essential items and can order specific components directly from the manufacturer if not in stock. Furthermore, their expertise can guide you in selecting the right parts for your particular machine.

Salvage Yards: For those seeking cost-effective options, salvage yards may have used items available. While these might not always be in pristine condition, they can be a valuable resource for hard-to-find components. Inspect the items thoroughly before purchase to ensure they meet your requirements.

Community Forums: Engaging with online forums dedicated to machinery enthusiasts can provide insights into where to find components. Members often share their experiences and recommendations for reliable suppliers, which can help you make informed decisions.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair of machinery. These visual representations provide a comprehensive overview of components and their relationships, allowing users to identify and locate specific elements quickly. Mastering the interpretation of these graphics can significantly enhance one’s ability to troubleshoot and replace parts accurately.

Key Elements of Assembly Illustrations

- Labels: Each component is usually labeled with a reference number or name, which corresponds to a list of parts.

- Lines and Arrows: These indicate connections between components, showcasing how parts interact within the overall structure.

- Views: Diagrams may present multiple views (top, side, exploded) to give a clearer understanding of the assembly.

Steps to Interpret the Illustrations

- Start by reviewing the key or legend, if available, to understand the symbols and notations used.

- Identify the main components first, using the labels as a guide.

- Trace connections and relationships between elements to visualize the overall assembly.

- Cross-reference the illustrated parts with the accompanying list for specific details like dimensions or materials.

Common Issues and Solutions

This section addresses frequently encountered problems that users may experience with their lawn equipment, along with practical solutions to resolve them effectively. Understanding these common issues can help maintain optimal performance and extend the lifespan of the machine.

Engine Performance Problems

One of the most common challenges is engine performance, which may manifest as difficulty starting, stalling, or running irregularly. To address these issues, check the fuel supply and ensure that fresh gasoline is being used. Additionally, inspect the air filter for any blockages and clean or replace it as needed. Regular maintenance of spark plugs is also essential to ensure smooth ignition.

Mechanical Wear and Tear

Over time, various components may experience wear, leading to reduced efficiency or failure. A thorough examination of belts, blades, and other moving parts is crucial. Replacing worn-out components promptly can prevent further damage and enhance overall functionality. Lubricating moving parts regularly will also help to minimize friction and extend their lifespan.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your outdoor equipment requires regular upkeep and attention to detail. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery and enhance its reliability during use.

Regular Inspection and Cleaning

Conducting routine checks on your equipment is crucial for identifying wear and tear before it leads to major issues. Thorough cleaning of components after each use helps prevent the buildup of dirt and debris, which can impair functionality. Pay special attention to the air filter and cooling system to maintain optimal performance.

Proper Lubrication and Fluid Checks

Ensuring that all moving parts are adequately lubricated is vital for reducing friction and preventing premature wear. Regularly check fluid levels such as oil and fuel, and change them as recommended by the manufacturer. This not only keeps the engine running smoothly but also contributes to overall efficiency and effectiveness.

Accessories for Enhanced Performance

Enhancing the capabilities of your machine can significantly improve its efficiency and functionality. Various attachments and accessories are designed to complement the core operations, ensuring that you get the most out of your equipment. These additions not only boost performance but also provide versatility for a range of tasks.

Attachments for Versatile Operations

Consider integrating various attachments that facilitate multiple functions. For instance, a snowblower attachment can turn your machine into a powerful snow removal tool, while a plow can help in clearing larger areas with ease. Utilizing such accessories allows for a seamless transition between different tasks, maximizing productivity throughout the year.

Performance-Enhancing Upgrades

Investing in performance-enhancing upgrades can also lead to noticeable improvements. Upgrading the cutting deck or engine components can result in better power output and efficiency. Regular maintenance and timely replacements ensure that your equipment operates at its best, providing reliable service for all your needs.

Tools Required for Repairs

When it comes to conducting maintenance or fixing equipment, having the right tools is essential for achieving optimal results. Properly equipped, individuals can tackle various issues effectively and efficiently. Below is a comprehensive list of essential instruments that can aid in repair tasks.

Essential Hand Tools

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for removing and installing screws.

- Pliers: These are useful for gripping, twisting, and cutting wires or other materials.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

Power Tools

- Drill: A reliable drill can simplify the process of creating holes or driving screws.

- Impact Driver: Useful for loosening stubborn fasteners and providing extra torque.

- Angle Grinder: Ideal for cutting or grinding metal components.

Equipped with these tools, performing repairs becomes a more manageable and precise endeavor. Ensuring you have the right instruments at hand can make all the difference in achieving successful maintenance outcomes.

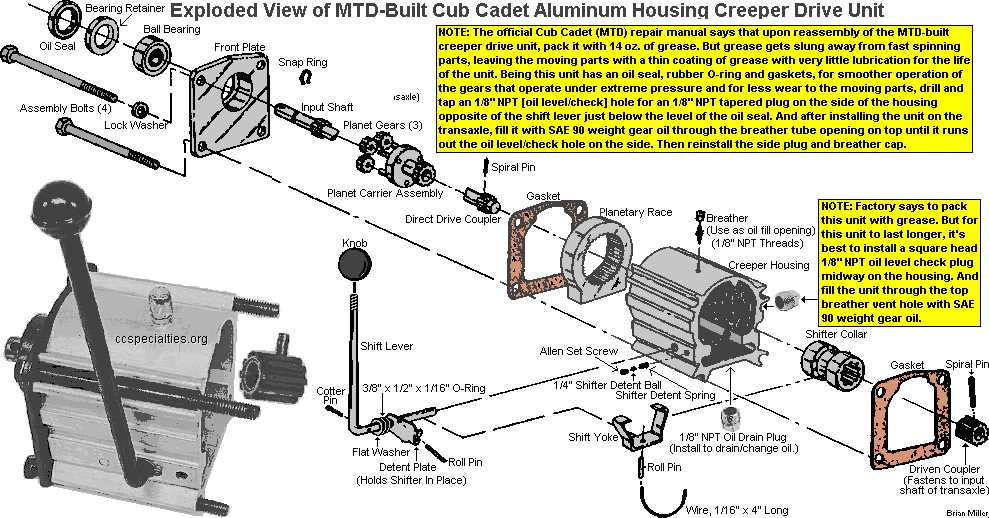

Assembly Instructions for Components

This section provides detailed guidance for the proper assembly of various components essential for optimal functionality. Following these instructions will ensure a smooth installation process and enhance the overall performance of the machine.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure that the workspace is clean and well-lit. It is advisable to read through all instructions carefully to familiarize yourself with the assembly sequence.

Assembly Procedure

Begin by aligning the primary components according to the designated points. Secure each piece using the specified fasteners, making sure to tighten them adequately to prevent any movement during operation. Double-check each connection to ensure everything is properly fitted. After completing the assembly, perform a thorough inspection to confirm that all components are securely attached and functioning correctly.

Finding Authorized Dealers

When seeking reliable support and genuine components for your equipment, locating certified distributors is essential. These authorized representatives ensure that you receive the highest quality service and authentic products tailored to your specific model.

Here are some effective strategies to find authorized dealers:

- Manufacturer’s Website: Visit the official website of the manufacturer to access a list of authorized dealers. Most brands maintain an updated directory of their certified representatives.

- Local Listings: Use online mapping services to search for dealers in your vicinity. Enter relevant terms related to your equipment to find nearby locations.

- Customer Reviews: Check online reviews and ratings for various dealers. Feedback from other customers can provide insight into their reliability and service quality.

- Community Recommendations: Engage with local forums or social media groups dedicated to your equipment type. Community members can share personal experiences and suggest reputable dealers.

By utilizing these approaches, you can ensure that you find trustworthy dealers who offer quality service and authentic products, enhancing the longevity and performance of your equipment.

Customer Reviews and Feedback

This section highlights the thoughts and opinions of users regarding their experiences with the equipment. Customer feedback provides valuable insights into performance, durability, and overall satisfaction, helping potential buyers make informed decisions.

Overall Satisfaction

- Many users express high levels of satisfaction with the reliability of the machinery.

- Positive remarks often highlight the ease of operation and maintenance.

- Customers frequently mention the effectiveness of the equipment in various tasks.

Areas for Improvement

- Some users suggest enhancing the user manual for better guidance.

- Feedback indicates a desire for more robust customer support services.

- A few reviews point out the need for additional accessories to improve functionality.