Maintaining a lawn tractor can be a rewarding yet challenging task for any enthusiast. Having a clear understanding of the various components that make up this machinery is essential for effective repairs and upgrades. This knowledge empowers owners to enhance the performance of their equipment and ensure its longevity.

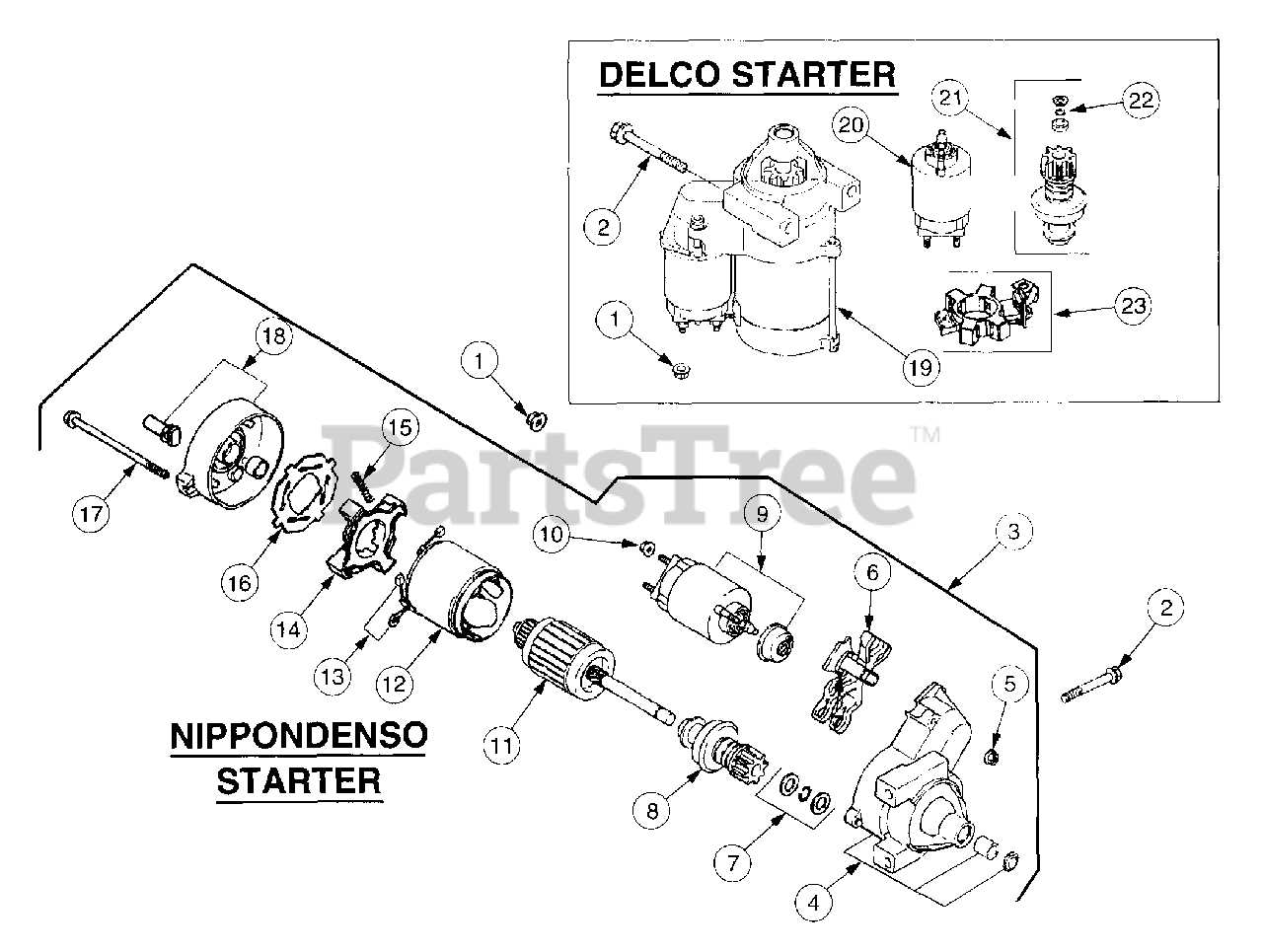

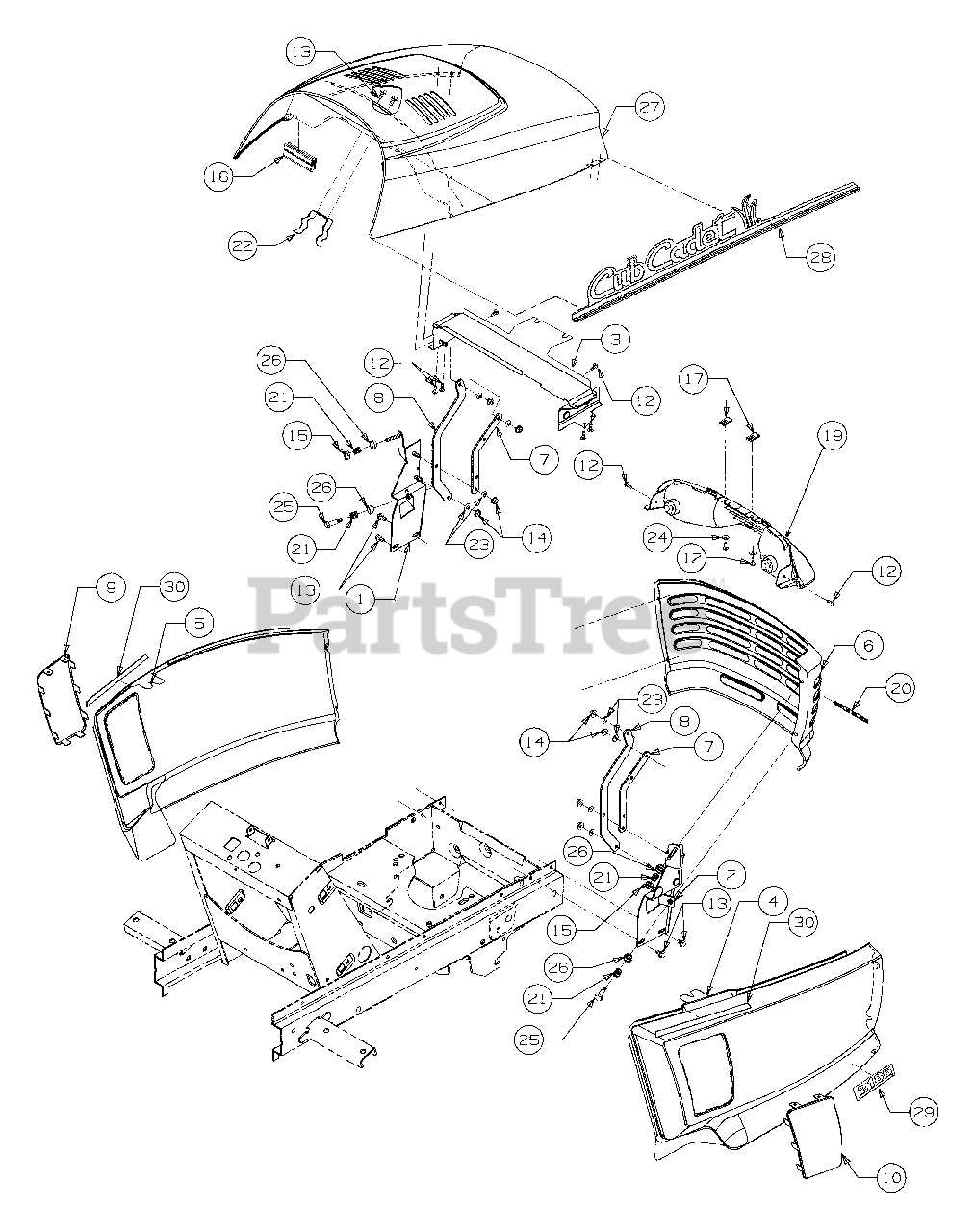

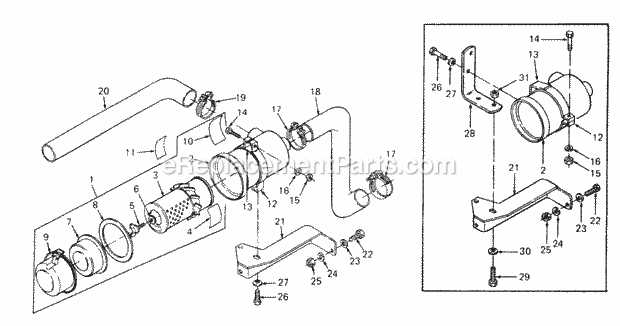

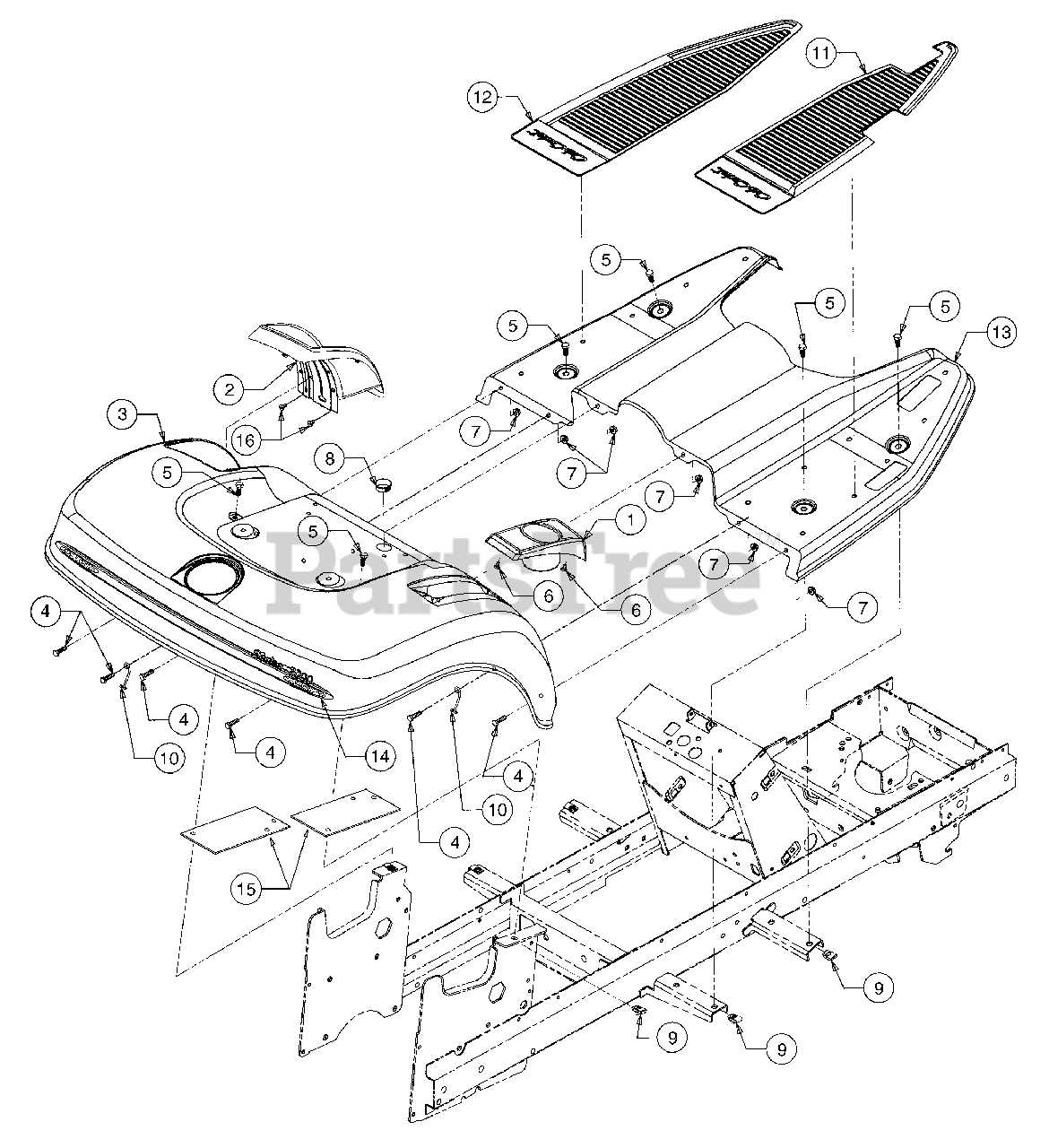

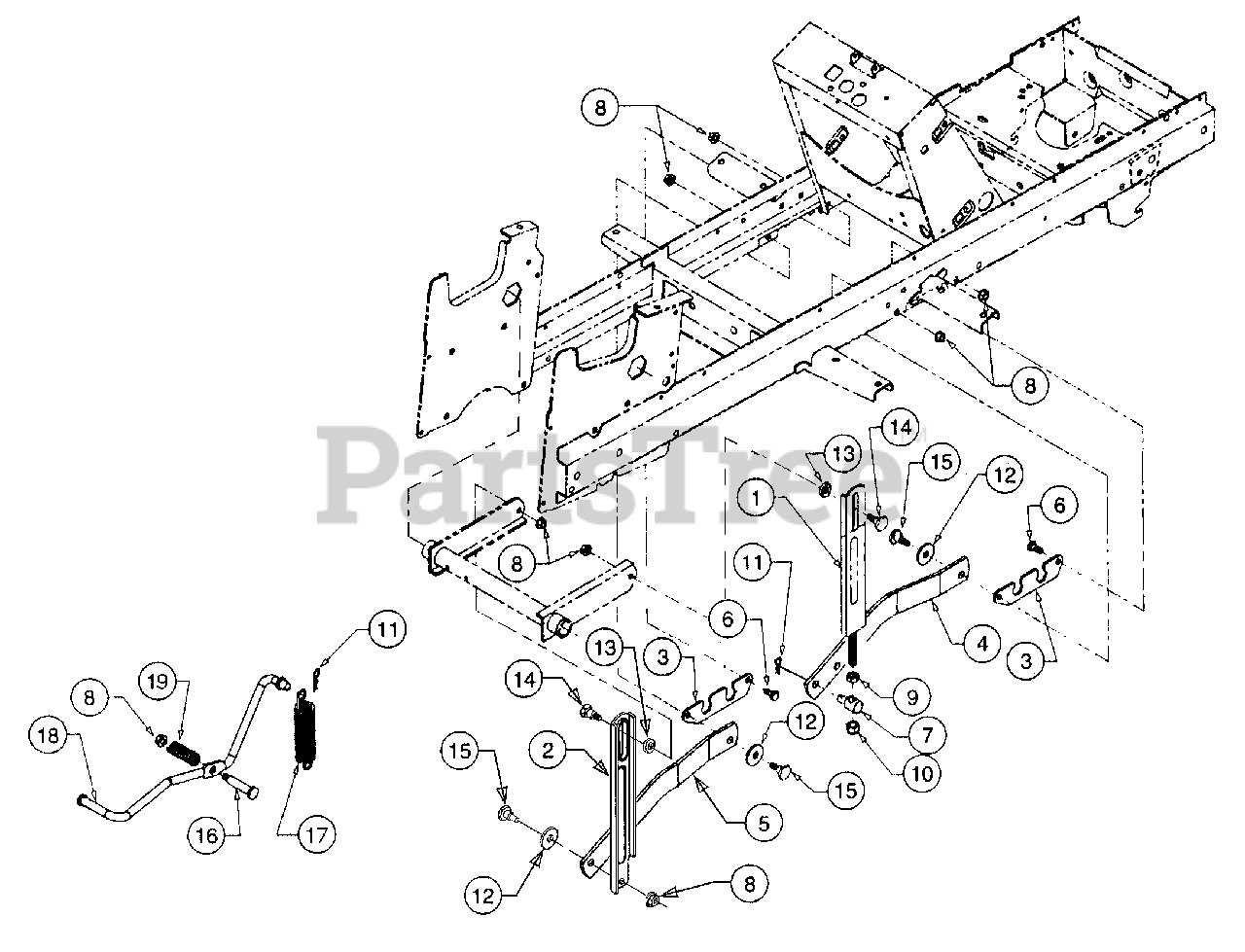

When it comes to troubleshooting or replacing certain elements, visual references become invaluable. By studying detailed illustrations that highlight each piece’s location and function, operators can navigate repairs with greater confidence. Such resources serve as guides, enabling users to identify parts and understand how they fit into the overall system.

In this exploration, we will delve into the intricate layout of the essential mechanisms involved. By examining each section, you’ll gain insights that not only simplify maintenance tasks but also improve your appreciation of the engineering behind your machine.

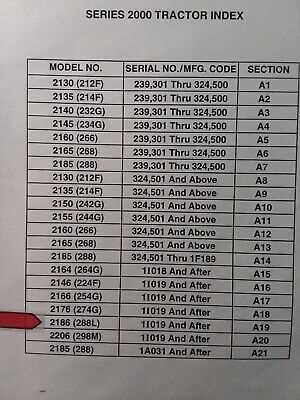

Overview

This section provides a comprehensive look at a specific model known for its durability and versatility. Designed for various outdoor tasks, it combines functionality with user-friendly features.

Key characteristics include:

- Robust engine for reliable performance

- Efficient transmission system for smooth operation

- Comfortable seating and controls for ease of use

Users appreciate its ability to handle a range of tasks, making it an ultimate choice for both homeowners and professionals. The thoughtful design ensures longevity and minimal maintenance, appealing to those who seek efficiency and reliability.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They provide an intuitive way to understand the relationship between various elements of machinery, enabling users to identify and locate individual items efficiently. This clarity is vital for ensuring that equipment remains in optimal condition and operates smoothly.

Enhanced Understanding

By using visual schematics, technicians and enthusiasts can gain a deeper insight into how machinery functions. These illustrations break down complex assemblies into manageable sections, making it easier to grasp the overall design and mechanics involved. Recognizing each component and its function promotes informed decision-making during repairs or upgrades.

Streamlined Repairs

Effective repair processes rely heavily on accurate identification of parts. Detailed illustrations allow for quicker diagnostics and reduce the likelihood of errors during assembly or disassembly. This efficiency not only saves time but also minimizes the risk of damaging components, ultimately leading to a more cost-effective maintenance routine.

Key Components of Cub Cadet 2186

Understanding the essential elements of this mower provides insights into its functionality and maintenance. Each component plays a critical role in ensuring optimal performance, longevity, and ease of use.

Essential Elements

- Engine: Powers the mower and influences its efficiency.

- Transmission: Transfers power from the engine to the wheels, affecting speed and maneuverability.

- Deck: Houses the blades and determines cutting quality.

- Wheels: Support movement and stability on various terrains.

- Steering Mechanism: Ensures precision in navigation and control.

Maintenance Considerations

- Regular oil changes keep the engine running smoothly.

- Inspecting the blades ensures clean cuts and efficient operation.

- Checking tire pressure enhances performance and safety.

- Lubricating moving parts reduces wear and tear.

- Cleaning the deck prevents grass buildup and maintains efficiency.

Where to Find Replacement Parts

Locating components for your equipment can often be a straightforward task if you know where to look. Various sources, both online and offline, provide access to these essential items, ensuring your machinery remains in optimal working condition. Consider exploring specialized retailers, manufacturer websites, and local hardware stores to find what you need.

Online marketplaces offer a vast selection, often including customer reviews that can guide your choices. Additionally, forums and community groups dedicated to equipment maintenance can be invaluable, as fellow enthusiasts frequently share recommendations and experiences. Don’t overlook the possibility of second-hand options, which can be both cost-effective and sustainable.

Common Issues and Solutions

When maintaining outdoor power equipment, users often encounter various challenges that can affect performance and reliability. Understanding these common issues and their corresponding solutions can help in ensuring smooth operation and prolonging the lifespan of the machinery.

Frequent Problems

- Engine not starting

- Poor cutting performance

- Overheating

- Unusual noises during operation

- Vibrations

Solutions and Preventive Measures

-

Engine not starting:

- Check fuel levels and ensure fresh fuel is being used.

- Inspect the spark plug for damage or dirt; replace if necessary.

-

Poor cutting performance:

- Sharpen or replace the blades if they are dull or damaged.

- Adjust the cutting height to suit the grass type.

-

Overheating:

- Ensure the cooling fins are clean and free from debris.

- Check the oil level and change if it appears dirty or low.

-

Unusual noises:

- Inspect for loose parts or worn bearings.

- Listen for any signs of mechanical issues that may require professional attention.

-

Vibrations:

- Ensure all fasteners are tightened properly.

- Balance the blades if they appear uneven.

By addressing these common issues promptly, users can enhance the performance and reliability of their outdoor equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your outdoor equipment. By following a few key practices, you can ensure reliable performance and prevent costly repairs. Regular attention to detail can make all the difference in maintaining efficiency and functionality.

Start with routine inspections to identify wear and tear. Check belts, blades, and fluid levels regularly. Clean any debris that accumulates, as this can lead to overheating or malfunctions. Also, ensure all moving parts are lubricated according to manufacturer recommendations to reduce friction and enhance performance.

Replacing worn components promptly is crucial. This proactive approach can prevent further damage and maintain optimal operation. Additionally, storing your equipment in a dry, sheltered area will protect it from the elements, prolonging its life significantly.

Finally, refer to the owner’s manual for specific guidelines related to your model. Following the manufacturer’s suggestions for service intervals will keep your machinery running smoothly for years to come.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repairs. These illustrations provide a detailed breakdown of components, helping users identify each part’s function and placement. By familiarizing yourself with these visuals, you can streamline the troubleshooting process and ensure accurate reassembly.

Start by identifying key elements. Look for labels and numbers that correspond to a legend or key, often found alongside the image. This will help clarify the specific components and their respective roles.

Next, pay attention to the layout. Components are usually arranged in a logical manner, reflecting their physical connection and assembly sequence. Understanding this arrangement is crucial for comprehending how each piece interacts with others.

Finally, reference the manual associated with the schematic. Manuals often include additional notes or diagrams that enhance understanding and provide context for each part’s importance. By combining these resources, you’ll gain a comprehensive grasp of the assembly.

Tools Required for Repairs

When undertaking maintenance or repair tasks on outdoor equipment, having the right tools is essential for efficiency and effectiveness. Properly selected instruments not only simplify the process but also ensure that the job is completed safely and accurately. Below is a list of essential tools you should consider having on hand.

Basic Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Hammer

- Utility knife

Specialized Tools

- Torque wrench

- Oil filter wrench

- Multimeter

- Fuel line clamp

- Diagnostic tools

Having these instruments readily available will streamline your repair efforts and enhance your ability to address any issues that arise effectively.

Upgrades for Cub Cadet 2186

Enhancing the performance of your lawn machine can significantly improve its efficiency and longevity. By integrating advanced components and features, you can elevate your mowing experience, making it more enjoyable and effective.

Engine Enhancements: Upgrading the engine with a more powerful model can provide increased torque and improved cutting capacity. Consider options that optimize fuel efficiency while delivering superior performance.

Transmission Improvements: Switching to a high-performance transmission can enhance responsiveness and control, allowing for smoother operation across varied terrains.

Deck Modifications: Installing a reinforced cutting deck or high-lift blades can lead to cleaner cuts and better grass discharge, resulting in a healthier lawn.

Accessory Additions: Adding features such as mulching kits or bagging systems can maximize versatility, catering to different lawn care needs and preferences.

Comfort Upgrades: Enhancing the seating and controls can significantly improve the user experience, making long mowing sessions more comfortable.

User Experiences and Testimonials

Gathering insights from individuals who have interacted with a specific model can provide invaluable information for potential users. These shared experiences often highlight the strengths and weaknesses of the machine, offering a well-rounded perspective on its performance and reliability.

Many users appreciate the efficiency and durability of the equipment. Here are some common themes in their feedback:

- Performance: Numerous testimonials praise the power and efficiency during various tasks, from mowing to snow removal.

- Maintenance: Users frequently mention the ease of finding replacement components, making upkeep straightforward and hassle-free.

- Comfort: Comfort features are often highlighted, with many noting that the ergonomic design enhances the overall experience.

However, there are also some critiques worth considering:

- Initial Setup: A few users found the initial assembly challenging and recommended careful reading of the manual.

- Weight: Some noted that the machine’s weight can be a factor in maneuverability, especially in tighter spaces.

- Cost of Parts: A handful of individuals expressed concerns about the pricing of specific components, suggesting that budgeting for replacements is essential.

Overall, the collective feedback paints a picture of a reliable machine that, with proper care and maintenance, can meet a variety of needs efficiently. Users encourage potential buyers to weigh these insights carefully to make an informed decision.