When it comes to maintaining outdoor machinery, having a clear understanding of its structure is essential for effective repairs and upkeep. Each unit comprises various elements that work in harmony, ensuring optimal performance. By familiarizing oneself with these components, users can troubleshoot issues more effectively and prolong the life of their equipment.

Identifying the individual elements of a machine not only simplifies the repair process but also empowers users with knowledge that can prevent future complications. A detailed overview of the specific sections and functionalities can serve as a valuable reference, guiding users in both routine maintenance and unexpected breakdowns.

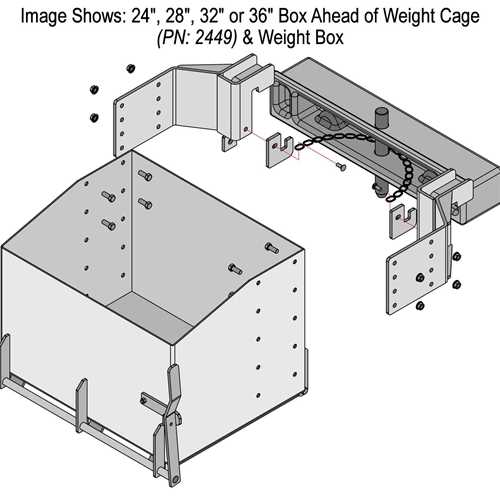

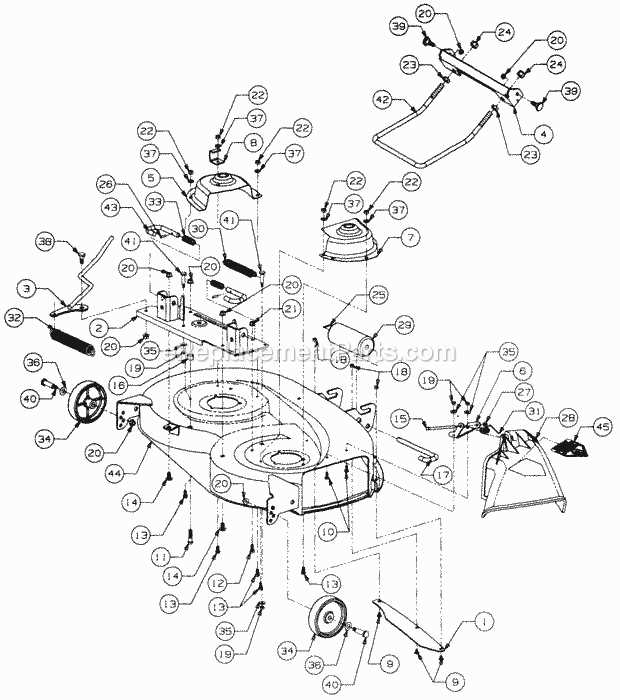

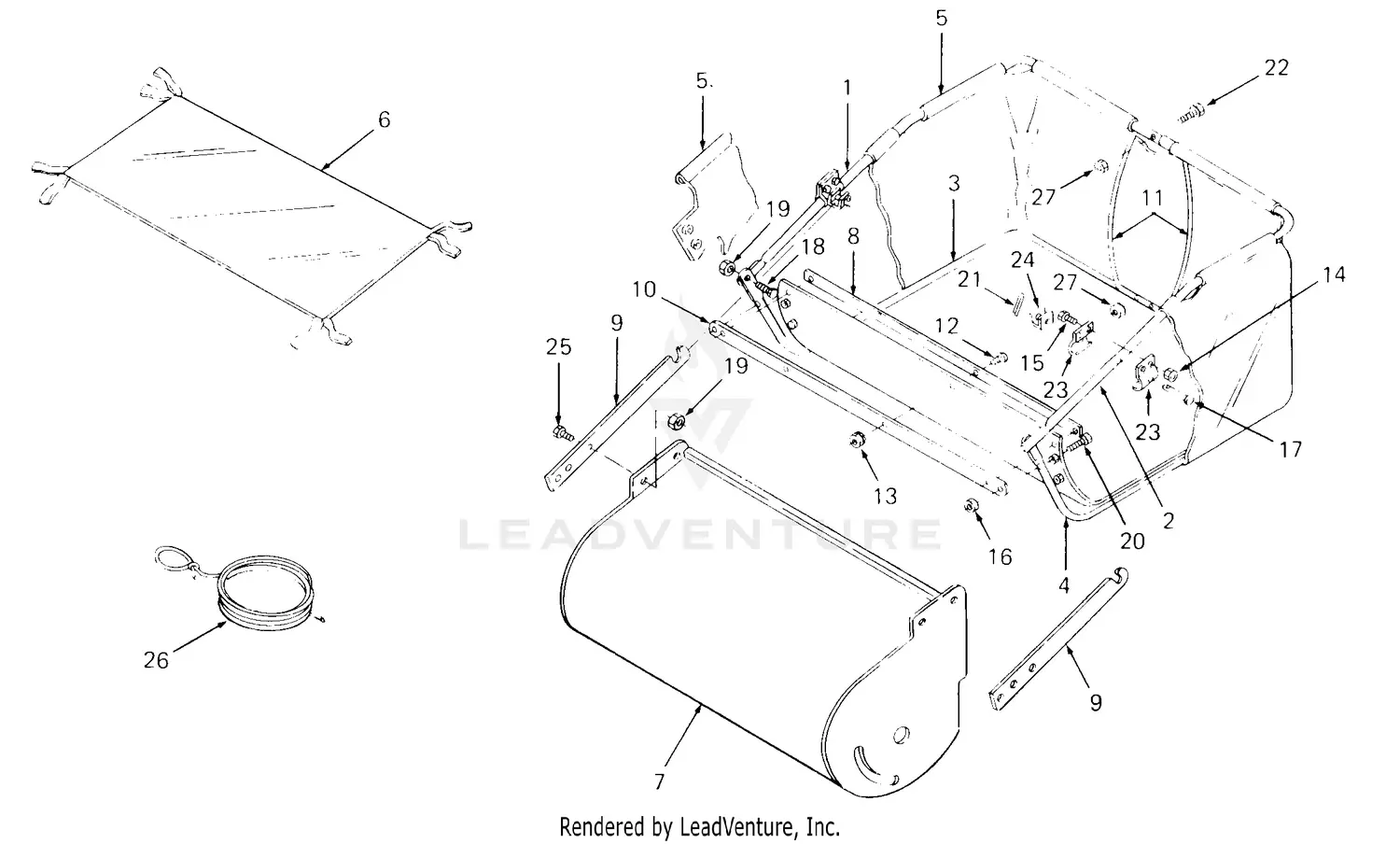

Moreover, having access to a comprehensive visual representation of these components enhances the ability to understand how each part interacts with others. This insight is crucial for anyone looking to improve their skills in equipment management and maintenance. Whether you’re a seasoned operator or a newcomer, grasping the layout and function of these essential parts is key to achieving efficiency and reliability.

Overview

This section provides an in-depth look at a specific model designed for outdoor maintenance tasks. Known for its efficiency and reliability, this equipment is a popular choice among homeowners and professionals alike.

Key features that stand out include:

- Powerful engine performance

- User-friendly controls

- Durable construction materials

- Versatile attachment options

Understanding the components of this machine can greatly enhance its usage and maintenance. Here are some important aspects to consider:

- Engine specifications

- Transmission details

- Maintenance intervals

- Common accessories and attachments

In conclusion, familiarity with this model ensures optimal performance and longevity, making it an invaluable asset for any landscaping or gardening endeavor.

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify and locate individual elements efficiently. Such illustrations enhance comprehension and ensure that tasks are executed accurately, reducing the likelihood of errors.

These visual aids offer several advantages:

| Benefit | Description |

|---|---|

| Clarity | Illustrations provide a clear view of the assembly, simplifying complex structures. |

| Efficiency | Quick identification of parts speeds up the repair process, saving time and effort. |

| Accuracy | Reduces the risk of using incorrect components, ensuring that replacements fit properly. |

| Training | Helpful for educating new technicians, facilitating a better understanding of machinery. |

In summary, these visual guides are indispensable resources that improve overall operational effectiveness and contribute to the longevity of equipment.

Key Components of the HDS 2135

Understanding the essential elements of this machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring the overall performance and longevity of the equipment. By familiarizing yourself with these components, you can enhance efficiency and troubleshoot issues effectively.

Engine and Transmission

The heart of any machinery lies in its engine and transmission system. These elements work together to provide power and facilitate smooth movement. Regular checks and maintenance of these components can prevent potential breakdowns and enhance functionality.

Chassis and Controls

The chassis provides the structural integrity, while the control systems offer the user interface for operation. Ensuring these components are in good condition is vital for safety and ease of use. Regular inspections can help identify wear and tear, allowing for timely repairs.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. These illustrations provide an organized overview of various elements, helping users identify and locate specific items quickly. By familiarizing yourself with this format, you can streamline your repair process and ensure you have the right components at hand.

1. Familiarize Yourself with Symbols: Each illustration often employs standardized symbols to represent different components. Taking time to learn these can save you confusion when searching for specific items. Pay attention to any legend or key that explains the symbols used.

2. Follow the Flow: Most illustrations are designed to guide you through the assembly or disassembly process. Begin from the starting point indicated and follow the flow of the illustration, which typically progresses from one component to the next, ensuring that you do not miss any steps.

3. Pay Attention to Numbering: Components are usually numbered for easy reference. Cross-reference these numbers with the corresponding list to verify you have the correct items. This practice can help prevent errors when ordering replacements.

4. Note Groupings: Components are often grouped by function or assembly. Recognizing these clusters can provide insights into how different parts interact and assist in understanding the overall structure. This knowledge is particularly useful when troubleshooting issues.

5. Use Additional Resources: For a comprehensive understanding, consult manuals or online resources that accompany the illustration. These documents often provide further explanations and details about the components and their specific functions.

Common Replacement Parts Explained

Understanding the essential components that may require substitution is vital for maintaining optimal performance and longevity of outdoor equipment. Various elements can wear out over time due to regular usage, environmental conditions, or lack of proper maintenance. Recognizing these key components allows for informed decisions when it comes to upkeep and repairs.

One frequently replaced item is the air filter, which ensures the engine receives clean air for efficient combustion. A clogged filter can hinder performance and fuel efficiency. Another critical element is the spark plug, responsible for igniting the fuel-air mixture. A worn spark plug can lead to starting issues or poor engine performance.

The fuel filter is equally important; it prevents contaminants from entering the engine, ensuring smooth operation. Additionally, belts, which transfer power from the engine to other parts, may need regular checks and replacements due to wear and tear. Understanding these common elements enables users to effectively manage maintenance and ensure their equipment runs smoothly.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular attention and care. By following a few key practices, you can significantly extend the lifespan of your machinery and keep it functioning efficiently. Here are some essential maintenance tips to consider.

Regular Cleaning

- Remove debris and dirt after each use to prevent buildup.

- Wash the exterior components with mild soap and water to maintain a clean appearance.

- Check and clear the air intake and exhaust areas to ensure proper airflow.

Routine Inspections

- Inspect belts and hoses for wear and tear, replacing them as necessary.

- Examine the blades regularly for sharpness and damage.

- Check fluid levels, including oil and fuel, and refill or change as needed.

By implementing these maintenance strategies, you can enhance the performance and longevity of your equipment, ensuring it remains reliable for years to come.

Where to Find Original Parts

Finding authentic components for your outdoor equipment is essential for maintaining its performance and longevity. The right sources ensure that you receive quality items that fit perfectly and function as intended. Below are some reliable options to consider when searching for these essential elements.

Authorized Dealers

One of the best ways to obtain genuine components is through authorized retailers. They often have direct access to the manufacturer’s inventory and can provide the following benefits:

- Guaranteed authenticity of items

- Expert advice from knowledgeable staff

- Access to the latest models and components

Online Marketplaces

In the digital age, many consumers turn to online platforms for their purchasing needs. Here are a few tips for navigating these marketplaces:

- Look for official brand stores on platforms like Amazon or eBay.

- Check customer reviews to ensure the credibility of the seller.

- Confirm that the items are labeled as original and not aftermarket versions.

By utilizing these resources, you can confidently acquire the necessary components to keep your equipment running smoothly and efficiently.

Comparing Aftermarket vs. OEM Parts

When maintaining equipment, choosing between alternative components and original manufacturer offerings is a crucial decision for many users. Each option presents unique advantages and potential drawbacks, which can significantly influence performance, longevity, and cost-effectiveness. Understanding these distinctions helps in making an informed choice that aligns with specific needs and preferences.

Advantages of Aftermarket Components

Alternative components often attract buyers due to their affordability and wide availability. Many users appreciate the variety of options that can sometimes exceed the original offerings in terms of innovation or enhanced features. Additionally, these alternatives can provide a more flexible approach, allowing users to tailor their purchases to fit their particular usage requirements.

Benefits of Original Manufacturer Offerings

On the other hand, components from the original manufacturer are typically engineered to meet precise specifications, ensuring compatibility and reliability. Users can have peace of mind knowing that these items are designed for optimal performance in their specific applications. Moreover, utilizing these components may come with warranties that can protect investments over time, further emphasizing their value in critical situations.

Ultimately, the choice between aftermarket and original offerings hinges on individual priorities, whether it be cost savings, performance guarantees, or a balance of both.

Assembly and Disassembly Guide

This section provides a comprehensive overview of how to efficiently put together and take apart the specified equipment. Understanding the proper techniques for assembling and disassembling ensures optimal functionality and prolongs the lifespan of the components. Following these guidelines will facilitate a smooth process for maintenance or repairs.

Tools Required

Before you begin, gather the necessary tools to make the process seamless. Here’s a list of items you will need:

| Tool | Description |

|---|---|

| Wrench Set | For loosening and tightening bolts. |

| Screwdriver | For removing screws from various parts. |

| Pliers | For gripping and twisting components. |

| Torque Wrench | For ensuring proper tightness of bolts. |

Step-by-Step Instructions

Follow these steps for an effective assembly and disassembly process:

- Begin with removing any loose parts and clean the components.

- Assemble the main unit by following the provided specifications.

- Use the appropriate tools to secure each component firmly.

- For disassembly, reverse the assembly steps carefully, ensuring all parts are stored securely.

Visual Aids for Repair Processes

Effective maintenance and repair tasks can greatly benefit from the inclusion of visual resources. These tools not only enhance understanding but also streamline the workflow, enabling technicians to identify components and procedures more efficiently. Visual aids serve as a bridge between theoretical knowledge and practical application, ensuring that individuals can tackle complex tasks with confidence.

Illustrations, diagrams, and photographs provide clear representations of equipment, highlighting specific areas that require attention. This visual support is especially crucial in intricate repair processes where written instructions may fall short. By utilizing such aids, technicians can minimize errors and improve their overall productivity.

| Type of Visual Aid | Benefits |

|---|---|

| Diagrams | Clarify the arrangement and function of parts. |

| Photographs | Offer real-life context and detail for components. |

| Videos | Demonstrate step-by-step procedures effectively. |

| Flowcharts | Simplify complex processes into manageable steps. |

Incorporating these visual tools into repair manuals or training materials can significantly enhance comprehension and retention. By fostering a clearer understanding of the tasks at hand, individuals are more likely to execute repairs successfully and efficiently.

FAQs About Cub Cadet Parts

This section aims to address common inquiries related to components for lawn equipment. Understanding the various elements that make up these machines can enhance maintenance practices and prolong their lifespan.

What should I consider when replacing components?

When looking to replace any part, it’s essential to check compatibility with your specific model. Additionally, consider the quality of the replacement; opting for original or high-quality aftermarket options can ensure better performance and durability.

How can I identify the right components for my equipment?

To identify suitable components, refer to the user manual that came with your machine. You can also check manufacturer websites or consult with authorized dealers for guidance. Providing the model number can significantly simplify the search process.

Resources for Further Research

Exploring comprehensive materials and references is essential for gaining a deeper understanding of machinery maintenance and repair. Various resources are available to enhance knowledge, assist in troubleshooting, and provide detailed information on specific components and their functions.

Online Forums and Communities

Joining online platforms where enthusiasts and professionals gather can be incredibly beneficial. These forums often feature discussions on troubleshooting techniques, user experiences, and recommendations for reliable suppliers. Engaging with these communities can lead to valuable insights and support.

Official Manuals and Guides

Consulting official documentation is crucial for anyone looking to perform maintenance or repairs. These manuals typically contain detailed illustrations, specifications, and safety precautions that are vital for effective work. Many manufacturers provide downloadable resources on their websites, making them easily accessible.

In addition to manuals, video tutorials on popular platforms can offer visual guidance and step-by-step instructions, making complex tasks more manageable. Utilizing a combination of these resources will empower individuals to tackle maintenance challenges confidently.